鸡油组织中的磷脂对鸡油挥发性风味化合物形成的影响

2020-03-03陈德慰杨晓莹刘思佚叶婷婷王勤志

陈德慰,杨晓莹,刘思佚,叶婷婷,郭 栋,王勤志

·农产品加工工程·

鸡油组织中的磷脂对鸡油挥发性风味化合物形成的影响

陈德慰,杨晓莹,刘思佚,叶婷婷,郭 栋,王勤志

(广西大学轻工与食品工程学院,南宁 530004)

磷脂是肉类特征性风味的重要前体物质。鸡油具有浓郁的脂香和鸡汤香气,磷脂可能对其风味有重要作用。该研究采用去除鸡油组织中的磷脂,以及在鸡油中添加磷脂等处理方法,结合顶空固相微萃取-气相色谱-质谱联用技术和感官评价方法研究经不同处理鸡油中的挥发性风味物质相对含量和风味的变化。结果表明添加了磷脂的鸡油,其特征性风味成分显著增加,特别是()-2,4-癸二烯醛和1-辛烯-3-酮分别增加了4.5倍和10.4倍;而去除磷脂鸡油的挥发性风味物质种类和丰度显著减少;感官评价结果也表明添加磷脂鸡油的风味最浓郁,而去除磷脂鸡油的风味最弱。因此,该研究证明鸡油组织中的磷脂对鸡油的风味具有重要的贡献作用,添加磷脂可显著增加鸡油的香气。该研究结果为浓香鸡油的开发提供理论依据和参考工艺。

油脂;磷脂;农产品;风味物质;顶空固相微萃取(HS-SPME);气相色谱-质谱法(GC-MS);感官评价

0 引 言

鸡油是采用肉鸡的鸡油组织为原料提取出来的油脂,其口感圆滑细腻,具有浓郁的脂香和鸡汤香气,烹饪时添加鸡油可以明显改善鸡肉汤的头香,赋予真实、浓厚的香气[1-2]。鸡肉脂肪对鸡肉的特异性风味有着重要的作用,可以用于天然鸡肉香精的制备[3]。鸡肉的关键性风味化合物已经被广泛报道,()-2,4-癸二烯醛、()-2,4-壬二烯醛、()-2-癸烯醛、()-2-壬烯醛、()-2-庚烯醛、己醛、1-辛烯-3-酮具有鸡汤味、油脂味、油炸味、青草味、蘑菇味等风味特征,是鸡肉中源于脂肪酸氧化降解的特征风味物质,因此它们也是影响鸡油风味的关键性风味化合物[4-6]。另外,脂肪酸氧化降解产生的酮类、醛类化合物可以在加热过程中与氨基化合物发生美拉德反应生成吡嗪、吡啶等具有肉香味的杂环化合物以及3-(甲硫基)丙醛等阈值较低的含硫化合物,它们也是影响鸡肉风味的重要物质[7-8]。

磷脂是肉类的特征性风味前体物质[9]。磷脂中不饱和脂肪酸含量丰富,受热后可产生大量的风味化合物,如Lin等[10]采用GC-MS-O和AEDA法鉴定和分析出鸡蛋磷脂酰胆碱(PC)和鸡蛋磷脂酰乙醇胺(PE)受热后产生大量的()-2,4-癸二烯醛、1-辛烯-3-酮、()-2-癸烯醛和()-2-十一烯醛等具有鸡肉特征气味的成分。在本课题组前期的研究中[11-12],将蛋黄磷脂添加至鸡肉中,可显著提高鸡肉的风味化合物含量和鸡肉的风味;在真空油炸薯条体系中添加蛋黄磷脂可以增加炸薯条关键风味物质的含量[13]。

近年来,由于中国肉鸡养殖加工业快速发展,产生大量的加工副产物,其中鸡油组织广泛用于提取鸡油,但目前关于鸡油风味的研究报道很少。本课题根据前期研究推测鸡油组织中的磷脂对鸡油的风味有重要贡献作用。因此本研究以新鲜鸡油组织为原料,采用乙醇提取磷脂,分别制备了常规炼制鸡油、去除磷脂鸡油、添加磷脂鸡油以及鸡油磷脂样品,利用顶空固相微萃取结合气相色谱-质谱(HS-SPME-GC-MS)联用仪技术分离鉴定其风味化合物,再采用排序检验法对样品进行感官评价。为浓香鸡油的开发提供理论依据和加工方法。

1 材料与方法

1.1 材料与试剂

鸡油组织购买自本地市场,置于−20 ℃冰箱冷藏。C5~C30正构烷烃标准品,Sigma-Aldrich公司;乙醇(分析纯),成都科隆化学品有限公司;正己烷,天津市富宇化工;丙酮,立达化工;2-甲基丁醛、己醛、()-2-戊烯醛、庚醛、辛醛、壬醛、()-2-辛烯醛、()-2,4-庚二烯醛、苯甲醛、()-2,4-壬二烯醛、()-2,4-癸二烯醛、1-戊烯-3-醇、甲基吡嗪、2,6-二甲基吡嗪、甲硫醇、二甲基二硫醚、二甲基三硫醚、壬酸标准品,Sigma-Aldrich公司。

