Design and manufacture of a 100 kA coaxial pulsed power cable for plasma generator and PPS in ETC guns

2019-11-18YongJinZhenxioLiYnjieNiXioGoGngWnChunxiYngBomingLiNtionlKeyLortoryofTrnsientPhysicsNnjingUniversityofSciencendTechnologyNnjing210094Chin

Yong Jin , Zhen-xio Li , Yn-jie Ni , Xio-y Go , Gng Wn , Chun-xi Yng ,Bo-ming Li ,c Ntionl Key Lortory of Trnsient Physics, Nnjing University of Science nd Technology, Nnjing 210094, Chin

b Information Central of China North Industries Group Corporation, Beijing,100089, China

c China Academy of Ordnance, Beijing,100089, China

Keywords:Pulsed power cable Pulsed power supply Electrothermal-chemical launch Coaxial structure

ABSTRACT Based on our previous pulsed current and internal overvoltage test data and the experience of common commercial high power cables, a 100 kA coaxial pulsed power cable is designed and manufactured to adapt the coaxial electric energy breech transmission between the plasma generator and the pulsed power supply (PPS) in electrothermal-chemical (ETC) guns. The index parameters are analyzed and determined.Semi-conductor layers and a shield stiffener are introduced to prevent the deformation and burst of the pulsed power cable structurally. The semi-conductor layer can eliminate the air gap and balance the electric field in the cable. The shield stiffener can multiply the mechanical strength to restrain the strong electrodynamic force produced by the core dislocation of the outer conductor. The multi-coupling of electromagnetic field,stress field and thermal field analysis are established to assist in aided design of electrical strength, mechanical strength and temperature rise characteristics. Both a DC voltage withstand test and pulsed discharge tests are introduced to verify and inspect the performance and dynamic response of the pulsed power cable.The 25 kV/5min DC voltage withstand test result shows that the sample leakage current is nearly 3 mA and no abnormal phenomena of the pulsed power cable sample occurred. The pulsed discharge tests show that the sample can sustain the 100 kA peak current.Furthermore, this 100 kA coaxial pulsed power cable can satisfy the ETC test requirements.

1. Introduction

Electrothermal-chemical(ETC)launch as a hypervelocity launch technology, takes advantage of the electromagnetic induction phenomenon [1e3]. An arc controlled ablation (ACA) plasma is always produced by a pulsed power supply (PPS) discharging to accelerate the projectile in ETC launchers.Under the interaction of a pulsed current,the ACA plasma produced in the plasma generator is mainly via electrically exploding the surface copper wires and ablating the insulators[4e6].The ACA plasma can rapidly diffuse in axial and radial directions simultaneously in the chamber.Also,the instantaneous energy can inject into the energetic propellant bed to improve and enhance the solid propellant ignition and combustion directly. As a necessary component of electric power transmission in ETC system, a pulsed power cable is often employed to connect the PPS and the plasma generator effectually [7e9].

According to the working conditions of the ETC launch system,a suitable pulsed power cable is designed and manufactured for the ETC tests and experiments. Based on recent test data, the pulsed power cable parameters are analyzed and determined. The structure and suitable materials of the pulsed power cable are confirmed via the theoretical calculation and simulation analysis. The PPS discharge test results show that the performance of this pulsed power cable can satisfy the ETC test requirements.

2. Research background

Fig.1. Prototype of the 500 kJ PPS.

In our previous work, a 500 kJ compact capacitive PPS [10,11],consisting of one constant current charger and two pulsed power modules (PPM), has been designed and manufactured to support electrical energy for the ETC launchers. The electrical circuit of a 250 kJ PPM and prototype of this PPS are shown in Fig. 1. In our early work, the PPS and ETC launchers are connected with copper bus bars or commercial cables.

Typical pulsed current and voltage curves is shown in Fig.2.The discharge voltage is 7 kV in the test and the peak current is nearly 95 kA. The time to the half value of the impulse current is nearly 1.7 ms.

Fig. 2. Pulsed current and voltage curves of 500 kJ PPS discharge tests via copper bus bars.

Fig. 3. Deformation and bursting fault of commercial high power cables.

We also tried to employ a commercial cable to obtain the pulsed current as in Fig.2,but the commercial cable cannot satisfy our test requirements. The deformation and bursting fault of commercial cables were often detected as in Fig.3 when the peak current is only near 60 kA in the commercial cables. The strong electromagnetic force causes the above deformation and bursting of the commercial cable.

We obtained the current waveform as in Fig. 2 via the copper bus bars. However, the copper bus bars have large structures and complex electromagnetic interference (EMI) for electric tests such as the pulsed current and voltage, chamber pressure measurements, etc. Hence, it is necessary to introduce a coaxial pulsed power cable instead of the copper bus bars in our ETC systems.

