欧姆加热对米饭蒸煮过程能耗及其品质的影响

2020-03-04丁辛亭熊秀芳李树旺王绍金李星恕

丁辛亭,熊秀芳,李树旺,王绍金,李星恕,2

欧姆加热对米饭蒸煮过程能耗及其品质的影响

丁辛亭1,熊秀芳1,李树旺1,王绍金1,李星恕1,2※

(1. 西北农林科技大学机械与电子工程学院,杨凌 712100;2. 陕西省农业装备工程技术研究中心,杨凌 712100)

针对电饭煲蒸煮米饭存在电热转化效率低、温度不易控制等不足,该研究设计了一种加热速率和保温温度自动可控的欧姆加热试验系统,研究了浸泡时间(5、15、30、50、80 min)和水米比(1.25∶1、1.50∶1、1.75∶1、2.00∶1 mL/g)对水米混合物的电导率、欧姆蒸煮加热速率、能耗以及米饭品质(膨胀率、吸水率、物性值和颜色)的影响,并与电饭煲蒸煮米饭的能耗和品质进行比较。结果表明:浸泡能够增大水米混合物电导率,水米比越小电导率增加越快,有效提高欧姆加热蒸煮米饭加热速率;浸泡还有利于减少米饭蒸煮能耗(<0.05),促进米饭软化;因此大米浸泡处理30 min后采用欧姆加热蒸煮米饭可行。欧姆蒸煮加热速率越快,米饭硬度上升(<0.05),而黏性和弹性则略有减小(<0.05),加热速率在3~9 ℃/min范围内为宜;水米比可取1.25∶1~1.50∶1 mL/g。蒸煮相同质量的大米,欧姆加热所需能耗仅为电饭煲蒸煮的20%~25%;相较于电饭煲蒸煮,欧姆加热蒸煮米饭硬度最大可减小21%,且膨胀率和吸水率较大(<0.05)、亮度值较小(<0.05)。研究结果可为研发基于欧姆加热的快速高效米饭自动蒸煮装置提供技术支撑。

电导率;品质控制;米饭;欧姆加热;大米浸泡;蒸煮能耗

0 引 言

大米富含碳水化合物和蛋白质以及人体所需的多种微量元素[1-2],是世界性主粮[3-4]。大米的食用方式以加热水米混合物蒸煮成米饭为主,但使用传统加热包括电饭煲蒸煮米饭时,均要经由加热容器传热给水米混合物,能量利用率低,耗时耗能。最近,有学者采用微波、射频等体积加热方法蒸煮米饭[5-6],虽然能有效提高电能利用率,但也存在设备能耗大、成本高、安全性差、故障率高等不足,限制了这些方法的进一步推广和应用。

欧姆加热又称通电加热,电流通过导电物料时,由于焦耳效应电能转换为热能,物料内部温度升高。欧姆加热具有电热转化率高、设备简单易控、加热均匀、迅速等优点[7-9],目前被广泛应用于杀菌、解冻、萃取、提纯等领域[8,10-13]。近期,有学者采用欧姆加热蒸煮谷物,发现与传统蒸煮方式相比,所得食品的物性值和颜色并无显著差异,同时还能够加速谷物软化、减少能耗,在谷物蒸煮方面具有较大优势[14-16]。欧姆加热时,单位体积物料单位时间产生的热量与物料电导率和电场强度的平方成正比;现有欧姆加热蒸煮米饭装置大多采用恒定电压加热,随着温度升高水米混合物电导率会增大,加热速率必定也会越来越大。然而加热速率是影响米饭品质的一个重要因素[17],但恒定电压蒸煮米饭很难获得一个恒定的加热速率。此外,由于水米混合物的电导率通常很低,因此很多学者在利用欧姆加热蒸煮米饭时,均要向水米混合物中添加食盐以提高其电导率,但这并不符合亚洲尤其是中国人的生活习惯。前期研究表明,浸泡能有效提高水米混合物的电导率,从而使欧姆加热蒸煮米饭成为可能;同时,国家标准也建议蒸煮前对大米进行浸泡,以提高米饭品质和缩短蒸煮时间[18]。但是,关于浸泡条件对水米混合物电导率及欧姆加热蒸煮过程的影响研究,迄今为止报道甚少。

本文拟设计一种能自动控制加热速率和保温温度的欧姆加热蒸煮米饭试验系统,研究浸泡时间、加热速率和水米比对欧姆加热蒸煮过程及米饭品质的影响,对比欧姆加热与电饭煲蒸煮在能耗与米饭品质方面的差异,为研发快速、节能的欧姆加热蒸煮米饭装置提供技术支撑。

1 材料与方法

1.1 试验材料

供试大米选用颗粒均匀的金龙鱼牌辽宁盘锦优质粳米,包装袋内充二氧化碳,置于阴凉、通风、干燥处保存。米粒平均长、宽、厚为(4.73±0.32) mm、(2.81±0.24) mm、(2.01±0.16) mm,初始湿基含水率为11.86%±0.19%。由于家庭蒸煮米饭通常使用自来水,同时也为消除自来水对水米混合物电导率的影响,取30 L自来水贮存于容器中待其充分静置后用于所有试验,25℃时该自来水电导率为(162.37±8.41)S/cm。

为了研究浸泡时间对欧姆加热米饭加热历程及米饭品质的影响,在25 ℃室温下,取100 g大米按照水米比[15](mL/g)1.25∶1、1.50∶1、1.75∶1、2.00∶1与自来水充分混合均匀(以下试验与此相同),分别浸泡5、15、30、50、80 min后进行欧姆加热蒸煮米饭试验,以大米未经浸泡的蒸煮试验作对照。

