Effects of Different Content of Nanomaterials on the Combustion Performance of RDX-CMDB Propellants

2019-12-30YUANZhifengYANGYanjingZHAOFengqiZHANGJiaoqiangSONGXiuduoGAOHongxuXUSiyu

YUAN Zhi-feng,YANG Yan-jing, ZHAO Feng-qi, ZHANG Jiao-qiang,SONG Xiu-duo, GAO Hong-xu, XU Si-yu

(1.Science and Technology on Combustion and Explosion Laboratory, Xi′an Modern Chemistry Research Institute, Xi′an 710065, China; 2.Science School of Northwestern Polytechnical University, Xi′an 710072, China)

Abstract:The influence of nano-copper (n-Cu), nano-nickel (n-Ni) and carbon nanotubes on the combustion performance of RDX-CMDB propellants was investigated. The mechanism of n-Ni on the combustion performance was also discussed by analysis of flame morphology and thermal decomposition performance. The results reveal that n-Ni with mass ratio of 0.6% would reduce the pressure exponent of RDX-CMDB propellant from 0.29 to 0.11 in the pressure range of 6-16MPa. By contrast, the effect was not obvious for the 0.2% n-Cu, which even causes the decrease of burning rate at 2MPa and 8-16MPa. For the 0.8% CNTs with conventional Pb-Cu-C as catalyst, the burning rate of RDX-CMDB propellant increases from 17.12 to 22.12mm/s at 10MPa. Furthermore, The thermal decomposition and flame morphology imply that n-Ni improves the decomposition heat, enhances the burning surface temperature and thermal feedback, which is contributed to the thermal decomposition rate.

Keywords:physical chemistry; nanomaterials; propellant; combustion performance; burning rate; mesa effect

Introduction

The low characteristic signal composited double-base propellants are widely used in many tactics missiles such as antitank missiles, gun missiles, aerial defense missiles and secondary planet engines for controlling direction and posture. Their combustion properties can be adjusted by the catalyst systems. But now the development of the catalyst system for low character signal composited double-base propellants is up against bottle-neck. It is hard to further enhance the burning rate or decrease the pressure exponent on the base of Pb-Cu-C three composition catalyst systems.

It was reported that some nanometer metal powders could enhance the burning rate and reduce the pressure exponent of propellants[1]. Moreover, there are also many papers describing the effects of nanometer materials on the thermal decomposition character of energetic materials such as AP and RDX or on the combustion properties of propellants[2-13]. But there are limited number of reports regarding the study on the effects the content of nanometer materials on the combustion properties of the composite double-base (CMDB) propellants with less smoke systematically.

In this study, three nanometer materials have been selected as examples and the effects of their contents on the combustion properties on RDX-CMDB propellant were investigated. This work may provide some technological auspice for the applications of nanometer materials in CMDB propellants.

1 Experiment

1.1 Materials

Nitrocellulose (NC, industrial pure, with nitrogen content of 12.0%, Sichuan north nitrocellulose limited company); nitroglycerine (NG, industrial pure, Xi ′an modern chemistry research institute), cyclotrimethylenetrinitramine (RDX, industrial pure, Liaoning qingyang chemistry engineering limited company); nanometer copper (n-Cu,d=50nm, 99.9%, Aladdin); nanometer nickel(n-Ni,d=20nm, 99.9%, Aladdin); carbon nanotubes(CNTs, diameter of 7-15nm, length of 5-15μm, 95.0%, Aladdin);micron nickel (μm-Ni,d=1μm, 99.9%, Aladdin); micron carbon (CB,d=2μm, 99.9%, Aladdin).

1.2 Preparation

On the base of previous work, the effects of n-Cu, n-Ni, CNTs on the combustion properties of RDX-CMDB propellant were notable, so we studied the effects of the content of the above three materials on RDX-CMDB propellant.

The RDX-CMDB propellant formulation contained NC+NG 61%, RDX 26%, catalyst 4.8%, others 8.2% and its theoretical calculating value was as follow: impulse was 2445.1 Nos/kg; combustion temperature was 2917.5K; average molecular weight of burning gas was 24.3. The nanometer materials, μm-Ni and CB were extra added. According to the dosage of catalyzer and experience, the four different mass fraction of 0.2%, 0.4%, 0.6% and 0.8% were utilized.

