椎动脉开窗血流动力学仿真分析

2020-07-10张雪莲

张雪莲,黄 伟

(1. 牡丹江医学院医学影像学院,黑龙江 牡丹江 157011;2. 牡丹江医学院教务处,黑龙江 牡丹江 157011)

0 引言

椎动脉开窗属于罕见的孔型脑动脉,即开窗畸形变异[1-2]。在影像学上脑动脉开窗畸形的发现率为0.3%-0.9%,常见于临近椎基底动脉交界处。椎动脉开窗常伴有脑动脉瘤发生[3-4]。临床上常根据脑动脉瘤的形成推断动脉存在开窗畸形。应用计算流体力学方法(computational fluid dynamics,CFD)数值模拟动脉的血流动力学指标,可对椎动脉开窗形态的血流状态进行定量分析[6-8],且可对动脉瘤的形成的危险因素进行预测、分析,对临床治疗进行指导。本文旨在通过对一例椎动脉开窗畸形影像数据进行三维重建,应用计算机数值模拟仿真,分析开窗畸形脑动脉的血流动力学指标及对动脉瘤的形成影响[9-12],对临床诊断与治疗预后提供借鉴和指导。

1 材料与方法

1.1 实验设备与软件

本实验分别采用医学交互式影像控制系统、CFD网格划分软件FLUENT MESHING、CFD仿真计算软件CFX、图像后处理软件ENSIGHT进行建模、网格划分、计算、结果分析(表 1)。应用TOSHIBA/AQUILION 64排 CT扫描,选取电流250 mA,电压120 kv,层厚0.5 mm;前臂肘静脉团注射造影剂,注射速度3.5 ml/s,总量为90 ml;CT数据以 DICOM3.0 格式存储。

表1 实验使用软件Tab.1 Experimental software

1.2 三维模型重建与网格划分

由牡丹江医学院附属红旗医院提供的椎动脉开窗畸形患者的 CTA影像数据,患者女性,68岁,突发头痛,CTA显示椎动脉开窗畸形。将采集的CTA影像数据以 DICOM格式导入MIMICS21.0软件中进行图像处理,采用阈值分割、计算三维等算法,生成初步的三维模型,然后导入3-matic软件进行表面网格光顺、除去细小分支,并经多次光滑、重画网格,切平出入口(2进4出),最后检查三角面片质量,最后将编辑完毕的椎动脉模型以STL格式导出保存。使用ANSYS FLUENT MESHING软件对构建好的STL格式三维模型进行网格划分,由于模型结构比较复杂,按照非结构化的四面体进行网格划分,为保证计算精度,边界层采用5层加密。

1.3 计算设置

1.3.1 边界设置

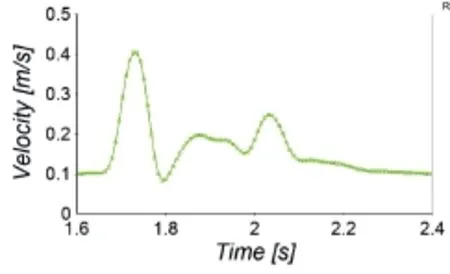

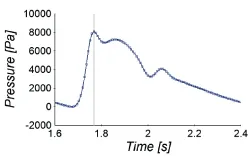

入口采用速度入口,为保证计算快速收敛,两个入口速度值存在较小的差别。入口速度曲线如图1-2所示。出口给予脉动压力,如图3所示。出口、入口位置如图4所示。

图1 入口1速度曲线Fig.1 Velocity of inlet1

图2 入口2速度曲线Fig.2 Velocity of inlet2

图3 出口压力曲线Fig.3 Pressure of outlet

图4 椎动脉入口、出口位置图Fig.4 Location of vertebral artery inlet and outlet

1.3.2 求解设置

根据雷诺数计算设置采用层流,牛顿、不可压缩流体,不考虑重力影响。本计算采用瞬态计算,计算三个周期。步长设为0.0008 s,总步数为1000步。为保证计算收敛稳定,取计算结果第三个周期进行分析。

1.4 观察指标

血流动力学参数选取:时间平均壁面切应力(time average wall shear stress,TAWSS)、平均壁面切应力梯度(time average wall shear stress grade,TAWSSG)、剪切震荡系数(oscillatory shear index,OSI)、动脉瘤形成指标(aneurysm formation index,AFI)),梯度震荡数值(GON)等参数作为观察指标。由于 CFX无法直接输出 TAWSS、TAWSSG、OSI、AFI、GON等指标,需要ccl语言编程。

