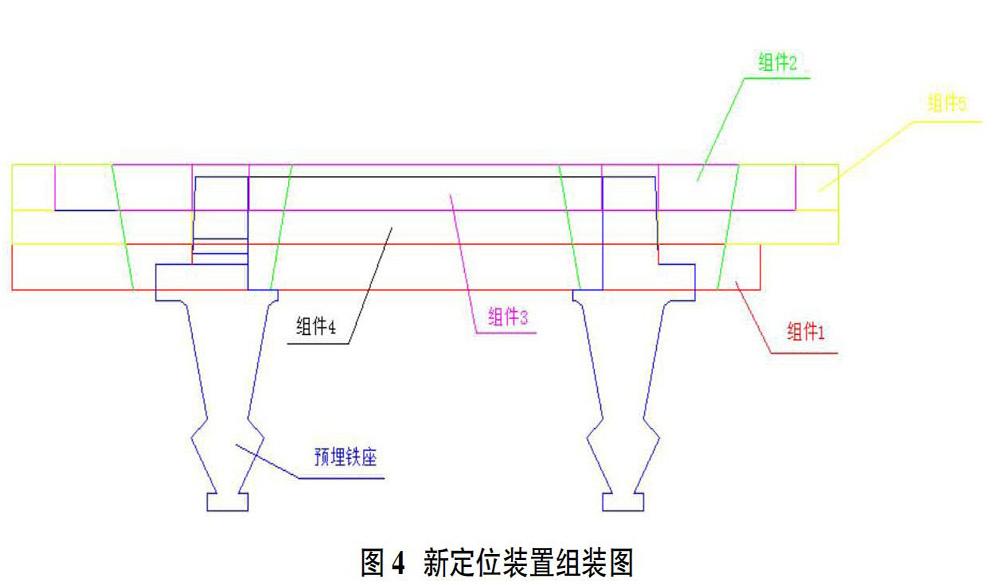

预埋铁座轨枕定位装置的改进研究

2020-05-25韩运涛

韩运涛

摘要:预埋铁座轨枕一般用于重载铁路的铺设。预埋铁座枕的生产难度远高于较普通预留孔轨枕及预埋套管轨枕,由于其预埋铁座部分突出于轨枕顶面,在预应力放张时,铁座与模具间会发生位移,故预埋铁座固定装置必须使铁座与壳体间存在缝隙,或采用柔性可压缩材料,为铁座与模具间留有一定伸缩量。预埋铁座的设计形式,使得生产此类轨枕时,定位精度与预埋铁座周围的密封成为主要难点;现有定位方式虽能满足预埋铁座的定位精度,但密封性较差,预埋铁座周围混凝土的外观质量较差;另一突出的问题是预埋铁座轨枕的生产效率较低,人工成本浪费严重。本文将围绕预埋铁件定位装置的改进研究,提供解决现有定位方式生产效率低下,铁座周边外观质量差的新思路,从而为所有预埋铁座轨枕生产提供一种,生产效率更高,成本进一步降低,外观质量更好的生产方式。

Abstract: The embedded iron seat sleeper is generally used for the laying of heavy-duty railway. The production difficulty of the embedded iron seat sleepers is much higher than that of the ordinary reserved hole sleepers and the embedded sleeve sleepers. Because the embedded iron seat part protrudes from the top of the sleepers, there will be displacement between the iron seat and the mold when the prestress is released, the fixed device of the embedded iron seat must keep the gap between the iron seat and the shell, or use flexible and compressible materials to leave a certain amount of expansion between the iron seat and the mold. The design form of the embedded iron seat makes the positioning accuracy and the sealing around the embedded iron seat become the main difficulties in the production of such sleepers; although the existing positioning method can meet the positioning accuracy of the embedded iron seat, it has poor sealing performance and poor appearance quality of the concrete around the embedded iron seat; another prominent problem is the low production efficiency of the embedded iron seat sleepers and serious waste of labor costs. This paper will focus on the improvement of the positioning device of embedded iron parts, and provide a new idea to solve the low production efficiency and poor appearance quality of the existing positioning mode, so as to provide a production mode with higher production efficiency, further cost reduction and better appearance quality for the production of all embedded iron seat sleepers.

关键词:预埋铁座定位装置设计;生产效率;外观质量;节约成本

0 引言

目前行业内采用的预埋铁座固定装置,均采用柔性可压缩材料方式,使用此装置的拆、装工艺步骤较多,整套拆装工艺占用行车较多,生产效率低;用于密封的胶圈损耗量大,人工用量大,成本高;因胶圈损坏变形导致预埋铁座周围混凝土凹凸不平,外观质量差。本文将通过总结以往定位装置的缺点分析,通过设计新形式定位装置,解决预埋铁座轨枕生产效率低、成本高、外观质量差的一系列问题。埋入式长枕产品如图1所示。

1 现有定位装置存在的问题

1.1 生产效率低

由于预埋件与定位装置间没有缝隙,摩擦力大,脱模只能用行车吊住单根轨枕,然后用锤敲击,缓慢将轨枕吊起,吊起过快易造成枕开裂产生废品,每模枕脱模时间不少于20分钟。

胶圈变形、损坏,灰浆粘在胶圈凹槽,不清理干净无法进行预埋件安装,清理工作非常耗费时间,胶圈清理、更换时间不少于20分钟。

预埋件顶丝位置空间狭小,不能采用电动工具提升装、卸效率,且数量很多,每模8根枕;每根枕4个预埋铁座,每个铁座2条顶丝,每模共有顶丝64条,均需用普通扳手拆除,4人拆除需、安装共需20分钟。预埋件顶丝如图2所示。

预埋件安装后,须由质检人员逐根对预埋件的大小轨距进行测量檢验,合格后进行最后紧固,每模耗费时间不小于15分钟。