数字化 智能化

2019-12-04

环保、节能、数字化监控与智能化是染整机械的发展重点;棉型机织物连续式前处理和染色设备(包括单元机)大多已经发展成熟,生产流程配置,在未来一段时间内,变化不会很大,市场基本饱和;短流程设备(如湿短蒸设备)受工艺制约,产品推广有一定难度;化纤长丝机织物连续处理工艺的研究正在进行,如果工艺研究成功,连续式设备可能会取代部分间歇设备,用于化纤长丝机织物大批量生产。

Digitization, Intelligence

As a connecting process between the preceding and the following, dyeing and printing is to improve the appearance and performance of textiles, and to give special functions to textiles. Adding value to textiles is the main source of materials for the fashion industry.

Environmental protection, energy conservation, digital monitoring and intelligence are the development focus of dyeing and finishing machinery; continuous pretreatment and dyeing equipment (including unit machines) of cotton woven fabric have mostly matured and the production process is configured. In the future, there is not much change; the market is basically saturated; short process equipment (such as shortened wet-steaming equipment) is subject to process constraints, so product promotion has certain difficulty; research on continuous processing technology of chemical fiber filament woven fabric is underway and if the process research is successful, continuous equipment may replace part of the batch equipment for mass production of chemical fiber filament woven fabrics.

恒天立信:主推智能制造染整方案

Smart dyeing & finishing CHTC FONGS innovations at SHANGHAITEX 2019

本届展会上,恒天立信集团将在染整馆W1馆A10号展台,向全球客户展示集团最新的染整设备及智能制造染整方案;在纱线馆E1馆A60号展台,展示纱线处理技术。双展台总面积达520平米。

此次随行参与的集团品牌涵盖:立信染整、特恩、高乐、立信门富士、德国门富士、立信水务和纱力拉。展示的内容包括:立信染整FONGS TECWIN高温染色机和ALC自动液态助剂计量与分配系统、高乐GOLLER新型双带液机构冷轧染机、立信门富士MONFONGS涂层定型生产线和烘干机以及德国门富士CYD連续式色织染色系统及最前沿的Qualitex全触摸屏控制系统。为了加强观众的体验,展台还加入了先进的虚拟实境AR技术的元素,为全球客户更好的展示涵盖前处理、染色及后整理,完整染整处理的智造方案。

近年来,智能智造的春风吹遍神州大地,染整行业的智能变革也是如火如荼的进行!恒天立信集团研发团队,深耕染整机械研发与发展多年,在染厂智能化的范畴,恒天立信也一直前行。目前,集团在浙江省绍兴市进行基础建设,该场地占地约76,000平方米,以此作为恒天立信智能印染机械的生产基地。另外,中山项目第二期建设亦如期完成,在中山生产基地,集团新建一个先进技术中心(ATC/STC),以满足客户试验需求。该中心已设立一个微型智能染厂,便于客户直观细致了解智能化生产全过程。

恒天立信集团将以智能制造、全面创新的舞台迎接全球到访者,向客户集中展示集团最新研发成果和设计制造理念。我们欢迎全球客户莅临观摩指导, 与我们共同探讨恒天立信所提供的绿色环保、智能化的一站式可持续染整解决方案!

CHTC Fongs has been committed to the development and manufacturing of dyeing and finishing equipment for more than 50 years. In the past decades, CHTC Fongs devoted to the development of energy-saving and emission reduction machines and now it becomes the basic conditions for dyeing factories. Today, we live in a digital era, though in the traditional textile industry, CHTC Fongs has been with the times. Together with its wellknown brands: Fongs, Monforts Fongs, Xorella, Then, Goller, FWT and Monforts, CHTC Fongs dedicated in the development of Smart Dyeing & Finishing and join with the customers to build the intelligent dyeing factory.

The CHTC FONGS Group is proud to present the “one-stop”sustainable solution in dyeing and finishing range of “pre-treatment, dyeing, post-treatment and waste water treatment” at Shanghaitex 2019 in W1, A10 and yarn conditioning and heat setting in E1, A60, Shanghai New International Expo Center, Shanghai, China from Nov. 25th to Nov. 28th. CHTC FONGS will exhibit a full line of the most advanced and innovative products and technology including our new product- FONGS TECWIN High Temperature Dyeing Machine, FONGS ALC Automatic Liquid Chemical Weighing and Dispensing System, GOLLER DYEPADDER ECONOMICA Nip-in-Trough, MONFORTS QUALITEX Full Touch Panel Control System, MONFORTS NEW CYD Continuous Yarn Dyeing System, MONFORTS FONGS Innovative Technology Center and MONFONGS STRAHM HiPer Shrink Astra Shrinkage& Relaxation Dryer. In addition, CHTC FONGS will also demonstrate the innovative smart dyeing and finishing at the booth. We are looking forward to your visits.

立信染整 FONGS

TECWIN高溫染色机

立信染整新研发的高温染色机TECWIN,其设计理念是优化TEC系列高温染色机的各项性能,扩大其适用性。设计中已保留一些原有的优良配置,增加了新设计改进,更切合市场需求。该设备具备以下各项专利设计:

可向客户提供两个不同配置的前雾化喷嘴:在标准配置里,织物在提升入主喷嘴前,增加一次液体与织物接触,可避免织物产生折痕。在任选配置里,风喷嘴搭配前雾化喷嘴,可助解决某些布种染色问题。

自动可调节间隙喷嘴,由牙箱马达带动,改变喷嘴流量, 无需更换喷嘴, 操作更便捷。

特别设计不锈钢底储布槽疏水筛, 提供更佳的高效疏水效果。

处理洗水溢流效果更好:在低水位溢流阶段,可保持主泵于低液位运行,保持水布分离,防止化纤在溢流洗水时,因水位过高造成织物浮乱,影响行布表现。在高水位溢流:保留传统的溢流洗水设计, 有效地收集溢流液面上的漂浮泡沫或杂质。

除此之外,水布分离的设计,配合可变载调节板及布槽的优化,使织物运行顺畅, 堆栈整齐, 有效降低浴比。

High Temperature Dyeing Machine

FONGS TECWIN is designed to satisfy the ever-changing market demands. The reliability and versatility of the machine are improved.