1.2 仪器与设备

7890b-5977型GC-MS联用仪,安捷伦公司(美国);HS-SPME装置、15 mL顶空样品瓶、50m DVB/CAR/PDMS萃取头,Supelco公司(美国);PL203型电子分析天平,梅特勒-托利多仪器(上海)有限公司;SY-1230型恒温水浴槽,上海沪粤明科学仪器有限公司;C-MAG HP10电热板,IK集团(德国)。

1.3 试验方法

1.3.1 样品制备

1)磷脂的提取。参考Gladkowski等[14]的方法,并稍作修改。取200 g鸡油组织,去除表层薄膜后放入匀浆机搅碎,加入200 mL乙醇,低温超声提取30 min。使用离心机在6 000 r/min转速下离心15 min,保留上清液,重复2次操作,将2次操作的上清液合并。使用真空旋转蒸发仪在45 ℃条件下将上清混合液中的乙醇挥发,然后将残余物溶于30 mL正己烷中并置于0 ℃冰浴中30 min使其冷却。接下来将60 mL冷丙酮(−20 ℃)加入混合液中以沉淀磷脂,取出沉淀并用20 mL冷丙酮清洗5次,最后使用真空泵抽取10 h以去除样品中的有机溶剂,得鸡油磷脂。

2)去磷脂鸡油样品的制备。使用乙醇提取鸡油组织后,收集沉淀油脂层,使用离心机在6 000 r/min转速下离心15 min,去除油脂中的乙醇,重复操作4次,然后用真空泵在室温下真空抽提10 h,去除去样品中少量残留的乙醇溶剂,获得去磷脂鸡油组织。然后将去磷脂鸡油组织在90 ℃温度下水浴提取40 min,在6 000 r/min,10 min条件下离心,收集澄清油脂层作为去磷脂鸡油样品备用。

3)常规炼制鸡油样品的制备。将鸡油组织在90 ℃温度下水浴提取40 min,在6 000 r/min,10 min条件下离心,收集澄清油脂层作为常规炼制鸡油样品备用。

4)样品设置。提取出的磷脂按照1∶100(磷脂∶NaCl)的比例混匀备用;样品制备如下:去除磷脂鸡油样品:5.00 g去磷脂鸡油、5.00 g NaCl;常规炼制鸡油样品:5.00 g鸡油、5.00 g NaCl;添加磷脂鸡油样品:5.00 g鸡油、0.05 g鸡油磷脂、5.00 gNaCl;鸡油磷脂样品:0.05 g鸡油磷脂、5.00 gNaCl;样品放置在100 mL蓝色瓶盖的玻璃瓶中,封盖密封,然后在150 ℃油浴中加热20 min,所有样品都是从同一批鸡油组织中出来的。每个样品重复3次。

1.3.2 磷脂含量的测定

参照国标SN/T 3851-2014中的钼蓝比色法。其原理是使用有机溶剂将样品中的磷脂提取并用马弗炉灼烧成灰白色的五氧化二磷,然后用热盐酸溶解变成磷酸,再与钼酸钠反应生成磷钼酸钠,接着被硫酸联胺还原成钼蓝。用分光光度计在650 nm波长处测定钼蓝的吸光度,采用外标法进行定量[15]。

1.3.3 顶空-固相微萃取(HS-SPME)

将每组样品置于15 mL的顶空瓶内,放置于加热至60 ℃的电子恒温水浴锅恒温平衡20 min,再将老化好的50m DVB/CAR/PDMS萃取头插入样品瓶中,同时推出纤维头,顶空平衡吸附40 min,然后将萃取头插入GC进样口,250 ℃解吸3 min。

1.3.4 挥发性化合物的气质联用色谱GC-MS分析

色谱柱:DB-WAX毛细管柱(30 m×0.25 mm× 0.25m)。

GC条件:40 ℃保持2 min,后以2 ℃/min速度升至45 ℃,再以3 ℃/min升至120 ℃保持2 min,再以6 ℃/min 速度升温至230 ℃,保持6 min。进样口温度为250 ℃,载气为He,流速1 mL/min,不分流进样。

MS条件:电子电离源;接口温度250 ℃;离子源温度230 ℃;电子能量70 eV;质量扫描范围30~550 m/z。

1.3.5 化合物的定性和定量

将样品总离子流色谱图中的每个峰与NIST14标准谱库中的化合物的质谱数据进行对比定性分析;同时使用正构烷烃(C5-C30),在与样品相同的色谱条件下进样,计算待测化合物的RI值进行定性;部分重要的化合物采用标准品进行定性。

