竖壁贴附送风改善冷藏库内流场特性

2019-02-21白通通南晓红金宝红初正鹏

白通通,南晓红,金宝红,初正鹏

竖壁贴附送风改善冷藏库内流场特性

白通通,南晓红※,金宝红,初正鹏

(西安建筑科技大学建筑设备科学与工程学院,西安 710055)

流场;冷藏库;竖壁贴附送风;数值模拟;不均匀系数;能量利用系数

0 引 言

冷藏库内温度和速度的均匀性对果蔬的贮藏品质具有重要的影响。其温度的不均匀性将加剧局部果蔬的变质,风速的不均匀性将引起果蔬的干耗,从而缩短果蔬的贮藏期,降低果蔬的经济价值。而冷藏库内温度与速度分布主要取决于冷库的气流组织方式。

流场均匀性的问题一直是冷库环境调控研究的热点问题,CFD(computational fluid dynamics)模拟论证了气流组织方式对冷藏库和冷藏车内的流场分布具有重要性[1-3]。Akdemir等[4]采用CFD模拟的方法研究了冷风机送风和孔板送风方式下冷藏库内温度与相对湿度的分布,阐明了孔板送风能够有效地提高冷藏库内流场分布的均匀性。Moureh等[5]为了改善冷藏车内的换气效率和气流分布而设计了一种具有新型结构的侧向风口,并研究了其流场的分布特性,通过对比中央风口所形成的流场分布特性,发现该侧向风口可以实现更高的换气效率和更为均匀的流场。杜子峥等[6]应用计算流体动力学的方法,研究了风机的摆放位置对冷藏库内流场和温度场分布的影响。刘晓菲等[7]通过数值模拟的方法阐明了均匀送风可以有效地改善冷藏库内温度和相对湿度的分布。由此可见,合理的气流组织方式能够有效地改善冷藏库内的流场分布特性。竖壁贴附送风是在混合通风的基础上发展起来的一种新型的通风方式。该送风方式不仅能够消除围护结构传热形成的负荷,而且可以实现置换通风的效果。为此,本研究将竖壁贴附送风方式引入果蔬冷藏库,探索其在低温贮藏环境应用的特性。本文以西安市某50 t苹果冷藏库为研究对象,研究竖壁贴附送风模式下冷藏库内的流场分布特性,并与传统的冷风机直吹送风方式进行对比,以此来阐明竖壁贴附送风能够有效地改善冷藏库内的流场分布特性。