TECWIN is equipped with several patented designs:

Combined Air and Front Spray Nozzle

Standard Feature: Increase the degree of dye liquor interchange before passing through the main nozzle.

Optional Feature: Optional blower is equipped. High pressure aerodynamic flow in spray nozzle is provided to resolve the special fabrics that demand high quality.

Automatic Adjustable Nozzle

Adjustment of nozzle setting is automatically done by means of motor drive system, and hence manual changing of nozzle is not required.

Liquor Dispersion Storage Chamber

This is a uniquely design chamber for providing a better liquor dispersion effect.

Upper and Lower Overflow

Lower Overflow: Maintaining pump operation with low water level to prevent disturbance caused by rinsing at a high water level.

Upper Overflow: This is adopted for conventional overflow rinsing function.

Furthermore, the dye liquor separation is specially designed in TECWIN. With the use of the variable loading storage chamber, the dyeing operation can be performed more smoothly and fabric patterns can be more organized, which eventually leads to a lower liquor ratio.

ALC自动液态助剂计量与分配系统

立信染整ALC自动液态助剂计量与分配系统,以先进计算机系统,实现按企业资源计划系统ERP定出的配料程序,透过精密质量流量计和计量泵,把液态助剂由储存箱精确定量称量,并利用管道与阀门等配合,以最有效方式准确快速地把定量助剂配送到指定的染色机台上。配合每次输送完毕后的高效清洗功能,不但提高染厂运作效率,更免却人为错误保障染色质量。

FONGS ALC Automatic Liquid Chemical Weighing and Dispensing System

The ALC Automatic Liquid Chemical Weighing and Dispensing System realizes unmanned dispensing according to the instructions fed from the Enterprise Resource Planning (ERP) system using advanced computer control technology. By means of precision mass flow-meter and metering pump, the liquid chemicals are accurately and precisely delivered and weighed from storage tanks, and with the application of valves and pipe network connections, the chemicals are accurately and rapidly distributed to the designated dyeing machine in the most effective way. With the efficient cleaning function after each delivery, not only is the operation efficiency of the dyeing plant improved but also it avoids human errors. Thus, dyeing quality is guaranteed.

高樂 GOLLER

新型双带液机构冷轧染机

新型双带液机构高乐冷轧染机-ECONOMICA Nip-inTrough是一台专门为针织面料染色而设计的机器。ECONOMICA优势在于为针织面料提供均匀的染色效果而不会引起起皱和纬斜的问题。新设计的高效双带液机构在提高带液效率的同时,也实践了更低的行机张力。透过运用ECONOMICA的染色原理于实际生产上,染色以后的针织面料高水准、一致重现性和顺滑平整的布面效果得以保证。

ECONOMICA的弧变控制辊采用了跟油压辊相同的设计原理,通过配有对中装置的辊筒调节、双压系统、内起液压作用的辊筒和应用了气压的杆轴末端,使得弧变控制辊在不同压力的应用下,也可以达到布面左、中、右染色均匀的效果。在弧变控制辊上方的大直径导布辊可确保针织面料在低张力状态下输送及进行染色。双带液机构包含了低容积的工作液浸槽,内含轧车,能确保针织面料在低张力的输送条件下达到带液充份的效果。 另外,Thermplates可保温和保冷的设计,使染糟不管在进行高温或低温的工艺时,均能够保持在设定的温度。

精准配料系统(碱和染料)的应用加上弧变控制辊所提供的准确、一致性的带液和线性的均匀施压,使得新型双带液机构高乐冷轧染机-ECONOMICA Nip-in-Trough成为用作中、小批量针织面料染色的最佳平幅染色机的选择。

Nip-in-Trough with Double Impregnation Mechanism

The New GOLLER DYEPADDER ECONOMICA Nip-inTrough with Double Impregnation Mechanism provides even dyeing for knitted fabric without crease mark and distortion incurred. The newly-designed double impregnation mechanism provides further improvement on the impregnation effectiveness in combination of a lower running tension. As the ECONOMICA guarantees reproducibility and handling in the highest standard, a smooth and clear fabric surface can be expected after dyeing.

The deflection-controlled rollers of ECONOMICA are working according to the principle of the swimming rollers, irrespective of the overall pressure of the padder- the deflection of the squeezing rollers is always consistent with the set values to ensure an even dyeing over the fabric width. On top of the deflectioncontrolled rollers, the large diameter guide rollers ensure a smooth knitted fabric transport with minimal tension incurred, which is beneficial to the dyeing process as a whole. The double impregnation mechanism consists of a trough with a padder inside and with the minimum level of working liquor required. This mechanism provides sufficient impregnation and low-tension running condition for knitted fabric during the dyeing process. Furthermore, Thermplates keep the temperature of the dyebath as per the set value throughout the dyeing process – no matter its cool or hot.

With the precise dosing of dyestuff-alkali mixed, the application of precise and homogeneous pick-up and the linear nip of the deflection-controlled rollers, the GOLLER DYEPADDER ECONOMICA Nip-in-Trough with Double Impregnation Mechanism will always be the most ideal open-width dyeing range for knitted fabrics dyeing in small to medium batches used.

立信门富士MONFORTS FONGS

烘干机介绍

Mongfongs Strahm烘干机是一款高效的松式平网烘干机,适用于开幅以及圆筒针织物。这款烘干机机械设计独特,具有烘干量高,低残余缩水率,柔软手感和低操作成本等优点。其显著设计特色也包括热能回用系统(EnRec 1&2),比标准的烘干机更节能。

该烘干机分为进布区、超喂区、震荡区、出布区等四个部分。进布区可选配置双轧车,可使织物获得均匀充分的带液率。

随后是超喂区,织物经过此区域,通过超喂量和横向拉伸使织物恢复原始宽度和长度,在低张力控制下进入烘箱的造波区。

烘干震荡区采用特有的喷嘴系统,热能可有效和快速的传递至织物内层核心。分别位于织物上方、下方的吹风和吸风嘴,可创造平行气流自然形成交替涡流,形成织物的高频震荡。因此烘干后织物残余收缩率低,可获得柔软手感,改善尺寸稳定性和提高产量。设计独特的箱体结构确保空气循环方向归一性,并可防止热能流失;整体空气管理式热回收系统,可在降低热能需求的同时,保持高效干燥效果。