采用色谱峰面积进行定量,目的是比较不同的处理方法对各个挥发性化合物含量的相对变化。

1.3.6 排序检验法

选择10名经感官评价培训的人员组成评定小组,对随机编号的3种鸡油样品的香气浓郁程度进行排序,鸡油特征香气最浓郁的排第一,鸡油特征香气最淡的排最后,根据评价员对样品的排序计算各个样品的排序总和。

1.3.7 数据处理

采用SPSS statistics 23.0对检出风味化合物的峰面积(去除磷脂鸡油、常规炼制鸡油、添加磷脂鸡油)进行进行单因素方差分析;采用 Friedman 检验法分析排序检验法中样品间的差异。

2 结果与分析

2.1 磷脂含量的测定

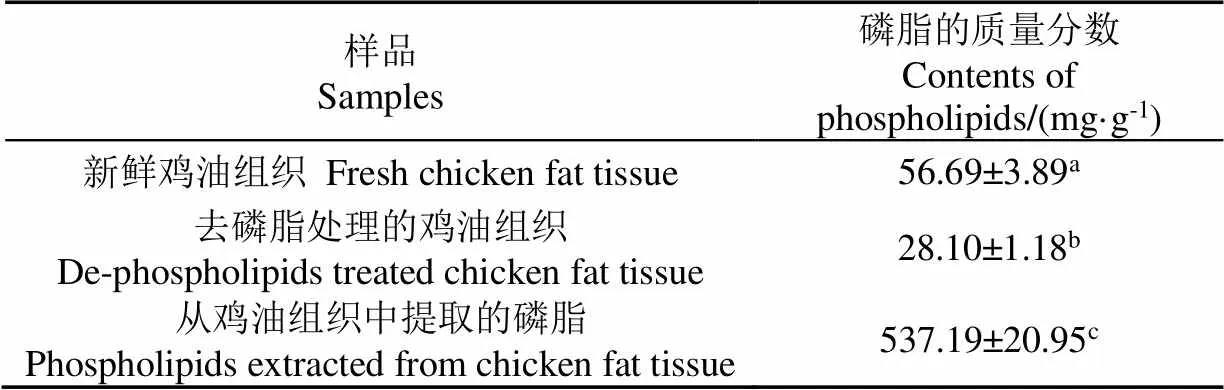

用钼蓝比色法测定不同样品的磷脂含量如表1所示。

表1 经不同处理的样品中磷脂的质量分数

注:不同小写字母表示存在显著性差异,<0.05。

Note: Column date marked with different superscripts mean significant difference,<0.05.

测定结果表明,新鲜鸡油组织中磷脂的含量为(56.69±3.89) mg/g,与王维亚[16]采用抗坏血酸-钼蓝比色法测定乌骨鸡油脂中磷脂质量分数为5.23%的结果相似。鸡油组织中的磷脂含量相比于蛋黄中约12%的磷脂[17]较低,但远高于瘦鸡肉中约0.5%的磷脂[16]。鸡油组织经乙醇处理后获得的去磷脂处理的鸡油组织,其磷脂含量与新鲜鸡油组织存在显著性差异(<0.05),但由于磷脂作为生物膜的组成成分与脂质体结合紧密,提取难度较大,仍有少量残留,同时可能有其他含磷组分的存在导致去磷脂鸡油组织的测定结果偏高。从鸡油组织中提取的磷脂样品的磷脂含量为(537.19±20.95) mg/g,相比于传统溶剂提取法提取的磷脂纯(35%)[18]较高,采用乙醇-正己烷-丙酮提取的方法会使部分非磷脂的脂质随磷脂析出,但这部分脂质氧化稳定性较高,对脂质氧化降解产生的风味物质影响较小[12]。

