农林废弃物田间曝氧水-火联动制炭设备及技术研究

2019-07-23袁国栋毕冬雪沈冠华

校 亮,袁国栋,毕冬雪,韦 婧,沈冠华

农林废弃物田间曝氧水-火联动制炭设备及技术研究

校 亮1,2,袁国栋3,4※,毕冬雪1,2,韦 婧1,沈冠华3

(1. 中国科学院烟台海岸带研究所,中国科学院海岸带环境过程与生态修复重点实验室,烟台 264003;2. 中国科学院大学,北京 100049;3. 肇庆学院环境与化学工程学院,肇庆 526061;4. 广东大众农业科技有限公司,东莞 523169)

生物炭具备固碳减排、提升地力、修复污染土壤等功效,但其推广应用面临着成本过高的难题。为降低其生产(设备与场地的运维费用)和使用成本(原料与炭品的运输费用),该文研发田间制炭技术,将生物质就地转化为生物炭。通过水-火联动技术,可在田间曝氧环境下制备得到生物炭。研究表明,原材料特性决定着成炭的操作工艺;其中,竹柳采用单向引燃、槽面喷水控温、通孔喷雾成炭的方式进行,棉秆采用单向引燃与控温、喷水横切炭体、喷雾成炭的方式进行,芦苇采用多位点引燃、槽面和通孔同时控温、逐层分区喷雾成炭的方式进行。采用该技术制备的生物炭表现出了较好的均质性,成炭率在30%左右;同时保存了较多的营养元素,如碳质量分数介于43.49%~60.30%、氮质量分数介于0.52%~0.86%;具有丰富的表面官能团,如羧基含量介于0.98~1.09 mol/kg、酚羟基含量介于0.53~0.59 mol/kg;具有较大的比表面积,介于16.0~262.2 m2/g。竹柳、棉秆和芦苇在成炭过程中产生的烟气经尾气处理系统处理后(PM 2.5(56、66、68g/m3)、PM 10(100、114、128g/m3))均达到排放标准。该文提供的田间制炭技术操作简单、成本低且效率高。实践表明,农民在自家田里可制炭达1 t/(d·人),成本仅需162.5元/t。该文研究结果可为生物炭的推广应用提供参考。

生物质;废弃物;生物炭;水-火联动;曝氧炭化

0 引 言

生物炭是由生物质在缺氧条件下经高温裂解生成的孔状固体物质,有较大的比表面积、较多的含氧活性基团及一些植物营养元素[1]。其不仅具有改善土壤性质、提升肥力、减轻土壤污染等农艺和生态功能[2-7],也是增加土壤碳汇、减少N2O和CH4等温室气体排放的技术选项之一[8-10]。

生物炭的生产是生物炭研究和应用的前提和基础。热裂解技术和水热炭化法是当前制备生物炭的主要方法。热裂解技术采用限氧、升温炭化的方法,根据反应条件可分为:700 ℃以上的快速裂解和300~500 ℃的常规裂解[11-12];水热炭化是指利用一定温度的饱和水,在自产蒸汽压力下将生物质转化为富碳固体水热焦[13-14]。目前,生物炭产业在中国尚处培育阶段,其应用也多见于科研用途,未能在农业生产中推广使用,主要是因为采用这2种方法制备生物炭的生产成本过高[15-16],这主要体现在原料与产品的运输费用、制炭设备的购置与运行维护费用、高剂量的投加费用等多个方面[17-19]。若能在田间直接将生物质转化为生物炭,并将其应用于退化土壤的改良与污染土壤的修复,不仅能够节省秸秆收集与前处理、制炭场地与设备运行维护、炭品运输等环节的费用,还可为年产约10亿多吨的农作物秸秆的综合利用探索新的出路,又能够为提升地力、净化土壤、固碳减排等做出有益贡献[20]。

在自然状态下,有薪柴、水和火就可以制炭;无须将原料烘干、粉碎等,也无须经过漫长的高温热裂解过程。本文在深入分析自然界成炭、古人制炭以及传统田间制炭成效的基础上[21-23],经反复试验,提出了在田间曝氧条件下将农林废弃物转化为生物炭的操作方案及其配套技术。本研究以黄河三角洲地区常见的竹柳、棉秆和芦苇为原材料,研发将这些农林废弃物在田间曝氧环境下采用水-火联动方法制备生物炭的设备和技术,以期获得性能稳定的生物炭产品,旨在为生物炭的农业和环保应用提供技术支撑。

