GC-MS,GC-O and OAV analyses of key aroma compounds in Jiaozi Steamed Bread

2020-05-08YuanhuiWangJingwenZhaoFeiXuXiaoyunWuWenxuanHuYongfengChangLanlanZhangJieChenChanghongLiu

Yuanhui Wang,Jingwen Zhao*,Fei Xu,Xiaoyun Wu,Wenxuan Hu,Yongfeng Chang,Lanlan Zhang,Jie Chen,Changhong Liu

College of Food Science and Technology,Henan University of Technology,Zhengzhou 450001,China

Keywords:

Volatile compounds

Simultaneous distillation and extraction

Headspace solid-phase microextraction

Quantitative analysis

Method validation

ABSTRACT

Jiaozi Steamed Bread(JSB)has a unique aroma as a traditional staple food in China.The volatile compounds in JSB were extracted by simultaneous distillation and extraction(SDE)and headspace solid-phase microextraction(HS-SPME).These volatile substances were analyzed by gas chromatography-mass spectrometry (GC-MS) and gas chromatographyolfactometry-mass spectrometry(GC-O-MS).The results demonstrated that 61 volatile compounds were identified totally in samples,of which 15 were confirmed as potent aroma compounds with odor active values(OAVs)>1.The 15 potent aroma compounds were ethanol,1-butanol,1-pentanol,1-hexanol,heptanol,1-octen-3-ol,3-methyl-1-butanol,hexanal,heptanal,nonanal,(E)-2-heptenal,benzaldehyde,(E,E)-2,4-decadienal,2-pentylfuran and naphthalene.The SDE method had better linearity with coefficients of determination(R2)equal to or higher than 0.9991.Furthermore,the SDE method also achieved lower sensitivity and better repeatability and recovery than HS-SPME.This work provides reference method and parameters for future research on the flavor of JSB for commercial products.

1.Introduction

Chinese steamed bread is a staple food in China deriving from the Han Dynasty since around 1500 CE[1].It is fermented with traditional dough starter-Jiaozi and commonly consumed in northern areas of China[2].Because of its high activity, instant dry yeast has been widely used in the commercial market.Besides, Jiaozi was used to make steamed bread that had a unique aroma and fantastic taste to meet the needs of people with the improvement of living standards [3].Depended on the raw materials used, Jiaozi can be classified as maize flour Jiaozi (MFJ) and rice flour Jiaozi (RFJ).MFJ is produced with maize flour, muskmelon and wheat flour.Moreover, RFJ is produced with rice flour, rice wine and Chinese Qu which is added for making Chinese liquor as a traditional starter [4].

The aroma is one of the most important characteristics of food,which is related to its acceptance by consumers [5].Ordinary methods of extracting aroma composition include simultaneous distillation extraction(SDE), ultrasound-assisted solvent extraction (UAE), liquid-liquid extraction (LLE) and headspace solid-phase microextraction (HS-SPME) [6].The single extraction method could not extract total volatiles,so different methods should be used in combination [7].SDE and HS-SPME have been adopted widely in most common methods due to the advantages of both extraction methods.SDE was employed to extract aroma compounds with medium and high boiling point and had excellent repeatability for quantitation.However, the SDE method is time-consuming comparing to HS-SPME.The HS-SPME method integrated sampling, extraction and concentration into one step with high sensitivity and relatively low repeatability [8,9].The volatile mixture was separated by the GC system and GC effluent was determined by MS system.At the same time,GC-MS coupled with an olfactory(GC-O)to obtain odor properties of volatiles [10].

So far, researches on physicochemical indexes of steamed bread have been widely studied [3,11,12].Others have also exerted efforts to investigate different starters which influenced aroma information in Chinese steamed bread[2,5].The results indicated that Jiaozi and type I sourdoughs had a significant difference on forming volatiles of steamed bread[2].Jiaozi with muchSaccharomyces cerevisiaehas the strongest fermentation capacity and produced more aroma compounds,such as 3-methyl-1-butanol and ethanol[5].However,the volatile compounds of Chinese steamed bread from different areas were only extracted by a single technic [1,5].Moreover, GC-O was rarely used to analyze the flavor of JSB.There was little previous research on the aroma of JSB by combining various extraction methods for qualitative and quantitative analysis.