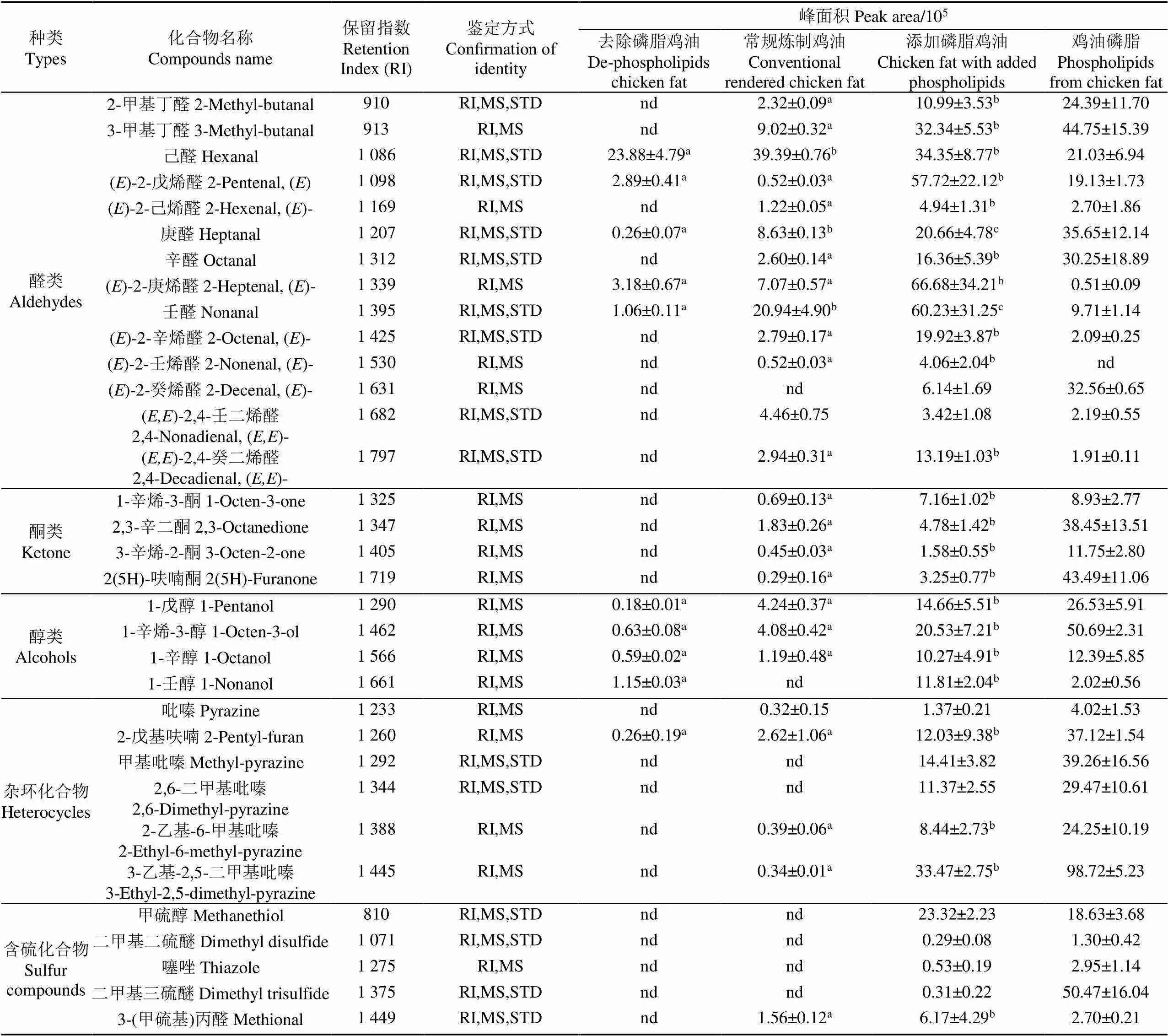

2.2 不同样品挥发性风味物质的整体比较

3种鸡油样品和鸡油磷脂样品中的挥发性风味物质的分离鉴定结果如表2所示。由表2可知,去除磷脂鸡油、常规炼制鸡油、添加磷脂鸡油和鸡油磷脂样品分别鉴定出10、25、33、32种重要挥发性风味化合物。在每个样品的挥发性化合物轮廓中,鉴定出种类最多的是羰基化合物,因为醛酮类化合物是脂质的主要氧化降解产物[19]。不同样品间挥发性化合物相对含量的轮廓清楚地证明了添加磷脂有助于风味化合物的形成。鸡油磷脂样品本身鉴定出最多的挥发性化合物也说明了磷脂氧化降解更易产生丰富的风味物质。因为磷脂中含有较高含量的不饱和脂肪酸,加热条件下更易氧化降解[12],另外由于磷脂的两亲性质,它们通常以分散的形式存在,可以增大其与助氧化剂的接触面积,使磷脂的加入增加了整体的氧化速率。而去除磷脂的鸡油大部分挥发性化合物种类和丰度显著降低,且醛类挥发性化合物仅鉴定出()-2-庚烯醛、()-2-戊烯醛两种不饱和醛,其余是饱和醛类。Mottram等[20]研究发现选择性去除牛肉中的磷脂可引起挥发性风味物质的减少;Chen等[12]将蛋黄磷脂添加至鸡肉中,可显著提高鸡肉的风味化合物含量,从而增强了鸡肉的风味。

表2 四种样品的挥发性风味物质及峰面积

注:鉴定方式:RI表示样品的线性保留指数与数据库(NIST Standard Reference Database, SRD Number 69)中报道的一致;MS表示质谱与NIST质谱数据库中的参考谱一致;STD表示加入外标物检出且RI值与样品中检出的一致;对去除磷脂鸡油、常规炼制鸡油、添加磷脂鸡油进行方差分析,同一行的不同字母表示差异性显著(<0.05);nd表示未检出。

Note: Confirmation of identity: RI mean the retention index value agrees with that in the database (NIST Standard Reference Database, SRD Number 69); MS mean mass spectrum agrees with reference spectrum in the NIST mass spectral database; STD mean mass spectrum and RI agree with those of an authentic compound; Analysis of variance was performed on de-phospholipids chicken fat, chicken fat and chicken fat with added phospholipids, the same superscript letters in the same row indicate no significant differences at<0.05; nd mean not be detected in the sample.

