Effects of Partial Replacement of Chemical Fertilizer by Bio-organic Fertilizer Kunyijian on Yield and Quality of Tobacco Leaves

2020-05-06*

*

1. Yunnan Agricultural University, Kunming 650201, China; 2. Kunming Branch Company of Yunnan Tobacco Company, Kunming 650051, China

Abstract To explore the application effect of bio-organic fertilizer Kunyijian in flue-cured tobacco and provide scientific basis for its application in production, a plot trial was conducted with K326, a flue-cured tobacco variety, in the Science and Technology Test Base of Xundian County, Yunnan. Taking local fertilizer consumption (control 1) and 70% local fertilizer consumption (control 2) as controls, the following replacement groups were designed: under uniformly replacement 70% local fertilizer consumption, (i) organic fertilizer∶microbial agent=80∶1 (kg),+600 kg/ha,+900 kg/ha,+1 200 kg/ha,+1 500 kg/ha Kunyijian; (ii) organic fertilizer∶microbial agent=40∶1 (kg),+900 kg/ha Kunyijian. The results show that in the treatment of 70% local fertilizer consumption+1 200 kg/ha Kunyijian [organic fertilizer∶microbial agent=80∶1 (kg)], the comprehensive performance of flue-cured tobacco was significantly better than that in the control groups, the yield of tobacco leaves reached 2 237.1 kg/ha, the output value was 45 505.2 yuan/ha, and the average price of the tobacco leaves was 20.53 yuan/kg. The performance of flue-cured tobacco in the treatment of 70% local fertilizer consumption+1 500 kg/ha Kunyijian ranked second. The performance of other fertilization treatments was not good, but it did not differ significantly from that of control 1. In terms of chemical composition of tobacco leaves, partial replacement of chemical fertilizer by bio-organic fertilizer Kunyijian, was beneficial to increase the sugar content and reduce the nicotine and total nitrogen contents in tobacco leaves, especially the treatment of 70% local fertilizer consumption+900 kg/ha Kunyijian [organic fertilizer∶microbial agent=80∶1 (kg)], and it was also beneficial to increase the chlorine content in tobacco leaves, especially the treatment of 70% local fertilizer consumption+1 500 kg/ha Kunyijian [organic fertilizer∶microbial agent=80∶1 (kg)]. Therefore, it is feasible to use the bio-organic fertilizer Kunyijian to replace 30% of chemical fertilizer in tobacco production. The rate is recommended to be 900-1 500 kg/ha [organic fertilizer ∶microbial agent=80∶1 (kg)]. It is suggested to further strengthen the demonstration and promotion of Kunyijian.

Key words Kunyijian, Bio-organic fertilizer, Alternative chemical fertilizer, Yield and quality

1 Introduction

Tobacco is one of the important economic crops in China, and its cultivation area and yield rank first in the world. It plays an important role in promoting the development of the national economy and meeting the needs of people’s lives[1]. Yunnan Province is the main high-quality flue-cured tobacco production area in China, and its tobacco leaf production accounts for more than one-third of the total in China[2]. In recent years, excessive application of chemical fertilizers and unreasonable farming systems have caused soil fertility in tobacco fields to decline. The soil microenvironment has been severely damaged, and the quality of tobacco leaves has been seriously affected[3]. In 2015, the State Tobacco Monopoly Administration of China, in accordance with the requirement of "one control, two reductions and three basics" of the Ministry of Agriculture, set a goal of reducing fertilizer use by 20% during the 13th Five-Year Plan period. Therefore, using new fertilizer alternatives and changing the previous mode of fertilizer use are of special significance for improving the yield and quality of tobacco leaves and protecting the sustainable development of the environment[4].