1 试验材料与方法

1.1 农林生物质原料与试验地点

本研究依托黄河三角洲地区,以当地林业局2016年冬季在林场、农田和滩地收集的该区常见的农林废弃物为生物质原料,于2017年8月在东营市河口区仙河镇黄河三角洲综合训练基地农业开发利用试验场,开展了采用水-火联动技术在田间曝氧环境下制备生物炭试验。

1.2 农林废弃物的田间制炭设备

1)砖垒制炭槽体,槽体规格:10 m×2.5 m×0.6 m(长×宽×高),砖体规格:0.5 m× 0.2 m×0.2 m(长×宽×高),槽体由砖块分3层垂向叠加垒造而成,底层与顶层砖块沿槽长方向紧密排列,中间层的每一砖块间隔0.15 m顺次排列,形成0.15 m× 0.2 m通孔,通孔在槽体两侧错位分布(便于引火后产生热压差、加速侧壁内空气流通,解决槽内深部秸秆燃烧问题),在紧邻槽体侧壁的两端,垂直于侧壁方向垒造一0.5 m长的挡墙,毗邻挡墙部位竖立砖体一块,以便控制横向通气速率[24]。农林生物质田间曝氧制炭槽体结构示意图如图1所示。2)喷雾装置:农业防虫用车带可调压式喷雾枪;3)探温仪器:红外测温仪,型号:DT-8833(北京华盛昌),量程:−50~800 ℃,分辨率:0.1 ℃;4)其他辅助设备:铁锹、铁叉。

图1 田间曝氧制炭槽体结构示意图

1.3 制炭尾气处理系统

1)集气系统:由①集气罩(规格:30 cm×40 cm,弧度1/2π)、②导气管(直径10 cm、长2.5 m空心铁皮管)、③三通阀(阀口直径10 cm,通口互成90°角,用以将集气罩和导气管串联)、④弯管(直径10 cm,90°弯角,用以连接纵梁和横梁),⑤抽气机(德鑫机械QLF50)、⑥排气管(直径10 cm、长1 m的空心铁皮管)依次连接而成[25]。

本次试验所用集气系统的纵梁经6个集气罩由6个三通阀依次串联8个2.5 m长的导气管组合而成,纵梁与横梁用4个弯管连接;其中一端的横梁经三通阀连接导气管至抽气机的进气口,抽气机的出气口连接有1 m长的排气管,共同构成本次试验的尾气收集系统,如图2所示。尾气收集及处理过程伴随着制炭过程同时进行,在进行尾气收集时,将尾气收集系统嵌套在制炭槽上,启动电动抽气机,尾气沿集气罩进入导气管,进而通过三通阀、弯管、抽气机最终进入排气管,完成尾气收集,以备尾气处理系统进行尾气处理。

2)尾气处理系统:由①机械阻隔除尘系统(烟尘过滤装置,核心部件为烟尘过滤网,沿气体走向依次为1、0.5、0.25和0.10 mm,烟尘过滤网设置在排气管的内部)、②电除尘系统(尾气燃烧再处理装置,由220 V农用直流电瓶、多组相变压器(将220 V直流电压升至10 000 V)、火线网、接地线、震荡开关等组成)、③化学除尘系统(烟尘及尾气喷淋装置,包含喷淋装置和淋洗液(饱和石灰水和饱和红黏土泥浆水))依次连接而成(图3)。

1.集气罩 2.导气管 3.三通阀 4.弯管 5.抽气机 6.排气管

1.Gas collecting cover 2.Airway 3.Three-way valve 4.Bent pipe 5.Air pump 6.Exhaust pipe

图2 烟气收集系统

Fig.2 Flue gas collection system

1.机械除尘系统 2.化学除尘系统 3.电除尘系统

1.Mechanical dust removal system 2.Chemical dust removal system 3.Electric dust removal system

注:0.5 mm、0.25 mm、0.10 mm分别为烟尘过滤网的孔径。

Note: 0.5 mm, 0.25 mm, and 0.10 mm are the diameter of apertures in the soot filter, respectively.