1.2 欧姆加热米饭蒸煮试验系统

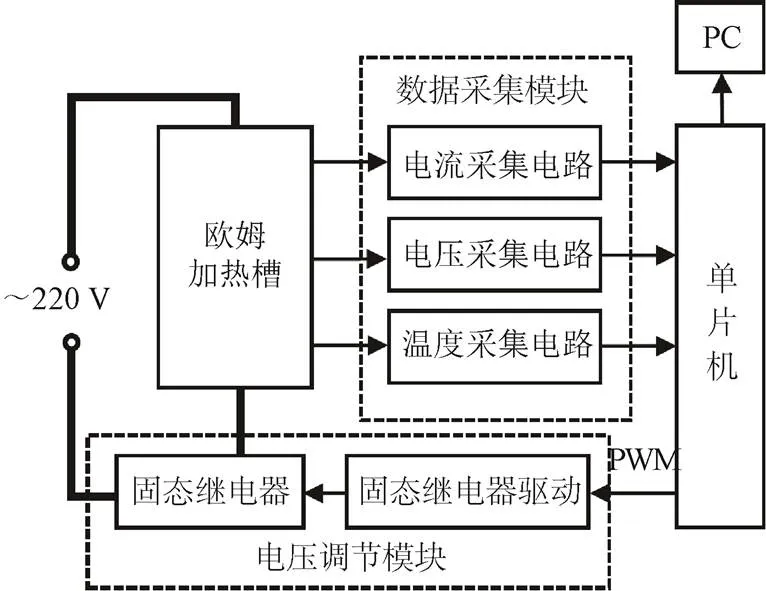

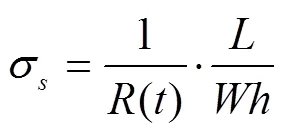

欧姆加热米饭蒸煮试验系统由控制系统、欧姆加热槽和PC机(ZX6-CP5S1,神舟电脑股份有限公司)组成,如图1所示。控制系统包括单片机(STC12C5A60S2,深圳宏晶技术有限公司)、数据采集模块和电压调节模块:数据采集模块采用电压(DL-PT202H1,南京向上电子有限公司)、电流(DL-CT1010A,南京向上电子有限公司)、温度(DS18B20,美国德州仪器公司)传感器实时采集欧姆加热蒸煮过程中电压、电流和温度数据;单片机从数据采集模块接收这些数据,并且采用前馈算法控制加热速率、PID算法控制保温温度,均通过输出不同占空比的PWM信号控制电压调节模块(包括固态继电器及其驱动器)持续通断,从而调节输出电压,实现加热速率和保温温度恒定。单片机接收的所有数据通过串口实时发送至PC机并保存,以便后续处理。为了观察欧姆加热蒸煮过程中大米的膨胀情况,加热槽体由厚度5 mm的透明耐热有机玻璃焊接而成[19],槽体内两侧安装一对厚度为1 mm的不锈钢平板电极,内部尺寸为75 mm×80 mm× 70 mm;在槽体一侧粘贴透明直尺,使用相机记录蒸煮过程中水米混合物高度变化。为了保温和防止蒸煮米饭过程中水分蒸发,试验时加热槽上端盖有带橡胶密封垫的泡沫板;除直尺的一侧外表面,其余表面均粘贴厚度10 mm的橡塑保温棉。欧姆加热槽结构及物料高度测量如图2所示。

图1 欧姆加热米饭蒸煮试验系统示意图

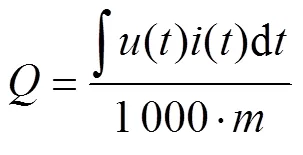

根据所测电压与电流以及大米质量可得欧姆加热蒸煮单位质量(1 kg)大米所需能耗[16]为

式中为蒸煮单位质量米饭所需能耗,(kW·h)/kg;为通电时间,h;为时刻的电压,V;为时刻的电流,A;为蒸煮大米的质量,kg。

1.橡塑保温棉 2.加热槽体 3.电极板 4. 橡胶密封垫 5.泡沫板 6.温度传感器 7.直尺 8.水层 9.水米混合层 10.相机

1.Insulation sponge 2.Heating container 3.Electrode 4.Rubber gasket 5.Cystosepiment 6.Temperature sensor 7.Ruler 8.Water layer 9.Water-rice mixed layer 10.Camera

图2 欧姆加热槽结构及物料高度测量

Fig.2 Ohmic heating container structure and material height measurement

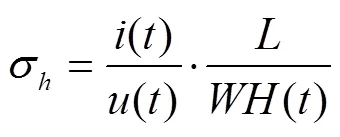

欧姆加热时以水米混合物作为蒸煮对象。根据欧姆加热蒸煮米饭过程的录像,提取水米混合物蒸煮过程中高度随时间的变化,结合电压和电流数据,可得蒸煮过程中某一时刻的水米混合物整体电导率[20]为

为了比较欧姆加热与电饭煲在蒸煮能耗与米饭品质方面的差异,采用水米比和浸泡时间完全相同的水米混合物进行对比试验;采用电阻丝式非高压电饭煲(FD10E型,广东天际电器股份有限公司)的精煮模式蒸煮米饭。为比较两种蒸煮方式的优劣,需确保两种蒸煮方式加热条件相同,本研究中采用单片机控制欧姆加热米饭蒸煮试验系统与电饭煲的米饭蒸煮加热历程保持一致。

1.3 浸泡过程中水米混合物电导率检测

为了研究浸泡时间对水米混合物电导率的影响,需要检测浸泡过程中水米混合物的电导率随时间的变化。浸泡过程中采用精度较高的阻抗测试仪(3532-50 LCR型,日本日置公司)检测水米混合物电导率变化,检测电压为1 V。检测时,水米混合物浸泡于欧姆加热槽中,室温下每5 min使用玻璃棒缓慢均匀搅拌水米混合物一次,待其稳定后测量其电阻[21-22],共测量17次持续80 min。浸泡过程中水米混合物总体积基本不变[23],则浸泡时电导率为

1.4 米饭品质检测

1.4.1 大米吸水率和膨胀率

大米的吸水率和膨胀率是评价米饭品质最为直观的指标。参考文献[23-24]中采用的测量方式,大米吸水率为

1.4.2 米饭物性值

取不同条件下蒸煮的米饭样品各约10 g,放入密封袋并快速冷却至25℃。检测米饭物性值时,取米饭样品中4颗完整米粒,十字状放置于质构仪(TA-XTC,上海保圣实业发展有限公司)载物台中心,采用两次压缩法检测其硬度、黏性和弹性。测试选用TA/36柱形探头,测前速度为3 mm/s,测试速度和测后速度为1 mm/s,触发力为0.05 N,以70%的形变进行压缩,压缩间隔为5 s[26-28]。每种条件下的米饭样品物性值检测重复上述试验6次。

1.4.3 米饭颜色值

米饭越亮、越白,其品质评价越好[18]。分别取各米饭样品中6颗完整米粒,利用色差仪(CS-210,杭州彩谱科技有限公司)测定其亮度值()、红绿度()和黄蓝度()。

1.5 数据分析

每组试验至少重复3次,采用IBM SPSS Statistics 23统计分析软件中Duncan多重比较检验,对试验数据进行单因素方差分析。

2 结果与分析

2.1 浸泡时间对水米混合物电导率及欧姆加热蒸煮米饭特性的影响

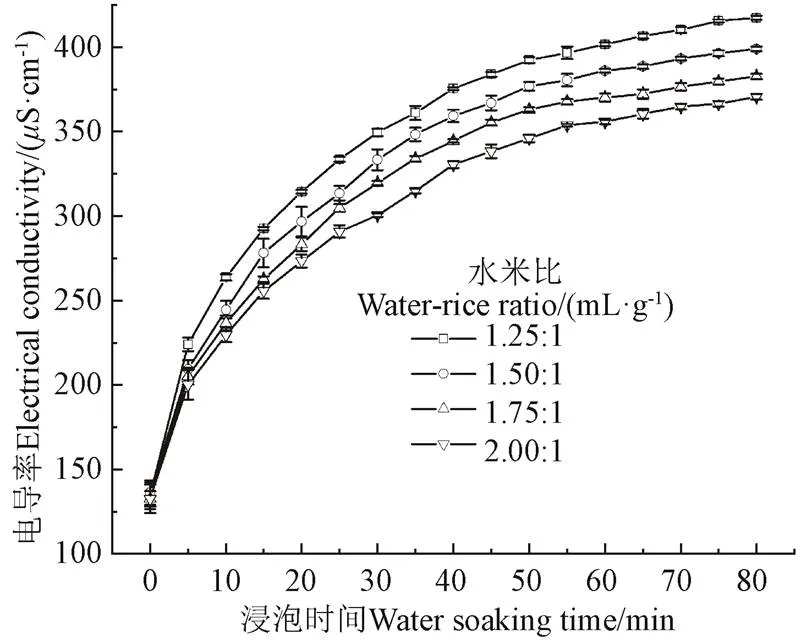

2.1.1 浸泡时间对水米混合物电导率的影响

不同水米比时,水米混合物的电导率随浸泡时间的变化如图3所示。由图3可知,水米混合物的初始电导率为130S/cm左右,略小于自来水的电导率。这是由于大米自身电导率很小,此时大米内部离子和极性分子等可导电物质并未释放至水中的缘故。水米混合物的电导率呈现先快速增大后变缓的趋势,浸泡80 min后,电导率由130S/cm增大至350~400S/cm左右。这是由于浸泡过程中大米吸收水分并随之软化,大米内部可导电物质快速析出[16,29],导致水米混合物的导电性能增强,其整体电导率提高;同时随着浸泡进行,大米内部可导电物质量减少、释放速率降低,从而电导率增速趋缓。另外,水米混合物的水米比越小,溶液中可自由移动的导电物质浓度越大,电导率也就越大,其增幅也越大。