In this study,the SDE and HS-SPME methods were used respectively for extracting volatile components from JSB.Linear retention index(LRI)and mass spectrogram of volatiles were used together for qualitative analysis[10].Likewise,GC-O-MS was worked for detecting the potent flavor substances.OAVs of the volatile substances were calculated to determine potent aroma compounds,of which the OAVs were larger than 1,for semi-quantitative analysis.Not only semi-quantitative analysis but also standard curve method was employed for quantitative analysis.In a more comprehensive analysis,the qualitative and quantitative information of the potent aroma compounds in JSB would be further understood and adopted.

2.Materials and methods

2.1.Chemicals

For identification and quantitation of aroma compounds,three HPLCgrade solvents(n-hexane,dichloromethane,diethyl ether)were obtained from Thermo(Shanghai,China).Anhydrous sodium sulfate(analytical reagent)and naphthalene(99%)were purchased from Innochem(Beijing,China).(E)-2-heptenal (99%) and 2-methyl-3-heptanone (99%) were sourced from Aladdin(Shanghai,China).Heptanal(98%),hexanal(98%),1-butanol (99%), 3-methyl-1-butanol (97%), 2-pentylfuran (97%), 1-pentanol(98%),1-hexanol(98%),nonanal(99%),1-octen-3-ol(98%),2-ethyl-1-hexanol(97%),benzaldehyde(99%),(E,E)-2,4-decadienal(98%),carbonic acid, dipentyl ester (98%), octanoic acid, methyl ester (98%),undecane (98%), heptadecane (98%), nonadecane (98%), camphor(99%), 6-methyl-5-hepten-2-one (99%), diethyl sulfide (98%),hexadecanoic acid(98%),acetic acid(97%)were obtained from Adams(Beijing,China).Then-alkanes standard(C7-C30,≥97%,1000 μg/mL)was obtained from Supelco(USA)for the calculation of LRIs.1-Heptanol(99%) was purchased from TCI (Shanghai, China).Wheat flour (0.48%ash,11.11%protein,13.6%moisture)was purchased from Jinyuan Flour Co.,Ltd.(Zhengzhou,China).Jiaozi was bought from a local supermarket(Nanyang,China).Yeast and edible alkali were sourced from Angel Yeast Co.,Ltd.

2.2.Jiaozi samples and JSB making

The conventional two-stage fermentation method was used to make JSB in this experiment.Wheat flour (200 g) was mixed with 100 mL of distilled water, 7.5 g of Jiaozi for 4-5 min in a mixing machine (SZM5, Xuzhong Co., Ltd., Guangzhou, China) to obtain dough before being placed in a thermostatic room for 6 h at 23 °C.Then the dough was mixed with 300 g of wheat flour which was adequately mixed with 1 g of yeast, 100 mL of distilled water and alkali solution (0.75 g alkali in 20 mL water in a flask), kneaded gently for 15-20 min until the dough became soft.The dough was pressed for 15 times, rolled into a round shape, then cut into a rectangular blocks, and fermented fully for 40 min.After that, the fermented dough blocks were put in a steamer and steamed for 25 min to obtain JSB.

2.3.Optimization of SDE

The SDE apparatus was refined to avoid foams,as shown in Fig.1.JSB was put into one side of the SDE apparatus and the other side was coupled with a 100 mL round-bottomed flask which was filled with extraction solvent(n-hexane,dichloromethane or anhydrous diethyl ether),solvent volume was 40,60,80 and 100 mL,extraction time was 30,40,50,60,70 and 80 min.The extraction solvent was treated with anhydrous Na2SO4and concentrated to 1 mL at 50°C using a Vigreux column(45 cm×2 cm)[9].SDE apparatus without steamed bread was treated under the above mentioned conditions as a blank.All samples were stored at-18°C before determination.