烘箱內空气循环由风机马达带动,热风经由喷嘴系统吹至布料上,再回风至大尺寸过滤系统进行过滤,以确保空气经常保持在最洁净的状态。最后经过回风信道,使热空气在烘箱内循环利用。

能源节约和能源回收系统设计独特,新鲜冷风从最后一节烘箱尾部进入,混合烘箱气流并且相对于织物运行方向逆向运动,这种设计使得只有一半的鲜风需要加热至烘干温度,同时仅有不到一半的饱和热空气排走,其排气量只有普通系统的50%。因此,可减少能源消耗和降低成本。

在出布区有残余湿度检测,可对织物烘干效果进行实时监测。

MONFONGS STRAHM HiPer Shrink Astra Shrinkage & Relaxation Dryer

Mongfongs Strahm is a Shrinkage & Relaxation Dryer for open width and tubular knit fabrics. Its unique design focuses on the highest drying capacity, low residual shrinkage and a soft hand feel by mechanical action inside the chambers. The uncompromising design also features an incorporated energy recovery system (EnRec 1&2) that saves energy consumption, particularly, when it is compared with standard common dryers in the market.

The relaxation dryer mainly includes infeed section, overfeed area, tumbling zone, and delivery section. It can also have an option to add the double padder configuration in the infeed section in order to give a more even pick-up to the fabrics.

The width and the length of fabrics in the overfeed zone can be restored to its original state by the overfeeding and the stretching on the pin chain. Fabrics under low tension subsequently enter the wave maker zone of chambers.

Due to its unique nozzle system in the tumbling zone, heat energy can be effectively transferred to the core of the fabric. The setup of the blowing and suction of nozzle positions create a parallel airflow above and underneath the fabric. The physical effect of vortex shedding (alternating swirls) creates a high-frequency vibration of the fabric, increasing tumbling frequency and tumbling effect. In that tumbling effect, outcome fabrics can have low residual shrinkage, soft hand feeling, and massive production. The design can prevent from any false air circulation and thermodynamic short cuts. Integral air management with energy recovery system allows an efficient drying with the lowest energy demand consumption.

The air flow inside chambers is driven by the circulation fan. After the hot air passes along the fabric (not through), it is directed and to be filtered by a large-sized filter to make sure the air inside chambers stays clean before it is reused in the dryer.

The unique designed Energy saving and Recovery system is achieved by circulating the fresh air firstly in the last chamber and then travels against the fabric running direction. The design gives an advantage that less than half the amount of fresh air is needed to heat up to the drying temperature. That also means less than half heat and saturated air will be exhausted, which can reduce energy consumption and the operation cost.

The infrared radiation residual moisture detector can control the drying.

立信門富士MONFORTS FONGS

涂层定型生产线介绍

ITC(Innovative Technology Center)是立信门富士公司为拓展产品的应用创新而新建的研发中心,主要用于技术纺织品的工艺研发及设备改进,同时为客户提供参观和来样实验的场所。

整个场地主要由用于涂层实验区,展机区,办公区,储藏室和接待访客的会议室。目前研发机构内展机区有一条由Montex 6500定型机和Monforts Texcoat涂层机构成的后整理生产线,以及一台Monfongs Strahm烘干机。

这条后整理生产线主要用于交通用纺织品,安全防护用纺织品以及无纺布等产业用纺织品的后整理加工。进布区由布车和退卷两种方式,退卷后经过张力补偿器可以控制织物经向张力。

对中装置确保织物的最佳进布路线,Matex6000轧车匀轧辊压力灵活可调节以达到最佳浸轧效果,轧辊表面的材料与硬度有多种选择,迎合织物与工艺的需要。液槽有不同容量以配合不同的浸透路程,可选择具有加热和温控系统的双层槽壁,液槽内辊可加配驱动。

這是Monforts Texcoat多功能版本的涂层机,集刮刀涂层,磁辊涂层和圆网印花为一体,可适用浆料的粘度范围较大,应用于广泛的布种以及不同工艺要求,所有操作和显示通过触摸屏来实现数字化操控。

该涂层机可同时装配有2把不同形状的刮刀,分别适用于不同的厚度和渗透性的涂层。刮刀的垂直高度,水平距离和刀的角度都可以被精准的调控和实时显示,垂直和水平调控精度高达0.1mm。

磁辊涂层是一个相对较独特的涂层方式,有直接涂层,间接涂层和进料辊的上方的磁辊涂层三种方式。通过改变磁力大小,辊之间的接触程度以及辊的转向可调节上浆量,也可将其与刮刀涂层结合使用,提高效率节约成本。

圆网印花可选择磁力模式,可应用于各种花型的印花,双面作用的涂层和3D涂层。

上针操作台处配备有针板布铗组合链,用于机织物,针织物及无纺布。超喂辊可气动升降至不同位置以满足涂层或定型的上针需求。定型机的横向拉伸张力可高达8000N,且均匀稳定,适用于超厚重材料的功能整理。德国制的在线测克重装置可以实时检测织物左中右涂层的厚度以便及时调节涂层工艺参数。

织物进出口有防风屏障,加上独特设计的保温箱板使烘箱有完美的保温效果,专利设计的TwinAir双风道可独立调节上风、下风的气流。内有混合式狭缝风嘴,可选择方孔或狭缝送风,保证涂层表面不会产生风痕。Bypass旁通风闸可在停机时自动将热风排除以免过度加热布面。烘箱内每根控制织物横向宽度的调幅丝杆均可独立驱动,滤网在机器运行过程中也可拉出清洁。

出布区配有一组冷风机和冷水辊,保证有效冷却织物,可选配落布或打卷方式。

AFD(Air Filtration Device)热回收装置由静电过滤单元,热交换器单元和自动清洗水箱组成,不仅可以高效的分离、过滤和净化涂层定型时排除的废气混合物,还能将烘箱中排风的余热进行回收再利用,实现高效率低能耗。

Innovative Technology Center

Innovative Technology Center is a new research and development center for exploring our innovation of the textile product application, which aims at improving the performance of equipment which is used for finishing processing in technical textiles. Meanwhile, we provide the platform for machine demonstration and bulk trial of coating fabric samples for our customers.

In ITC, there are laboratory area, machine showing area, office area, storage room, and meeting room. Up to now, we have a coating line which is consisted of Montex 6500 stenter and Monforts Texcoat coating machine, and a Monfongs Strahm HiPer Shrink Astra dryer.