Bio-organic fertilizer is a kind of fertilizer that is added with a certain proportion of inorganic components such as nitrogen, phosphorus, potassium and trace elements, as well as microorganisms that are conducive to specific functions such as soil fertility, crop absorption and element release, with organic materials such as animal manure, crop stalks and domestic waste as substrate and carrier, and has been treated harmlessly, decomposed and mixed. It has the functions of both organic fertilizer and microorganisms[5]. As the main member of new fertilizers, it has the characteristics of high fertilizer efficiency and no pollution, and can effectively reduce the use of pesticides and fertilizers, thus reducing production costs and improving economic benefits[6]. In this paper, the new type of bio-organic fertilizer Kunyijian was applied in combination with chemical fertilizer, and its dosage and efficacy were explored, with a view to providing theoretical basis for its future application in tobacco production.

2 Materials and methods

In 2018, at the Xundian Science and Technology Test Base of Yunnan Tobacco Leaf Co., Ltd., an experiment research on bio-organic fertilizer was conducted with K326, a variety of flue-cured tobacco, as the test material. The test fertilizers included chemical fertilizers[tobacco-specific compound fertilizer (N∶P2O5∶K2O=15∶18∶25), farm manure, potassium nitrate, potassium sulfate]and bio-organic fertilizer Kunyijian (Tianjin Kunhe Biological Technology Co., Ltd., organic matter ≥ 40%, crude protein ≥ 15%,Bacillussubtilis,Paenibacilluskribbensis, andBacilluslicheniformis, CFU ≥ 100 million/g, and execution standard NY-884-2012). A total of five treatments and two controls were designed. The application amount of the bio-organic fertilizer Kunyijian in each treatment is shown in Table 1. Randomized block design was adopted. A total of 21 plots were arranged, with three replicates for each group, and in each plot, 80 tobacco plants were cultivated. In the test field, total 1 920 tobacco plants were planted. The plant and row spacing was 120 cm × 60 cm. There were protection lines around each plot. Bio-organic fertilizer was uniformly applied in planting holes once during transplantation. Potassium nitrate (75 kg/ha) was used as seedling fertilizer. Potassium sulphate (75 kg/ha) was dissolved in water and applied about 40 d after transplantation. Field management was carried out in accordance with local high-quality tobacco leaf production standards.

The seeds were uniformly sown on March 1. From March 11 on, seedlings started to emerge. They were formed seedlings on April 10 and transplanted on April 15. After transplantation, the growth period and field growth of the tobacco plants in each group were observed uniformly. Disease investigation was carried out referring to YC/T 39-1996. One week after topping and sucking, agronomic traits of the tobacco plants were surveyed with reference to YC/T 142-2010. After the tobacco leaves matured, they were picked and baked from each plot separately. The single leaf weight of the middle and upper tobacco leaves was measured. Grading of tobacco leaves was conducted according to GB 2635-1992. The overall appearance quality of the tobacco leaves was evaluated. The yield, output value, first-grade tobacco leaf proportion, first and medium-grade tobacco leaf proportion and production index were calculated. Data processing and analysis was performed using Excel2010 and Spss19.0. Analysis of variance was conducted using theLSDmethod.