图3 不同水米比时浸泡时间对水米混合物的电导率的影响

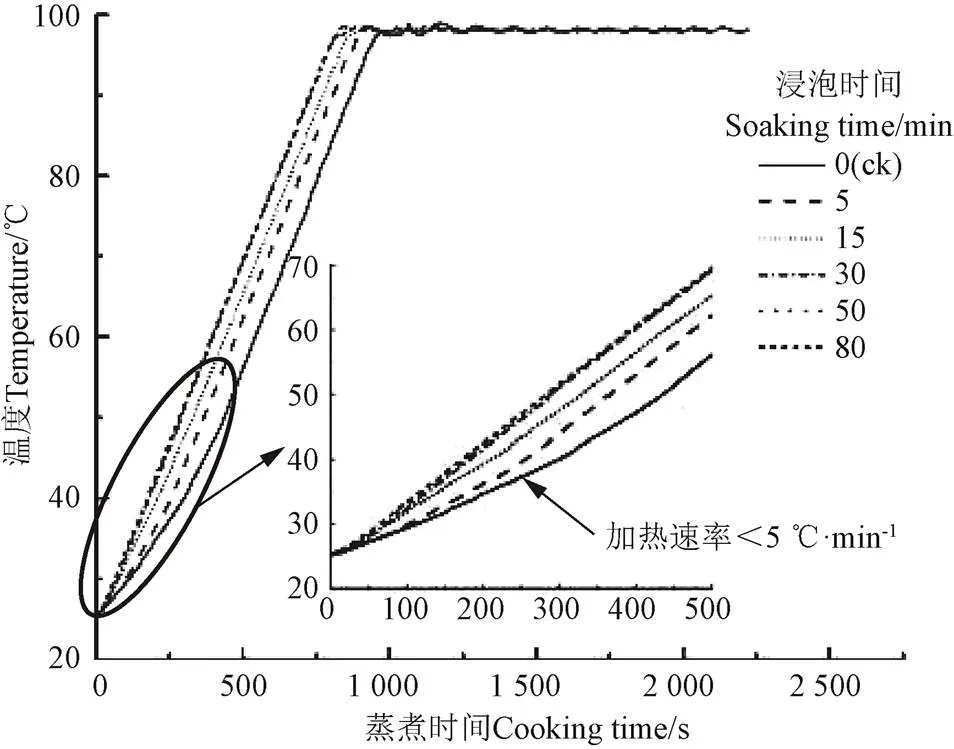

2.1.2 浸泡时间对欧姆加热蒸煮米饭加热历程的影响

浸泡能有效提高水米混合物电导率,使欧姆加热蒸煮米饭成为可能。图4为不同浸泡时间时欧姆加热水米混合物加热历程。图中数据是水米比为1.50∶1 mL/g的水米混合物浸泡不同时间后,在目标加热速率为5 ℃/min、98 ℃时保温20 min后测得。由图4可知,加热段的开始阶段各水米混合物加热速率小于5 ℃/min,随着蒸煮进行,加热速率逐渐达到设定的加热速率。对照组的水米混合物约需435 s达到目标加热速率,而浸泡5、15、30、50、80 min的水米混合物分别需要405、255、70、50、35 s,即浸泡时间越长,达到目标速率所需时间越短。主要原因是浸泡时间越长,电导率越大,恒定电压时产生热量就越多[30-31],温升越快,达到稳定的目标速率所需时间就越少。其他水米比时结果类似,此处没有给出。

注:水米比为1.50∶1 mL·g-1。

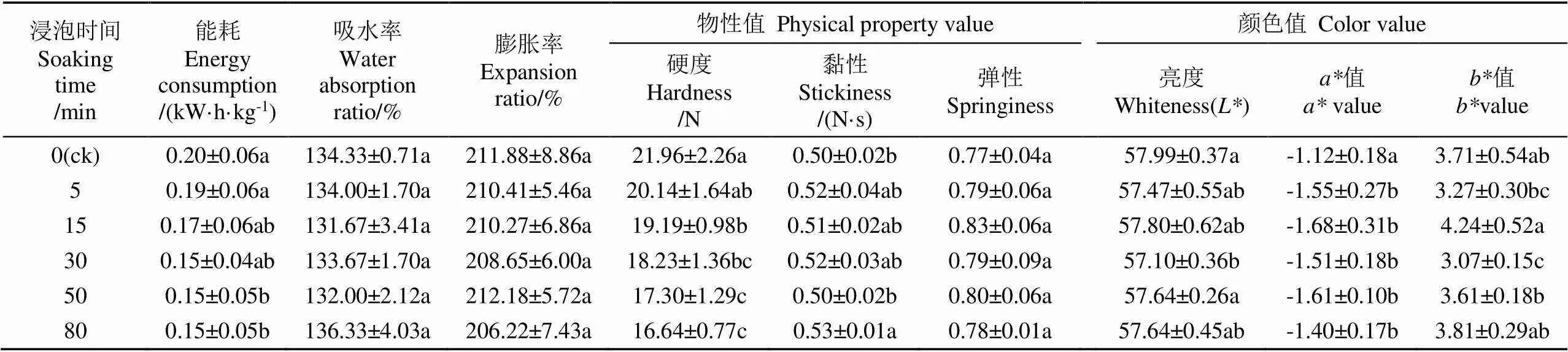

2.1.3 浸泡时间对欧姆加热能耗的影响

浸泡时间对欧姆加热蒸煮大米能耗的影响见表1。由表1可知,水米比1.50∶1 mL/g的水米混合物未浸泡时,每1 kg大米蒸煮为米饭需要约0.20 kW·h电能,而浸泡30~80 min后的大米仅消耗约0.15 kW·h电能即可,减少约1/4。电能消耗随浸泡时长增加逐渐降低,因此浸泡有利于降低欧姆加热蒸煮米饭的能耗。

表1 浸泡时间对欧姆加热蒸煮米饭的能耗与品质的影响

注:同列中不同字母表示水米比1.50∶1 mL·g-1时,浸泡不同时间后蒸煮米饭的能耗与品质均值差异显著(<0.05)。

Note: Different letters in the same column indicate that when the water-rice ratio is 1.50∶1 mL·g-1, there is a significant difference (<0.05) in the means of energy consumption and quality of cooking rice after soaking for different times.

2.1.4 浸泡时间对欧姆加热米饭品质的影响

浸泡时间对欧姆加热米饭品质的影响如表1所示。由表1可知,米饭硬度随浸泡时间增加呈现逐渐减小的趋势,对照组米饭硬度为21.96 N,但浸泡80 min后的米饭硬度为16.64 N;大米浸泡30 min以后,其米饭硬度有所减小但与浸泡80 min比较差异不显著(>0.05)。浸泡时间对欧姆加热蒸煮米饭的吸水率、膨胀率、黏性、弹性、亮度、值等均无显著影响。这是因为在浸泡过程中,大米逐渐吸水膨胀,其内部组织结构开始疏松[32],米饭软化,米饭硬度减小;浸泡30 min后大米吸水减缓,米饭硬度基本不变。

综上所述,试验表明采用欧姆加热技术蒸煮米饭完全可行。浸泡可以提高水米混合物电导率、精准控制欧姆加热蒸煮速率,更有助于减少米饭蒸煮能耗(<0.05),促进米饭软化。浸泡时间超过30 min时,电导率、欧姆加热蒸煮速率、米饭蒸煮能耗及米饭品质均变化较小。因此,为了分析欧姆加热速率和加热方法对蒸煮米饭的影响,后续蒸煮米饭前将大米浸泡30 min。

