Simultaneous Denitrification and Carbon Removal in Microbial Fuel Cells

2019-07-30*

*

1. Shandong Engineering and Technology Research Center for Ecological Fragile Belt of Yellow River Delta, Binzhou University, Binzhou 256603, China; 2. College of Environmental Science and Engineering, Zhejiang Gongshang University, Hangzhou 310018, China

AbstractIn this article, microbial fuel cell (MFC) was used for simultaneous denitrification and carbon removal to ascertain their electricity generation performance. The results showed that strengthening domestication and enrichment of electrogenic bacteria had the best start-up effect. An increase in volumetric loading reduced the rate of pollutant removal but promoted the output voltage. The changes of working conditions such as influent concentration, sludge concentration and temperature had a great influence on the electricity generation performance of MFC, and their optimum values were 500 mg/L, 2 000 mg/L and 35℃, respectively.

Key wordsMicrobial fuel cell (MFC), Denitrification, Carbon removal, Electricity production performance

1 Introduction

Microbial fuel cell (MFC) technology, which has emerged in recent years, directly converts the chemical energy contained in pollutants in sewage into electrical energy under the catalysis of microorganisms. It is a promising new sustainable wastewater treatment technology[1-3]. However, there are very few studies on the use of ammonia as a fuel for MFCs to produce electricity[4-5]. The use of MFCs for simultaneous denitrification and carbon removal has not been reported in the literature. Anaerobic ammonium-oxidizing bacteria are microorganisms that oxidize ammonia under anaerobic conditions, and the MFCs with them as the electrogenic bacteria can achieve simultaneous denitrification and carbon removal. The anaerobic ammonium-oxidizing rate reported in the literature has reached 76.7 kg N/(m3·d)[6]. At such a high rate of ammonia oxidation, there will inevitably be a high flux of metabolic electrons. The potential of electricity generation of MFCs through simultaneous denitrification and carbon removal is expected. In this article, the electricity generation performance of MFC through simultaneous denitrification and carbon removal was studied in order to develop new biological denitrification technology.

2 Materials and methods

2.1 Experimental deviceThe material of electricity-generating MFC of simultaneous denitrification and carbon removal is plexiglass. The anode and cathode chambers are all of the same cylindrical structure with a bottom diameter of 85 mm and a height of 120 mm. The reactor has an effective volume of 350 L. The two chambers are separated by a proton exchange membrane (Nafion 117) sandwiched between the circular side tubes. The cross section of the side tubes used is 50 mm. The caps of the anode and cathode chambers have small holes, used for sampling, aeration and electrode fixation. The anode electrode and the cathode electrode are both made of graphite felt and have an effective area of 100 cm2. The electricity generated by the MFC is exported through a steel wire (diameter 2 mm), and the steel wire is connected to the wire. The center distance between the two electrodes is 170 mm.

2.2 Inoculation of microorganismsThe inoculated microorganisms were enrichment cultures of anaerobic digestion and anaerobic ammonium-oxidizing bacteria, respectively, which were taken from a stable reactor operating in the laboratory. The SS, VSS and VSS/SS were 2 530 mg/L, 1 956 mg/L and 0.773, respectively. The innovation amount accounted for 20% of the effective chamber volume of the MFC of simultaneous denitrification and carbon removal.

2.5 Analysis methodsCOD was determined by potassium dichromate method; ammonia nitrogen was determined by salicylic acid-hypochlorite spectrophotometry; nitrous oxide was determined by N-(1-naphthyl)-ethylenediamine spectrophotometry; nitrate nitrogen was determined by ultraviolet spectrophotometry; SS and VSS were determined by gravimetric method; pH was measured using an FE20 pH meter (Mettler Toledo, Switzerland); and temperature was measured using a mercury thermometer[8].

3 Results and discussions

3.1 Start-up performance of electricity-generating MFC of simultaneous denitrification and carbon removalMicroorganisms were inoculated into the anode and cathode chambers of the MFC, respectively, which were then added with the simulated wastewater. Under suitable environmental conditions, ectopic domestication (not connected to the circuit),in-situdomestication (connected to the circuit) and enhanced domestication (applied voltage) were used to enrich the electrogenic bacteria. Taking the start time, pollutant removal rate, internal resistance and output voltage as indicators, the above three start-up methods were compared. The starting performance of MFC of simultaneous denitrification and carbon removal under different conditions is shown in Table 1. Among the three start-up methods, the effect of enhanced domestication was the best, followed by that of in-situ domestication, and the effect of ectopic domestication was the worst. Under enhanced domestication (additional voltage), the start-up period was 28 d, the removal rate of pollutants was 1.13 kg/(m3·d), the internal resistance was 430.6 Ω, and the output voltage was as high as 387.7 mV, which were comparable to other types of MFC reported in the literature.