1 模型与方法

1.1 物理模型

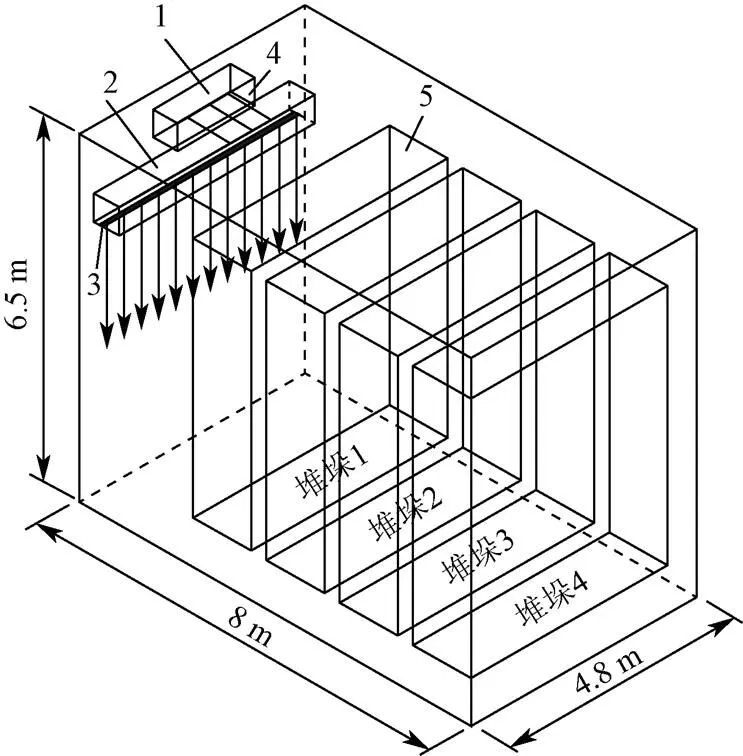

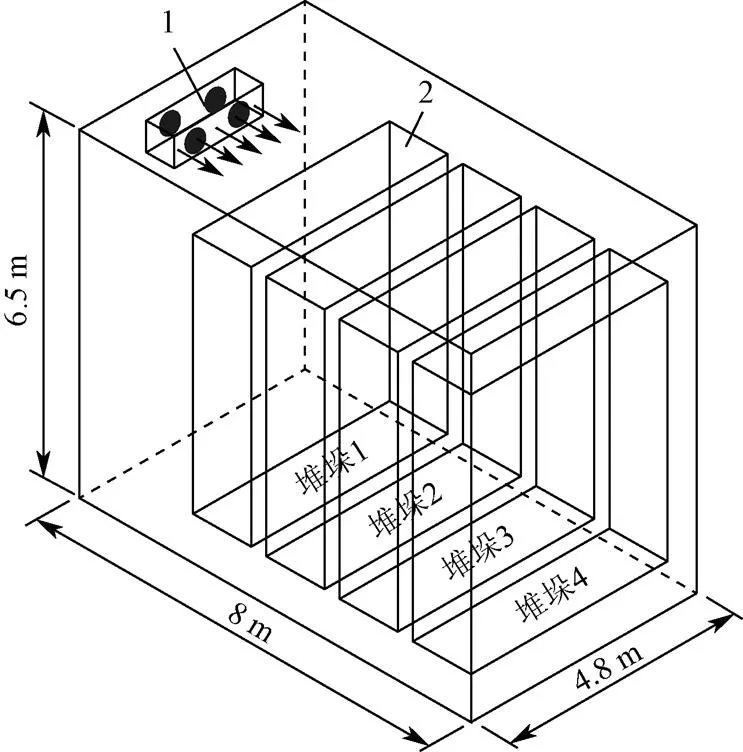

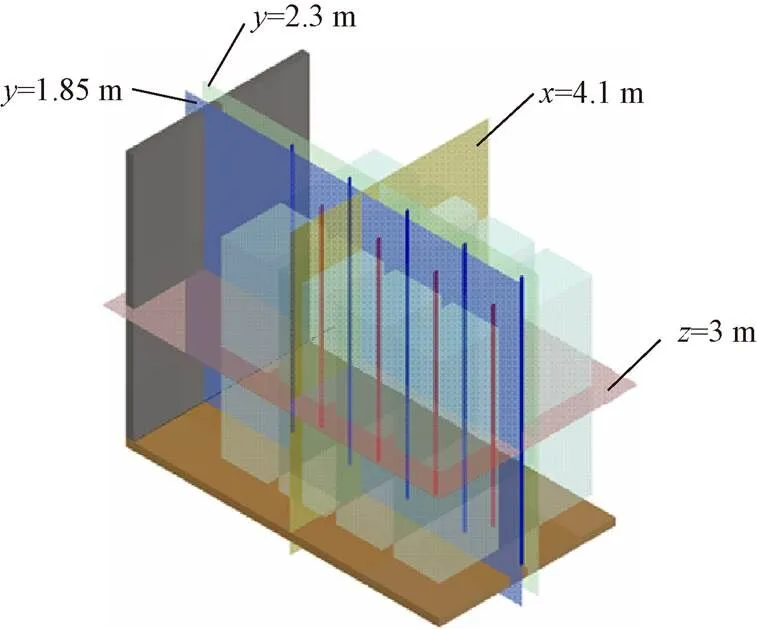

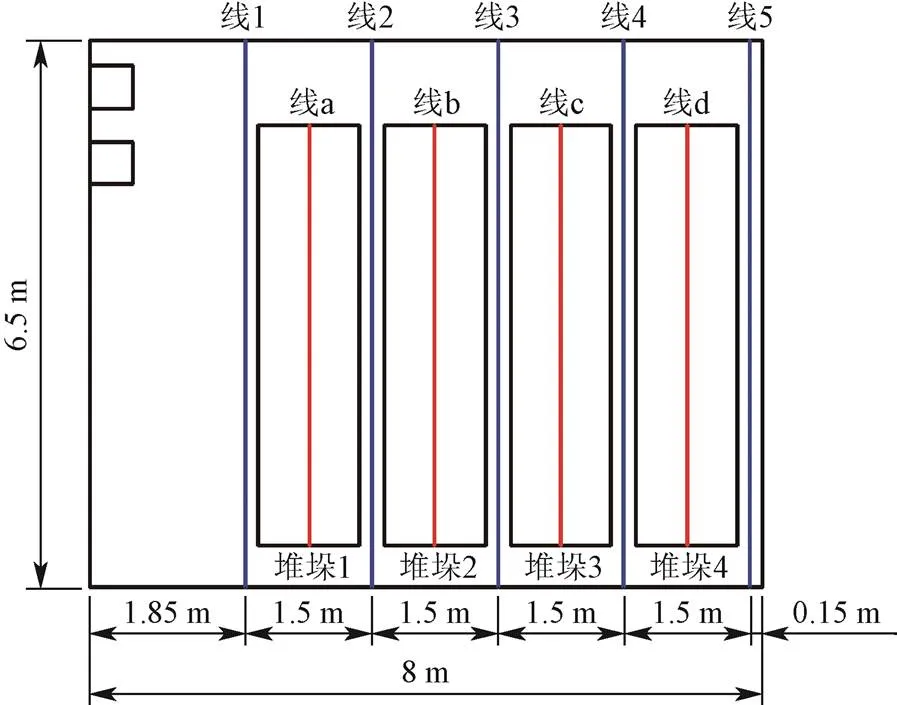

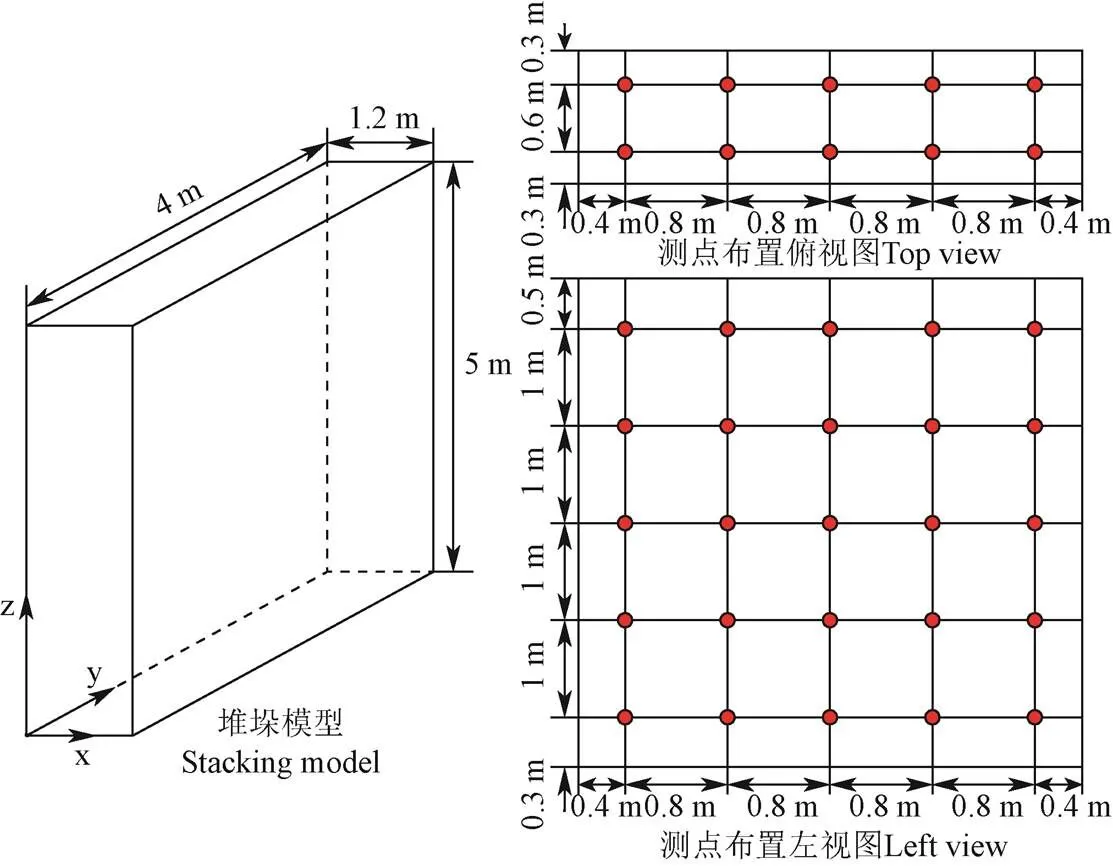

本文以50 t苹果冷藏库为研究对象,该冷藏库的尺寸为8.0 m(长)×4.6 m(宽)×6.5 m(高)。根据冷库设计规范计算该冷库的冷却设备负荷,并确定冷风机送风量。该冷风机尺寸为1.6 m(长)×0.5 m(宽)×0.5 m(高)。