2.2 欧姆加热蒸煮米饭过程中水米混合物电导率与体积变化

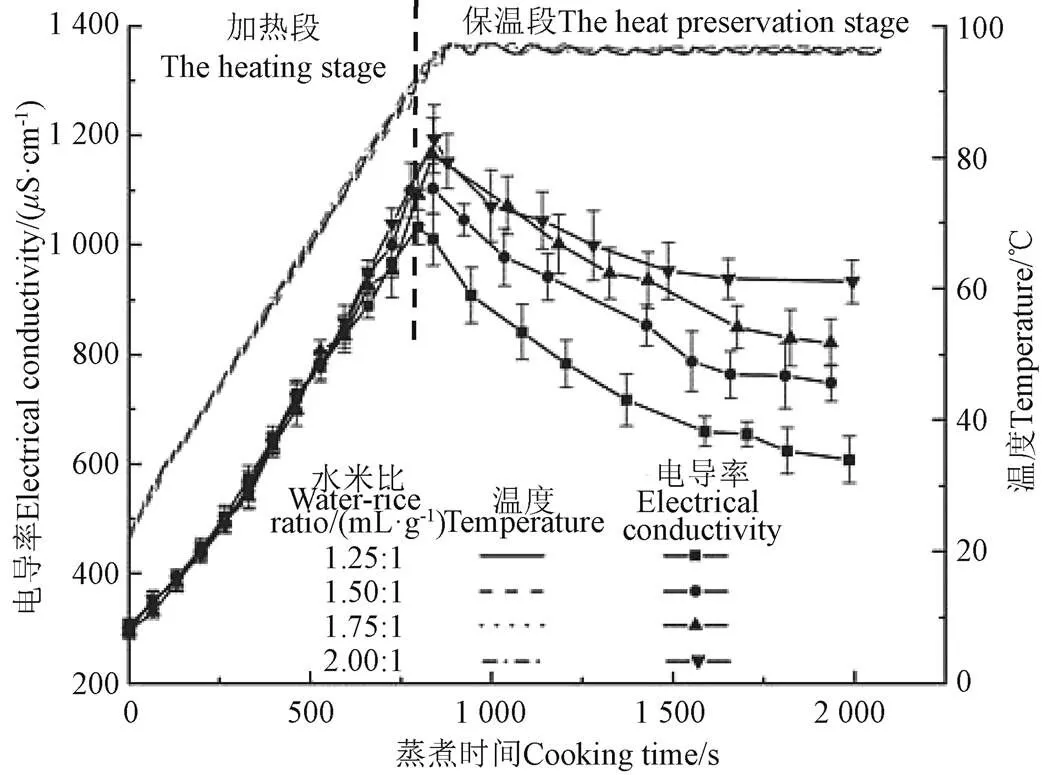

电导率是影响欧姆加热蒸煮过程的关键参数,研究欧姆加热蒸煮过程中水米混合物的电导率变化对于控制加热历程有重要的意义。图5为欧姆加热蒸煮米饭过程中水米混合物的电导率和温度变化。由图5可知,在加热段,水米混合物的电导率随蒸煮时间的增加而增大,由最初的320S/cm左右逐渐增大至850 s的1 000S/cm,呈现指数趋势增加。主要原因是水米混合物的电导率除了随温度升高电导率越大[33]之外,大米膨胀也会促进大米内部的可导电物质不断加速释放到水中,导致水米混合物的电导率增加速率逐渐增快[23]。水米比不同时,初始电导率之间虽然存在差异,但不显著,这是由于随着温度的升高,电导率受温度影响渐大,同时电压处于实时调整状态,动态通电导致电导率的计算存在一定误差,从而导致不同水米比的水米混合物电导率差异不明显。随着温度的升高,在加热段末期水米比越小,电导率越小,这是由于水米比较小时,加热段末期水分减小,导电物质移动受阻,电导率则略小。

注:大米浸泡30 min后,以目标加热速率5 ℃·min-1加热到98 ℃,并保温20 min。

在保温段,水米混合物的电导率随着保温时间的增加而逐渐降低;且水米比越大,整体电导率越大,其减小速率更慢。主要原因是由于保温过程中水米混合物温度恒定,电导率不再受温度影响,而大米在此阶段会继续吸水膨胀,同时部分水分蒸发流失,自由水逐渐减少,导电分子因此移动受阻[14],则电导率整体减小。当水米比越大时,大米吸收水分越多,较大的含水率使得导电物质在大米内部运动阻碍较小,水米混合物导电性好,因此电导率较大。

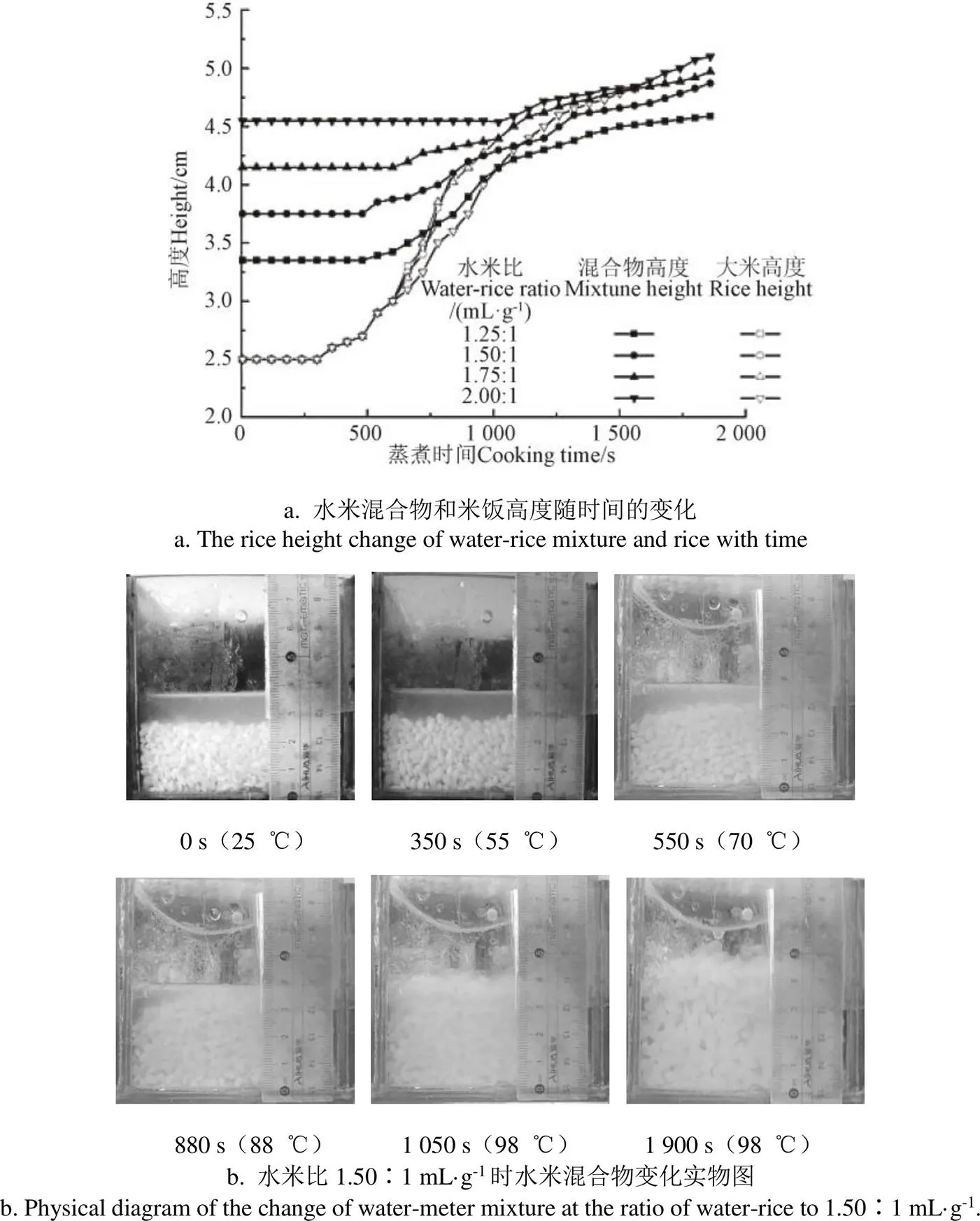

欧姆加热米饭蒸煮过程中的水米混合物和米饭高度的变化如图6所示。由图6可知,水米混合物总高度呈现先不变后增大最后趋于平衡的趋势,与前期研究结果相同[23];米饭高度也呈现类似趋势,且后期米饭体积与总高度趋于相同且逐渐增加。另外,水米比越大,蒸煮完成后米饭总高度越大,这是因为水米比大时,大米吸收水分较多,膨胀率更大的缘故。

