Application Advantages of Fan-Water Curtain Cooling System in Pig Production

2020-08-01TaiyinLIJiarongWUKejunLIUHongyingDENGZhengyuCHENQishengYANGChunhuaHUANG

Taiyin LI, Jiarong WU, Kejun LIU, Hongying DENG, Zhengyu CHEN, Qisheng YANG, Chunhua HUANG

1. Aquatic Animal Husbandry and Veterinary Station of Fenghuang Township, Zhaoping County, Zhaoping 546808, China; 2. Animal Husbandry Research Institute of Guangxi Zhuang Autonomous Region, Nanning 530001, China; 3. Bureau of Agriculture and Rural Affairs of Binyang County, Binyang 530400, China

Abstract [Objectives] The purpose was to solve the problem that high temperature and high humidity will seriously affect the health and weight gain of pigs. [Methods] The fan-water curtain cooling system was popularized in large-scale pig farms. [Results] The pigs using the water curtain cooling system gained 1.5 kg from weaning to the day of slaughter. The feed-to-gain ratio was 2.43∶1, a year-on-year decrease of 0.05. The average weight gain per pig was about 5-10 kg. [Conclusions] The application of fan-water curtain cooling system in pig production can accelerate the growth rate of pigs, reduce the occurrence of diseases and improve the utilization of feed, eventually improving the productivity of pigs.

Key words Water curtain, Fan, Fattening pig, Productivity

1 Introduction

At present, the commercial pig production in China mainly adopts the large-scale breeding mode, in which the breeding density is high and the pig pen is small. In the hot season, the air in the pens is not circulated. Coupled with elevated ambient temperature and pigs’ heat dissipation, the temperature inside the pig house is higher than the outdoor temperature consequently. If the temperature is too high, harmful gases such as ammonia and hydrogen sulfide produced by fecal fermentation will increase, causing pinkeye symptom in pigs. In severe cases, it will cause respiratory diseases or ammonia poisoning. Fattening pigs have thicker subcutaneous fat and underdeveloped sweat glands, and it is basically impossible for them to regulate body temperature through sweating and heat dissipation. As a result, the ability of fattening pigs to withstand high temperatures is poor. When the temperature in the pig house exceeds the appropriate level, heat production and heat dissipation in the body of pigs will be out of balance, leading to a series of physiological and functional adverse reactions in the pigs. This has a serious impact on the health and weight gain of pigs, such as reduced food intake, decreased resistance, increased morbidity, increased elimination rate and increased mortality. Sows also show the phenomena of decreased conception rate, miscarriage, stillbirth,etc[1].

The fan-water curtain cooling system is composed of water curtain, circulating water channel, exhaust fan and temperature control device. The water curtain is formed by bonding corrugated fiber paper. In the raw materials, special chemical components that do not decompose with water flow and air flow and have the characteristics of corrosion resistance and long duration are added. In a closed pig house, the water pump at one end sends the water in the reservoir to the water spray pipe and sprays the water toward the water reflection board, and the water evenly flows down from the water reflection board to wet the entire curtain. Thus, the water circulates between the sink and the curtain, so as to ensure that the air is in contact with the surface of the fully wetted water curtain. At the other end, a negative-pressure fan is installed to draw out air, and a negative pressure zone is formed in the pig house. The air outside the house is sucked into the house through the water curtain, and the heat in the pig house is discharged outside through the fan, thereby achieving the purpose of cooling[1].

Since 2012, the large-scale pig farms in Fenghuang Township, Zhaoping County, Guangxi began to promote the fan-water curtain cooling system in the pig houses, and obvious results were achieved in two pig farms. In 2013, another three pig farms began to use fan-water curtain cooling system. By the end of 2018, the fan-water curtain cooling system had been introduced to 13 large-scale pig farms with a total stock of 4 610 heads, of which 2 farms had a stock of 800 heads, 3 farms had a stock of 450 heads, 2 farms had a stock of 350 heads, 2 farms had a stock of 280 heads and 4 farms had a stock of 150 heads.