为了实现竖壁贴附送风,设计了一个尺寸为4.0 m(长)×0.5 m(宽)×0.5 m(高)的静压箱,该静压箱底部开设长度为4.0 m,宽度为0.1 m的条形风口用于实现向下的贴附送风。回风口设置在冷风机的侧面,回风口的长度为1.6 m,宽度为0.5 m,其物理模型如图1所示;作为对比,选择冷负荷相同、送风温差一致的冷风机直吹式冷库作为比较对象。在该冷藏库中,冷风机的送风口是2个直径为0.4 m的圆形风口,回风口位于冷风机背面,距离墙壁0.5 m,其物理模型如图2所示。

在2种送风方式下,4堆货物平行摆放。其中,每个堆垛的尺寸为4.0 m(长)×1.2 m(宽)×5.0 m(高)。堆垛间距为0.3 m,距侧墙分别为0.3 m,距地面0.5 m。

1.吊顶式冷风机 2.静压箱 3.条形送风口 4.回风口 5.货物

1.吊顶式冷风机 2.货物

1.2 数学模型

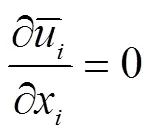

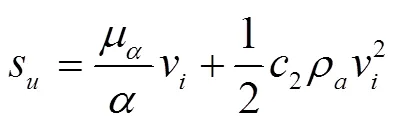

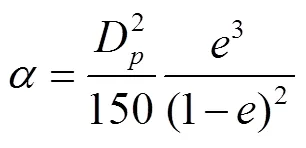

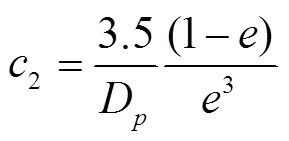

为了较为准确地反映冷藏库内的流场分布,本文采用三维不可压的雷诺平均方程对冷藏库进行建模。考虑到货物区数学模型的复杂性,相关学者将其简化为多孔介质[8-9],即在原有数学模型的基础上附加了黏性阻力和惯性阻力引起的动量源项。经过这样的简化后,该数学模型在稳态工况下的表达式如下所示[10-12]