The propellant samples were prepared by solventless extrusion technology which including absorbing, dehydrating, extrusion and cutting.

1.3 Measurement

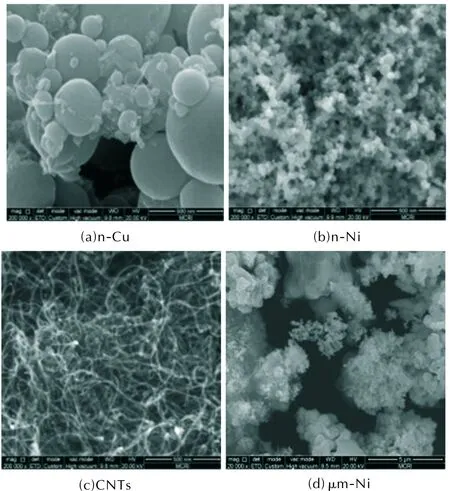

The SEM images of three nanometer materials tested by Scanning Electronic Microscopy were shown in Fig.1. The n-Cu possesses oblate-shape and the diameters of some partices were large. The particles of n-Ni were even and globe-shape. The CNTs appeared thin tube.

The burning rates were tested following the method of GJB770B-2005 706.1. The samples for test were Φ5mm×160mm strand which covered with polyvinyl alcohol ,the burning rate was tested in the nitrogen, then the pressure exponents were calculated according to the relation ofu=apn, whereuwas the burning rate,pwas the pressure andawas a constant.

Fig.1 SEM images of several materials

2 Results and Discussion

2.1 Effect of the content of n-Cu

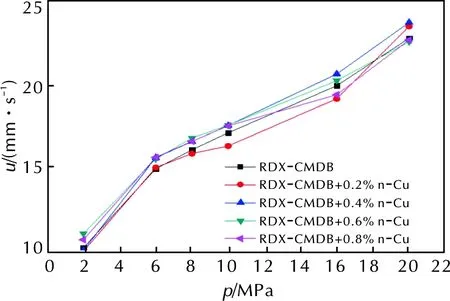

Effects of the content of n-Cu on the combustion properties of RDX-CMDB propellant were investigated, andu—pcurves with different contents of n-Cu were shown in Fig.2.

Fig.2 The u—p curves of RDX-CMDB propellant with different n-Cu contents

As shown in Fig.2, the RDX-CMDB propellant appeared overspeed burning between 2-6MPa, and plateau burning between 6-10MPa was also observed. The burning rates of propellant at 10-20MPa increased greatly. Adding 0.2% n-Cu into the RDX-CMDB propellant made the burning rates at 2MPa and 8-16MPa decreased, but the burning rates at 6MPa and 20MPa were enhanced within 1mm/s. The pressure exponent between 6-10MPa decreased from 0.26 to 0.16.

The burning rate of RDX-CMDB propellant increased firstly and then decreased with increasing the n-Cu mass fraction from 0.2% to 0.8%. The burning rate at 2MPa and 8-10MPa reached the highest when the content of n-Cu was 0.6%, the burning rate at 6MPa reached the highest when the mass fraction of n-Cu was 0.8%, the burning rate at 16-20MPa reached the highest when the content of n-Cu was 0.4%. The pressure exponent between 6-16MPa decreased with increasing the n-Cu content. Especially, the minimum of pressure exponent between 6-16 MPa was determined to be 0.22.