Fig.1.Refined SDE apparatus.

2.4.Optimization of HS-SPME

Different fiber coatings,extraction temperature(45,55,65,75,85°C),extraction time(20,30,40 min)and desorption time(4,6,8 min)had a remarkable influence on the HS-SPME analysis.Firstly,six HS-SPME fibers(100 μm PDMS,7 μm PDMS,65 μm PDMS/DVB,75 μm CAR/PDMS,50/30 μm CAR/DVB/PDMS)were cleaned thermally before being used for a blank analysis.The HS-SPME extraction process comprised the following steps:placing 3 g of JSB crumbs in a 30 mL vial,optimizing the extraction temperature,setting the optimum temperature for the water bath,fixing the vial in the water bath,then inserting the aged HS-SMPE extraction needle into the via through silicon rubber pads rapidly,pushing out fiber coating,balancing for a period of time,inserting the extraction needle into the injection port of GC for desorption,and optimizing the effect of different desorption time on the extraction effect.

2.5.GC-MS analysis

The volatile compounds were determined by GC-MS(7890A GC System,5975C MSD,Agilent Technologies,Santa Clara,USA)with both DB-5MS and DB-WAXETR capillary columns(J&W Scientific,USA,60 m×0.25 mm×0.25 μm).Chromatographic analysis condition 1:chromatographic column was DB-5MS;the helium was used as carrier gas and at a rate of 1.0 mL/min; the injection mode was splitless; injection volume was 1 μL;the injection temperature was 250°C,and the transfer line temperature was 280°C;the oven temperature was 40°C and held for 2 min,then increased 3°C/min to 50°C and held for 1 min,ramped to 110°C at 5 °C/min and held for 1 min, raised to 250 °C at 6°C/min and held for 1 min and finally held at 300°C for 10 min.Electron-impact mass spectra were generally at 70 eV using ion source temperature at 230°C;the MS quadrupole temperature was 150°C.The full scan mode ranged from 30-550 amu(atomic mass unit).The scan mode was ion-monitoring when some compounds were quantitative.

Chromatographic analysis condition 2:chromatographic column was DB-WAXETR;the chromatographic analysis condition was as the same as condition 1,and the transfer line temperature was 250°C.

2.6.GC-FID analysis

The volatile compounds were analyzed using GC-FID(7890A,Agilent Technologies,Santa Clara,USA).The chromatographic column and heating program executed in GC-FID were exactly the same as those of GC-MS.The split mode was splitless.The constant flow rates of three gases were as follows:N2(99.999%),3 mL/min;air,400 mL/min;H2,47 mL/min.

2.7.GC-O analysis

To prevent olfactory fatigue,six trained sensory panelists who recorded flavor characteristics and intensity were selected for sensory analysis.The trained panelists consisted of three males and three females of different ages from the department of food science and technology of Henan University of Technology.During the experiment, at least two sensory panelists could get the same sensory description at the same time,and then they recorded down the final result.The temperature program was as same as the GC-MS analysis.

2.8.Identification of volatile compound

The qualitative method relied on the mass spectrometry library,LRI[13],and authentic flavor standards.The mass spectrometry library was NIST17.0 mass spectrometry database.LRI was put forward in calculating the retention time of volatile compounds which were compared with reported literature[14].

2.9.Quantitation of aroma compounds

The quantifications of volatile components from JSB were based on the peak area with response factors(RFs)[15].The volatile component classes were differentiated based on their functional groups and chemical classes.The RFs recorded in Table 1 are the average values of the response factors for the manufacture of each standard compound within the chemical category.The analytical method was applied to the determination of all volatile compounds'concentrations(g/100 g).