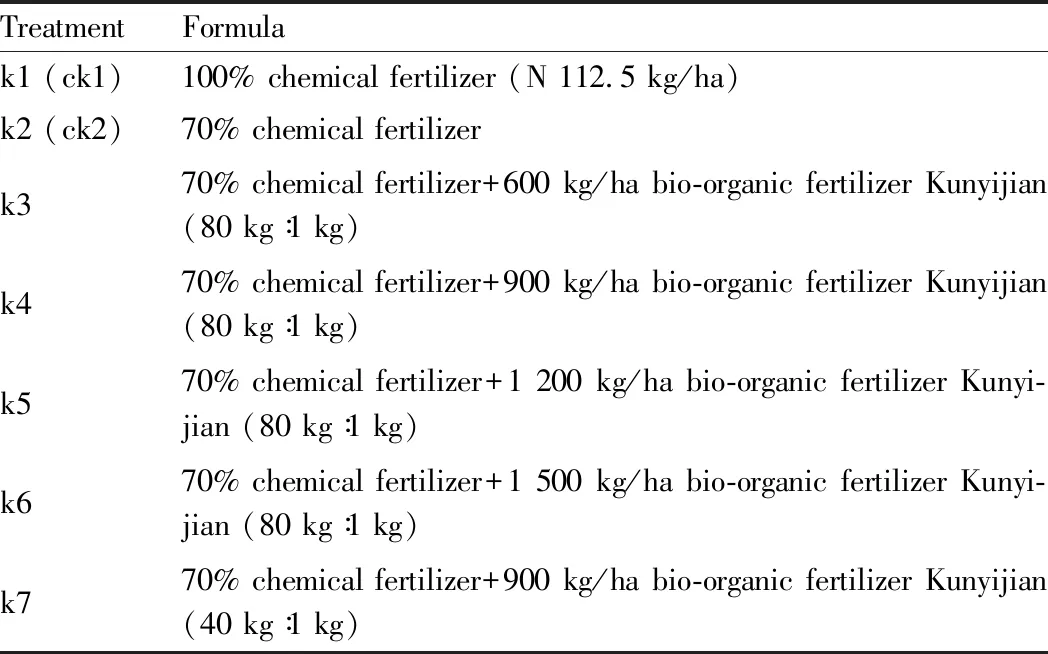

Table 1 Fertilization formula in each treatment

TreatmentFormulak1 (ck1)100% chemical fertilizer (N 112.5 kg/ha)k2 (ck2)70% chemical fertilizerk370% chemical fertilizer+600 kg/ha bio-organic fertilizer Kunyijian (80 kg∶1 kg)k470% chemical fertilizer+900 kg/ha bio-organic fertilizer Kunyijian (80 kg∶1 kg)k570% chemical fertilizer+1 200 kg/ha bio-organic fertilizer Kunyi-jian (80 kg∶1 kg)k670% chemical fertilizer+1 500 kg/ha bio-organic fertilizer Kunyi-jian (80 kg∶1 kg)k770% chemical fertilizer+900 kg/ha bio-organic fertilizer Kunyijian (40 kg∶1 kg)

Note: Farm manure was not used in the experimental area; T3-T7, the ratios in brackets represent the weight ratio of organic fertilizer to microbial agent.

3 Results and analysis

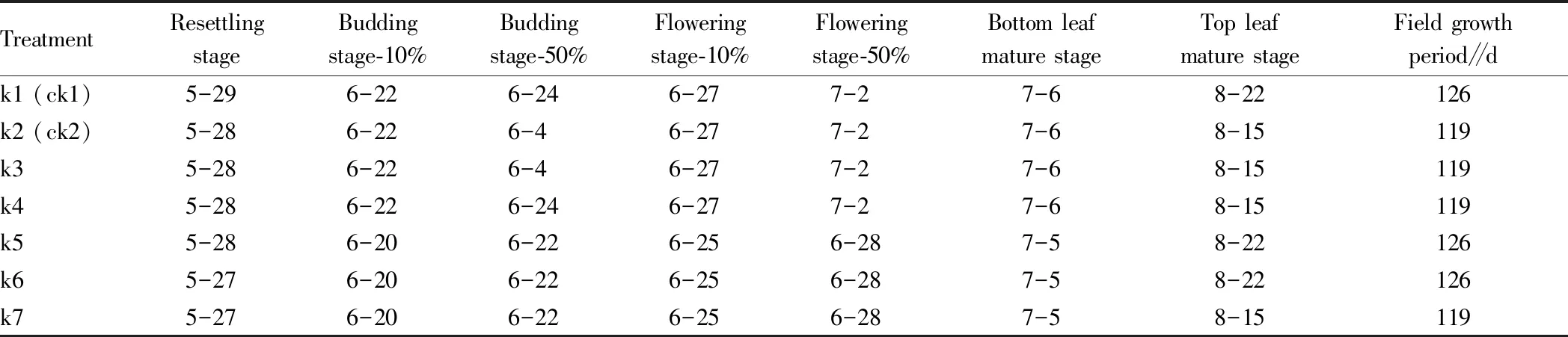

3.1 Growth period of flue-cured tobacco in different treatmentsAs shown in Table 2, there were some differences in the filed growth period, especially the top leaf maturation period of flue-cured tobacco between the treatments. The growth period of flue-cured tobacco in k1, k5 and k6 was longer (126 d), while that in k2, k3, k4 and k7 was shorter (119 d).