2 结果

2.1 OSI云图

由OSI云图(图5)可见在椎动脉开窗处,存在高OSI区域,其他区域表现低OSI区域。表明由于椎动脉存在开窗畸形导致不同的椎动脉区域血流震荡,高低OSI震荡易导致动脉瘤的发生。

图5 椎动脉开窗OSI云图Fig.5 Vertebral artery fenestration OSI cloud

2.2 TAWSS云图

图6 为椎动脉TAWSS云图,TAWSS为脉动流在一个心脏周期内用每个节点上积分 WSS量的值来计算 TAWSS,TAWSS云图中椎动脉各区域中呈现出分布不均,TAWSS呈现红色,表明TAWSS较大,TAWSS呈现蓝色表明 TAWSS较小,图中高TAWSS区域分布于椎动脉的出口附近区域:主干、分叉。由于主干区域的血流速度较大,该区域TAWSS较其他区域集中,数值较大。

图6 TAWSS云图Fig.6 TAWSS Distribution Nephogram

2.3 椎动脉GON云图

图7 为GON云图,由图可见,椎动脉GON分布极其不均匀,在椎动脉开窗附近的主血管区域呈现较大的GON值,表明椎动脉表面存在强烈的震荡力和压缩力,原因是血液在进入瘤腔后形成涡流,导致动脉壁震荡,这种冲击对血管壁造成膨胀或者扩张。

图7 GON云图Fig.7 GON distribution nephogram

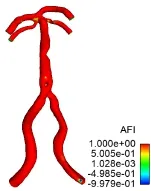

2.4 椎动脉AFI云图

图8 中椎动脉AFI值普遍较大,在椎动脉的分叉处,存在相对较小的AFI值,说明血流不断冲击管壁,形成涡流,血流运动极其不稳定,容易导致脑动脉瘤的形成。

图8 AFI云图Fig.8 AFI distribution nephogram

2.5 TAWSSG云图

图9 为椎动脉开窗畸形的TAWSSG云图,由图中可见,高 TAWSSG均分布于分叉、开窗区域,TAWSSG较大易造成血管壁损伤。椎动脉开窗畸形导致血流在狭窄、分叉区域速度较快,冲击血管壁,导致血管壁局部区域TAWSSG较高。

图9 TAWSSG云图Fig.9 TAWSSG distribution nephogram

3 结论

椎动脉开窗畸形引起血液异常流动,在此基础上,AFI表征动脉瘤形成指数[13-15],椎动脉开窗畸形血管形成动脉瘤的风险较大。同时,OSI震荡表明,血液在流动过程中,局部区域速度忽高忽低,来回震荡,形成动脉瘤易发因素。此外,在其他血流动力学指标上,椎动脉开窗畸形也导致了异常情况的发生,发展。通过计算机三维建模与计算流体力学仿真,可获取椎动脉开窗畸形的内部血液流变指标,进而可为临床应用提供指导与借鉴。

4 讨论

椎动脉瘤与椎动脉开窗畸形有一定的因果关系,一些学者[16-20]已通过宏观血流动力学特征证实,椎动脉开窗畸形动脉瘤与两支血管之间形成囊动脉瘤[21-28]是由于血流动力学参数剧烈变化的导致的结构改变,血液流动时,椎动脉左血管管径较粗,形成优势支,其血流量、流速均大于右支[29-33]在血管分叉处,形成最大压力。

5 ccl部分源代码

ADDITIONAL VARIABLE:

ADDITIONAL VARIABLE: Gmag

Additional Variable Value = sqrt(Gx *Gx + Gy * Gy + Gz * Gz)