图3 尾气处理系统

Fig.3 Flue gas treatment system

其中,机械除尘系统用以阻隔烟尘颗粒,起过滤大颗粒的作用;电除尘装置用以引燃未充分燃烧的烟尘及气体,起促进完全燃烧的作用;化学除尘系统用以喷淋残余的烟尘颗粒和中和尾气(如CO2、SO2等)。最后,采用BR-Smart-126S便携式环境监测仪测定经尾气处理系统处理后烟气的PM 2.5、PM 10及挥发性有机碳(volatile organic carbon,VOCs)等指标的含量,监测烟气排放是否达标,烟气监测在制炭过程中每5 min进行1次,取数据平均值进行表示。

1.4 生物炭的表征分析

1)成炭率:采用炭化处理前、后物料干质量的质量差进行计算;2)灰分:样品在马弗炉中经800 ℃灰化处理4 h后其残余灰渣含量占总物料质量的百分比表征[26];3)pH值:按生物炭与去离子水质量体积比1:5混合(160 r/min下震荡24 h),静置1 h后用pH计(Five Easy Plus,METTLER TOLEDO)测定[27];4)元素组成:元素分析仪(Vario Micro cube,德国Elementar)测定;5)官能团:酸碱滴定法[28];6)比表面积测定用氮气吸附BET法在全自动比表面积和孔径分布分析仪(Autosorb-iQ,美国Quantachrome)上进行。

2 田间曝氧制炭技术

在田间用砖块垒造规格为10 m×2.5 m×0.6 m(长×宽×高)的槽体,槽体两侧错位分布的通孔起两方面作用,一方面作引火点、并在秸秆燃烧后与槽体深部秸秆、外界空气等产生热压差,加速空气流通;另一方面为木质素类秸秆成炭折断跌落于槽底后提供喷雾通道、为纤维素类秸秆成炭后分区制炭提供喷雾通道。槽体两端的挡墙和竖立砖块依据物料燃烧状况适当开闭,起加速/限制空气流通的作用。图4展示了田间曝氧环境下采用水-火联动技术制备生物炭的过程。

图4 制炭槽填料

2.1 水-火联动技术制备竹柳炭

供试竹柳树枝每槽计900 kg,其多为不规则柱状枝条,直径介于0.5~6.0 cm,长50~400 cm。将竹柳枝条随机填充至制炭槽体内,每隔20cm填充层进行踩踏压实。竹柳树枝的制炭引火过程采用槽体端口引燃的方式进行。自槽体一端用固体酒精引燃物料,受热压差的作用,明火会以类似于潮退的方式自引燃端向槽体的另一端蔓延。起初,细枝条燃烧,并在自身重力作用下节段式(5~8 cm)跌落,而粗枝条仍以明火的形式悬空燃烧;此时,启动车带喷雾器转轴,开启喷枪阀门,透过槽体两侧通孔进行首轮喷雾操作,确保跌落的细枝条成炭。随后,紧贴槽面喷射水汽,控制悬空燃烧粗枝条的明火,同时借助喷水冲击力将粗枝条表面生成的龟裂状炭体剥离,促进枝条内部木质部分的燃烧。待新一轮的枝条跌落后,沿通孔喷射水汽,确保跌落的枝条成炭,如此往复,待槽内枝条完全成炭后终止。单槽制炭用时约30 min,耗水约150 L。

2.2 水-火联动技术制备棉秆炭

供试棉花秸秆每槽计450 kg,其多为不规则柱状茎秆,直径介于1.0~2.0 cm,长60~80 cm。将棉花秸秆随机填充至制炭槽体内,每隔20 cm填充层进行踩踏压实。棉花秸秆的制炭引火过程采用槽体端口引燃的方式进行。自槽体一端用固体酒精引燃物料,受热压差的作用,明火会以类似于潮退的方式自引燃端向槽体的另一端蔓延。因棉花秸秆物料形状较为均一,明火燃烧可快速将秸秆高温裂解并齐茬式跌落。依据燃烧形式,棉花秸秆的喷雾成炭过程采用异压控水操作的方式进行。启动车带喷雾器转轴,开启喷枪阀门。将1号喷枪调至最大压力,呈雾状水汽,用以控制明火火势;将2号喷枪调至最大压力,呈柱状水体,用以截断已成炭体;将3号喷枪调至中等压力,用以喷灭跌落炭体。棉花秸秆制炭过程自引燃端至槽体末端进行,直至槽内秸秆全部成炭,单槽制炭用时约40 min、耗水约250 L。