Table 2 Growth period of flue-cured tobacco in different treatments month-day

3.2 Growth of flue-cured tobacco under different treatments

As shown in Table 3, there was no significant difference in leaf color, field uniformity or growth potential of flue-cured tobacco between the treatments 35 and 50 d after transplanting. The growth potential of flue-cured tobacco in k7 was stronger than those in the other treatments. During the budding period, no significant difference was observed in leaf color of flue-cured tobacco among the treatments. The field uniformity of flue-cured tobacco in the chemical fertilizer replacement treatments was more neat than that in the control groups. The growth potential of flue-cured tobacco in k1, k6 and k7 was stronger, the growth potential of flue-cured tobacco in k2 and k5 was medium, and the growth potential of flue-cured tobacco in k3 and k4 was weak.

3.3 Agronomic traits of flue-cured tobacco in different treatmentsAs shown in Table 4, the plant height of flue-cured tobacco in k7 was greatest (130.0 cm), and that in k5 was smallest (125.0 cm). There was no significant difference between the treatments. In terms of leaf number, k2 was greatest (24.7), while k6 was the smallest (22.9), and the two treatments showed significant difference. There was no significant difference between the other treatments. The topping height differed insignificantly among the treatments. The topping height was greatest in k4 (113.2 cm) and smallest in k6 (106.67 cm). There was no significant difference in leaf area of flue-cured tobacco between the treatments. The leaf area of flue-cured tobacco in k7 was greatest (0.137 9 m2), while that in k6 was smallest (0.121 0 m2). Stem girth of flue-cured tobacco showed no significant difference between the treatments. The stem girth of k2 was the largest (12.59 cm), while that of k3 was the smallest (9.9 cm).

Table 3 Growth potential of flue-cured tobacco under different treatments

Treatment35 d after transplantingField uniformityGrowth potential50 d after transplantingField uniformityGrowth potentialBudding stageField uniformityGrowth potentialk1 (ck1)UniformMediumUniformMediumLess uniformStrongk2 (ck2)Less uniformMediumUniformMediumNot uniformMediumk3UniformMediumUniformMediumUniformWeakk4UniformMediumUniformMediumUniformWeakk5UniformMediumUniformMediumUniformMediumk6UniformMediumUniformMedium-strongUniformStrongk7UniformStrongUniformStrongUniformStrong

Note: The leaf color of all treatments was green at 35, 50 d after transplanting and the budding stage.