假设空气密度仅是温度的函数,即空气密度的变化遵循Boussinesq假设,由此动量方程可以表示为

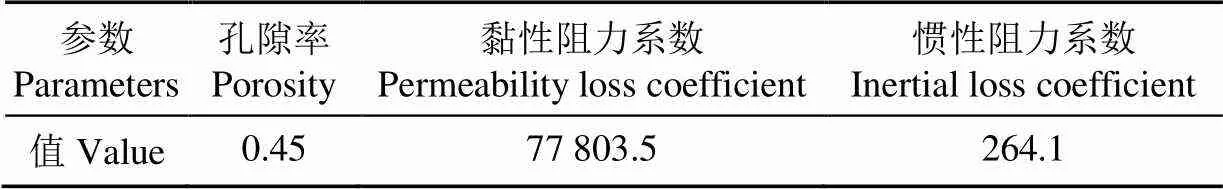

表1 多孔介质区的孔隙率及阻力系数

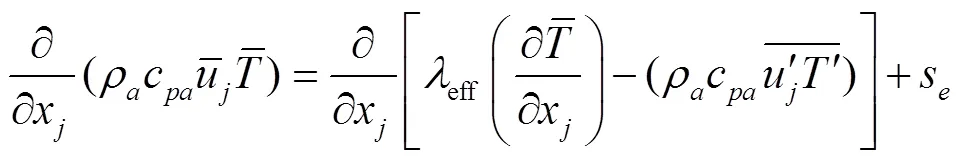

假设空气和苹果处于局部热平衡状态(空气和多孔固体基质的温度被假定为相等),则能量方程可以表示为

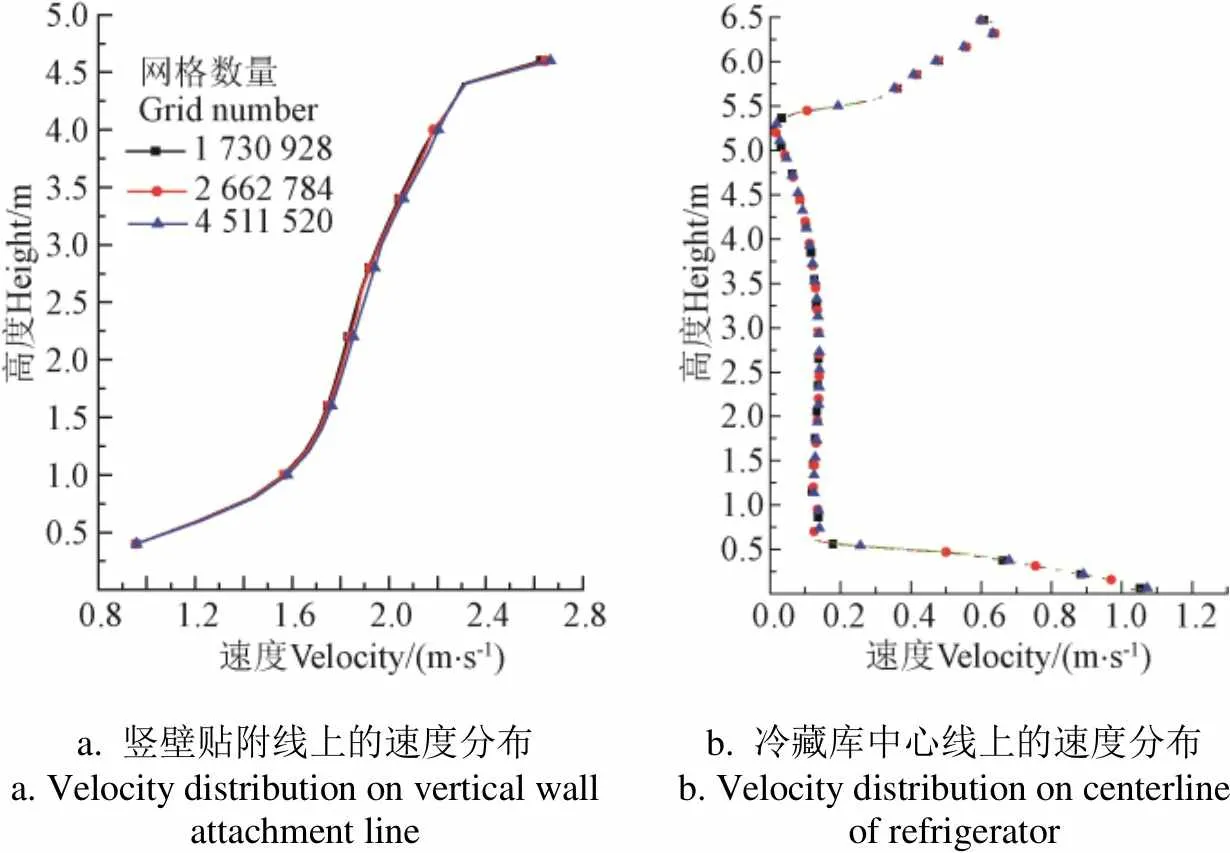

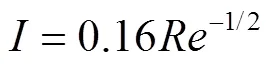

为了保证数值模拟的准确性和数学模型的可靠性,必须对其计算结果进行一定的验证。数值模拟的准确性主要取决于离散步长[19]。为了避免离散步长对数值计算的影响,本文进行了网格无关性验证。而稳态数学模型的合理性主要取决于湍流模型的选择以及边界条件的设置。本文通过选取恰当的湍流模型,设置合理的边界条件,并通过试验拟合公式对其进行了验证,来确保数学模型的可靠性。