The coating line is mainly applied to textile finishing processes in technical textiles aspect such as mobile textiles, protective textiles and also non-woven fabrics. The infeed unit has options of either plaiter or batch unwinding. The fabric tension in the warpwise direction can be optimized by the two-loop float compensator in the cloth path.

The centering device can ensure the fabric always feeding in the center position. The even pressure roller of “Matex 6000”s padder is allowed to be adjusted for optimal padding effect. There are various texture and different hardness of the roller wrappings which are available for padding of different fabric processing demands. The different capacity of the liquid trough is designed to have different length of immersion path. A double-walled execution for indirect heating or cooling with temperature control system is also available. Besides, the immersion roller in the liquid trough can be driven actively by the motor.

The “Monforts texcoat” coating machine is for multi-functional coating purpose, which integrates knife coating, magnetic roller coating and rotary screen printing. The multi-functional coating could be adapted to a wide range of applications for different fabrics and finishing demands. The control panel allows ease of mastering the control of all operation for the machines.

Two different shapes of the knife could be set up on the machine, which is used for coatings with different thickness and coating paste penetration. The vertical distance, the horizontal distance from knife to coating roller and the angle of the knife can be adjusted precisely. The accuracy of the vertical and horizontal distance is up to 0.1mm tolerance.

Magnetic roller coating is a unique coating way with the means of direct magnetic roller coating, indirect magnetic roller coating and dosing roller over magnetic coating. The add on can be increased or decreased by regulating the magnet power, the contact level of coating roller and the coating roller rotating direction. Magnet coating can also be combined with knife coating to improve efficiency and save cost.

Rotary screen printing is available for magnet mode by equipping a dosing roller in a screen of printing. It can be applied to printing of various patterns and coating with a double side effect.

It is available to select pin or clip chain working with direct pinning device, which could be adapted to woven fabric, knitted fabric and non-woven fabrics. The overfeed roller can be pneumatically lifted up and lowered to several positions for different pinning ways. The tensile strength of stenter is 8000N, which can be used for thick and densely woven fabrics. The weight at the left, right and middle of the fabric could be monitored by our controlling system on online basis.

The air barriers at chambers inlet and the outlet opening and the unique designed chamber claddings of stenter give perfect thermal insulation of machine. The airflow of upper and lower nozzles can be regulated independently through the patented design “TwinAir” air circulation system. There are slot nozzles allowing air circulated inside the chambers without causing stripes or marks on the coating surface. Bypass flaps of chambers can avoid overheating marks on fabric during machine emergency stop. The spindle width adjustment device in every chamber could be driven individually by the motor. The lint filter can be pulled out for cleaning during production without stopping the machine.

At outlet zone, it is equipped with a cooling system and a group of the cooling cylinder to decrease fabrics temperature effectively after. Beam winder or folder is both available at outlet zone.

Air Filtration Device “AFD” is a heat recovery unit consisting of electrostatic filtration module, heat recovery module, and automatic cleaning water tank. The exhaust air from the stenter can be filtered and cleaned effectively. Besides, the heat energy of exhaust air can be recovered and utilized for other purposes to achieve overall low energy consumption of the machine.

德國门富士 Monforts

Qualitex控制系统

MONFORTS最新的Qualitex全触摸面板控制系统,其数字化结对功能,智能检测和智能支援等应用程序,并通过全面的Monforts智能传感器机器监控程序得以加强。在最新的Monforts机器上,Monforts智能传感器技术可控制选定的处理参数和组件,从而可以使用智能支援和智能检测应用程序从任何位置访问全面的技术机器数据。数据实时储存在云端,并提供机器性能的即时状态概览。

MONFORTS QUALITEX Full Touch Panel Control System

Its well-known that the astonishing success of Chinas economy over the past decade has sent wages soaring and made it difficult for the countrys textile manufacturers to find and retain trained machine operators, while operating in a highly competitive market where optimised production and full resource efficiency are of paramount importance.

In direct response to this situation, A. Monforts Textilmaschinen GmbH & Co. KG has introduced a range of new Industry 4.0 technologies aimed at simplifying machine operation while providing easy access to all data and instant or remote assistance.

At the forthcoming Shanghaitex 2019 textile machinery exhibition, which takes place from November 25th - 28th in Shanghai, Monforts specialists will be at stand A10 in Hall W and look forward to discussing the companys latest developments in this area with valued Chinese customers.

They include the latest Qualitex full touch panel control system, with its digital twinning capability and Smart Check and Smart Support apps, reinforced by the comprehensive Monforts Smart Sensor machine monitoring programme.

“On the very latest Monforts machines, our Smart Sensor technologies are controlling selected processing parameter and component, making it possible to access comprehensive technical machine data from any location using the Smart Support and Smart Check apps,” explains Monforts Vice-President Klaus Heinrichs. “The data is virtually mapped in the cloud in real time and provides an instant status overview of a machines performance.”

This, he adds, allows for vastly simplified and targeted analysis for both controlled planning and production, and insights harnessed from the data can subsequently be used to further optimise the production process.

“At the same time, potential sources of error can be remotely anticipated and eliminated to considerably minimise downtime while the digital twin capability provides information on the individual wear parts of a system ” says Mr. Heinrichs. “As a result, operators can now see how long a part will last and when maintenance or replacement is necessary. Direct access to the integrated Monforts webshop then allows users to order spares at the press of the button whenever they are required.”

This full digital control package is being made available for all Monforts machine ranges and makes operation smarter, and at the same time, considerably simpler.