Table 4 Agronomic traits of flue-cured tobacco in different treatments

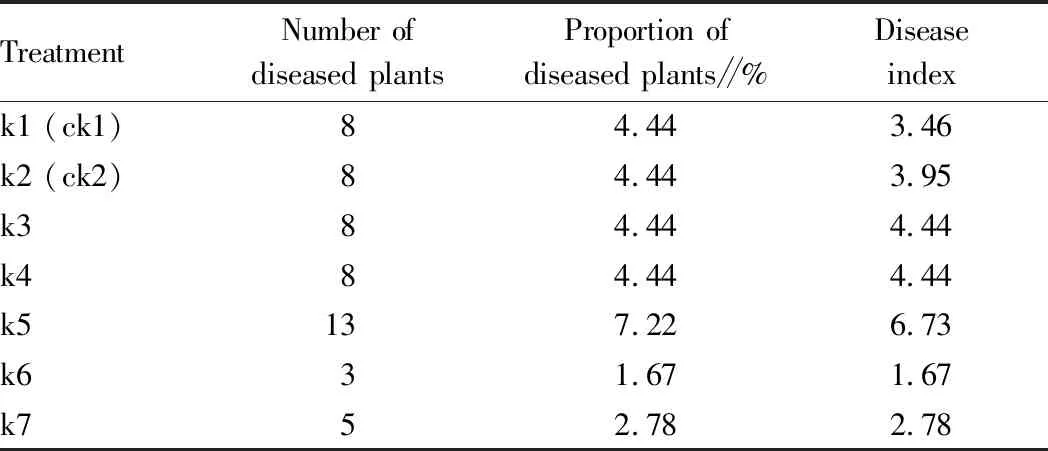

3.4 Occurrence of tomato spotted wilt in different treatmentsField investigation revealed that tomato spotted wilt occurred in only a small amount of tobacco plants. It can be seen from Table 5 that tomato spotted wilt occurred in all the treatments. It was most serious in k5, in which the number of diseased plants, proportion of diseased plants and disease index were 13, 7.22% and 6.73, respectively, and was mildest in k6, in which the number of diseased plants, proportion of diseased plants and disease index were 3, 1.67% and 1.67, respectively.

Table 5 Occurrence of tomato spotted wilt in flue-cured tobacco of different treatments

TreatmentNumber ofdiseased plantsProportion ofdiseased plants∥%Diseaseindexk1 (ck1)84.443.46k2 (ck2)84.443.95k384.444.44k484.444.44k5137.226.73k631.671.67k752.782.78

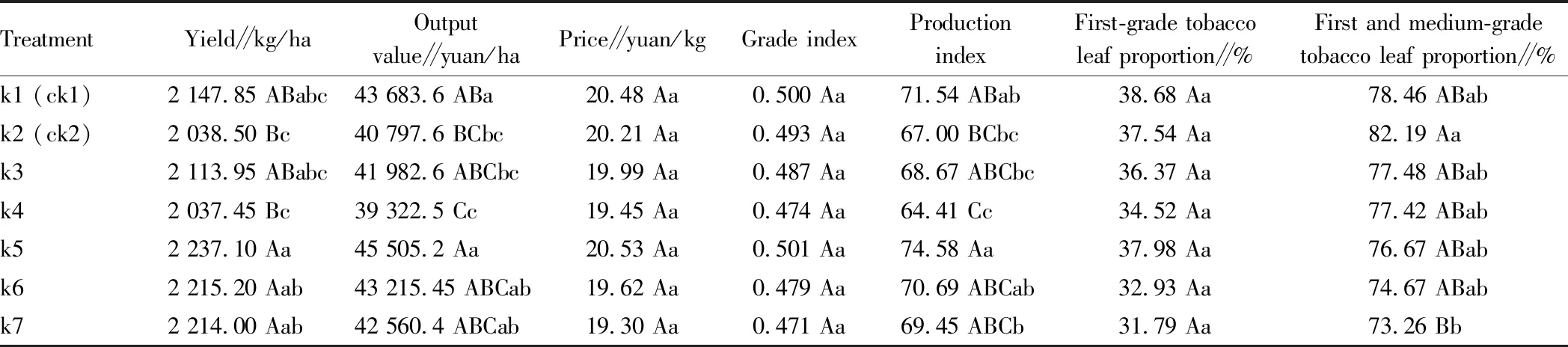

3.5 Economic benefits of tobacco leaves in different treatmentsAs shown in Table 6, there were certain differences in economic benefits between the chemical fertilizer replacement treatments and the controls. The overall performance of k5 was the best, and the differences in individual indicators between the treatments were significant. In terms of yield, the treatments ranked as k5> k6> k7> k1> k3> k2> k4. The yield of tobacco leaves in k5 was 2 237.1 kg/ha, while that in k4 was 2 037.45 kg/ha. The treatments k5, k6 and k7 showed significant differences from k2 and k4, and showed no significant differences from k1 and k3. In terms of output value, the treatments ranked as k5 > k1 > k6 > k7 > k3 > k2 > k4. k5 had the highest output value (45 505.2 yuan/ha), and k4 had the lowest output value (39 322.5 yuan/ha). There were significant differences between k5 and k2, k4, between k1 and k4, and between k6, k7 and k4. The differences between k6, k7 and k2, k3 were insignificant. From the perspective of average price, the treatments ranked as k5 > k1 > k2 > k3 > k6 > k4 > k7. The tobacco leaves in k5 had the highest price (20.53 yuan/kg), and those in k7 had the lowest price (19.30 yuan/kg). There was no significant difference between the treatments. In terms of grade index, the treatments were in the order as k5 > k1 > k2 > k3 > k6 > k4 > k7. The grade index of k5 was greatest (74.58), and that of k4 was smallest (64.41). There were significant differences between k5 and k2, k4, between k1 and k4, and between k6, k7 and k4. In terms of first-grade tobacco leaf proportion, the treatments ranked as k1 > k5 > k2 > k3 > k4 > k6 > k7. The proportion of first-grade tobacco leaves in k1 was highest (38.68%), and that in k7 was lowest (31.79%). The differences between the treatments were not significant. In terms of first and medium-grade tobacco leaf proportion, the treatments were in the order as k2 > k1 > k3 > k4 > k5 > k6 > k7. k2 showed the highest first and medium-grade tobacco leaf proportion (82.19%), and k7 showed the lowest first and medium-grade tobacco leaf proportion (73.26%). The difference between k2 and k7 was significant.