The internal calibration principle was used in the quantitation of aroma compounds from JSB[16].The reagent of 2-methyl-3-heptanone was used as an inner standard.Some volatile substances with OAVs >1 were selected for quantitative analysis.The SDE method comprised the steps of weighing standards accurately,dissolving the standards with different weights in nhexane in a volumetric flask as the mother liquor,transferring 10,30,50,75,100,200,300,400 and 500 μL mother liquor to a 10 mL volumetric flask,adding 2-methyl-3-heptanone(0.105 mg/mL,0.2 mL),dissolving withn-hexane to metered volume to obtain solutions with 9 concentration gradients,sucking 1 mL solution of each concentration gradient into a sample bottle,and drawing 1 μL solution for GC-MS analysis.

In the HS-SPME method,an artificial odorless matrix was a primary task.According to the literature[17],an odorless matrix was done as follows:mixing diethyl ether,n-pentane and crushed steamed bread core in a ratio of 2:1:1,shaking for 8 h,removing organic solvent in which many aromas in JSB were dissolved,repeating the above steps at least three times,and drying under vacuum.Next,the SPME technique was quantified in the same way.The peak area ratio between the compound and internal standard(IS)was calculated from the peak area of specific segments of the analyte and 2-methyl-3-heptanone(m/z=85,86,128)[8].

2.10.Method validation

The minimum standard concentrations were repeated ten times and the standard deviation(SD)was confirmed to verify the accuracy and efficiency of the two methods.The limit of detection(LOD)and the limit of quantitation(LOQ)were calculated respectively,as three times and ten times of the standard deviation [18].The recovery rate by the standard addition method and three additional levels were spiked according to the actual measurement content of the sample.The spiked three levels were 50%,100%and 200%of each real sample concentration,respectively.The samples were reprocessed six times and the relative standard deviation(RSD)of each quantitative substance was calculated as repeatability[6].

2.11.Statistical analysis

All experiments were carried out in triplicates, and the data were expressed as mean values±standard deviation.Statistical analysis used one-way analysis of ANOVA and some database was expressed by SPSS(version 22.0,IBM Corporation,USA),and other graphs were performed by Origin 2018 software(Origin Lab Corporation,USA).

Table 1 Response factors(RFs)of the different chemical components.

3.Results and discussion

3.1.SDE optimization

The results of the optimal SDE parameters were shown in Fig.2.The content of volatiles in extraction solvents was represented by peak area in the determination of GC-FID.The contents of volatiles in the three solvents had significant difference,wherein the content of volatiles in diethyl ether was the highest,and that inn-hexane was the lowest(Fig.2a).In the light of its physical properties,anhydrous ether has a low boiling point(34.6°C),relatively low solubility in water and low polarity,making it suitable for dissolving volatile substances.The volatile content was the largest when the volume of extraction solvent was 80 mL(Fig.2b).The extract content increased to the maximum value at 50 min,then decreased sharply with the extraction time(Fig.2c),resulting from that compounds with low boiling points and low molecular weights would be reduced in contents with the increase of extraction time.In a word, the optimal extraction solvent was anhydrous diethyl ether,extraction volume was 80 mL,and extraction time was 50 min.

3.2.HS-SPME optimization

The results of fiber coating type,extraction temperature,extraction time,and desorption time in HS-SPME on DB-5MS column and DB-WAXETRE column were presented in Fig.3 and Fig.4,respectively.The results showed that the adsorption ability of fiber coating(50/30 μm DVB/CAR/PDMS)was the strongest to the volatiles from JSB,and the extraction efficiency was the best among the six fiber coating(Fig.3a,Fig.4a),not only on the DB-5MS but also on the DB-WAXETRE column.The rise in temperature could accelerate the molecular diffusion speed of the determined substances[19].While the adsorption step of HS-SPME was an exothermic process,further raising temperature would lead to the decline of the extraction rate[6].On DB-5MS column,the extract content increased at temperature from 45°C to 55°C,then reached the maximum value at 55°C,and decreased from 55°C to 75°C(Fig.3b).The content of extract increased firstly,reached the maximum value at 30 min and then declined sharply over the time of adsorption(Fig.3c).It is well known that HS-SPME is a dynamic equilibrium process and the adsorption might reach saturation at an optimal time.Desorption time was another factor affecting HSSPME.However,high temperatures could shorten the life span of the fiber coating.The results showed that from 4 to 8 min(desorption time),the peak area was at 6 min with a small desorption area at 4 and 8 min, respectively(Fig.3d).In the same way,the optimal parameters on the DB-WAXETR column were shown in Fig.4.The type of fiber coating was 50/30 DVB/CAR/PDMS(Fig.4a), extraction temperature was 75 °C (Fig.4b), extraction time was 30 min(Fig.4c)and desorption time was 4 min(Fig.4d).