2.3 加热速率对欧姆加热米饭品质的影响

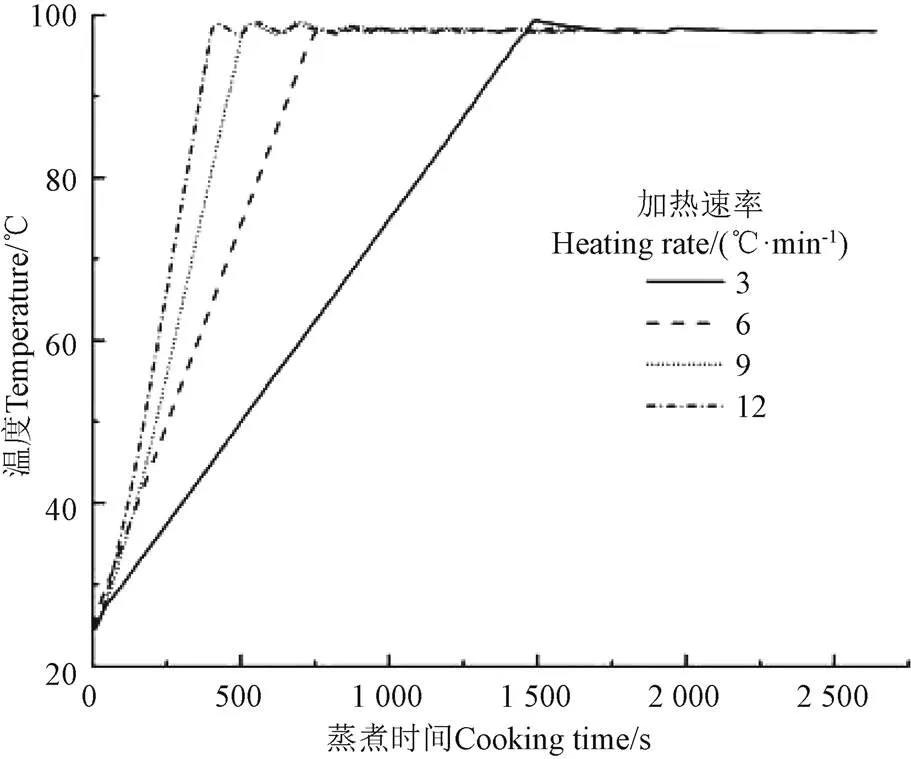

为了研究欧姆加热速率对蒸煮米饭品质的影响,分别设定3、6、9、12 ℃/min加热速率加热水米混合物,不同加热速率时欧姆加热温度曲线如图7所示。由图可知,水米混合物温度升高速率分别为3.01、6.07、9.17、12.30 ℃/min,表明水米混合物温度变化满足设定的恒速率加热要求。

图6 欧姆加热蒸煮过程中的水米混合物和米饭高度的变化

注:大米浸泡30 min后,水米比为1.50∶1 mL·g-1的水米混合物在98 ℃下保温20 min。

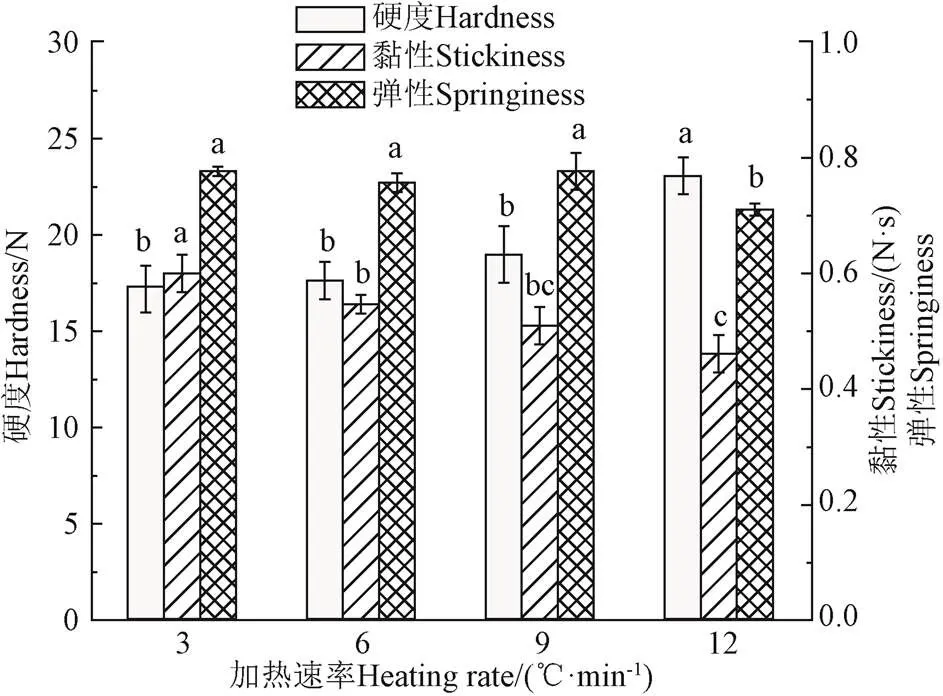

图8为欧姆加热速率对米饭硬度、黏性和弹性的影响。结果表明,随着加热速率加快,米饭的硬度增加,而黏性和弹性略有减小。这可能是由于随着加热速率加快,米饭糊化时间缩短,使得米饭糊化不均匀,内部有硬芯,最终导致硬度升高,而黏性和弹性降低。由图8可知,虽然加热速率较高时可以缩短蒸煮时间,但米饭硬度较大、黏性和弹性较小,影响口感;因此适当降低米饭蒸煮加热速率,有利于减小米饭硬度;欧姆加热速率可设置在3~9 ℃/min范围内,且米饭品质差异不大(>0.05)。

注:不同字母表示物性值均值差异显著(P<0.05)。

2.4 欧姆加热与电饭煲蒸煮时能耗与米饭品质比较

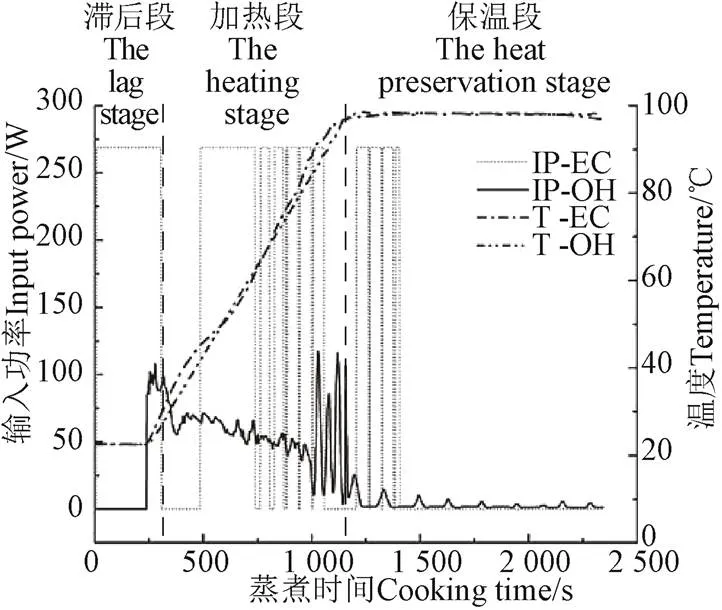

由于加热速率对米饭品质影响较大,为了对比欧姆加热与电饭煲在蒸煮米饭时的能耗以及米饭品质,因此要确保两者所用物料和加热历程完全一致。电饭煲蒸煮米饭时加热历程如图9所示,由于加热滞后性的缘故,最初一段时间温度没有变化。因此,控制欧姆加热米饭蒸煮试验系统前242 s不通电,之后以加热速率为4.86 ℃ /min加热并于98 ℃保温1 164 s。图9为水米比1.50∶1 mL/g、浸泡时间为30 min时,欧姆加热与电饭煲蒸煮米饭的水米混合物温度和输入功率变化。结果表明,两种方式的加热历程基本相似,且其他水米比加热结果与此水米比一致。