3. Parameters and structure design

3.1. Parameters design

The design of a pulsed power cable should focus on the pulsed current, voltage and continuous working ability. And the parameters of the pulsed power cable are determined by the launch condition. The main parameters of the pulsed power cable are shown in Table 1. The parameters in Table 1 are mainly based on our previous research and tests of the 500 kJ PPS such as in Fig.2,while also increasing the margin of safety and reliability. If the pulsed power cable can survive these conditions then it will satisfy our ETC test requirements.

Relevant research[9]shows that the load electric contact during the discharging transmission will cause an overvoltage in the system, and the overvoltage amplitude can be more than twice the working voltage.Hence,the peak voltage of the pulsed power cable we selected is 25 kV to ensure the whole system working properly.

The conductive material and its cross section are the most important factors to the design of pulsed power cable.Uniformizing the distribution of pulsed current in the cable is an effective way to reduce the cable resistance and improve the material conductivity.The amplitude and frequency characteristics of pulsed current in Fig.2 are analyzed by the fast Fourier transform(FFT)method.It is shown in Fig. 4 that the high amplitude component of the pulsed current is mainly concentrated in the low frequency band. The current skin effect still should be considered and eliminated as far as possible in our cable designing.After comprehensive analysis,an outer diameter of 0.49 mm insulating enameled copper single wireis selected to weave the inner/outer conductors of the pulsed power cable.

Table 1 Main parameters of the high power cable.

Fig. 4. Amplitude spectrum curve of the pulsed current by FFT.

The actual capacity of the pulsed power cable is determined by the inner/outer conductors'cross section.According to the overload discharge test results of the commercial cable,it is detected that the cable is often deformed and damaged when the current density of the inner/outer conductors (weaved by 0.49 mm insulating enameled copper single wire) is greater than 2.5 kA/mm2. It may even burst when the current density is greater than 3.0 kA/mm2as shown in Fig.3.Similar experiments are also described in Ref.[12].The cable was manufactured with a copper single wire having a cross sectional area of 1.0 mm2. Both outer conductor layer and outer sheath burst when the pulsed current density achieved 3.2 kA/mm2. Hence, we designed the cross section of inner/outer conductors as 90 mm2to ensure the current density is only 1.0 kA/mm2, which has high security and reliability.

3.2. Structure design

Fig. 5. Structure of the 100 kA pulsed power cable.

Commercial coaxial high power cables mainly consists of 4 layers. From the inside out are the inner conductor core, the insulating layer, the outer conductor layer and the outer sheath,respectively [12,13]. The detailed structure of the pulsed power cable we designed is shown schematically in Fig.5.Some adaptive improvements have been introduced including the shield strengthening layer, the semi-conductive layer and the isolation layer, etc.

There are 8 layers from the inside to the outside. The inner conductor core is spirally weaved with 480 insulating enameled copper single wires and the external diameter is 11.6 mm.The outer conductor layer is braided by the same amount of the insulating enameled copper single wires tightly and this layer thickness is 2.0 mm. The inner/outer semi-conductor layer is composed of a semi-conductive cross linked polyethylene(XLPE)cloth,a polymer material mixed with carbon black and extremely purity micronsized ultrafine copper powder. The thickness of both the inner and outer semi-conductor layers is 0.1 mm.This layer is designed to fill the air gap, balance the electric field, and eliminate the air gap between the insulating layer and the metal layer. Ethylenepropylene rubber (EPR) has excellent electrical insulation and corona resistance and has better electrical and mechanical properties at low temperature condition.The insulation layer is vacuum extruded by a 3 mm thickness EPR. The shield stiffener layer is braided by 48 insulating paint coating stainless steel wires to increase the cable mechanical strength and constrain the outer conductor layer.The stainless steel wire diameter is 0.3 mm and the shield stiffener layer thickness is 1 mm. The thickness of the isolation layer with polyester nonwovens is 0.1 mm. And the thickness of the outer sheath with thermoplastic polyurethane(TPU) material is 2.0 mm. Hence, the external diameter of the pulsed power cable is nearly 28 mm.

4. Simulation and analysis

The multi-coupling of electromagnetic field, stress field and thermal field analysis are established to simulate the response of the above pulsed power cable under the ETC launch conditions by ANSYS software.