2.3 磷脂对鸡油关键挥发性风味物质的影响

鸡肉组织中的脂质氧化降解产生的()-2,4-癸二烯醛(油脂、鸡汤气息)、()-2,4-壬二烯醛(油脂、鸡汤气息)、()-2-癸烯醛(油脂气息)、()-2-壬烯醛(油脂气息)、()-2-庚烯醛(油脂气息)、己醛(青草气息)、1-辛烯-3-酮(蘑菇气息)和1-辛烯-3-醇(蘑菇气息)等化合物是赋予鸡肉或鸡汤中浓郁鸡油香气的关键化合物[4-6,21-22]。其中()-2,4-癸二烯醛不仅是鸡汤中最重要的化合物,具有浓郁的油脂气味,而且可以增强食物的鲜味[23]。另外()-2,4-癸二烯醛气味阈值较低(0.07g/kg),Feng等[5]发现()-2,4-癸二烯醛是鸡汤中气味稀释因子最高的风味化合物,而且该化合物在土鸡鸡汤中的气味稀释因子是速养鸡鸡汤的4倍。在本试验中,添加磷脂鸡油样品中的()-2,4-癸二烯醛含量是常规炼制鸡油样品的4.5倍,说明鸡油磷脂是()-2,4-癸二烯醛的重要前体物质,鸡油中添加磷脂可显著提高其含量,而去除磷脂则未能检测出。类似的,其他的关键化合物的变化趋势也和()-2,4-癸二烯醛的相似,如()-2-壬烯醛、()-2-庚烯醛、1-辛烯-3-醇和1-辛烯-3-酮在添加磷脂鸡油样品中都有显著的增加,分别增加了7.8倍、9.4倍、5.0倍和10.4倍;但()-2,4-壬二烯醛和己醛的变化不大。此实验结果与本课题组前期利用蛋黄磷脂增强食品风味的结果相似[11-12]:添加磷脂后,大部分脂质氧化降解产物大幅度提高,特别是()-2,4-癸二烯醛、()-2-壬烯醛和1-辛烯-3-酮;而少数化合物,如己醛的增加幅度不大。

亚油酸是鸡油磷脂和甘油三酯中主要的不饱和脂肪酸,()-2,4-癸二烯醛、()-2,4-壬二烯醛、()-2-壬烯醛、()-2-庚烯醛、1-辛烯-3-醇和1-辛烯-3-酮和己醛都是亚油酸氧化降解的产物[19]。亚油酸氧化诱导异构化可以产生C9-和C13-氢过氧化物,其中C9-氢过氧化物是()-2,4-癸二烯醛、()-2,4-壬二烯醛、()-2-壬烯醛、()-2-庚烯醛、1-辛烯-3-醇和1-辛烯-3-酮的前体物质,而C13-氢过氧化物是己醛的前体物质[19,24]。有研究指出,磷脂分子中的亚油酸基团在自动氧化过程中更易形成C9位置的氢过氧化物[25],而甘油三酯中的亚油酸基团在脂质氧化初始阶段在C9和C13位置都可以形成氢过氧化物[26-27]。因此,添加磷脂后()-2,4-癸二烯醛、()-2-壬烯醛、()-2-庚烯醛、1-辛烯-3-醇和1-辛烯-3-酮的含量显著增加而己醛含量变化不大。同样的,由于鸡油磷脂样品更易氧化,相同条件下的氧化程度大,()-2,4-癸二烯醛发生二次氧化生成己醛[6],导致鸡油磷脂样品中的()-2,4-癸二烯醛含量反而比己醛的含量低。尽管己醛对鸡汤风味具有一定的积极作用,但当它含量较高时,反而对风味有不利作用,如己醛通常被作为鸡肉过热风味(Warmed-Over Flavor, WOF)的鉴定指标[6,28]。

饱和的饱和醇类和甲基酮类物质,如1-戊醇(青草气息)、1-辛醇(油脂气息)、1-壬醇(油脂气息)等主要由饱和脂肪酸的氧化降解产生,这类产物在添加磷脂的样品也显著性增加,可能是添加磷脂后体系富含活跃的不饱和脂肪酸可以促进活性较低的脂肪酸的氧化,另外磷脂的极性性质也有助于促进脂质的氧化降解[29]。但这类物质的阈值较高,对风味贡献作用较小[19]。

一些美拉德反应产物,如2-甲基丁醛、3-甲基丁醛、甲基吡嗪、2,6-二甲基吡嗪、2-乙基-6-甲基吡嗪、3-乙基-2,5-二甲基吡嗪、3-(甲硫基)丙醛、二甲基二硫醚、二甲基三硫醚物质在磷脂含量较高的样品中检出较高的丰度,主要原因一方面是磷脂中磷脂酰乙醇胺可以作为美拉德反应的前体物质,另一方面是低含量的美拉德反应前体物质与磷脂共同被提取出来。美拉德反应产物可以给油脂样品提供了类似烤肉风味[30-31]。