2.3 水-火联动技术制备芦苇炭

供试芦苇秸秆每槽计600 kg,其多为规则的柱状茎秆,直径介于0.3~0.5 cm,长60~100 cm。将芦苇秸秆随机填充至制炭槽体内,每隔20 cm填充层进行踩踏压实。因芦苇秆径较小、填充紧实,芦苇秸秆的制炭引火过程采用多位点引燃的方式进行。在槽体两端及侧壁错位通孔处引燃物料,此时,点状明火会以片状形式蔓延,直至槽内与空气直接接触的物料表面完全燃烧。启动车带喷雾器转轴,开启喷枪阀门,将1、2、3号喷枪调至最大压力,呈雾状水汽。1、2号喷枪用以控制槽体左、右侧壁通孔处明火,即透过槽体两侧通孔进行喷水控火操作,3号喷枪用以控制槽面明火,即沿槽面进行喷水控火操作。三管齐下,促使暗火内延,逐层剥离成炭。该过程中,错位的通孔在暗火内延和喷水压力作用下最终被连通,将槽内物料截断为多个块区,各块区暗火继续内延,喷雾后分块区成炭。单槽制炭用时约90 min、耗水约500 L。

3 结果与分析

3.1 生物炭产率及品质表征分析

采用非接触式红外测温仪探测结果显示,同槽物料不同部位的炭体(每2 m槽长内探测1次、共计5次)和同一物料分批入槽制得的炭(同一物料在同一槽体内以相同填充量分3次制炭)的成炭温度较为均一,竹柳秸秆的成炭温度介于485~527 ℃((502±14.3) ℃),棉花秸秆的成炭温度介于487~493 ℃((491±1.8) ℃),芦苇秸秆的成炭温度介于274~282 ℃((277±3.0) ℃)。一般而言,在物源一致的条件下,生物炭的性质主要受成炭温度影响[29-34]。试验结果表明,采用水-火联动技术在田间曝氧环境下制备生物炭的成炭温度表现出了较好的同槽均一性和异槽同质性。也就是说,采用田间水-火联动曝氧技术能够制备出性能稳定的生物炭产品。

田间曝氧环境下制备的生物炭均表现出较高的成炭率(24.3%~37.4%),保存了较多的N(0.52%~0.86%)。(表1)。农林生物质于田间经水-火联动技术在曝氧环境下制备的生物炭的基本理化性质如表1所示,3种废弃物生物炭都呈现碱性pH值。更为重要的是,获得的生物炭比表面积较大(16.0~262.2 m2/g),且含有丰富的表面官能团,羧基-COOH含量介于0.98~1.09 mol/kg、酚羟基phenolic-OH含量介于0.53~0.59 mol/kg。因此,它们具备吸附剂的基本属性和较大的阳离子交换能力。

3.2 制炭成本分析

生物炭基本理化性质分析结果表明,采用水-火联动技术在田间曝氧环境下制备生成的生物炭,有较大的比表面积和丰富的官能团,显然不同于秸秆直接燃烧所得的草木灰。制炭成本是决定生物炭应用前景的关键因素,在田间曝氧环境下采用水-火联动技术来制备生物炭不仅成本低廉、效率高、产率高,生产成本仅需162.5元/t、效率达1 t/(d·人)(表2);且技术上操作简单易学,制备的生物炭质地也较为均一。