2 Comparison of cooling effect between traditional method and fan-water curtain cooling system

2.1 Effect of different cooling method on mental state of the pigsThe cooling effect test was conducted in an 800-pig farm in Fenghuang Township, Zhaoping County. The water curtain cooling equipment produced by a manufacturer in Nanning City was adopted. The manufacturer sent people to the pig farm to install the equipment. The space of the pig house was 1 200 m3. A set of fan-water curtain cooling equipment was installed. The 20 m2of water curtain was divided into 2 groups, 10 m2for each group, and four negative-pressure fans with rated power of 1.1 kW were installed.

The cooling effect of the fan-water curtain cooling system was examined on September 18, 2017 (Table 1). On September 19, 2017, the fan-water curtain cooling system was not turned on, and the temperature inside and outside the pig house was measured (Table 2). As shown in Table 1, when the fan-water curtain cooling system was turned on, the temperature inside the pig house was 3-7 ℃ lower than the ambient temperature. The cooling effect was obvious, the inside of the pig house was not greatly affected by the outside temperature, the temperature in the pens was kept basically constant, and the pigs ate freely and normally, and they were quiet. In contrast, the cooling effect of the traditional method was not obvious. The temperature of the pens did not decrease obviously. Only a small proportion of the pigs had appetite. The pigs breathed quickly and were restless.

Table 1 Cooling effect of fan-water curtain cooling system (September 18, 2017)

Table 2 Cooling effect of traditional method (September 19, 2017)

2.2 Effect of different cooling method on growth performance of the pigsThe pig feeding and growth experiment was conducted from September to October 2017 in two pig houses with different cooling conditions. The test period was 60 d. For traditional cooling, electric fan and top water spray were used. In the fan-water curtain cooling system, water curtain, circulating water channel exhaust fan and temperature control device were used to cool down. The pigs in the two groups of the breeding and growth experiment, 70 pigs in each group, were all ternary hybrid (Duroc×Landrace×Yorkshire), with body weight of 45-55 kg. The area of each feeding pen was 25 m2. Density and management conditions were basically the same. Feed was also the same. The concentrate formula was as follows: corn 59%, soybean meal 20%, wheat bran 13%, fish meal 4%, premix 4%, digestive energy 3 113 cal and crude protein 15.2%. Each test pig was fed with 2 kg of feed in two times (9:00 and 17:30) every day.

2.2.1Measurement methods of indices. The daily feed intake and the remaining feed in each replicate were recorded. The empty body weight of the pigs was measured and recorded in the morning of 0, 30 and 60 days. The average daily feed intake, daily weight gain and feed-to-gain ratio of each group were calculated. The growth status of the pigs, including mental status, fecal changes and fecal contamination in the anus,etc. were observed and recorded. At the end of the test, the relevant data were sorted out, and morbidity and mortality were calculated.

2.2.2Effect of different cooling method on growth performance of the pigs. The effect of different cooling method on growth performance of the pigs is shown in Table 3. In the pigs under traditional cooling mode, the average daily body weight gain was 0.715 kg, and the feed-to-gain ratio was 2.48∶1. In the pigs using the fan-water curtain cooling system, from weaning to slaughter, the daily body weight gain reached 0.75 kg, and the feed-to-gain ratio was 2.43∶1, a year-on-year decrease of 0.05. The body weight of the pigs increased by 2.5-5.0 kg on average.