Table 6 Economic benefits of flue-cured tobacco in different treatments

TreatmentYield∥kg/haOutputvalue∥yuan/haPrice∥yuan/kgGrade indexProductionindexFirst-grade tobaccoleaf proportion∥%First and medium-gradetobacco leaf proportion∥%k1 (ck1)2 147.85 ABabc43 683.6 ABa20.48 Aa0.500 Aa71.54 ABab 38.68 Aa78.46 ABab k2 (ck2)2 038.50 Bc40 797.6 BCbc20.21 Aa0.493 Aa67.00 BCbc37.54 Aa82.19 Aak32 113.95 ABabc41 982.6 ABCbc19.99 Aa0.487 Aa68.67 ABCbc36.37 Aa77.48 ABabk42 037.45 Bc39 322.5 Cc19.45 Aa0.474 Aa64.41 Cc34.52 Aa77.42 ABabk52 237.10 Aa45 505.2 Aa20.53 Aa0.501 Aa74.58 Aa 37.98 Aa76.67 ABabk62 215.20 Aab43 215.45 ABCab19.62 Aa0.479 Aa70.69 ABCab 32.93 Aa74.67 ABabk72 214.00 Aab42 560.4 ABCab19.30 Aa0.471 Aa69.45 ABCb 31.79 Aa73.26 Bb

3.6 Appearance quality of flue-cured tobacco leaves in different treatmentsAs shown in Table 7, the overall appearance quality of flue-cured tobacco leaves in the bio-organic fertilizer application groups was better than that in the control groups. There was no significant difference in color, maturity degree or leaf thickness among the treatments. The structure of tobacco leaves in the bio-organic fertilizer application groups was loose, and that in the control groups was looser. The oil contents of tobacco leaves in k3 and k6 were higher than those in the other treatments. The tobacco leaves in k3 had stronger color intensity than those in the other treatments. The single leaf weight of middle and upper leaves differed insignificantly among the treatments. The single leaf weight of middle leaves of k3 was the largest (11.26 g/leaf), and that of the treatment k6 was the smallest (10.69 g/leaf). The single leaf weight of upper leaves of k4 was the largest (10.38 g/leaf), and that of k3 was the smallest (9.07 g/leaf).

Table 7 Appearance quality of flue-cured tobacco in different treatments

TreatmentLeaf structureOilColor intensitySingle leaf weight∥g/leafMiddleUpperk1 (ck1)Less looseLess highLess strong11.14 Aa9.40 Aak2 (ck2)Less looseLess highLess strong10.89 Aa9.40 Aak3LooseHighStrong11.26 Aa9.07 Aak4LooseLess highLess strong10.70 Aa10.38 Aak5LooseLess highLess strong11.10 Aa10.07 Aak6LooseHighLess strong10.69 Aa9.63 Aak7LooseLess highLess strong10.81 Aa9.91 Aa

Note: The tobacco leaves in all the treatments were orange, mature and moderate in thickness.