表1 田间制备的生物炭的基本理化性质

表2 田间制炭成本核算

3.3 烟气排放分析

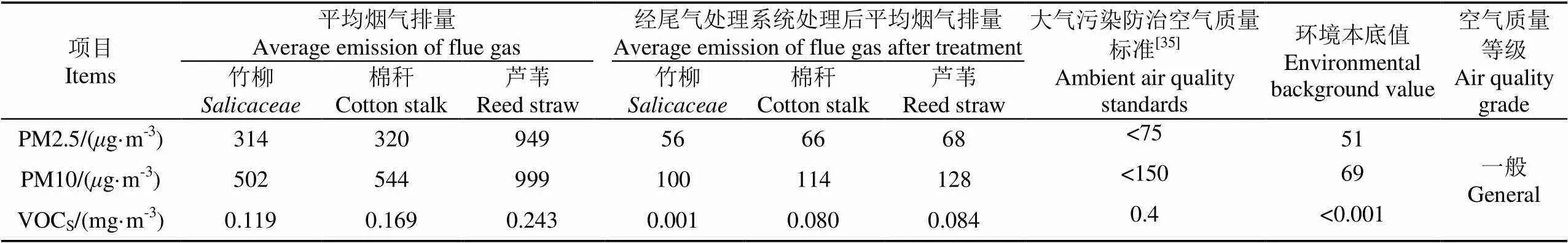

烟气收集及尾气处理系统的具体指标参数、操作规程以及运行原理详见1.3部分。尾气处理系统运行过程中,制炭烟气会经集气罩进入导气管,通过抽气机带动进入排气管。烟气经排气管后通过机械除尘、电除尘和化学除尘过程,之后排放至空气中。监测数据表明(表3),制炭烟气经尾气处理系统后,其PM 2.5、PM 10及VOCs含量均大幅降低。如竹柳在成炭过程中,PM 2.5自314降至56g/m3,PM 10自502降至100g/m3,VOCs自0.119降至0.001 mg/m3;棉秆在成炭过程中,PM 2.5自320降至66g/m3,PM 10自544降至114g/m3,VOCs自0.169降至0.080 mg/m3;芦苇在成炭过程中,PM 2.5自949降至68g/m3,PM 10自999降至128g/m3,VOCs自0.243降至0.084 mg/m3。结合空气质量标准数据,烟气经尾气处理系统后排放至大气中的烟气量符合国家大气污染管控标准,制炭过程中烟气排放对周围环境空气质量的影响在可控的范围内[35]。

表3 烟气排放情况

注:环境本底值为制炭开始前试验田块所在区域的大气污染物浓度。

Note: Environmental background value is the atmospheric pollutant concentration in the test field before biochar production.

4 讨 论

中国理论生物质资源大约为50亿t/a,其中农作物秸秆10亿多吨[20],其可再生性和有害物质(如重金属)含量低等属性使得生物质具有营养元素和有机质循环利用等生态学意义,可通过秸秆还田将有机质和养分归还至土壤。但由于秸秆直接还田会影响下季作物生长及增加土传病虫害等原因,实际上不容易推广;而秸秆炭化还田可为生物质归还土壤提供新的技术选项。

已有学者指出缺氧条件下的高温热裂解技术效率低、成本高[4,18-19],就目前而言,很难推广应用。为解决此难题,本课题组研制出了适合中国农业和环保用途的生物炭制备技术。本文研发的田间制炭设备及技术,可通过水-火联动方法在曝氧环境下将废弃生物质转化为生物炭。本技术突破了传统高温裂解技术需要建立工厂和炭炉来制备生物炭的局限,规避了原材料和生物炭产品的运输费用、省去了仓储成本、不需要昂贵的设备,制炭效率大幅提升且不再受场地的限制。该方法制成的炭品性能相对稳定,保存了较多的营养元素、含有丰富的表面官能团和较大的比表面积。

该技术能够让农民在自己的地里用自家的秸秆以易学的技术制备出生物炭,用于当地农业生产和环境修复,以实现提升地力、减轻污染等国家战略目标;也可将生物炭产品外销,变废为宝,增加农村就业、提高农民收入;助力乡村振兴和农村环境综合整治。

5 结 论

1)农林废弃物田间曝氧水-火联动制炭技术依托侧壁留有通孔的制炭槽体,辅助以水-火联动技术,可在田间实现生物质的曝氧碳化。竹柳采用单向引燃、槽面喷水控温、通孔喷雾成炭的方式进行,棉秆采用单向引燃与控温、喷水横切炭体、喷雾成炭的方式进行,芦苇采用多位点引燃、槽面和通孔同时控温、逐层分区喷雾成炭的方式进行。

2)采用水-火联动技术制备的生物炭表现出了较好的均质性,成炭率在30%左右;同时保存了较多的营养元素,碳质量分数介于43.49%~60.30%之间、氮质量分数介于0.52%~0.86%之间;具有丰富的表面官能团,如羧基含量介于0.98~1.09 mol/kg之间、酚羟基含量介于0.53~0.59 mol/kg之间;且具有较大的比表面积,比表面积介于16.0~262.2 m2/g之间。竹柳、棉秆和芦苇在成炭过程中产生的烟气经尾气处理系统处理后(PM 2.5(56、66、68g/m3)、PM 10(100、114、128g/m3))均达到排放标准。

3)田间水-火联动制炭技术简单易学、农民可操作,其生产成本仅需162.5 元/t,可为生物炭的农业和环保应用提供技术支持。

[1] Antal M J, Gronli M. The art, science, and technology of charcoal production[J]. Industrial & Engineering Chemistry Research, 2003, 42(8): 1619-1640.