Fig.2.SDE optimization.

Fig.3.SPME optimization on DB-5MS column.

Fig.4.SPME optimization on DB-WAXETR column.

3.3.Identification of volatile compounds in JSB

Volatile components of JSB were determined by SDE and HS-SPME technologies coupled with GC-MS.A total of 61 aroma compounds could be divided into 8 chemical families (Table 2), including alcohols (13), aldehydes (6), esters (9), aromatic compounds (8), hydrocarbons (18), ethers (3), ketones (2), organic acids (2).The content of alcohols accounted for an enormous number of volatile compounds in JSB.It was reported that phenyl ethyl alcohol was produced by phenylalanine in flour [5].Also, 2-methyl-1-propanol and 3-methyl-1-butanol were derived from valine and leucine, respectively.However, 2-ethyl-1-hexanol has not been reported before.The content of aldehydes was secondary which surpassing esters.In this study,these six aldehydes have been identified in previous fermented steamed bread [1,5,9].Hydrocarbons contained many volatile compounds with a characteristic of high thresholds with low aroma activity [1].Besides, both ethers and organic acid played an important role in fermented steamed bread.Similarly as, organic acid not only produced the smell of acid but also provided precursors of other fragrance substances [1].As seen in Table 2, the two extraction methods presented the difference.The content of hydrocarbons extracted by HS-SPME were more than the extract from SDE.

3.4.Determination of the key compounds in JSB using GC-O and OAVs

The aroma compounds in JSB samples were characterized by GC-O and compared with authentic standards.The OAVs of volatile compounds were calculated by dividing the concentrations by the reported threshold [5,26,31].The significance of aroma in JSB depends on the amounts of compounds and their OAVs.As shown in Table 3,fifteen compounds with OAVs >1 were as followed: ethanol,1-butanol, 1-pentanol, 1-hexanol, 3-methyl-1-butanol, 1-octen-3-ol,1-heptanol, hexanal, heptanal, (E)-2-heptenal, nonanal, (E,E)-2,4-decadienal, naphthalene, 2-pentylfuran, and benzaldehyde.Such as heptanal, 2-pentylfuran, 1-pentanol, 1-octen-3-ol, 1-heptanol, (E)-2-heptenal, naphthalene and (E,E)-2,4-decadienal, they had low thresholds and high concentrations in aroma compounds.

The odor descriptions of fifteen compounds are presented in Table 3.According to the previous literature[20],the production of hexanal,heptanal and nonanal maybe was the result of the increase activity of oxidative yeasts.Aldehydes in carbonyl compounds contribute more than ketones about the flavor of JSB[1].Aldehydes'production might be the result of enzymatic oxidation of linoleic acid through the Ehrlich pathway in dough mixing and fermentation by the degradation of a few amino acids[21].Hexanal had a grassy,green and fatty fragrance,and it was assumed to be a characteristic feature of homofermentativelactobacilli[20].In addition,hexanal has been reported in ahead of benzaldehyde in sourdough bread[22].Nonanal had a citrus-like and soapy flavor.(E,E)-2,4-decadienal and(E)-2-heptenal extracted by SDE and HS-SPME techniques were all with fatty and aldehydic flavor.They were considered as the critical aroma in the bread crumb[23].