Table 1 Start-up performance of electricity-generating MFC of simultaneous denitrification and carbon removal under different conditions

EctopicdomesticationIn-situdomesticationEnhanceddomesticationStart-up period∥d453328Pollutant removal rate∥kg/(m3·d)0.980.961.13Internal resistance∥Ω850.3652.1430.6Output voltage∥mV151.8254.3387.7

3.2 Operating performance of electricity-generating MFCs of simultaneous denitrification and carbon removalAfter start-up, the efficiency and stability of electricity-generating MFC of simultaneous denitrification and carbon removal were tested by continuously increasing the influent flow rate to increase the volumetric loading (the influent flow rate was gradually increased from 0.01 to 0.5 L/h). The operating performance of electricity-generating MFC of simultaneous denitrification and carbon removal under different influent flows is shown in Table 2. As shown in Table 2, under fixed influent concentration, when the influent flow rate was gradually increased from 0.01 to 0.5 L/h, the COD removal rate, ammonia removal rate and coulombic efficiency were gradually reduced, from 93.2%, 89.1% and 15.6% to 78.9%, 69.5% and 3.7%. However, the output voltage gradually increased from 286.5 to 387.7 mV and then reduced to 254.6 mV. It suggests that under certain conditions, the increase in volumetric loading reduces the rate of pollutant removal, but promotes the output voltage[9]. Therefore, in the operation of electricity-generating MFC of simultaneous denitrification and carbon removal, care should be taken to select a suitable influent flow rate to balance the removal of pollutants and the function of producing electricity.

Table 2 Operating performance of MFC at different influent flow rates

Influent flowrate∥L/hCODremovalrate∥%Ammoniaremovalrate∥%OutputvoltagemVCoulombicefficiency%0.0193.289.1286.515.60.0590.286.7302.910.70.1086.880.2387.78.90.2080.475.6402.84.60.5078.969.5254.63.7