[2] Johannes L, Matthias C R, Janice T. Biochar effects on soil biota: A review[J]. Soil Biology& Biochemistry, 2011, 43: 1812-1836.

[3] Gul S, Whalen J K, Thomas B W, et al. Physico-chemical properties and microbial responses in biochar-amended soils: Mechanisms and future directions[J]. Agriculture Ecosystems & Environment, 2015, 206: 46-59.

[4] Jeffery S, Bezemer T M, Cornelissen G, et al. The way forward in biochar research: Targeting trade-offs between the potential wins[J]. Global Change Biology Bioenergy, 2015, 7(1): 1-13.

[5] Tan X F, Liu Y G, Zeng G M, et al. Application of biochar for the removal of pollutants from aqueous solutions[J]. Chemosphere, 2015, 125: 70-85.

[6] Ding Y, Liu Y X, Wu W X, et al. Evaluation of biochar effects on nitrogen retention and leaching in multi-layered soil columns[J]. Water Air Soil Pollution, 2010, 213: 47-55.

[7] Wu W D, Li J H, Lan T, et al. Unraveling sorption of lead in aqueous solutions by chemically modified biochar derived from coconut fiber: A microscopic and spectroscopic investigation[J]. Science of the Total Environment, 2017, 576: 766-774

[8] Lehmann J. Bio-energy in the black[J]. Frontiers in Ecology and the Environment, 2007, 5: 381-387.

[9] Wu M X, Feng Q B, Sun X, et al. Rice () plantation affects the stability of biochar in paddy soil[J/OL]. Scientific Reports, 2015, 5: 10001. Doi: 10.10381 Screp10001

[10] 刘玉学,刘微,吴伟祥,等. 土壤生物质炭环境行为与环境效应[J]. 应用生态学报,2009,20(4):977-982.

Liu Yuxue, Liu Wei, Wu Weixiang, et al. Environmental behavior and effect of biomass derived black carbon in soil: A review[J]. Chinese Journal of Applied Ecology, 2009, 20(4): 977-982. (in Chinese with English abstract)

[11] Dinesh M, Charles U, Pittman J, et al. Pyrolysis of wood/biomass for bio-oil: A critical review[J]. Energy and Fuels, 2006, 20(3): 848-889.

[12] Wu W D, Li J H, Niazi N K, et al. Influence of pyrolysis temperature on lead immobilization by chemically modified coconut fiber-derived biochars in aqueous environments[J]. Environmental Science and Pollution Research, 2016, 23: 22890-22896.

[13] Libra J A, Ro K S, Kammann C, et al. Hydrothermal carbonization of biomass residuals: A comparative review of the chemistry, processes and applications of wet and dry pyrolysis[J]. Biofuels, 2011, 2(1): 89-124.

[14] Kang S, Li X L, Fan J, et al. Characterization of hydro chars produced by hydrothermal carbonization of lignin, cellulose, D-xylose, and wood meal[J]. Industrial & Engineering Chemistry Research, 2012, 51: 9023-9031.

[15] 袁帅,赵立欣,孟海波,等. 生物炭主要类型、理化性质及其研究展望[J]. 植物营养与肥料学报,2016,22(5):1402-1417.

Yuan Shuai, Zhao Lixin, Meng Haibo, et al. The main types of biochar and their properties and expectative researches[J]. Journal of Plant and Fertilizer, 2016, 22(5): 1402-1417. (in Chinese with English abstract)

[16] Maroušek J, Vochozka M, Plachý J, et al. Glory and misery of biochar [J]. Clean Technologies and Environmental Policy, 2017, 19(2): 311-317.

[17] 丛宏斌,赵立欣,孟海波,等. 生物质连续炭化中试系统产物特性及其运行效果评估[J]. 农业工程学报,2018,34(22):199-205.

Cong Hongbin, Zhao Lixin, Meng Haibo, et al. Product characteristics and operation evaluation of biomass continuous pyrolysis pilot-scale plant [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(22): 199-205. (in Chinese with English abstract)

[18] Blackwell P, Reithmuller G, Collins M. Biochar Application to Soil[M]//Biochar for Environmental Management: Science and Technology. London: Taylor and Francis, 2009.