注:IP-输入功率,T-温度,EC-电饭煲,OH-欧姆加热。

2.4.1 能耗

由图9可知,电饭煲通过通断电来实现水米混合物的加热和保温,而欧姆加热米饭蒸煮试验系统动态调节输出电压,因此存在功率波动,但在加热段由于加热速率相同,功率基本保持相等;在保温段,两加热方式的输入功率均很小,主要用于弥补热量散失。

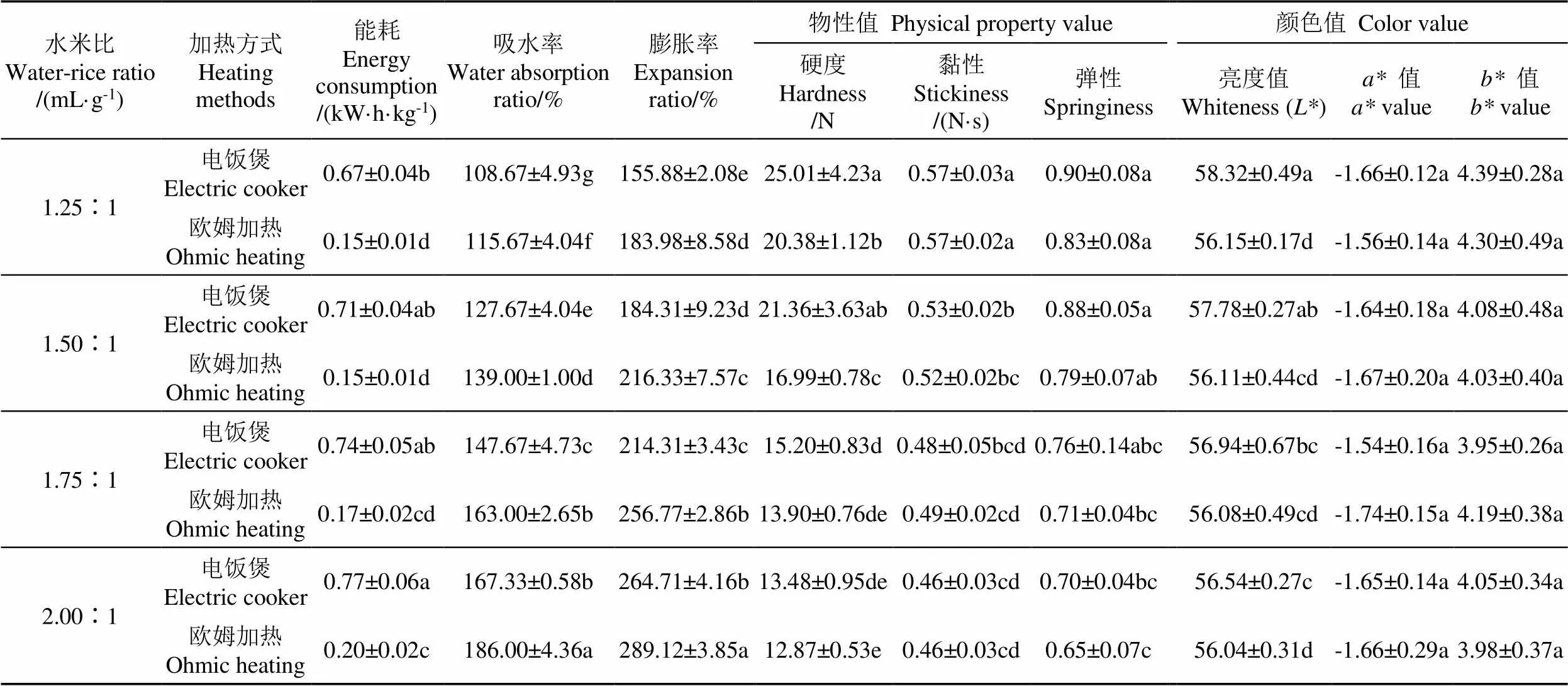

表2为欧姆加热与电饭煲加热蒸煮米饭的能耗与米饭品质对比。由表2可知,欧姆加热所需能耗约为电饭煲加热的20%~25%,这是由于欧姆加热属于体积加热[34],热量散失更少的缘故,国外多位学者也得到相似结论[14-15,23]。

表2 欧姆加热与电饭煲加热蒸煮米饭的能耗与米饭品质对比

注:同列中不同字母表示不同处理间均值差异显著(<0.05)。浸泡时间为30 min。

Note: Different letters in the same column indicated that the means were significantly different (<0.05) among the different treatments. The soaking time is 30 min.

2.4.2 米饭品质

1)膨胀率和吸水率

由表2可知,加热方式与水米比对米饭膨胀率和吸水率均有显著影响(<0.05);相比电饭煲加热,欧姆加热蒸煮米饭的膨胀率和吸水率更大(<0.05)。这是由于加水量相同时,电饭煲的加热内胆底面温度较高,水分散失较多;欧姆加热时水米混合物自身产生热量,物料内部温度分布均匀,且欧姆加热时其电场可以破坏米粒组织结构,促进水分子进入米粒,加速大米糊化[35],使得欧姆加热过程中米粒吸收水分较多、更加膨胀,因此大米进行欧姆加热比电饭煲加热吸水率和膨胀率更高。

2)硬度、黏性和弹性

由表2可知,加热方式对米饭的黏性和弹性无显著影响(>0.05),加热小米也得到相似结论[16];但在水米比为1.25∶1和1.50∶1 mL/g时,加热方式对米饭硬度影响显著(<0.05),水米比相同时欧姆加热米饭硬度最高可减小21%。这是由于欧姆加热时米粒吸水较多,内部组织较为蓬松的缘故[15]。同时,水米比越大米饭的硬度、黏性和弹性均越小。主要原因是水米比越大,大米吸水越多,米饭越膨胀使其硬度降低;同时米粒组织较为松散、不够紧致,故弹性较小;另外黏性通常与米饭表层有关,吸水越多的米粒表层黏性越低[15]。

比较可知,当水米比为1.25∶1 mL/g时,电饭煲蒸煮的米饭较硬,水米比为2.00∶1 mL/g时,米饭过软;采用欧姆加热蒸煮米饭,水米比大于1.75∶1 mL/g时,米饭较软。因此,电饭煲蒸煮米饭的水米比可取1.50∶1~1.75∶1 mL/g,欧姆加热蒸煮米饭的水米比范围为1.25∶1~1.50∶1 mL/g。

3)颜色值

研究表明,米饭越亮、越白品质越好。由表2可知,水米比相同时,电饭煲蒸煮的米饭值较欧姆加热大且差异显著(<0.05);加热方式相同时,值随水米比增大而减小,而米饭的值和值无明显差异(0.05)。主要原因是值与其米饭含水率和膨胀率有关,含水率和膨胀率较小时,米粒结构紧密、表面光滑,反射光较多,因此米饭值较大。