1.2.1 网格无关性分析

a. 竖壁贴附线上的速度分布b. 冷藏库中心线上的速度分布 a. Velocity distribution on vertical wall attachment lineb. Velocity distribution on centerline of refrigerator

1.2.2 湍流模型的选择

在竖壁贴附送风中,空气在射流冲击区会发生较大的弯曲现象。而RNG、SST模型均对流体流动过程的强弯曲现象进行了考虑与修正[20]。但是,通过比较预测精度可以发现SST模型具有较好的预测性能[21]。于是,本文选取了SST湍流模型,并采用Simple算法[22]对该数学模型进行了求解。

1.2.3 边界条件的设置

2)回风口边界条件:回风口采用自由出流(outflow)边界条件,即速度在流线方向的梯度为零。

1.2.4 模型验证

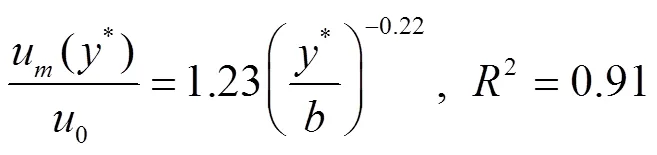

为了验证数值模拟计算的可靠性,该研究将空库状态下竖壁贴附轴线处的速度分布与尹海国[21]提出的竖壁贴附轴线处无因次速度拟合式进行了对比,其对比结果如图4所示。

由图4可知;数值模拟的无因次速度变化趋势与拟合公式的无因次速度变化趋势基本一致,其中无因次轴线速度的平均偏差为8.86%。引起该偏差的原因主要有2点:1)当无因次距离在10时,不同入口风速对应的无因次轴线速度曲线是略高于拟合曲线的,这部分的误差主要受送风速度、风口尺寸及贴附距离等因素的影响;2)当时,速度的无因次曲线是低于拟合曲线的,这部分的误差主要受限于拟合公式拟合精度。由于偏差小于9%,因此,该结果可以验证数值模拟的可靠性。

2 结果与分析

2.1 代表性截面与监测线的选取

图5 监测面的三维示意图

图6 监测线的平面布置图

2.2 流场的速度监测

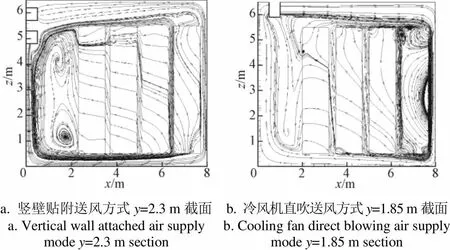

2.2.1 监测面的速度矢量

a. 竖壁贴附送风方式y=2.3 m截面 a. Vertical wall attached air supply mode y=2.3 m sectionb. 冷风机直吹送风方式y=1.85 m截面 b. Cooling fan direct blowing air supply mode y=1.85 m section

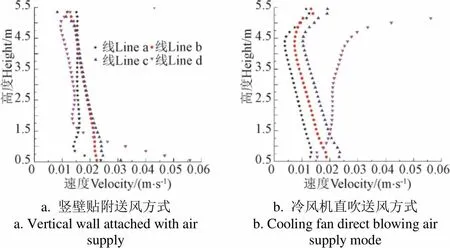

2.2.2 监测线上的速度分布

a. 竖壁贴附送风方式a. Vertical wall attached with air supplyb. 冷风机直吹送风方式b. Cooling fan direct blowing air supply mode