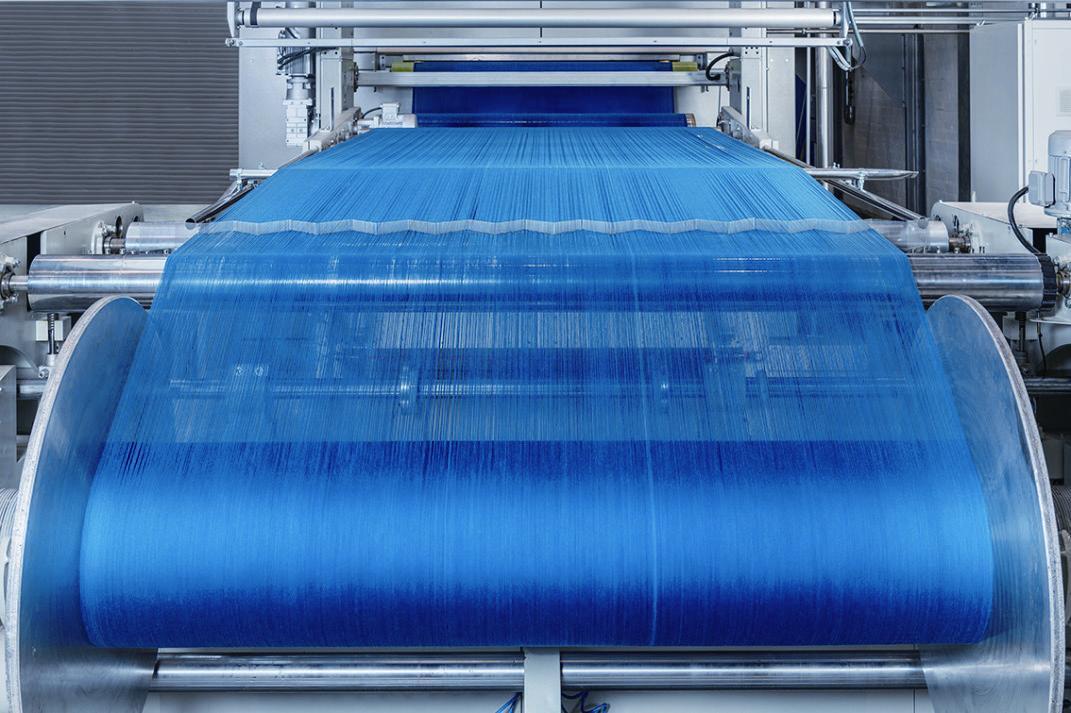

CYD連续纱线染色系统

Monforts新型CYD连续纱线染色系统采用Econtrol?技术- 这是目前应用于纱线染色的牛仔布织物最有效和最成熟的染色工艺。Econtrol?染色工艺可确保活性染料在干燥过程中固定在织物的纤维素纤维上。

CYD系统还将新的功能和工艺集成到纺纱织造准备工艺中,可直接在纺纱,束纱和整经后,进行上浆和染色——以提高质量,灵活性和生产率。

MONFORTS NEW CYD Continuous Yarn Dyeing System

Monforts will also be providing full details of its new CYD continuous yarn dyeing system which is based on the Econtrol? technique – the most effective and established dyeing process for denim fabrics that is now being applied for yarn dyeing. *

Econtrol? is a pad-dry process employed in Monforts continuous dyeing in which the reactive dyestuff is fixed to the cellulose fibres during drying.

The fixing medium is a controlled by a steam/air mixture within the Monforts Thermex unit. With sulphur and reactive dyes in particular, the improvement in both quality and fixation is considerable, and with significant savings in energy and time due to the combined bleaching and padder fixation. The use of the Econtrol T-CA technique also allows the dyeing of cotton/polyester and other yarn blends.

Weaving preparation

The CYD system also integrates new functions and processes into the weaving preparation processes – spinning, direct beaming, warping and assembly beaming, followed by sizing and dyeing– in order to increase quality, flexibility, economic viability and productivity.

Further new concepts include the unique Eco Bleach process. This is the first bleaching system for yarn treatment available on the market and is combined with the washing units, after which the fabric is then dyed immediately, resulting in considerable savings in wastewater and chemicals.

It is possible to process short batches of yarn in order to produce minimum runs of finished fabrics in a single continuous process. By comparing the usual processing sequences within the denim industry with the new CYD system, the advantages become immediately clear.

“We are expecting keen interest in our new CYD continuous yarn dyeing system from valued customers in China who did not have the opportunity to visit ITMA 2019,” says Monforts Head of Denim Hans Wroblowski, “especially from the countrys denim manufacturers. We know from the feedback weve already received that the CYD system is something the market has been waiting for.”

Trials are currently being carried out with customers on the new CYD yarn dyeing pilot line at the Monforts Advanced Technology Centre in M?nchengladbach, Germany.

* Econtrol is a registered trademark of Dystar Colours Distribution GmbH.

紗力拉 XORELLA

XO-Series系列节能型真空调湿定形机

纱力拉XO系列节能型真空调湿定形机自推出以来,已广泛应用于改良纱线以及成衣定型领域。经过纱力拉设备的XO-汽蒸系统处理,可均匀地对纺织品进行调湿、定捻、化纤预缩、消除静电、数码印花布固色和成衣预定形等。

新型的饱和蒸汽产生系统比水漕式加热系统减少30%安装功率及节省能耗达15%~25%。

为满足不同用户的使用要求,纱力拉配有圆形或方形机款供选择,并可配备多款装卸系统和不同规格的工作门。目前,XO-系列设备已在全球超过50多个国家中投入使用。

XORELLA XO-Series

Vacuum Conditioning and Heat Setting Machine

XORELLA XO-Series energy saving vacuum conditioning and heat setting machines has been well used in improving the quality of yarn and also heat setting of garment. The Xorella XO-Steaming treatment could even penetrate the textile products for humidification, twist setting, preshrinking the synthetic filament, anti-static, colour fixation of digital printed fabric and heat setting of garment. The latest saturated steam generating system could reduce 30% of connected power loading and save between 15% to 25% energy consumption.

In order to satisfy the requirement of different users, Xorella provides both round and cubical machine and also variety of loading and door opening systems for customer selection. Nowadays, XO-Series machines were used in more than 50 countries in the world.

立信水务 FWT

立信中水回用系統

中国恒天立信集团的业务面对全球印染行业,特别关注行业与生态环境之间的平衡发展,不断致力于研发和制造节能降耗之染整设备。近年来,更投放大量资源发展污水处理科技,按照环境友好和资源综合利用的原则,于2007年,立信采用自身研发的中水回用技术,实现了印染达标排放污水通过全自动化操作的双膜法中水回用系统,向广大印染企业提供一站式环保创新、持续升级的污水处理方案。

本次在中国恒天立信工业展台展示的“立信中水回用系统”,采用最先进及稳定的双膜法工艺(超滤结合反渗透),能对各种达标排放印染废水进行回用处理。有效脱除废水中的矿物盐、钙镁硬度、色度、浊度及COD成分等,所产生的再生水水质优于一般自来水,能满足所有印染工艺的高品质用水要求。

FONGS Water Recycling System

With global service for the dyeing and finishing industry, CHTC Fongs Group has focused on its principal business in design, research and manufacture of innovative and energy saving dyeing and finishing machines to help a sustainable balance between the industry development and environment protection. In recent years, Fongs has researched and developed the wastewater treatment technology, to achieve fully automatic operation water recycling system with dual-membrane processes, providing onestop sustainable solutions of dyeing wastewater treatment especially for the dyeing and finishing industries.