3 结 论

1)浸泡大米30 min,能够有效提高水米混合物的电导率,可实现较高的欧姆蒸煮加热速率;同时还能减少米饭蒸煮能耗,促进米饭软化,但不影响米饭的吸水率、膨胀率、黏性、弹性和颜色。延长浸泡时间对欧姆加热蒸煮米饭影响不显著(>0.05)。

2)欧姆加热蒸煮米饭过程中,加热段水米混合物的电导率最初为320S/cm,加热850 s内逐渐增大至1 000S/cm。保温段电导率则逐渐降低;且水米比越大,整体电导率越大。水米混合物和大米体积均呈现先不变后增大最后趋于平衡的趋势,并且水米比越大,蒸煮完成后米饭总体积越大。

3)欧姆加热速率较高时米饭硬度较大、黏性和弹性较小,加热速率设置在3~9 ℃/min范围内为宜。电饭煲蒸煮米饭的水米比可取1.50∶1~1.75∶1 mL/g,而欧姆加热水米比为1.25∶1~1.50∶1 mL/g。

4)欧姆加热蒸煮米饭所需能耗仅为电饭煲蒸煮的20%~25%。与电饭煲蒸煮相比,欧姆加热蒸煮米饭无加热滞后性,显著增加米饭膨胀率和吸水率(<0.05),减小硬度(<0.05);但黏性、弹性、值和值无显著差异(>0.05)。

[1]Qiu R, Liu C, Cui N, et al. Evapotranspiration estimation using a modified Priestley-Taylor model in a rice-wheat rotation system[J]. Agricultural Water Management, 2019, 224: 105755. doi: 10. 1016/j. agwat.

[2]孙俊,靳海涛,芦兵,等. 基于高光谱图像及深度特征的大米蛋白质含量预测模型[J]. 农业工程学报,2019,35(15):295-303. Sun Jun, Jin Haitao, Lu Bing, et al. Prediction model of rice protein content based on hyperspectral image and deep feature[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(15): 295-303. (in Chinese with English abstract)

[3]Jiang X, Hua M, Yang X, et al. Impacts of mist spray on rice field micrometeorology and rice yield under heat stress condition[J]. Scientific Reports, 2020, 10(1): 1579.

[4]Zhang Q, Xia S, Li J, et al. Effect of moisture transfer on texture uniformity of cooked rice after heat preservation with electric rice cooker[J]. Journal of Cereal Science, 2020, 91: 102862.

[5]Thuengtung S, Ogawa Y. Comparative study of conventional steam cooking and microwave cooking on cooked pigmented rice texture and their phenolic antioxidant[J]. Food Science and Nutrition, 2020, 8(2): 965-972.

[6]范大明,陈卫,李春香,等. 方便米饭微波复热过程温度分布的尺寸效应[J]. 农业工程学报,2012,28(增刊1):273-280. Fan Daming, Chen Wei, Li Chunxiang, et al. Size effect on temperature distribution of instant rice during microwave reheatingprocess[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(Supp.1): 273-280. (in Chinese with English abstract)

[7]Imai T, Uemura K, Noguchi A. Heating rate of egg albumin solution and its change during ohmic heating[J]. Advances in Experimental Medicine and Biology, 1998, 434: 101-108.

[8]Mannozzi C, Fauster T, Haas K, et al. Role of thermal and electric field effects during the pre-treatment of fruit and vegetable mash by pulsed electric fields (PEF) and ohmic heating (OH)[J]. Innovative Food Science & Emerging Technologies, 2018, 48: 131-137.

[9]Roux S, Courel M, Birlouez-Aragon I, et al. Comparative thermal impact of two UHT technologies, continuous ohmic heating and direct steam injection, on the nutritional properties of liquid infant formula[J]. Journal of Food Engineering, 2016, 179: 36-43.

[10]Li F, Li L, Li Z, et al. Determination of starch gelatinization temperature by ohmic heating[J]. Journal of Food Engineering, 2004, 62(2): 113-120.

[11]Mesías M, Wagner M, George S, et al. Impact of conventional sterilization and ohmic heating on the amino acid profile in vegetable baby foods[J]. Innovative Food Science & Emerging Technologies, 2016, 34: 24-28.

[12]Cevik M, Icier F. Effects of voltage gradient and fat content on changes of electrical conductivity of frozen minced beef meat during ohmic thawing[J/OL]. Journal of Food Process Engineering, 2018, 41(4): e12675.

[13]Gavahian M, Sastry S, Farhoosh R, et al. Ohmic heating as a promising technique for extraction of herbal essential oils: Understanding mechanisms, recent findings, and associated challenges[J]. Advances in Food and Nutrition Research, 2020, 91: 227-273.

[14]Gavahian M, Chu Y H, Farahnaky A. Effects of ohmic and microwave cooking on textural softening and physical properties of rice[J]. Journal of Food Engineering, 2019, 243: 114-124.

[15]Jittanit W, Khuenpet K, Kaewsri P, et al. Ohmic heating for cooking rice: Electrical conductivity measurements, textural quality determination and energy analysis[J]. Innovative Food Science & Emerging Technologies, 2017, 42: 16-24.

[16]Dias-Martins A M, Cappato L P, Mariana D C M, et al. Impacts of ohmic heating on decorticated and whole pearl millet grains compared to open-pan cooking[J]. Journal of Cereal Science, 2018, 85: 120-129.

[17]Zhu L, Bi S, Wu G, et al. Comparative analysis of the texture and physicochemical properties of cooked rice based on adjustable rice cooker[J]. LWT - Food Science and Technology, 2020, 130: 109650.

[18]中国国家标准化管理委员会. 粮油检验稻谷、大米蒸煮食用品质感官评价方法:GB/T 15682-2008[S]. 北京:中国标准出版社,2008.

[19]Derde L J, Gomand S V, Courtin C M, et al. Moisture distribution during conventional or electrical resistance oven baking of bread dough and subsequent storage[J]. Journal of Agricultural and Food Chemistry, 2014, 62(27): 6445-6453.

[20]Icier F, Yildiz H, Sabanci S, et al. Ohmic heating assisted vacuum evaporation of pomegranate juice: Electrical conductivity changes[J]. Innovative Food Science & Emerging Technologies, 2017, 39: 241-246.

[21]Liu L, Llave Y, Jin Y, et al. Electrical conductivity and ohmic thawing of frozen tuna at high frequencies[J]. Journal of Food Engineering, 2017, 197: 68-77.

[22]李星恕,张博,靳莉珍,等. 加热温度对苹果组织中细胞阻抗特性及水分分布的影响[J]. 农业工程学报,2015,31(14):284-290. Li Xingshu, Zhang Bo, Jin Lizhen, et al. Effect of heating temperature on cell impedance properties and water distribution in apple tissue[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(14): 284-290. (in Chinese with English abstract)

[23]Kanjanapongkul K. Rice cooking using ohmic heating: Determination of electrical conductivity, water diffusion and cooking energy[J]. Journal of Food Engineering, 2017, 192: 1-10.