Overall,among alcohols,1-hexanol and ethanol were abundant,and 3-methyl-1-butanol also has been reported in yeast bread which was the same as JSB's[24].Mainly,3-methyl-1-butanol was an essential compound in bread flavor,and it had a positive correlation with alcoholic and malty flavor [5].Hexanol had a strong aroma of grass and flowers, and the same flavor as the investigated results[25].Butanol had a flavor of malty and solvent-like the same as reported study[26].1-octen-3-ol generated mushroom,earthy and fungal smells,and 1-pentanol was smelt intense fusel and fermented.

Because of the lower aromatic threshold and high relative content, and aromatic compounds contributed a lot.Benzaldehyde had a smell of almonds.2-Pentylfuran was commonly found in potato and coffee with fruit, vegetable and soil scent due to the low threshold [27].It was typically considered that the aroma thresholds of olefins were less than alkane and had little contribution to steamed bread flavor [28].In this work, acetic acid was a low content in steamed bread processing and generated fromlactobacillus(LAB)[29].

Table 2 GC-O-MS identification of volatiles in Jiaozi Steamed Bread obtained by SDE and SPME on two different capillary columns.

3.5.Quantitation analysis of aroma compounds in JSB

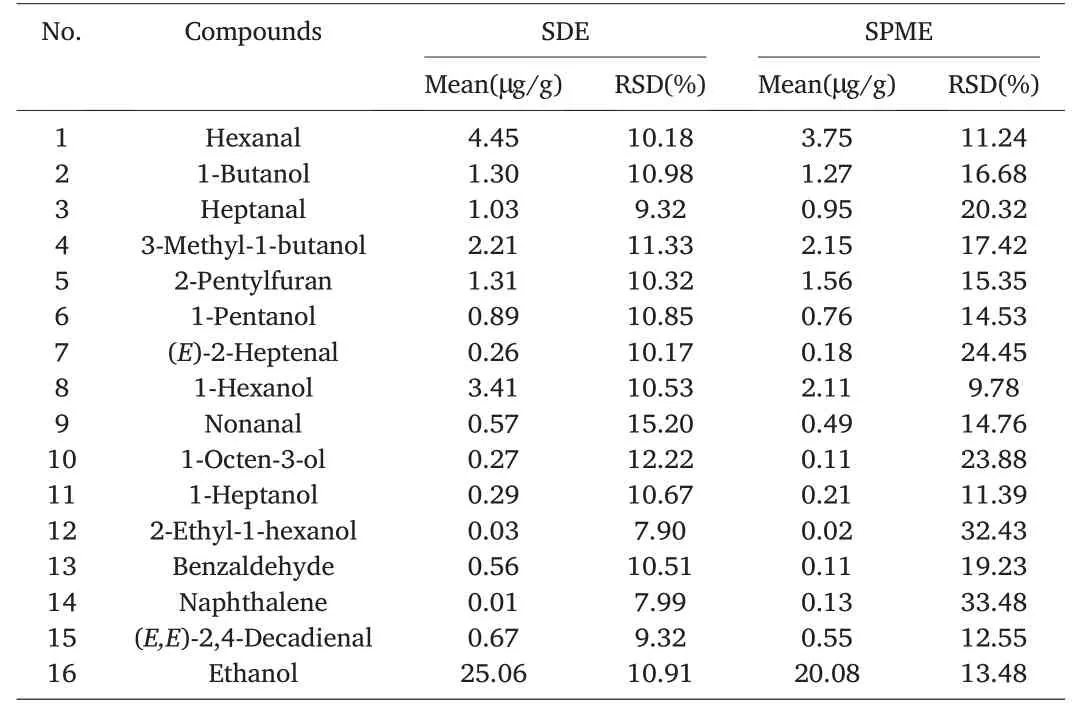

The validated method was used to assess the reliabilities of two extraction methods(SDE and HS-SPME).Sixteen aroma compounds were selected together for quantitative analysis with calibration curves by SDE and HS-SPME combined with GC-MS,respectively.SDE displayed excellent linearity with correlation coefficients higher than 0.9990 for aroma compounds (Table 4).The values of LOD varied range from 0.0040 μg/mL to 0.5642 μg/mL,with LOQ between 0.0133 μg/mL and 1.8806 μg/mL, which all reflected sensitivity of SDE.As seen from Table 5, the LOD and LOQ of SPME were lower, which indicated that its sensitivity was higher than that of SDE.