Fongs Water Recycling System which can reuse any kind of qualified discharge water by using the most advanced and reliable dual-membrane processes (ultrafiltration system combined with reverse osmosis membrane system). The recycled water can be directly used for all dyeing processes after most of the mineral salts, calcium, magnesium hardness, Chroma, turbidity and COD composition are effectively removed from the waste water. The quality indicator of recycling water is superior to the normal tap water.

桑德森力玛:致力于提供创新面料后整理方案

SANTEX RIMAR GROUP: Aiming to provide the innovative fabric finishing solutions

桑德森力玛集团作为全球顶尖的织造、纺织后整理、产业用纺织和水处理及烘干工艺绿色环保方案的设备制造厂商,凭借现代科技及多年的经验,一直致力于为我们的客户提供创新的面料后整理方案。

作为定制化方案的设备制造商和技术合作伙伴,桑德森力玛保证产品生命周期的每一个阶段具备卓越的竞争力:高性能的设备包含着竞争力、激情、承诺和高端的研发。

桑德森力玛在生产力、节能和可持续性上提供最佳科技,低维护成本和最先进的生产流程。

本次,公司将在展台W1C20上向大家展示Sperotto Rimar品牌最新最先进的设备:VELURA起毛机和DECOFAST3.5连续加压蒸呢机3.5。

VELURA起毛机与CALIBRA剪毛机、SOFTA磨毛机一起,代表着面对现代纺织工厂对织物的高标准需求下最先进的表面后整理方案。VELURA 起毛机可以通过双鼓/单鼓、24辊/28辊应用在各种针织及机织面料上。通过张力控制给予面料特殊处理,设备内各部件之间精密的控制能够避免中心至布边之间的不均匀性,从而使面料获得密集的长绒或短绒效果。机器配备高质量起毛辊驱动皮带,相比较大尺寸的皮带,更具灵活性和耐久性。使用5根驱动皮带支撑起毛辊驱动,以确保完全的附着力以及最大的能量传输,从而获得更加高效的起毛效果。顶级的起毛针布能够保证在任何面料上达到最佳以及持久的起毛效果。可调速的三层扩幅辊能够避免在生产过程中面料表面折痕或不均匀。DECOFAST3.5连续加压蒸呢机3.5广泛运用于针织及机织的精纺毛织物、仿毛类产品以及丝织品等面料。蒸汽蒸呢的压力可达2巴(可调),温度最高可达135度。蒸汽、蒸汽抽吸单元及冷却单元均可控制。使用的织物呢毯为渗透性呢毯,张力可调。可连续整理,操作简单,实现工艺的连续性。相对于传统的间隙式罐蒸机,解决了包布印,搭头印以及色差等一系列问题。提高织物的定制质量并领导市场流行趋势。

桑德森力玛集团积极与客户互动,大力投資研发,推成出新,不断给予客户新的解决方案。

SANTEX RIMAR GROUP is the world top machine manufacture in the market of weaving, textile finishing, technical textiles,and green technologies for water treatment, aiming to provide the customers with the innovative fabric finishing solutions by virtue of the modern technology and profound experience.

As the machine manufacturers and technology partners for customized solutions, the company guarantees an excellent level of competence at each stage of the products lifecycle: the machines are made with competence, passion and high level of research.

SANTEX RIMAR GROUP provides the most efficient technology in respect to productivity, energy savings and sustainability, low maintenance costs and state of the art production processes.

At BOOTH W1C20, it will exhibit Sperotto Rimar VELURA(Raising Machine) and DECOFAST3.5 (Decatizing Machine) as the latest and most advanced finishing solutions.

Together with CALIBRA and SOFTA, VELURA, represent the newest surface finishing solutions for the most advanced and demanding textile mills.

VELURA (Raising Machine) is able to treat on various kinds of knitting and woven fabrics via Double Drums/Single Drum, 24 rolls/28 rolls. Special care has been given to the fabric tension control. The very short distance among the different parts of the machine avoid any unevenness between the center and the edges thus obtaining a dense full long or short pile. The machine is equipped with high quality raising rollers driving belts which are more flexible and durable compared to bigger size belts. Five driving belts for raising rollers drive are provided for the raising rollers drive in order to ensure a full grip and the maximum possible energy transmission granting a more efficient raising effect. Triple fabric spreading screw rollers with adjustable speed prevents the formation of any crease or unevenness during the process.

DECOFAST 3.5 (Decatizing Machine) - Decofast 3.5 is suitable for knitted fabrics, woven fabrics, worsted fabrics and other fabrics. Hot-water decatizing under pressure up to 2 bar adjustable and with temp, up to 135°C. Steaming, exhausting and cooling system with changeable conditions. Reproducibility of the results thanks to the treatment in continuous and to the easy working of the machine. It solved traditional Decatizing machine sewing joint mark, wrap mark and colour difference problems. And it also enhances the tailoring qualities of the fabrics and leads the market fashion trend as well.

SANTEX RIMAR GROUP innovates interacting with customers and makes serious investments in Research and Development in order to always have new relevant solutions to offer.