2.2 Effect of the content of n-Ni

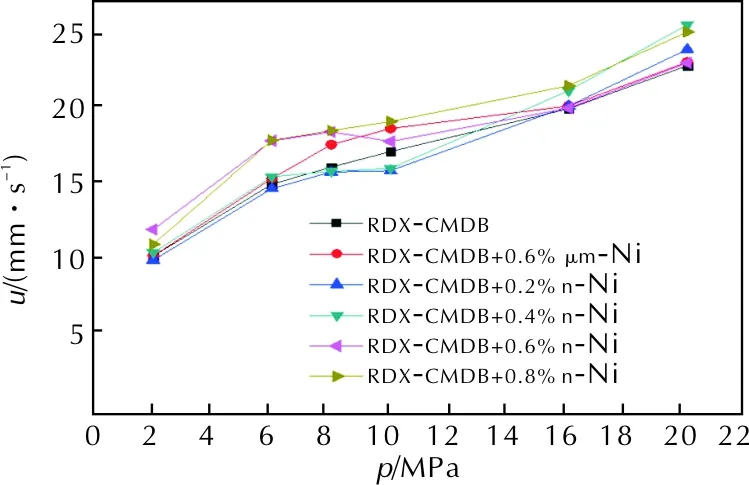

The effects of the content of n-Ni on the combustion properties of RDX-CMDB propellant were investigated ,and theu—pcurves were shown in Fig.3.

Fig.3 The u—p curves of RDX-CMDB propellant with different n-Ni contents

As shown in Fig.3, adding 0.2% n-Ni could reduce the burning rates of RDX-CMDB propellant at 2-10MPa , the burning rate at 10MPa was reduced by 1.26mm/s. The burning rates at 16-20MPa increased, but the burning rates at 16 and 20MPa were increased by 0.18mm/s and 1.07mm/s, respectively. The pressure exponent at 6-10MPa reduced from 0.26 to 0.14.

With increasing the content of n-Ni from 0.2% to 0.8%, the burning rate of propellant between 6-16MPa increased, and a maximum increase was achieved at 10MPa. The burning rate of propellant at 2MPa and 20MPa increased firstly and then reduced, and the burning rate reached the highest when the mass fraction of n-Ni was 0.6%. The pressure exponent of propellant between 6-10MPa was reduced firstly and then increased when the mass fraction of n-Ni increased from 0.2% to 0.8%, and the minimum was -0.02 when the mass fraction of n-Ni was 0.6%. The pressure exponent at 10-16MPa of propellant increased first from 0.51 to 0.59 and then reduced to 0.25, when the mass fraction of n-Ni was 0.6% or 0.8%.In general, the pressure exponent of RDX-CMDB propellant reduced to the minimum when the content of n-Ni was 0.6%, and the pressure exponent between 6-16MPa was 0.12 when the mass fraction of n-Ni was 0.6%.

The burning rate between 2-8MPa of RDX-CMDB propellant containing 0.6% n-Ni was higher than propellant with 0.6%μm-Ni, and lower between 10-20MPa, higher by 2.49mm/s at 6MPa, lower by 0.85mm/s at 10MPa. The pressure exponent of RDX-CMDB propellant of 6-16MPa with 0.6% n-Ni was reduced from 0.62 of the one with 0.6%μm-Ni to 0.11.

It could be concluded that n-Ni had better effect on enhancing the burning rate at low and middle pressure zone of RDX-CMDB propellant than μm-Ni. And n-Ni could reduce the pressure exponent between 6-16MPa more effectively than μm-Ni too.

2.3 Effect of the content of CNTs

The effects of the content of CNTs on the combustion properties of RDX-CMDB propellant were investigated,and theu—pcurves were shown in Fig.4.

Fig.4 The u—p curves of RDX-CMDB propellant with different CNTs contents

As shown in Fig.4, adding CNTs could enhance the burning rate of RDX-CMDB propellant between 2-20MPa, and the burning rate at 20MPa changed from 22.78mm/s to 26.25mm/s. Adding 0.2% CNTs enhanced the burning rate between 2-16MPa but reduced the pressure exponent at 16-20MPa.