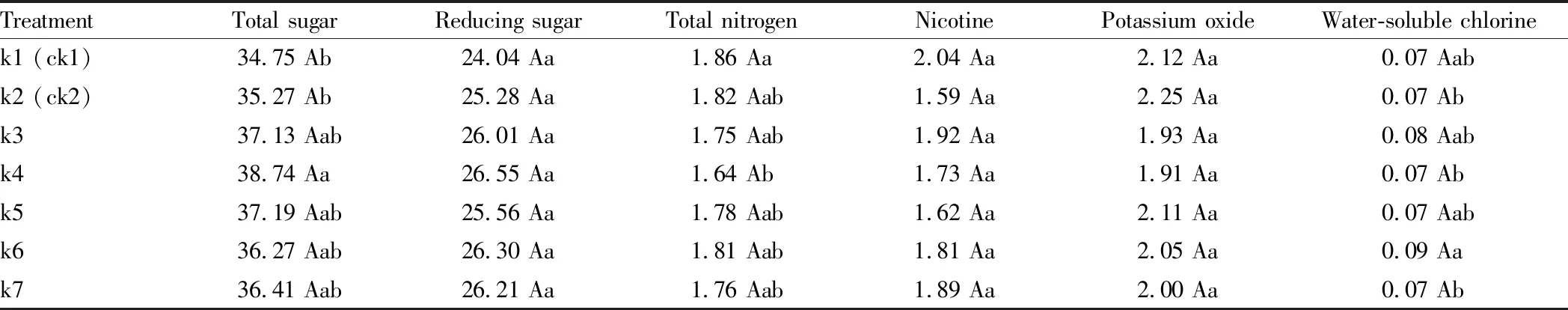

3.7 Chemical composition of flue-cured tobacco leaves in different treatmentsThe application of bio-organic fertilizer had different effects on the internal chemical components of middle tobacco leaves. As shown in Table 8, the application of bio-organic fertilizer improved the total sugar content in tobacco leaves compared with the control groups. The total sugar content in middle leaves in k4 was the highest. It was significantly higher than those in the two control groups, and was different insignificantly from those in the other treatments. The application of bio-organic fertilizer increased the reducing sugar content of tobacco leaves compared with the controls, but no significant difference was observed among the treatments. Compared with those in the control groups, the total nitrogen contents of tobacco leaves in the bio-organic fertilizer application groups decreased in varying degrees. The total nitrogen content of k4 was the lowest. It was different significantly from that of k1 (ck1), and was different insignificantly from that of k2 (ck2). The application of bio-organic fertilizer reduced the nicotine content of tobacco leaves compared with k1 (ck1). No significant difference was observed among the treatments. The tobacco leaves in k1 (ck1) had the highest nicotine content, and those in k2 (ck2) had the lowest nicotine content. In terms of potassium oxide, the differences between the treatments were not significant. The content of potassium oxide in the tobacco leaves of k2 (ck2) was the highest, and that of k1 (ck1) was the lowest. In terms of water-soluble chlorine content, k6 was the highest, and it was different significantly from k2 (ck2) and k4. No significant difference was found between the other treatments.