[19] Saifullah, Dahlawi S, Naeem A, et al. Biochar application for the remediation of salt-affected soils: Challenges and opportunities[J]. Science of the Total Environment, 2018, 625: 320-335.

[20] 王亚静,王飞,石祖梁,等. 基于农业供给侧结构性改革背景的秸秆资源与利用研究[J]. 中国农业资源与区划,2017,38(6):13-20.

Wang Yajing, Wang Fei, Shi Zuliang, et al. Straw resources and its utilization in China from the perspective of agricultural supply-side structural reform[J]. Chinese Journal of Agricultural Resources and Regional Planning, 2017, 38(6): 13-20. (in Chinese with English abstract)

[21] Harder B. Smoldered-Earth policy: Created by ancient Amazonian natives, fertile, dark soils retain abundant carbon[J]. Science, 2006, 169(9): 133.

[22] Marris E. Putting the carbon back: Black is the new green[J]. Nature, 2006, 442(7103): 624-626.

[23] 校亮,韦婧,袁国栋,等. 田间“限氧喷雾”制备生物炭技术与炭质表征[J]. 西南大学学报:自然科学版,2019,41(6):15-20.

Xiao Liang, Wei Jing, Yuan Guodong, et al. Biochars made in the field using coupled oxygen-limiting and mist-spraying technique and their properties[J]. Journal of Southwest University: Natural Science Edition, 2019, 41(6): 15-20. (in Chinese with English abstract)

[24] 袁国栋,校亮. 一种可移动式田间原位耗氧制备生物炭的设备与方法:201711396526.6[P]. 2017-12-22.

[25] 袁国栋,校亮,冯丽蓉,等. 一种用于田间制炭尾气处理的可移动式系统及使用该系统处理制炭尾气的方法:201811229011.1[P]. 2018-12-04.

[26] 鲍士旦. 土壤农化分析[M]. 北京:中国农业出版社,2000:258-260.

[27] 王群. 生物质源和制炭温度对生物炭构效的影响[D]. 上海:上海交通大学,2013.

Wang Qun. Influence of Biomass Feedstocks and Production Temperatures on the Structure-Activities of Biochar[D]. Shanghai: Shanghai Jiao Tong University, 2013. (in Chinese with English abstract)

[28] International Humic Substances Society (IHSS). [2019-06-01]. https://www.humicsubstances.org/acidity.html.

[29] 王煌平,张青,章赞德,等. 不同热解温度限氧制备的禽畜粪便生物炭养分特征[J]. 农业工程学报,2018,34(20):233-239.

Wang Huangping, Zhang Qing, Zhang Zande, et al. Nutrient characteristics of biochar prepared from animal manures at different temperature with limited oxygen[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(20): 233-239. (in Chinese with English abstract)

[30] Katyal S, Thambimuthu K, Valix M. Carbonisation of bagasse in a fixed bed reactor: Influence of process variables on char yield and characteristics[J]. Renewable Energy, 2003, 28: 713-725.

[31] Lehmann J, Gaunt J, Rondon M. Biochar sequestration in terrestrial ecosystems: A review[J]. Mitigation and Adaptation Strategies for Global Change, 2006, 11: 403-427.

[32] Yue Y, Lin Q M, Xu Y Q, et al. Slow pyrolysis as a measure for rapidly treating cow manure and the biochar characteristics[J]. Journal of Analytical and Applied Pyrolysis, 2017, 124: 355-361.

[33] Wei J, Tu C, Yuan G D, et al. Pyrolysis temperature-dependent changes in the characteristics of biochar-borne dissolved organic matter and its copper binding properties[J/OL]. Bulletin of Environmental Contamination and Toxicology, 2018. Doi: 10.1007/s00128-018-2392-7.

[34] 刘朝霞,牛文娟,楚合营,等. 秸秆热解工艺优化与生物炭理化特性分析[J]. 农业工程学报,2018,34(5):196-203.

Liu Zhaoxia, Niu Wenjuan, Chu Heying, et al. Process optimization for straws pyrolysis and analysis of biochar physiochemical properties[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(5): 196-203. (in Chinese with English abstract)

[35] 中华人民共和国生态环境部. 中华人民共和国国家标准:环境空气质量标准:GB3094-2012[S]. 2012.