With increasing in content of CNTs from 0.2% to 0.8%, the burning rate of the propellant at 2MPa changed little, and the burning rate at 6-20MPa increased slowly first and then quickly. The burning rate at 6-20MPa reached the lowest when the mass fraction of CNTs was 0.4% and reached the highest when the content of CNTs was 0.8%. The burning rate of RDX-CMDB propellant with 0.8% CNTs at 10MPa was enhanced from 17.12mm/s to 22.12mm/s. The burning rate at 20MPa increased with increasing the CNTs content from 0.2% to 0.8% and the maximum rate was reached when the mass fraction of CNTs was 0.8%, and the burning rate was 29.24mm/s, higher than 22.78mm/s for propellant without CNTs. The pressure exponent at 2-20MPa had increasing tendency with increasing the content of CNTs from 0.2% to 0.8%.

Adding 0.2% CNTs made the burning rate between 2—20MPa RDX-CMDB propellant higher than that of adding 0.2% CB. At 10MPa, the difference was 3.43mm/s. Adding 0.2% CB made the burning rate reduce instead of increase. Based on the comprehensive pre-research work, it could be concluded that when the content of CB reached a certain value, the burning rate of propellant reached an extreme value. If adding more CB, the burning rate of propellant decreased, but at this time if the addition was CNTs, the burning rate of propellant would have a lot of room for improvement.

2.4 The effect mechanism of n-Ni

In the three nanometer materials, the effect of n-Cu is the least. And from pre-research the reason of the enhance of burning rate could be attributed to the promotion of heat conduction and heat feedback of the solid phase by CNTs[14].So we mainly study the effect of n-Ni on the combustion properties of RDX-CMDB propellant. The formulas YZF-1 (RDX-CMDB propellant without nano-metal powder) and YZF-3 (RDX-CMDB propellant containing 0.6% mass fraction nm-Ni) were collected. Some properties of YZF-1 and YZF-3 at 2MPa and 4MPa were tested, the flame photo were shown in figure 5, the combustion waves were shown in figure 6, the flame surface analysis of the elements were shown in table 1, and thermal decomposition curves and main thermal decomposition parameter were shown in figure 7 and table 2.

Fig.5 Flame photographs of RDX-CMDB propellant included and not included n-Ni

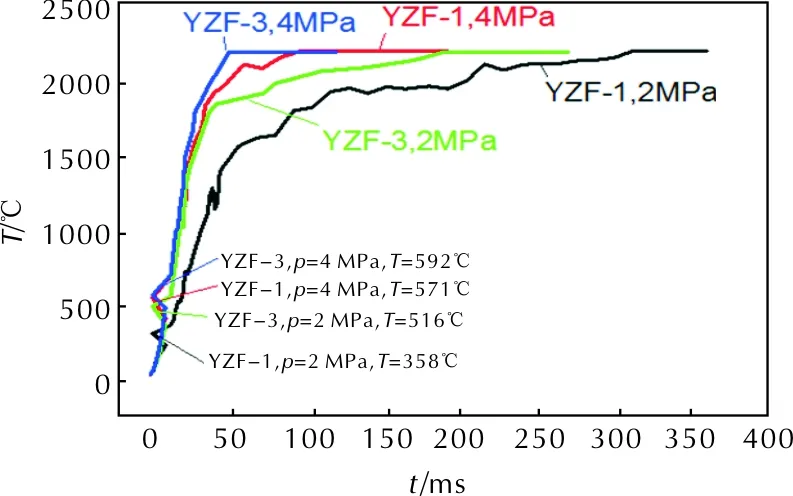

Fig.6 The effect of n-Ni on combustion waves of RDX-CMDB propellant

Fig.7 The DSC curves and the exothermic quantity of YZF-1 and YZF-3

The flameout surface analysis of the elements were shown in table 1, wherewnwas the molecular percentage.

It could be seen from figure 5 that, adding n-Ni made flame photos of RDX-CMDB propellant at 2MPa appear a clear white bright line, so it could be considered that some of the components of the propellant burned more intensively. Comparison the flame burning diagram between 2MPa and 4MPa suggested that adding n-Ni made the RDX-CMDB propellant flamed brighter, part of original yellow flame changed to white flame.

It could be seen in figure 6 that, the burning surface temperature of RDX-CMDB propellant at 2MPa and 4MPa had been enhanced because of adding n-Ni. The difference was that n-Ni has no significant effect on the flame temperature of the RDX-CMDB propellant, but the time from the ignition to burning to flame temperature had been significantly reduced.