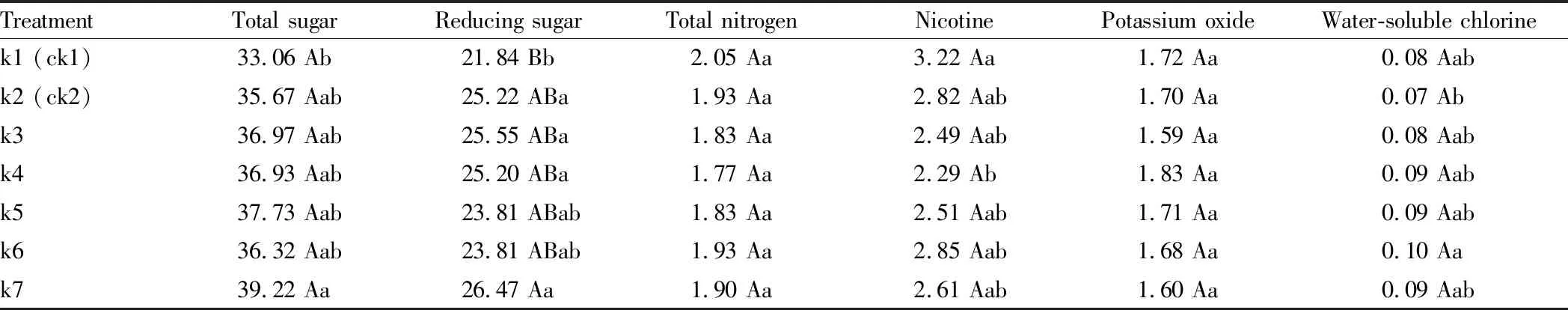

In upper tobacco leaves, the application of bio-organic fertilizer increased the total sugar content compared with the two control groups. The total sugar content in tobacco leaves in k7 was the highest, and that in k1 (k1) was the lowest, and the difference was significant. The application of bio-organic fertilizer also produced an effect on the reducing sugar content in upper tobacco leaves compared to k1 (ck1). There were significant differences in reducing sugar content of upper tobacco leaves between k7 and k1 (ck1), and between k2 (ck2), k3, k4 and k1 (ck1). The total nitrogen contents of upper tobacco leaves in the bio-organic fertilizer application groups reduced to varying degrees, but no significant difference was found between the treatments. The nicotine contents in the bio-organic fertilizer application groups also decreased, and the difference between k4 and k1 (ck1) was significant. There was no significant difference in potassium oxide content between the treatments, and it was highest in k4 and lowest in k3. The upper tobacco leaves in k6 showed the highest water-soluble chlorine content, and those in k2 (ck2) showed the lowest content, and the difference was significant (Table 9).

Table 8 Chemical composition of middle C3F tobacco leaves in different treatments %

Table 9 Chemical composition of middle B2F tobacco leaves in different treatments %

4 Conclusions and discussion

Taking local fertilizer consumption (control 1) and 70% local fertilizer consumption (control 2) as control groups, different doses of bio-organic fertilizer Kunyijian were used to replace the 30% of chemical fertilizer. The results show that from the agricultural perspective, compared with the control groups, the overall performance of k5 (1 200 kg/ha bio-organic fertilizer replacing 30% chemical fertilizer) was better, with yield of 2 237.1 kg/ha, output value of 45 505.2 yuan/ha and average price of 20.53 yuan/kg. The overall performance of k6 (1 500 kg/ha bio-organic fertilizer replacing 30% chemical fertilizer) ranked second, but it differed insignificantly from that of control 1. The other fertilization treatments performed poorly. In terms of intrinsic quality, the application of bio-organic fertilizer Kunyijian increased the sugar and chlorine contents and reduced the nicotine and total nitrogen contents in tobacco leaves, and it did not change the potassium content in tobacco leaves. The trend was most obvious in k4 (900 kg/ha bio-organic fertilizer replacing 30% chemical fertilizer), and the performance of the middle and upper tobacco leaves was basically the same. But in terms of k6 and k7, increasing the amount of bio-organic fertilizer helped increase the chlorine content of tobacco leaves, indicating that increasing the number of microorganisms was beneficial to increase the reducing sugar content in the upper leaves.

In conclusion, it is feasible to use bio-organic fertilizer Kunyijian to replace 30% of chemical fertilizer in tobacco production, and its application amount is recommended to be 1 200-1 500 kg/ha. Application of Kunyijian not only can effectively improve the economic benefits of tobacco leaves but also help to improve the intrinsic quality of tobacco leaves. It is recommended to appropriately increase the number of microorganisms in bio-organic fertilizer.

杂志排行

Asian Agricultural Research的其它文章

- Organic Connection between Small Farmers and Modern Agriculture Development Based on Farmers’ Cooperatives in China

- Spectral Characteristics and Quantitative Analysis of Troxerutin-Cu2+ Complex

- Research on the Development of Rural Collective Economy in Shandong Province

- Progress in Research on Propagation Technology of Machilus Nees

- Effects of Soil Testing and Formulated Fertilization on Yield and Economic Benefit of Major Crops in Burundi

- Application of Genetic Rules of Quality Traits in the Selection of Watermelon Inbred Lines