常州宏大:主推印染智能化設备

本届展会上,常州宏大公司将展出Hawk Vision?智能图像整花整纬机、HV-T500智能化定型工艺系统、HV-PC高精度针织定型自动克重在线测控系统等设备。

Hawk Vision?智能图像整花整纬机是由“霍克威视”品牌依托其强大的欧洲技术背景和常州宏大深厚的技术研发实力,首创国际领先的“全幅扫描整花整纬技术”。它运用了全新的科技手段,彻底解决了光电整纬无法矫正和识别的纺织品花形变形、纬斜、纬弯问题,适用于色织布、印花布、提花布、转移印花、磨毛布、针织布、牛仔布、沙发布、窗帘布、斜纹布、厚重织物、高支高密布、真丝仿真丝雪纺、数码印花上浆、复合加工等各种织法的纺织品,打破光电整纬机和普通图像整纬机对纺织品面料织法、纹理、厚度等的种种限制,超越了光电整纬和普通图像整纬的价值,为纺织品企业创造了核心价值!该产品荣获2017年“纺织之光”中国纺织工业联合会技术进步奖一等奖,经中国纺织工业联合会专家组鉴定为国际领先水平。

該机采用封闭式圆网座,传动精度高。同时,设计充分考虑了零配件的互换性和易维修性,主要易损件如圆网轴承,密封圈,网座构件等均与行业内在用机型(如佶龙彩蝶、日本东伸等)的零件,具有一定互换性。

凹版(柔版)精密印花机采用卧式排列,用户可根据工艺需要任意选择凹版数量和排列位置,并且可以与圆网组合;该机可使用市场上的各种普通印花浆料,适应任何工作环境;控制部分采用独创的直驱传动技术,同步控制精度可以达到0.015毫米;可实现连续精细印花,圆网印花由于受到网目数的和浆料粘度限制,线条精细度很难实现突破,而平网印花的速度已无法提高同时存在接版的难题,腾智系列凹版精密印花机正好能弥补二者的不足;可以印制施浆量极少的朦胧罩印,这种独特风格也是圆网和平网很难实现的。

纺织品数码喷墨印花作为一种全新的印花方式,是印花行业的又一次重大革命。随着计算机技术及喷墨打印技术的发展,数码打印从扫描式的打印模式到Single Pass连续打印模式,从初期的每小时几平方到现在的120米/分钟,特别是工业级打印喷头的发展,使工业化大规模的数码印刷生产成为了现实。数码打印技术在各种印刷领域也得到了广泛应用充分发挥两种印花模式的优点,扬长避短。

圆网(平网)+数码联合印花优点:大面积的底色和特殊浆料由传统圆网(平网)印花机完成,花型不受限,很好的结合了数码印花机不拘泥于花型套色数、渐变云纹过度柔和与传统印花颜色饱满、渗透性优良的特点;生产成本低,大块面和满地使用传统印花的色浆,数码印花墨水使用量仅需纯数码印花墨水使用量的约30%;劳动强度低,大幅降低圆网/平网网版制作成本与时间,减少换色和换网版时的人工消耗,减轻了残留浆料和污水处理的负担。

此外,公司还将展出248英寸宽幅经编机3GET-248-E28。该机可采用涤纶和锦纶长丝、腈纶丝、氨纶丝、涤纶变形丝、混纺纱等原料,编织平素织物、弹力织物和绒类织物的坯布,并经相应的后整理工艺加工后,可以生产服装用织物、席梦思面料和床罩、室内装饰和产业用织物。包括外衣、运动服、内衣、泳装、汽车内装饰、鞋子面料、涂层织物和特殊结构的网眼织物以及带毛圈装置和不带毛圈装置形成的毛绒织物。

YP high-precision rotary printing machine is the latest type of highly precise products launched by Fujian Jilong Machine Technologies Co., Ltd. It is suitable for rotary screen printing of natural fiber, chemical fiber and its blended textile fabric.

It adopts closed screen head basement which takes high-accuracy driving. Its spare parts are interchangeable and easy to be maintained, and the major consumable parts, like screen bear, seal, screen basement frame, are interchangebale to most machines in market (like Caidie, ICHINOSE, etc.).

Gravure (Flexo) accurate printing machine adopts horizontal arrangement, so that users are able to choose gravure quantity and position, and combine with rotary screen. On this machine, all normal paste can be used, and it is suitable for all kinds of working surroundings. Its control system is individually direct driving, and the synchronous accuracy can reach 0.015 mm.

Advantages of rotary (flat) and digital combined printing: large-area background color and special paste are completed by traditional rotary screen (flat screen) printing machine with un-limited patterns. Advantage of digital printing machine is well combined with those of the traditional printing. Low production cost, for digital printing ink usage only needs about 30% of pure digital printing ink usage; low labor intensity, greatly reducing the cost of rotary screen / flat screen production and time, reducing the manual consumption of color change and screen change, and reducing the burden of residual slurry and sewage treatment.

In addition, Jilong will show Tricot Warp Knitting Machine of GET3-248-E28, which can use polyester and polyamide filament, acrylic fiber, spandex silk, polyester deformed yarn, blended yarn and other raw materials and raw fabrics of woven plain fabric, elastic fabric and pile fabric. After the corresponding finishing process, we can produce clothing fabrics, Simmons fabric and bedspread, interior decoration and industrial fabrics. Examples are the outerwear, sportswear, underwear, swimsuit, car interior decoration, shoe fabric, coated fabric and pile fabrics of special structure, and plush fabric made with or without looped pile device.

宏華数码:推出两款高速数码印花机

Atexco: Exhibiting two high-speed digital textile printers

本届展会上,宏华公司将展出VEGA3000DT、Model系列设备是宏华推出的纸印花高速数码印花机。

VEGA3000DT是宏华VEGA系列的旗舰级机器,拥有省墨低成本的产品优势,采用稳健的整机构造,最多搭配48个工业级京瓷喷头,最高支持1800dpi精度打印,可支持4色、6色、8色和12色印花生产,同时支持1.8米、2.5米、3.2米宽幅规格。设备稳定性高,能够24小时连续稳定生产,日产量高达3000-10000m。在日常使用中可实现产量与墨量的智能管理,有效节约用墨量。

设备在运行时采用导带连续输送织物,机体自动恒张力同步放卷,热压式贴布的模式保证面料打印的稳定。同时打印时机头以大功率直线电机扫描驱动,支持喷头高速横移。使用大功率高精度步进电机保证高精度的步进。采用高架进布单元,柔性放卷,支持针织梭织面料的张力要求,切换方便。

导带水洗支持毛刷辊、刮刀、海绵辊混合配置,具有节水控制系统,导带烘干加强且节能控制。同时具有完备的智能喷头清洗系统,自动回墨系统,三重喷头保护系统,环境保护系统,智能环保,保护喷头。完美的机身系统和搭配宏华专用色彩管理软件,更加高效稳定。

Model系列设备是宏华推出的纸印花高速数码印花机。该系列产品拥有很高的性价比,设备产能高,价格低,同时设备支持超薄纸印花,搭配宏华的高浓墨水,为客户提供了一个高性价比的方案。根据不同客户的需求,Model系列的设备可搭载4/8/16个喷头,最高打印精度2400dpi,同时支持4色/8色打印。并且除了窄幅数码印花机以外,我们还精心推出了适用于宽幅市场的打纸机,Model系列的设备同时支持1800mm/2650mm幅宽打印。Model系列设备生产连续稳定,并且能达到日产万米的高产量,是凹版印花厂的转型首选,数码工厂的扩产利器!