Equipment and technology of field preparation of biochars from agricultural and forest residues under aerobic conditions with water-fire coupled method

Xiao Liang1,2, Yuan Guodong3,4※, Bi Dongxue1,2, Wei Jing1, Shen Guanhua3

(1./,264003,; 2.,100049,; 3,,526061,; 4.,, 523169,)

Biochar has been reported for its beneficial effects on soil carbon sequestration, soil fertility improvement, and the immobilization of metal and organic contaminants in soils. Its large-scale agricultural and environmental application, however, is constrained by its highproduction cost in association with expensive equipment and operations and its high transportation cost of moving agricultural and forest residues to biochar production plant and delivering biochar to the end users. Exploring a technology for directed conversion from agricultural and forest residues to biochar in the field for local applications can significantly reduce the production and transportation costs of biochar, thus helping its applications.By mimicking the nature, where only agricultural and forest residues, water and fire were required for biomass carbonization and charcoal formation, a method for biochar production in the field was proposed and described in details. Briefly, this involved an aerobic process of biomass carbonization in a brick-constructed trough, and the formation of biochar by a fire-water coupled method. The carbonization process had the dual features: combustion on the surface of biomass and oxygen-limiting pyrolysis inside of the biomass. Three operational processes of aerobic carbonization and its termination were used to suit the production of biochars from different types of residues: 1) Largebranches were ignited at one direction of the trough for aerobic carbonization, followed by a water-mist spray for immediate termination of the carbonization; 2) Medium-size cotton stalk was ignited at one direction for carbonization and then sprayed by a water column to crosscut formed biochar; 3) Small hollow reed straw was ignited at multiple directions, then water mist was sprayed layer by layer on biomass. The dislocated holes on side walls of brick trough performed as ignition points, channels for water mist and air ventilation channels. The biochars produced in the field by the proposed technology were characterized in this study. The biochars were relatively homogeneous, and the conversion rates from biomass to biochar were about 30%. Carbon content of biochar was 43.49%-60.30%, and nitrogen content was 0.52%-0.86%. The biochar also contained the abundant surface functional groups, with a carboxyl group content of 0.98-1.09 mol/kg and a phenolic hydroxyl group content of 0.53-0.59 mol/kg, and the specific surface area of the biochars varied between 16.0 and 262.2 m2/g, which underpins their use as adsorbents for cations, such as ammonium ions and some heavy metals and other extraneous ions and molecules. The flue gas generated from the burning of the, cotton stalk, and reed straw in the carbonization process was treated by a multiple-step process to reduce particulate matter concentrations. PM 2.5 in the treated flue gas was reduced to 56, 66 and 68g/m3for, cotton stalk, and reed straw, respectively, and the corresponding PM 10 was reduced to 100, 114 and 128g/m3, which meet the national emission standard. The biochar preparation technology provided herein is simple to operate, low in cost, and highly efficient.Based on labor, fuel, and water inputs, the productivity was 1 t/d per person, and the cost was 162.5 yuan/t by farmers. This technology for producing low-cost biochar would make its agricultural and environmental applications feasible.

biomass; wastes; biochar;water-fire coordinated control; aerobic carbonization

2018-12-27

2019-05-28

国家重点研发计划项目(2016YFD0200303);山东省重点研发计划项目(2016CYJS05A01-1);国家自然科学基金会青年基金(41501522)及东莞市引进创新科研团队项目(2014607101003)资助

校 亮,博士生,主要从事土壤改良与修复材料研究。Email:lxiao@yic.ac.cn

袁国栋,博士,特聘教授。长期从事黏土矿物、有机质及污染物研究。Email:yuanguodong@zqu.edu.cn

10.11975/j.issn.1002-6819.2019.11.028

S2

A

1002-6819(2019)-11-0239-06

校 亮,袁国栋,毕冬雪,韦 婧,沈冠华. 农林废弃物田间曝氧水-火联动制炭设备及技术研究[J]. 农业工程学报,2019,35(11):239-244. doi:10.11975/j.issn.1002-6819.2019.11.028 http://www.tcsae.org

Xiao Liang, Yuan Guodong, Bi Dongxue, Wei Jing, Shen Guanhua. Equipment and technology of field preparation of biochars from agricultural and forest residues under aerobic conditions with water-fire coupled method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(11): 239-244. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.11.028 http://www.tcsae.org