[24]周小理,王惠,周一鸣,等. 不同烹煮方式对米饭食味品质的影响[J]. 食品科学,2017,38(11):75-80. Zhou Xiaoli, Wang Hui, ZhouYiming, et al. Influence of different cooking methods on eating quality of rice[J]. Food Science, 2017, 38(11): 75-80. (in Chinese with English abstract)

[25]刘庆庆,朱松明,张洁,等. 预糊化条件对萌芽糙米蒸煮质构特性及品质的影响[J]. 农业工程学报,2017,33(21):289-297. Liu Qingqing, Zhu Songming, Zhang Jie, et al. Effects of parboiling conditions on cooking properties, textural properties and quality characters of germinated brown rice[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(21): 289-297. (in Chinese with English abstract)

[26]于殿宇,王彤,唐洪琳,等. 挤压法制备富钙强化重组大米的工艺优化及其结构表征[J]. 农业工程学报,2018,34(22):291-298. Yu Dianyu, Wang Tong, Tang Honglin, et al. Process optimization and structure characterization of calcium-fortified recombinant rice prepared by extrusion[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(22): 291-298. (in Chinese with English abstract)

[27]Miao W, Wang L, Xu X, et al. Evaluation of cooked rice texture using a novel sampling technique[J]. Measurement, 2016, 89: 21-27.

[28]谢涛,李英,易翠平,等. 回生抗性淀粉种类对米淀粉凝胶形成的影响[J]. 农业工程学报,2017,33(4):309-314. Xie Tao, Li Ying, Yi Cuiping, et al. Effect of retrograded resistant starch types on forming rice starch gel[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(4): 309-314. (in Chinese with English abstract)

[29]Taghinezhad E, Khoshtaghaza M H, Suzuki T, et al. Quantifying the relationship between rice starch gelatinization and moisture - electrical conductivity of paddy during soaking[J]. Journal of Food Process Engineering, 2016, 39(5): 442-452.

[30]熊秀芳,李星恕,郭康权,等. 豆浆通电加热过程有限元解析与验证[J]. 农业机械学报,2011,42(12):158-163. Xiong Xiufang, Li Xingshu, Guo Kangquan, et al. FEM analysis and validation of ohmic heating process of soymilk[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(12): 158-163. (in Chinese with English abstract)

[31]周亚军,闫琳娜,殷涌光,等. 含水果颗粒液态食品物料通电加热温度场研究[J]. 农业工程学报,2005,21(5):159-162. Zhou Yajun, Yan Linna, Yin Yongguang, et al. Ohmic heating temperature field of liquid food materials with fruit granule[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2005, 21(5): 159-162. (in Chinese with English abstract)

[32]韩雪琴,刘磊,黄立新. 浸泡工艺对不同品种糯米理化特性的影响[J/OL]. 现代食品科技,2020,36(2). [2020-06-03]. http: //kns. cnki. net/kcms/detail/44. 1620. TS. 20191220. 1055. 006. html Han Xueqin, Liu Lei, Huang Lixin. Effect of soaking process on physicochenical properties of glutinous rice from different varieties[J/OL]. Modern Food Science and Technology, 2020, 36(2). [2020-06-03]. http://kns. cnki. net/kcms/detail/44. 1620. TS. 20191220. 1055. 006. html (in Chinese with English abstract)

[33]郭文川,杨彪. 数显式豆浆总固形物含量检测仪设计与试验[J]. 农业机械学报,2016,47(10):287-292. Guo Wenchuan, Yang Biao. Design and test of digital detector on total solids content of soybean milk[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(10): 287-292. (in Chinese with English abstract)

[34]Jo Y J, Park S H. Evaluation of energy efficacy and texture of ohmically cooked noodles[J]. Journal of Food Engineering, 2019, 248: 71-79.

[35]Jean-Francois C M, Jason G, Bradley P, et al. Sensory descriptive texture analyses of cooked rice and its correlation to instrumental parameters using an extrusion cell[J]. Cereal Chemistry, 1998, 75(5): 714-720.

Effects of ohmic heating on the cooking process energy consumption and quality of cooked rice

Ding Xinting1, Xiong Xiufang1, Li Shuwang1, Wang Shaojin1, Li Xingshu1,2※

(1.,,712100,; 2.,712100,)

Rice is one of the most important food source for a major portion of the world’s population. In cooking rice, a traditional electric cooker has low efficiency of electro-thermal conversion, and low accuracy of temperature control. Alternatively, an ohmic heating has attract much attention, due to its high electro-thermal conversion efficiency, simple structure, easy control of equipment, as well as uniform and rapid heating. In this study, an ohmic heating experimental system was designed for cooking rice. The system was consisted of a control system, an ohmic heating container, and a personal computer. Its function was to collect the voltage, current, and temperature signals, then to send the collected data to the computer. The feedforward compensation was used to control the heating rate, whilst the PID controller was used to control the heat preservation temperature. PWM signals were both output with different duty cycles to adjust the output voltage, achieving the purposes of constant heating rate and heat preservation temperature. A systematic investigation was made to study the effects of soaking time (5, 15, 30, 50, 80 min) and water-rice ratio (1.25:1, 1.50:1, 1.75:1, and 2.00:1 mL/g) on the electrical conductivity of water-rice mixture, ohmic heating rate, energy consumption, and rice quality (expansion ratio, water absorption ratio, physical property value, and color) during ohmic heating. The effect of ohmic heating rate on the rice quality was explored, in order to compare energy consumption and quality of rice cooked by ohmic heating and electric cooker, where the same material and heating process were used during cooking rice. The results showed that during soaking rice, the electrical conductivity of rice-water mixture increased, due to the conductive material inside the rice, indicating an increase in the ohmic heating rate. The soaking rice reduced the energy consumption (<0.05), further to obtain the soft rice. Nevertheless, there was no any influence on the water absorption ratio, expansion ratio, stickiness, springiness, and color of rice, indicating that the cooking rice by ohmic heating was completely feasible under the situation that the rice had been soaked for 30 min. During the process of ohmic cooking rice, the electrical conductivity of rice-water mixture initially increased with the increase of cooking time, and then gradually decreased during the heat preservation stage. The electrical conductivity of water-rice mixture became greater, as the water-rice ratio increased. At the same time, the volume of water-rice mixture and the rice both showed the trend of being unchanged first, then increasing, and finally tending to balance. The total volume of rice was larger after cooking, as the water-rice ratio increased. The hardness of rice increased (<0.05), as the heating rate of ohmic cooking was higher, but thestickiness and springiness decreased slightly (<0.05). The heating rate can be within the range of 3-9 ℃/min. When the water-rice ratio was from 1.25:1 mL/g to 1.50:1 mL/g, the rice tasted better, indicating that the more suitable water-rice ratio was 1.50:1 mL/g to 1.75:1 mL/g in a electric cooker. In addition, the ohmic cooking rice had no heating hysteresis, where the temperature of heating and heat preservation can be control accurately, compared with an electric cooker. In the same amount of rice, the energy consumption of ohmic heating was only 20%-25% of energy required for electric cooker. Compared with an electric cooker, the hardness of rice cooked by ohmic heating can be reduced by 21%, and the expansion ratio and water absorption ratio were larger (<0.05), while the whiteness value () of rice were lower (<0.05). This finding can provide a technical support to develop automatic rice cooking device with a high efficiency using ohmic heating.

electrical conductivity; quality control; rice; ohmic heating; rice soaking; heating energy consumption

丁辛亭,熊秀芳,李树旺,等. 欧姆加热对米饭蒸煮过程能耗及其品质的影响[J]. 农业工程学报,2020,36(24):310-318.doi:10.11975/j.issn.1002-6819.2020.24.036 http://www.tcsae.org

Ding Xinting, Xiong Xiufang, Li Shuwang, et al. Effects of ohmic heating on the cooking process energy consumption and quality of cooked rice[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(24): 310-318. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.24.036 http://www.tcsae.org

2020-08-12

2020-10-24

国家自然科学基金项目(31972209)

丁辛亭,主要从事农产品加工技术与装备研究。Email:dingxinting@qq.com

李星恕,教授,博士,从事农业装备研发与农产品无损检测方面的研究。Email:xingshu-li@nwsuaf.edu.cn

10.11975/j.issn.1002-6819.2020.24.036

TS213.3

A

1002-6819(2020)-24-0310-09