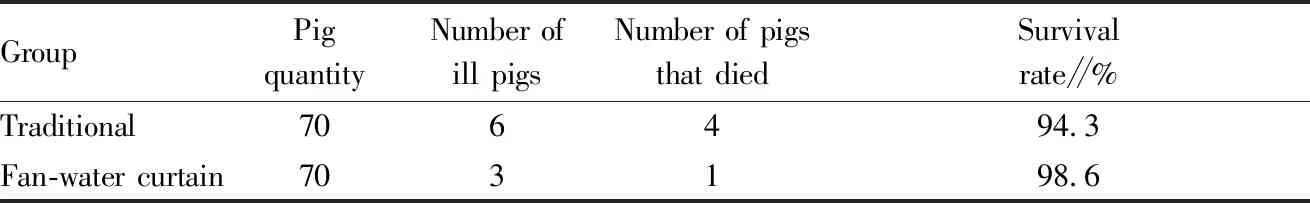

2.3 Effect of different cooling method on disease resistance of the pigsA total of 70 pigs were selected for each of the two cooling methods, traditional cooling and fan-water curtain cooling. During the test, 6 pigs in the traditional cooling group suffered from onset and 4 of them died; and in the fan-water curtain cooling group, there were 3 cases, and one of them died (Table 4). In the large-scale breeding model of closed pig houses, when the advanced fan-water curtain cooling system is used, the inside of the pig houses will be not greatly affected by the outside temperature, and the temperature in the pens will be kept basically constant. In this way, the problem of inevitable stuffiness in the hot summer season in the process of pig breeding is solved easily. In addition, the problem of air pollution in the pens of pig farms is also solved. The installation of fan-water curtain cooling system in pig farms could keep the air in circulation, reduce ammonia emission, control the entry of mice, reduce the spread of bacteria and reduce the breeding of flies and mosquitoes in closed pig houses, thereby improving the environment of pig houses and reducing the occurrence of epidemics.

Table 4 Morbidity and mortality of the pigs during the experiment

3 Conclusions

(i) Installing fan-water curtain cooling device is an effective measure for modern large-scale pig farms to cool down. It will help to avoid the serious effect of hot season on pig production, keep the pig house ventilated and improve the environmental conditions of the pig house, so that the feed intake of the pigs increases significantly and their weight gain accelerates. At the same time, the occurrence of diseases, especially respiratory diseases, decreases significantly. In this study, the feed-to-gain ratio of the pigs under the fan-water curtain cooling system decreased by 0.05. (ii) The fan water curtain cooling system is easy to install and maintain. The cooling structure of wet curtain is simple. The operation and management are convenient. No professional maintenance personnel are required. A simple maintenance procedure is enough. In addition, the investment is small, the effect is rapid, the project progress is fast, and the construction cost and operating cost are much lower than other cooling methods. During the operation of the system, a large amount of fresh outdoor air is drawn into pig houses to increase the oxygen content of the air. During the process of ventilation and cooling, new air continuously enters, and the volume is large, so that negative pressure is formed, thus preventing dust outside from entering. During the evaporation of water on the surface of the wet curtain, a part of the humid air enters the room, which can increase the humidity and prevent drying[2]. (iii) Guangxi is affected by the hot season for up to 6 months (May to October) every year. In high-temperature and high-humidity Guangxi, reducing the impact of high temperature is one of the keys to breeding commercial pigs. Therefore, it is very suitable for the installation of water curtain cooling system to reduce the impact of high temperature. Compared with the traditional cooling measures of electric fan and water spray on the top, the water curtain cooling system is more suitable for large-scale pig breeding. For a 600-pig farm, the installation of fan-water curtain cooling system will help to save feed by 3 700 kg, save cost by 13 000 yuan, and save medical expenses and pig deaths by about 12 000 yuan.

杂志排行

Asian Agricultural Research的其它文章

- Empirical Study on Relationship between Income Structure and Consumption of Rural Residents in Jiangsu

- Tillage Effect and Development Prospect of Fenlong Farming Tools with "Drill"

- Estimation of Economic and Ecological Value of Raising Sheep in Pastoral Area

- Construction of Platform-based Business Ecosystem

- Analysis of Industrial Transformation of Resource-based Towns in Qingyang City: Taking Qingcheng County as an Example

- Treatment Effect of Pig Manure-derived Biochar-based Metal Catalyst for Pig Breeding Wastewater