2.3 流场的温度监测

2.3.1 代表截面的温度监测

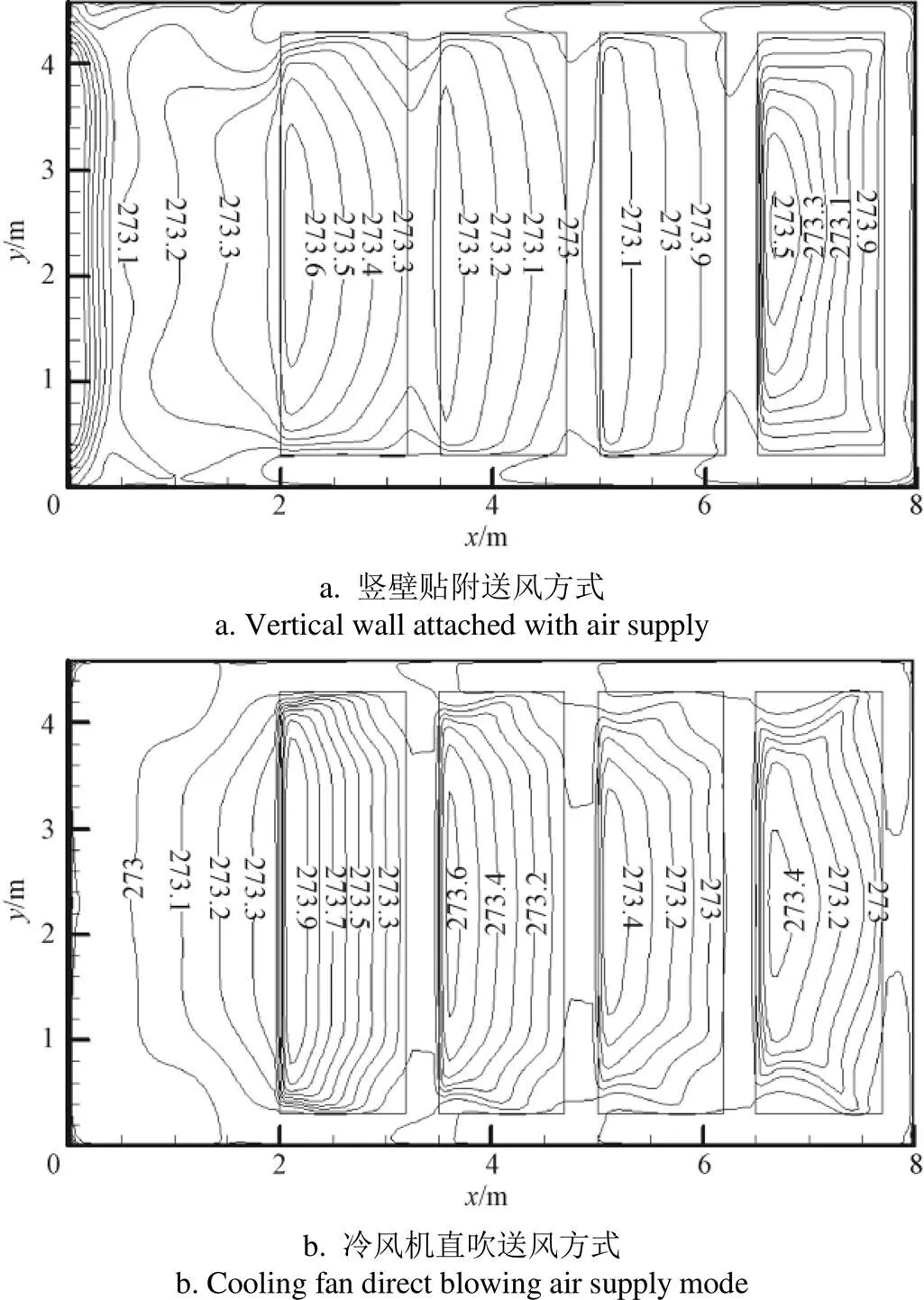

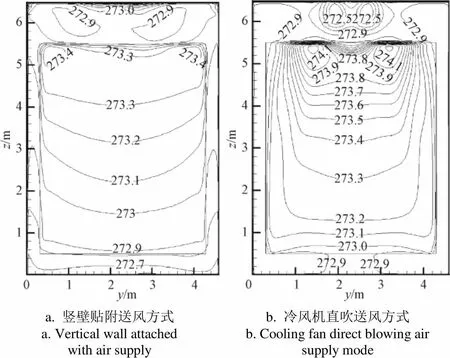

图9-10显示了2种不同送风方式下典型截面的温度分布图,从图中可以看出,2种不同的送风射流都能及时带走冷库壁面的热流量,有效抑制了壁面的传热对冷藏库贮藏环境的破坏。但是,相比冷风机直吹的送风方式,竖壁贴附送风方式形成的温度场更为均匀。在冷风直吹送风方式下,气流受送风射流的卷吸作用,使得一部分换热后的气流未被冷却又随射流进入循环,进而导致货物上部区域的温度较高。