Option = Algebraic Equation

END

ADDITIONAL VARIABLE: Gx

Additional Variable Value = -(1.0-Normal X*Normal X)*WSSxF.Gradient

X -(0.0-Normal X*Normal Y)*WSSxF.Gradient Y -(0.0-Normal X*Normal

Z)*WSSxF.Gradient Z

Option = Algebraic Equation

END

ADDITIONAL VARIABLE: Gy

Additional Variable Value = -(0.0-Normal Y*Normal X)*WSSyF.Gradient

X -(1.0-Normal Y*Normal Y)*WSSyF.Gradient Y -(0.0-Normal Y*Normal

Z)*WSSyF.Gradient Z

Option = Algebraic Equation

END

ADDITIONAL VARIABLE: Gz

Additional Variable Value = -(0.0-Normal Z*Normal X)*WSSzF.Gradient

X -(0.0-Normal Z*Normal Y)*WSSzF.Gradient Y -(1.0-Normal Z*Normal

Z)*WSSzF.Gradient Z

Option = Algebraic Equation

END

ADDITIONAL VARIABLE: PressGauge

Additional Variable Value = pref +Pressure

Option = Algebraic Equation

END

ADDITIONAL VARIABLE: Qvar

Additional Variable Value = -0.5*(0.5*Shear Strain Rate^2 -

0.5 *vortmag2)

Option = Algebraic Equation

END

ADDITIONAL VARIABLE: ViscDisp

Additional Variable Value = (Shear Strain Rate)^2

Option = Algebraic Equation

END

ADDITIONAL VARIABLE: WSSField

Kinematic Diffusivity = 1e-15 [m^2 s^-1]

Option = Poisson Equation

END

ADDITIONAL VARIABLE: WSSG

Option = Vector Algebraic Equation

Vector xValue = -(1.0-Normal X*Normal X)*WSSField.Gradient X

-(0.0-Normal X*Normal Y)*WSSField.Gradient Y -(0.0-Normal X*Normal

Z)*WSSField.Gradient Z

Vector yValue = -(0.0-Normal Y*Normal X)*WSSField.Gradient X

-(1.0-Normal Y*Normal Y)*WSSField.Gradient Y -(0.0-Normal Y*Normal

Z)*WSSField.Gradient Z

Vector zValue = -(0.0-Normal Z*Normal X)*WSSField.Gradient X

-(0.0-Normal Z*Normal Y)*WSSField.Gradient Y -(1.0-Normal Z*Normal

Z)*WSSField.Gradient Z

END

ADDITIONAL VARIABLE: WSSxF

Kinematic Diffusivity = 1e-15 [m^2 s^-1]

Option = Poisson Equation

END

ADDITIONAL VARIABLE: WSSyF

Kinematic Diffusivity = 1e-15 [m^2 s^-1]

Option = Poisson Equation

END

ADDITIONAL VARIABLE: WSSzF

Kinematic Diffusivity = 1e-15 [m^2 s^-1]

Option = Poisson Equation

END

COMBUSTION MODEL:

Option = None

END

HEAT TRANSFER MODEL:

Option = None

END

THERMAL RADIATION MODEL:

Option = None

END

TURBULENCE MODEL:

Option = Laminar

END

END

END

INITIALISATION:

Option = Automatic

INITIAL CONDITIONS:

Velocity Type = Cartesian

ADDITIONAL VARIABLE: WSSField

Additional Variable Value = 0 [kg m^-1 s^-2]

Option = Automatic with Value

END

ADDITIONAL VARIABLE: WSSxF

Additional Variable Value = 0 [kg m^-1 s^-2]

Option = Automatic with Value

END

ADDITIONAL VARIABLE: WSSyF

Additional Variable Value = 0 [kg m^-1 s^-2]

Option = Automatic with Value

END

ADDITIONAL VARIABLE: WSSzF

Additional Variable Value = 0 [kg m^-1 s^-2]

Option = Automatic with Value

END

CARTESIAN VELOCITY COMPONENTS:

Option = Automatic with Value

U = 0 [m s^-1]

V = 0 [m s^-1]

W = 0 [m s^-1]

END

STATIC PRESSURE:

Option = Automatic with Value

Relative Pressure = 0 [Pa]

END

END

END

OUTPUT CONTROL:

RESULTS:

File Compression Level = Default

Option = Standard

END

TRANSIENT RESULTS: Transient Results 1

File Compression Level = Default

Include Mesh = No

Option = Selected Variables

Output Variables List = Absolute Pressure,Total Pressure,Pressure,PressGauge,Velocity,Velocity u,Velocity v,Velocity

w,Vorticity,Vorticity X,Vorticity Y,Vorticity Z,Wall Shear,Wall

Shear X,Wall Shear Y,Wall Shear Z,Shear Strain

Rate,Qvar,ViscDisp,WSSField,WSSG,AFI

OUTPUT FREQUENCY:

Option = Time List

Time List = 1.6 [s], 1.608 [s], 1.616 [s],1.624 [s], 1.632 [s],

1.64 [s], 1.648 [s], 1.656 [s], 1.664[s], 1.672 [s], 1.68 [s],

1.688 [s], 1.696 [s], 1.704 [s], 1.712[s], 1.72 [s], 1.728 [s],

1.736 [s], 1.744 [s], 1.752 [s], 1.76[s], 1.768 [s], 1.776 [s],

1.784 [s], 1.792 [s], 1.8 [s], 1.808 [s],1.816 [s], 1.824 [s],

1.832 [s], 1.84 [s], 1.848 [s], 1.856[s], 1.864 [s], 1.872 [s],

1.88 [s], 1.888 [s], 1.896 [s], 1.904[s], 1.912 [s], 1.92 [s],

1.928 [s], 1.936 [s], 1.944 [s], 1.952[s], 1.96 [s], 1.968 [s],

1.976 [s], 1.984 [s], 1.992 [s], 2 [s],2.008 [s], 2.016 [s],

2.024 [s], 2.032 [s], 2.04 [s], 2.048[s], 2.056 [s], 2.064 [s],

2.072 [s], 2.08 [s], 2.088 [s], 2.096[s], 2.104 [s], 2.112 [s],

2.12 [s], 2.128 [s], 2.136 [s], 2.144[s], 2.152 [s], 2.16 [s],

2.168 [s], 2.176 [s], 2.184 [s], 2.192[s], 2.2 [s], 2.208 [s],

2.216 [s], 2.224 [s], 2.232 [s], 2.24[s], 2.248 [s], 2.256 [s],

2.264 [s], 2.272 [s], 2.28 [s], 2.288[s], 2.296 [s], 2.304 [s],

2.312 [s], 2.32 [s], 2.328 [s], 2.336[s], 2.344 [s], 2.352 [s],

2.36 [s], 2.368 [s], 2.376 [s], 2.384[s], 2.392 [s], 2.4 [s]

END

END

TRANSIENT STATISTICS: Trans2

Option = Maximum

Output Variables List = OSIfield,WSSField,WSSG

Start Iteration List = 201

Stop Iteration List = 300

END

TRANSIENT STATISTICS: Transient-StatsMin

Option = Minimum

Output Variables List = AFI

Start Iteration List = 201

Stop Iteration List = 300

END

TRANSIENT STATISTICS: trnstat1

Option = Arithmetic Average

Output Variables List = Velocity,Wall Shear,WSSField,AFI,Gx,Gy,Gz,Gmag

Start Iteration List = 201

Stop Iteration List = 300

END

END

SOLVER CONTROL:

ADVECTION SCHEME:

Blend Factor = 1.0

Option = Specified Blend Factor

END

CONVERGENCE CONTROL:

Maximum Number of Coefficient Loops= 5

Minimum Number of Coefficient Loops = 1

Timescale Control = Coefficient Loops

END

CONVERGENCE CRITERIA:

Residual Target = 0.005

Residual Type = MAX

END

EQUATION CLASS: av

ADVECTION SCHEME:

Option = High Resolution

END

END

TRANSIENT SCHEME:

Option = Second Order Backward Euler

TIMESTEP INITIALISATION:

Option = Extrapolation

END

END

END

EXPERT PARAMETERS:

linearly exact numerics = t

END

END

INTERPOLATOR STEP CONTROL:

Runtime Priority = Standard

MEMORY CONTROL:

Memory Allocation Factor = 1.0

END

END

PARALLEL HOST LIBRARY:

HOST DEFINITION: desktop0jjvpii

Remote Host Name = DESKTOP-0JJVPII

Host Architecture String = winntamd64

Installation Root = D:Program FilesANSYS Incv%vCFX

END

END

PARTITIONER STEP CONTROL:

Multidomain Option = Automatic

Runtime Priority = Standard

MEMORY CONTROL:

Memory Allocation Factor = 1.0

END

PARTITION SMOOTHING:

Maximum Partition Smoothing Sweeps= 100

Option = Smooth

END

PARTITIONING TYPE:

MeTiS Type = k-way

Option = MeTiS

Partition Size Rule = Automatic

END

END

RUN DEFINITION:

Run Mode = Full

SOLVER STEP CONTROL:

Runtime Priority = Standard

MEMORY CONTROL:

Memory Allocation Factor = 1.0

END

PARALLEL ENVIRONMENT:

Number of Processes = 1

Start Method = Serial

END

END

END

END