Table 3 Scanned ions and odor descriptions of aroma compounds with OAVs >1.

Table 4 Linear ranges,coefficients of determinations(R2),limit of detections(LOD),and quantitation(LOQ)for 16 aroma compounds obtained by SDE method.

Table 5 Linear ranges,coefficients of determinations(R2),limit of detections(LOD),and quantitation(LOQ)for 16 aroma compounds obtained by SPME method.

Table 5(continued)

As far as the precision of extraction methods was concerned,as seen in Table 6,the coefficients of variation of SDE were lower than 10.98%,except for 3-methyl-1-butanol,1-octen-3-ol,and nonanal.The coefficients of variation of HS-SPME were lower 24.45%,except for 2-ethyl-1-hexanol,naphthalene.By contrast,the SDE method was more accurate and more suitable for precise quantitation.HS-SPME was applied to higher sensitivity for LOD and LOQ measurements.Nevertheless,the repeatability of HS-SPME was unsatisfactory.The accuracy and precision were evaluated by the recovery experiment.In the recovery test(Table 7),the SDE method provided a range of 34%-113% (average recovery 78%, average RSD 9.95%) while HSSPME was significantly lower than the SDE.

Table 6 Aroma compound concentrations and relative standard deviations(RSD)of two extraction methods for Jiaozi Steamed Bread(n=6).

Table 7 Recoveries and RSDs of the sixteen aroma compounds in Jiaozi Steamed Bread extracts(n=5).

HS-SPME was a dynamic equilibrium extraction method.Its extraction efficiency was primarily attributed to the partitioning coefficient of volatiles between the samples and the DVB/PDMS/CAR phase[32].HS-SPME is a popular extraction method for numerous researches on volatile components,and the acknowledged disadvantage of HS-SPME is the lower recovery and reproducibility of volatile compounds[6,32,33].Meanwhile,it is undeniable that HS-SPME has high sensitivity to extract volatile compounds with low molecular weight[33].

4.Conclusions

The volatile compounds of JSB were obtained using SDE and HSSPME, and the processing parameters were optimized.The collected volatile compounds were determined by GC-MS and GC-FID, and 61 volatile compounds were found in JSB.GC-O was used to analyze the aroma of JSB, and 15 compounds were confirmed as potent aroma with odor active values(OAVs)>1 among them,and strong alcoholic,fruity,malty and citrus-like were the odor characteristic.The 15 potent aroma compounds were quantified by SDE-GC-MS and HS-SPME-GCMS, and two methods were verified by methodology.SDE method was more accurate for quantitation,and HS-SPME had high sensitivity to determine volatile compounds.The complementary combination of SDE and HS-SPME will provide more information about the aroma compounds of JSB,and they will provide a reliable and effective combination method for the aroma analysis of steamed bread.

Conflicts of interest

The authors declare that there are no conflicts of interest.

Acknowledgments

This project was supported by the National Natural Science Foundation of China(No.31701635),the Key Laboratory of Staple Grain Processing,Ministry of Agriculture(No.DZLS201703) and the Henan University of Technology High-level Talents Fund(No.2015BS009).

The authors sincerely thank Dr.Yongli Zong,Dr.Qidong Zhang,Dr.Guobi Chai(Zhengzhou Tobacco Research Institute of CNTC,China)for providing GC-MS and GC-O-MS analysis.

杂志排行

Grain & Oil Science and Technology的其它文章

- Anti-fungal properties of Puroindoline A against Aspergillus glaucus

- Physicochemical and structural characteristics of the Venn components of wheat gliadin

- Influence of low temperature on lethal time extension for different life stages of Cryptolestes ferrugineus(Stephens)with strong resistance to phosphine fumigation

- Quality deterioration and improvement of wheat gluten protein in frozen dough

- Grain & Oil Science and Technology