2.4 不同方式处理的鸡油样品的感官评价

制备去除磷脂鸡油、常规炼制鸡油和添加磷脂鸡油样品后,采用排序检验法进行感官分析。样品的秩和及其大小排序见表3。

表3 样品的秩次和秩和

对感官评价结果利用Friedman检验法进行统计分析,统计量=16.20,在0.05检验水平上,临界值(10,3)=6.20<16.20,所以样品间存在显著性差异,进一步利用最小显著差数LSD=8.76进行多重比较与分组,发现经不同处理的鸡油的风味浓郁程度从小到大排序为:去除磷脂鸡油、常规炼制鸡油、添加磷脂鸡油。由此可见感官评价结果与GC-MS分析中峰面积的变化趋势一致,去除鸡油中磷脂后大部分脂肪降解产物的丰度和种类减少从而减弱了鸡油的香气,而在鸡油中添加1.0%的磷脂后,()-2,4-癸二烯醛(鸡汤味、油脂味、油炸味)、()-2-癸烯醛(鸡肉味、油脂味、蜡味)、()-2-壬烯醛(油脂味、油炸味、青草味)、()-2-庚烯醛(油脂味、杏仁味)、1-辛烯-3-酮(蘑菇味、金属味)等鸡油关键性风味物质丰度的显著性增加增强了鸡油样品的鸡肉味、油脂味,使鸡油的特征香气更为浓郁,从而可以制备出浓香鸡油。

3 结 论

去除磷脂的鸡油相对于鸡油挥发性化合物种类减少,丰度降低;而添加了磷脂的鸡油,其绝大部分特征性风味物质显著增加,特别是鸡汤的特征性风味化合物()-2,4-癸二烯醛和1-辛烯-3-酮分别增加了4.5倍和10.4倍。检验排序法表明添加磷脂鸡油的风味最浓郁,常规炼制鸡油次之,而去除了磷脂鸡油的风味最弱。由此可见鸡油磷脂是鸡油挥发性风味化合物的重要前体物质,它对鸡油的风味具有重要贡献作用,添加磷脂可以显著提高鸡油的风味。研究结果为浓香鸡油的开发提供理论依据和参考加工工艺。

[1] 王天泽,谭佳,杜文斌,等. 北京油鸡鸡汤滋味物质分析[J]. 食品科学,2020,41(8):159-164. Wang Tianze, Tan Jia, Du Wenbin, et al. Analysis of taste compounds in stewed chicken broth of Beijing Youji[J].Food Science, 2020, 41(8): 159-164. (in Chinese with English abstract)

[2] 殷比. 纯鸡粉生产关键技术研究[D]. 广州:华南理工大学,2011.

Yin Bi. Research on the Key Technologies of Chicken Powder[D]. Guangzhou: South China University of Technology, 2011. (in Chinese with English abstract)

[3] 宋诗清,袁霖,张晓鸣,等. 鸡脂的酶解对鸡肉风味前体物形成的影响[J]. 食品科学,2013,34(11):168-172.

Song Shiqing, Yuan Lin, Zhang Xiaoming, et al. Effect of enzymatic hydrolysis of chicken fat on the formation of characteristic flavor precursors[J]. Food Science, 2013, 34(11): 168-172. (in Chinese with English abstract)

[4] Fan M, Xiao Q, Xie J, et al. Aroma compounds in chicken broths of Beijing Youji and commercial broilers[J]. Journal of Agricultural and Food Chemistry, 2018, 66(39): 10242-10251.

[5] Feng Yunzi, Cai Yu, Fu Xiong, et al. Comparison of aroma-active compounds in broiler broth and native chicken broth by Aroma Extract Dilution Analysis (AEDA), Odor Activity Value (OAV) and omission experiment[J]. Food Chemistry, 2018, 265: 274-280.

[6] Jayasena Dinesh D, Ahn Dong Uk, Nam Ki Chang, et al. Flavour chemistry of chicken meat: A review[J]. Asian-Australasian Journal of Animal Sciences, 2013, 26(5): 732-742.

[7] Farmer Linda J, Mottram Donald S. Interaction of lipid in the maillard reaction between cysteine and ribose: The effect of a triglyceride and three phospholipids on the volatile products[J]. Journal of the Science of Food and Agriculture, 1990, 53(4): 505-525.

[8] Whitfield Frank B, Mottram Donald S. Volatiles from interactions of Maillard reactions and lipids[J]. Critical Reviews in Food Science and Nutrition, 2009, 31(1/2): 1-58.

[9] Aliani M, Farmer L J. Precursors of chicken flavor. II. Identification of key flavor precursors using sensory methods[J]. Journal of Agricultural and Food Chemistry, 2005, 53(16): 6455-6462.

[10] Lin Jianming, Blank Imre. Odorants generated by thermally induced degradation of phospholipids[J]. Journal of Agricultural and Food Chemistry, 2003, 51(15): 4364-4369.