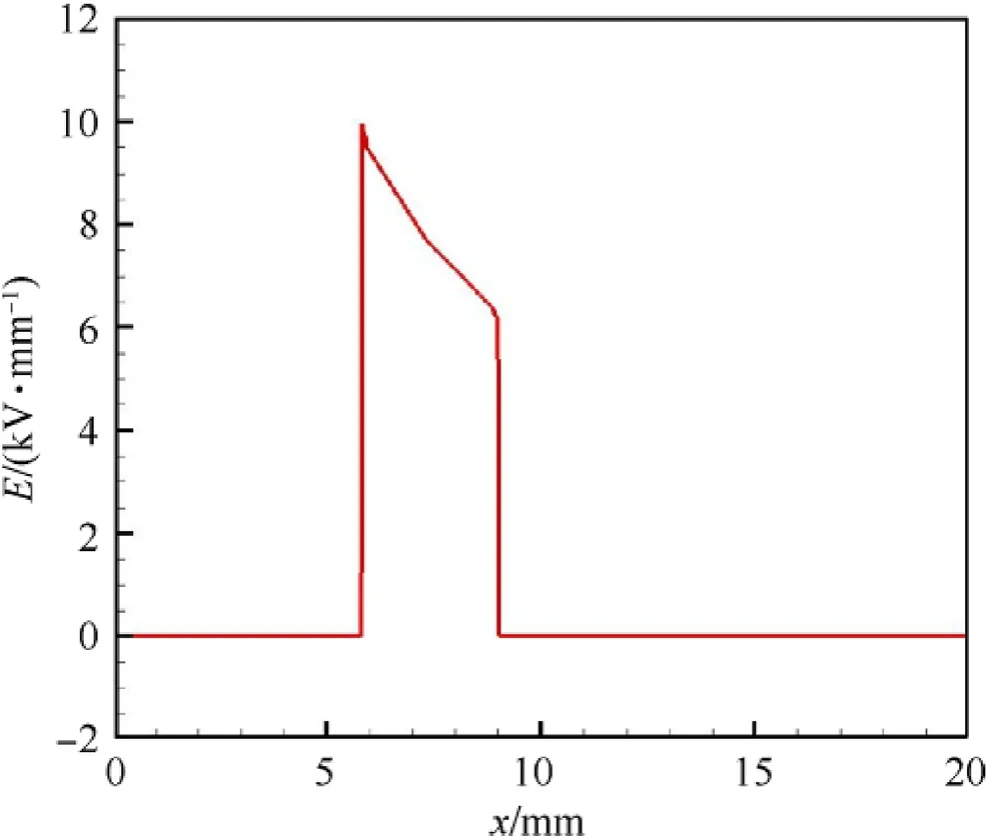

The electric field model of pulsed power cable simulated the electric field distribution in the insulating layer. The voltage between the inner and outer conductor was 25 kV (the maximum voltage in Table 1). Fig. 6 shows the internal field intensity trend with radius. The largest electric field density is shown on the EPR insulation layer and the inner conductor boundary about 10.0 kV/mm. The dielectric constant of EPR is 2.6 at 298 K and 2.7 at 77 K.The dielectric strength of EPR extrusion insulation is about 20 kV/mm at 298 K and 40 kV/mm at 77 K [13,14]. Hence, the insulation design of the pulsed power cable is reliable.

Fig. 6. Calculation of electric field strength in the pulsed power cable.

The pulsed current as in Fig. 2 is input into the model to calculate the magnetic field distribution in the pulsed power cable(as the gray-scale shown in Fig. 7). The red circle is the inner conductor boundary and the blue circles are the outer conductor boundaries. The pink curve in Fig. 7 is the magnetic induction intensity trend along the radial direction when the peak current is attained. The horizontal axis of the pink curve is the same as the contour diagram.And the ordinate of the pink curve is the magnetic induction intensity. It is shown that the magnetic induction intensity increased from the inside to the outside of the inner conductor,and reached a maximum of nearly 3.5 Tat the boundary of the inner conductor. Also, the magnetic induction intensity decreased in both the EPR and outer conductor successively. The magnetic induction intensity returned to zero in the outer boundary of the outer conductor.

The shield stiffener designed in this paper can support enough binding force to prevent the deformation of the pulsed power cable.The outer conductor layer is braided by the multiple insulating enameled copper single wires tightly, even a small bending radius usually will not cause all braided conductors in a certain part to slip in the same direction and with greater distance.