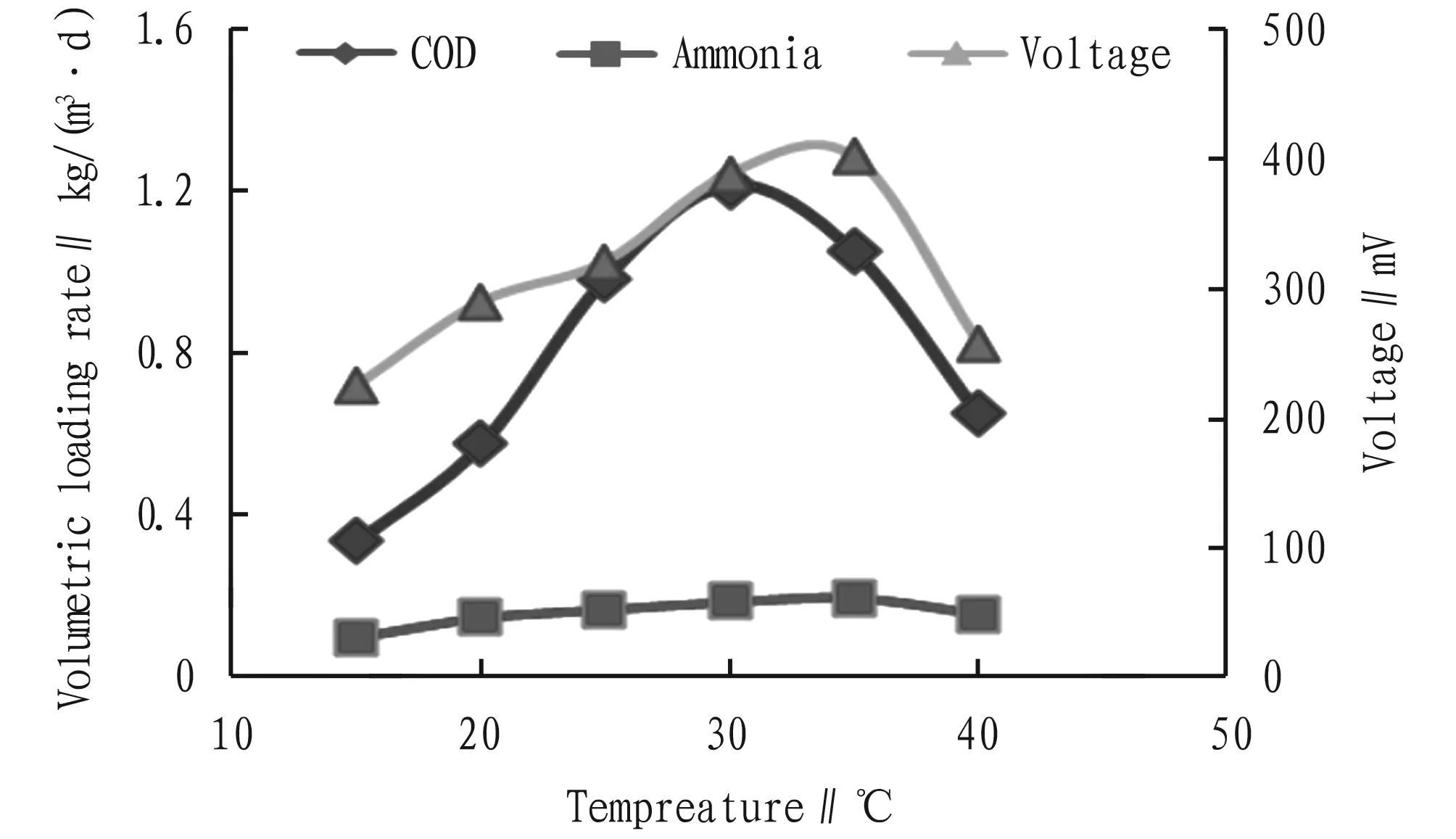

3.3 Working conditions of electricity-generating MFC of simultaneous denitrification and carbon removalThe optimum working conditions for electricity-generating MFC of simultaneous denitrification and carbon removal were explored through chemical analysis and electrochemical monitoring analysis, in order to provide technical parameters for the application of MFCs of simultaneous denitrification and carbon removal. As shown in Fig.1, when the influent concentration was gradually increased from 100 to 2 000 mg/L, the COD removal rate and output voltage first increased and then decreased, and the ammonia removal rate gradually stabilized. The optimum influent concentration was about 500 mg/L. Fig.2 showed that when the sludge concentration was gradually increased from 1 000 to 8 000 mg/L, the COD removal rate and ammonia removal rate first increased and then stabilized, and the output voltage rose first and then fell. The optimum sludge concentration was about 2 000 mg/L. As shown in Fig.3, when the temperature was gradually increased from 15℃ to 40℃, the COD removal rate, ammonia removal rate and output voltage all increased first and then decreased. At a temperature of about 35℃, the performance indicators all reached the maximum. The results above showed that the changes in working conditions such as influent concentration, sludge concentration and temperature had a great influence on the operating performance of electricitygener-

Fig.1 Electricity-generating performance of MFC of simultaneous denitrification and carbon removal at different influent concentrations

ating MFC of simultaneous denitrification and carbon removal. Therefore, when operating the electricity-generating MFCs of simultaneous denitrification and carbon removal in the future, the appropriate parameters should be determined through process optimization experiments to ensure the stable and efficient operation of MFCs[10].

Fig.2 Electricity-generating performance of MFC of simultaneous denitrification and carbon removal at different sludge concentrations

Fig.3 Electricity-generating performance of MFC of simultaneous denitrification and carbon removal at different temperatures

4 Conclusions

The effects of ectopic domestication (not connected to the circuit), in-situ domestication (connected to the circuit) and enhanced domestication (additional voltage) on enriching the electrogenic bacteria were compared, with start-up time, pollutant removal rate, internal resistance and output voltage as indicators. The results showed that the effect of enhanced domestication was the best, followed by that of in-situ domestication, and the effect of ectopic domestication was the worst. The efficiency and stability of the electricity-generating MFC of simultaneous denitrification and carbon removal were tested by continuously increasing the influent flow rate to increase the volumetric loading (the influent flow rate was gradually increased from 0.01 to 0.5 L/h). When the influent flow rate was gradually increased from 0.01 to 0.5 L/h, the COD removal rate, ammonia removal rate and coulombic efficiency were gradually reduced, from 93.2%, 89.1% and 15.6% to 78.9%, 69.5% and 3.7%; and the output voltage was gradually increased from 286.5 to 387.7 mV and then gradually reduced to 254.6 mV. An increase in volumetric loading reduced the rate of removal of pollutants, but it had a positive effect on the output voltage. By changing the working conditions such as influent concentration, sludge concentration and temperature, the optimum process parameters for electricity-generating MFC of simultaneous denitrification and carbon removal were explored. The study found that the changes of working conditions such as influent concentration, sludge concentration and temperature had a great influence on the operating performance of electricity-generating MFC of simultaneous denitrification and carbon removal, and their optimum values were 500 mg/L, 2 000 mg/L and 35℃, respectively.

杂志排行

Asian Agricultural Research的其它文章

- Personnel Cultivation Program for Innovative and Entrepreneurial Biopharmaceutical Discipline under the Credit System

- Screening and Analysis of Cadmium-tolerant Rice Variety Resources

- Comparison of Soil Nutritional Status between Different Muscat Hamburg Vineyards in Coastal Areas of Tianjin

- Supporting Techniques for High Yield and High Quality Huayu 22 Peanut

- Drought Tolerance Identification and Eevluation of Maize during Flowering Stage in Guangxi

- The Model of "Party Branch+" in Promoting Industrial Poverty Alleviation in Poverty-stricken Mountainous Areas of China: A Case Study of Xundian in Yunnan Province