[11] Chen De Wei, Balagiannis Dimitrios P, Parker Jane K. Egg yolk phospholipids: A functional food material to generate deep-fat frying odorants[J]. Journal of the Science of Food and Agriculture, 2019, 99(14): 6638-6643.

[12] Chen D W, Balagiannis D P, Parker J K. Use of egg yolk phospholipids to generate chicken meat odorants[J]. Food Chemistry, 2019, 286: 71-77.

[13] Guo Dong, Wan Peng, Liu Jie, et al. Use of egg yolk phospholipids to boost the generation of the key odorants as well as maintain a lower level of acrylamide for vacuum fried French fries[J]. Food Control, 2021, 121: 107592.

[14] Gładkowski Witold, Chojnacka Anna, Kiełbowicz Grzegorz, et al. Isolation of pure phospholipid fraction from egg yolk[J]. Journal of the American Oil Chemists’ Society, 2012, 89(1): 179-182.

[15] 张毅. 钼蓝分光光度法测定食品中的磷[D]. 哈尔滨:东北农业大学,2018.

Zhang Yi. A Study of Molybdenum Blue Spectrophotometric Determination of Phosphorus in Food[D]. Harbin: Northeast Agricultural University, 2018. (in Chinese with English abstract)

[16] 王维亚. 乌骨鸡磷脂的提取、成分分析及活性研究[D]. 南昌:南昌大学,2007.

Wang Weiya. Study on Extraction, Components Analysis and Bioactivity of Phospholipids from Black-bone Silky Fowl[D]. Nanchang: Nanchang University, 2007. (in Chinese with English abstract)

[17] 朱玲娇. 禽蛋磷脂组成及其结构特点分析研究[D]. 武汉:华中农业大学,2013.

Zhu Lingjiao. Studies on the Composition and Characteristics of Egg Yolk Phospholipids and Fatty Acid Composition[D]. Wuhan: Huazhong Agricultural University, 2013. (in Chinese with English abstract)

[18] 刘坤. 湿基南极磷虾中磷虾油的超临界CO2萃取工艺研究[D]. 青岛:中国海洋大学,2014.

Liu Kun. Research on Supercritical CO2Extraction Process of Krill Oil from Wet Antarctic krill ()[D]. Qingdao: Ocean University of China, 2014. (in Chinese with English abstract)

[19] Frankel E N. Volatile lipid oxidation products[J]. Progress in Lipid Research, 1983, 22(1): 1-33.

[20] Mottram D S, Edwards R A. The role of triglycerides and phospholipids in the aroma of cooked beef[J]. Journal of the Science of Food and Agriculture, 1983, 34(5): 517-522.

[21] Niu Yunwei, Wu Minling, Xiao Zuobing, et al. Effect of fatty acids profile with thermal oxidation of chicken fat on characteristic aroma of chicken flavors assessed by gas chromatography-mass spectrometry and descriptive sensory analysis[J]. Food Science and Technology Research, 2016, 22(2): 245-254.

[22] Ma Naiting, Chyau Charngcherng, Pan Bonniesun. Fatty acid profile and aroma compounds of lipoxygenase-modified chicken oil[J]. Journal of the American Oil Chemists’ Society, 2004, 81(10): 921-926.

[23] He Rongqiang, Wan Peng, Liu Jie, et al. Characterisation of aroma-active compounds in Guilin Huaqiao white sufu and their influence on umami aftertaste and palatability of umami solution[J]. Food Chemistry, 2020, 321: 126739.

[24] Katz Michael Alexander, Dugan L R S, Dawson L E. Fatty acids in neutral lipids and phospholipids from chicken tissues[J]. Journal of Food Science, 1966, 31(5): 18-21.

[25] Reis Ana, Spickett Corinne M. Chemistry of phospholipid oxidation[J]. Biochimica et Biophysica Acta (BBA)- Biomembranes, 2012, 1818(10): 2374-2387.

[26] Ho C T, Chen Q. Lipids in food flavors: An overview[J]. ACS Symposium Series, 1994, 558(1): 2-14.

[27] Choe Eunok, Min David B. Mechanisms and factors for edible oil oxidation[J]. Comprehensive Reviews in Food Science and Food Safety, 2006, 5(4): 169-186.

[28] Lai Shumei, Gray J Ian, Booren Alden M, et al. Assessment of off-flavor development in restructured chicken nuggets using hexanal and TBARS measurements and sensory evaluation[J]. Journal of the Science of Food and Agriculture, 1995, 67(4): 447-452.

[29] Elmore J Stephen, Mottram Donald S, Enser Michael, et al. Effect of the polyunsaturated fatty acid composition of beef muscle on the profile of aroma volatiles[J]. Journal of Agricultural and Food Chemistry, 1999, 47(4): 1619-1625.

[30] Mottram Donald S, Madruga Marta S. Important sulfur- containing aroma volatiles in meat[J]. ACS Symposium Series, 1994, 42(3): 180-187.