During the exhibition, Atexco will exhibit two high speed digital textile printers, VEGA 3000DT/DL and the Model series.

VEGA 3000DT/DL, the flagship printer of VEGA series, ensuring the highest standard of quality, reliability and productivity, with up to 48 industrial print heads. 4, 6 , 8, 12 colours, with the width of 1.8m, 2.5m and 3.2m printing width, VEGA3000DT/DL is designed for 24 hours printing. Daily output is 10,000 sqm. Stable and efficient media transportation, with constant tension unwinding system, linear motor, heat press fabric-stick, closed-loop high accuracy feeding system. The intelligent head cleaning, and ink circulating system largely reduce the ink consumption. And dual head protection system, avoids print head damages.

Model series is the industrial sublimation printer launched in 2018. This series of products are with high cost-effective, high production and low printing cost. The machines are capable to printing ultra thin paper, down-to 18 gsm. With Atexcos high-density ink, it provides a higher cost-effective solution for customers. Model series is equipped with 4 / 8 / 16 print heads, with the highest printing resolution of 2,400 dpi, and 4, 6 or 8 colors optional. Beside 1,800 mm, a wide width of 2,650 mm is also available and was launched in middle of 2019. With the daily production of 10,000 meters, it is the first choice for the transformation of gravure printing factory, as well as for the digital printing mills.

遠信工业:热风拉幅定形机节能降耗

Yoantion Industrial: The hot air stentering machine

远信工业股份有限公司是一家专业生产纺织机械、印染机械、机械配件的高新技术企业。公司成立之初就瞄准国内外中高端市场,依托专业技术团队和高端制造设备,创造远信品质、远信品牌,迅速成为高端染整设备专业制造商。公司主导产品热风拉幅定形机在有效提高产品质量的同时实现了纺织行业的节能降耗,具有很强的市场竞争实力;拥有UG、PRO-E等CAD/CAM软件,具备了较强的技术创新能力;运用ERP管理系统,推行6S管理,实施ISO9001:2015质量管理体系,全面规范公司管理。公司累计申请专利近百项,其中已授权专利80余项;被新认定为国家重点扶持高新技术企业、省重点企业研究院、浙江省隐形冠军企业、省级研发中心、浙江名牌等荣誉称号。

热风拉幅定形机

远信公司自主研发的热风拉幅定形机,适用于针织全棉、涤棉混纺及新型纤维机织物和弹力机织物进行干织物的拉幅和定型。在有效提高产品质量的同时实现了纺织行业的节能降耗。发明的内置式风道结构,通过结构设计优化,实现风道内置,有效降低能耗和提高设备整体美观度;发明的热风喷嘴,利用喷嘴风筒上多个吹风口,使得热风能均匀扩散到布面,烘干定型效率高;研制的静压装置,上下风管各由独立的变频电机控制,调节方便;发明的热能再利用装置,通过换热筒中的热交换液进行高效热交换,实现热能回收利用,有效降低能耗和排放;创新设计了扩幅对中装置,采用涡轮蜗杆变速箱进行调节,使布面扩幅对中效果更好。研制了定型机智能控制系统,内置定型工艺专家数据库,自动对生产数据进行维护,方便生产;开发的伺服多轴同步驱动系统,可实现对定型机的在线闭环控制,确保定型织物牵拉张力均匀和系统的稳定运行。

Yoantion Industrial Co., Ltd. is a professional production of textile machinery, dyeing and printing machinery, machinery accessories high-tech enterprises. At the beginning of its establishment, the company aimed at the domestic and foreign high-end market, relying on the professional technical team and advanced manufacturing equipment, to create the quality and brand of Yoantion, and quickly become a professional manufacturer of high-end dyeing and finishing equipment. The main products of the company are hot air stentering machine, which can effectively improve product quality and achieve energy saving and consumption reduction in textile industry. It has strong market competition strength;using cad/cam software such as UG, PRO-E, with strong technical innovation ability. The application of ERP management system, implementation of 6S management, and ISO9001:2015 quality management system comprehensively regulate the company management. The company has applied for nearly 100 patents, of which more than 80 patents have been authorized. Newly recognized as the national key support high-tech enterprises, provincial key enterprise research institute, Zhejiang Province invisible champion enterprise, provincial R&D center, Zhejiang famous brand and other honorary titles.

The hot air stentering machine

The hot air stentering machine developed by Yoantion is suitable for knitting cotton, polyester and cotton blended fabrics, new fiber woven fabrics and elastic woven fabrics for stretching and setting of dry fabrics. While improving product quality effectively, energy saving and consumption reduction in textile industry have been realized at the same time.The inventive built-in air duct structure, through structural design optimization, can effectively reduce energy consumption and improve the overall aesthetic degree of the equipment.The hot air nozzle of the invention makes use of a plurality of air blowing ports on the nozzle tube to make the hot air spread evenly to the cloth surface, and the drying setting efficiency is high.The hydrostatic pressure device with the upper and lower air pipes controlled by independent frequency conversion motor can be adjusted conveniently. The invented heat energy recovery system can efficiently exchange heat through the heat exchange liquid in the heat exchanger, realizing the recovery and utilization of heat energy, and effectively reduce the energy consumption and emission.Innovative design of the expanding alignment device, using the turbine worm gearbox to adjust, so that the fabric expansion alignment effect is better. The intelligent control system and the builtin database of process experts , which can automatically maintain the production data and facilitate the production.The servo multi-axis synchronous drive system can realize the on-line closed-loop control of the stentering machine and ensure the uniform drawing tension and the stable operation of the system.