Based on the pulsed current in the actual transmission process,a simplified thermal simulation model of the pulsed power cable is established based on the following assumptions, and the temperature of the pulsed power cable is discussed. The heat is instantaneous. The average temperature coefficient of resistance (TCR) of the copper conductors is only 0.004 ppm/℃ (20℃). The influence of the wire resistance to the temperature in the discharge process can be ignored.The heat transfer coefficient is 9.0 W/(m2$K)[13,14].We calculated the electric action of the pulsed current waveform in Fig. 2 is 7.39×107A2s. The resistance of the single copper wire is 93.7 mU/m (20℃). The distribution resistance of the inner conductor core and outer conductor is 0.20 mU/m. Calculation shows that the joule heating produced by the inner conductor core and outer conductor is about 14.8 kJ/m. The thermal simulation results show that the internal peak temperature occurred in the center of the inner conductor core.Its temperature is about 31.5℃ after the discharging. It cools down to 31.2℃ after 10 s. The peak temperature of the EPR insulation layer occurred on the surface of the inner conductor core. Its temperature is about 31.4℃. The internal temperature of the EPR insulation layer changed slowly.The allowed working temperature of the EPR insulation layer is about 90℃ [13,14]. Hence, the pulsed power cable designed above can completely satisfy the requirements of the system for three pulses per minute.

Fig. 7. Calculation of magnetic field distribution in the pulsed power cable.

5. Experimental verification

5.1. Voltage withstand test

A DC voltage withstand test is introduced after the manufacture of the pulsed power cable. The length of the test sample is about 10 m. A ZGSIII high-voltage DC generator and ZGS-B full-shielded digital high-voltage microammeter are employed to control the voltage stability within 0.5%.The test voltage is 25 kV and hold time is 5 minutes. Test results show that the sample leakage current is nearly 3 mA and no abnormal phenomena of the pulsed power cable sample occurred in the DC voltage withstand test process.

5.2. Pulsed discharge tests

The pulsed discharge tests, including both single pulsed discharge and three shots pulsed discharge, are also introduced to inspect the dynamic response of the pulsed power cable. The pulsed power cable sample is 3 m length, and is connected to the PPS with an analog load.The initial resistance of the analog load is slightly lower than that of the plasma generator for the ETC launch experiment. The analog load is placed in air and the discharging voltage is 7.0 kV.

The sample of pulsed power cable in both single and three shots pulsed discharge tests is shown in Fig.8.The pulsed current curve of the single pulsed discharge test is shown in Fig.9(a).It is shown that the peak current is nearly 100 kA.The time to half value of the impulse current is more than 2.0 ms. The pulsed current curves of the three shots pulsed discharge test is shown in Fig. 9(b). It is shown that three shots pulsed discharge are executed in 30 s serially.The peak current is nearly 82 kA and the time to half value of impulse current is about 2.0 ms in each discharging. After the pulsed discharge tests, no obvious deformation of the sample was observed.The DC voltage withstand test is also executed before and after the pulsed discharge test.It is shown that the sample leakage current did not change significantly and no abnormal phenomena of the pulsed power cable sample occurred.Hence,the test results show that the pulsed power cable complies with the development requirements.

6. Conclusions

Fig. 8. Sample of 100 kA pulsed power cable.

Fig. 9. Pulsed current curves of pulsed discharge tests.

Based on our previous work, a 100 kA coaxial pulsed power cable with new structures is designed and manufactured to adapt the coaxial electric energy breech transmission between the plasma generator and the pulsed power supply (PPS) in electrothermal-chemical (ETC) guns. Both semi-conductor layers and a stainless steel shield stiffener are introduced to prevent the deformation and bursting of the pulsed power cable structurally.The semi-conductor layer can eliminate the air gap and balance the electric field in the cable. The shield stiffener can enhance the mechanical strength to restrain the strong electrodynamic force produced by the core dislocation of the outer conductor. The insulation layer is vacuum extruded by a 3 mm thickness ethylenepropylene rubber(EPR).Both DC voltage withstand test and pulsed discharge tests show that the pulsed power cable sample can endure the 25 kV/5min DC voltage withstand test, the sample leakage current is nearly 3 mA and no abnormal phenomena occurred.The sample also can sustain the 100 kA peak current.This 100 kA coaxial pulsed power cable can satisfy the ETC test requirements. The 100 kA pulsed power cable also can bring great convenience to the design and maintenance in the engineering application. We also consider to design and manufacture the higher-level pulsed power cable via the same craft.

Acknowledgments

This work is supported by the United Foundation of China Ordnance Industry (Grant No. 6141B010220).

杂志排行

Defence Technology的其它文章

- Comparative analysis of the effects of gunpowder and plasma ignition in closed vessel tests

- Numerical simulation on the pressure wave in a 30 mm electrothermal-chemical gun with the discharge rod plasma generator

- Design optimization for a launching system with novel structure

- Influence of multiple structural parameters on interior ballistics based on orthogonal test methods

- A prediction method for the performance of a low-recoil gun with front nozzle

- Effect of the firing position on aiming error and probability of hit