[31] 蔡路昀,年琳玉,曹爱玲,等. 不同干燥方式对中国对虾风味组分的影响[J]. 农业工程学报,2017,33(11):291-298.

Cai Luyun, Nian Linyu, Cao Ailing, et al. Effect of different drying methods on flavor components of Chinese shrimp (Fenneropnaeus Chinensis)[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(11): 291-298. (in Chinese with English abstract)

Effect of phospholipids on the formation of volatile flavor compounds in chicken fat

Chen Dewei, Yang Xiaoying, Liu Siyi, Ye Tingting, Guo Dong, Wang Qinzhi

(,,530004,)

Phospholipids are one of the most important flavor precursors of the meat.Chicken fat is normally derived from fatty and chicken soup aroma. The oxidation of fatty acids, especially the degradation of unsaturated fatty acids, is critical to the formation of chicken characteristics. Phospholipids in the deposit fat of chicken can play a significant role in the characteristic aroma of chicken fat. In this study, phospholipids in chicken fat tissue were extracted by ethanol, and then precipitation of phospholipids using acetone. A Phosphomolybdate Blue Spectrophotometry was selected to determine the contents of phospholipids in chicken fat tissue, de-phospholipids treated chicken fat tissue, and extracted phospholipids. The relative contents of volatile compounds were analyzed by headspace solid-phase microextraction/gas chromatography-mass spectrometry (HS-SPME-GC-MS), and aroma intensities of chicken fat samples were characterized by sensory evaluation of sequencing test. The results showed that the contents of phospholipids in chicken fat tissue, de-phospholipids treated chicken fat tissue, and extracted phospholipids were 56.69±3.89, 28.10±1.18 and 537.19±20.95 mg/g, respectively. Ethanol can be expected to serve as an effective solution in the extracting of phospholipids, where most of the phospholipids were removed from chicken fat tissue. Volatile compounds were identified by GC-MS analysis in de-phospholipids chicken fat, chicken fat, chicken fat with added phospholipids, and phospholipids sample, respectively. The removal of phospholipids showed a markedly different volatile profile, and the quantities of aliphatic aldehydes were considerably reduced, where only traces of unsaturated aldehyde of ()-2-heptenal,()-2-pentenalwere found. The chicken fat with added phospholipids sample had a significant increase in most of the lipid-derived compounds, compared with the de-phospholipids chicken fat sample, especially, ()-2,4-decadienal, ()-2-nonenal, ()-2-heptenal, 1-octen-3-ol and 1-octen-3-one, where the characteristic odorants of chicken meat increased 4.5, 7.8, 9.4, 5.0 and 10.4 times, respectively. When linoleate residues assembled in a phospholipid, the C9 position can be the most favored position for the formation of hydroperoxides during the radical initiation step of autoxidation.Since the C9 hydroperoxide was the precursor for ()-2, 4-decadienal, the chicken fat with added phospholipids sample was more likely to form ()-2,4-decadienal, indicating a characteristic odor impact compound in chicken. Meanwhile, hexanal was usually used as the index of warmed-over flavor, and the relative contents of hexanal had no significant difference between the chicken fat with added phospholipids sample and chicken fat sample. Besides, methyl ketones and saturated alcohols, which had higher odor thresholds to be produced by oxidative and thermal degradation of saturated fatty acids, also tended to increase in chicken fat with added phospholipids sample. The main reason was that phospholipids were rich in unsaturated fatty acids, thereby to be more prone to oxidative degradation under heating conditions. Moreover, once the lipid oxidation process had been initiated by the more reactive and more unsaturated fatty acids, this reaction can promote the oxidation of the less reactive fatty acids. Sensory analysis of sequencing test showed that the addition of phospholipids can significantly increase the aroma intensity of chicken fat, whereas, the de-phospholipids chicken fat sample had the weakest intensity. This finding can provide a sound evidence that the phospholipids extracted from chicken deposit fat tissue can be used to significantly increase the aroma intensity of chicken fat. It is highly expected for a potential use for the research and development of chicken fat with strong aroma.

lipid; phospholipids; agricultural products; volatile flavor compounds; Headspace Solid-Phase Microextraction (HS-SPME); Gas Chromatography-Mass Spectrometry (GC-MS); sensory evaluation

陈德慰,杨晓莹,刘思佚,等. 鸡油组织中的磷脂对鸡油挥发性风味化合物形成的影响[J]. 农业工程学报,2020,36(23):279-284.doi:10.11975/j.issn.1002-6819.2020.23.032 http://www.tcsae.org

Chen Dewei, Yang Xiaoying, Liu Siyi, et al. Effect of phospholipids on the formation of volatile flavor compounds in chicken fat[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(23): 279-284. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.23.032 http://www.tcsae.org

2020-07-22

2020-10-21

国家自然科学基金(31960513,31660448)

陈德慰,教授,博士生导师,主要从事食品风味技术研究。Email:chendw@gxu.edu.cn

10.11975/j.issn.1002-6819.2020.23.032

TS22

A

1002-6819(2020)-23-0279-06