Table 1 The flame surface analysis of the elements of formulations of YZF-1 and YZF-3

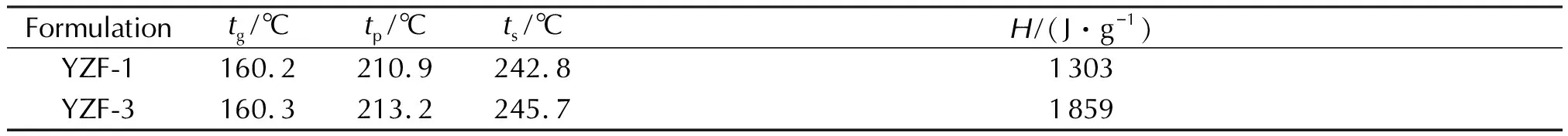

Table 2 The major thermal decomposition performance parameter

Notes:tgis decomposition temperature;tpis peak temperature;tsis shoulder peak temperature;His decomposition heat.

As could be seen from table 1, adding n-Ni increased content of the carbon and nickel on the RDX-CMDB propellant flameout surface significantly. The nickel content on the quenched surface exceeded its proportion in formulation greatly, and it was clear that the nickel element was enriched on the propellant surface and participated in the catalytic reaction. Carbon elements had a greater impact on the combustion properties of the propellant, which could form a carbon skeleton on the combustion surface of the propellant. The carbon skeleton could act as a catalyst active component enriched bed, which prevents agglomeration of metal. The case could catalyze the combustion of the propellant better. When carbon skeleton was well built, carbon skeleton could make the gas zone thermal conductivity increased by about 19 times[15]. Studies had shown that the carbon produced by the combustion of the propellant plays a critical role in the combustion of propellants[16-17]. Therefore, it could be considered that n-Ni adsorbed more carbon to form a carbon skeleton and participated in the catalytic combustion reaction.

It could be concluded from figure 7 and table 2 that n-Ni caused the main and shoulder decomposition peak of the RDX-CMDB propellant to be dissipated. The main peak shifted from 210.9℃ to 213.2℃, the shoulder shifted from 242.8℃ to 245.7℃, indicating the enhanced stability of the propellant, the decomposition temperature changed little. n-Ni increased the decomposition heat of RDX-CMDB propellant from 1303J/g to 1859 J/g by 42.7%.

It could be concluded that n-Ni was involved in the catalytic combustion reaction, n-Ni improved the decomposition heat of the propellant, enhanced the burning surface temperature of the propellant, enhanced the thermal feedback of the propellant burning surface, contributed to increase the propellant thermal decomposition rate, so n-Ni increased the burning rate of in low pressure zone of RDX-CMDB propellant. About the mechanism how the content of the n-Ni affected the properties, the content decided the concentration of n-Ni in the combustion reactive center, when the content exceed a certain extent the n-Ni may agglomeration, so the catalytic effect would decline.

3 Conclusions

(1)Adding 0.2% n-Cu into the RDX-CMDB propellant made the burning rates at 2MPa and 8-16MPa decreased, while the burning rates at 6MPa and 20MPa were enhanced within 1mm/s. The pressure exponent between 6-10MPa decreased from 0.26 to 0.16.

(2) 0.6% n-Ni Made the pressure exponent between 6-10MPa of RDX-CMDB propellant reduced from 0.26 to -0.02.

(3) 0.8% CNTs Enhanced the burning rate in 10MPa of The RDX-CMDB propellant which had already included of Pb-Cu-C catalyst from 17.12mm/s to 22.12mm/s.

(4) n-Ni Made the flame of RDX-CMDB propellant brighter, enhanced the surface temperature of the propellant, significantly reduced the time from the ignition to burning to flame temperature. n-Ni Increased the decomposition heat of RDX-CMDB propellant from 1303J/g to 1859J/g by 42.7%. So n-Ni enhanced the thermal feedback to the burning surface of propellant. Maybe this was the reason n-Ni improved the burning rate of RDX-CMDB propellant.