图9 两种不同送风方式下z=3 m截面的温度(K)分布

a. 竖壁贴附送风方式 a. Vertical wall attached with air supplyb. 冷风机直吹送风方式 b. Cooling fan direct blowing air supply mode

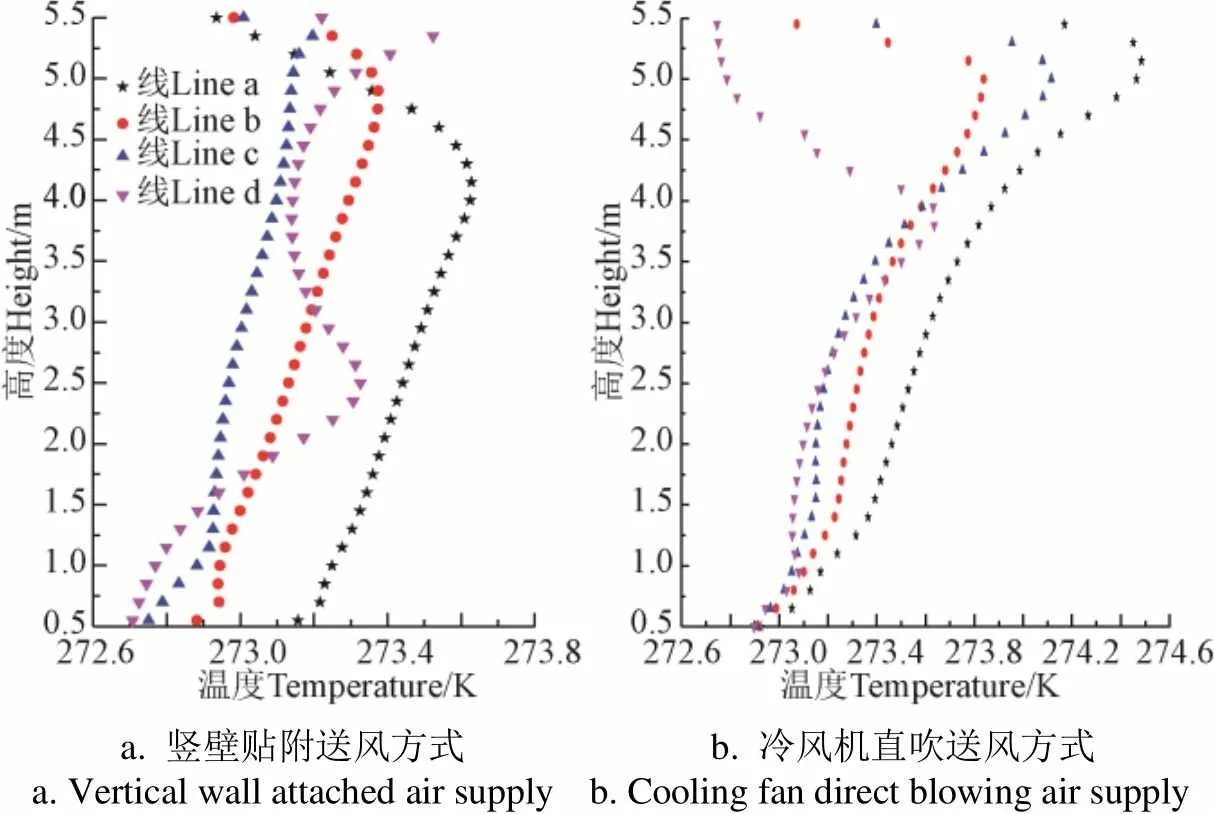

2.3.2 监测线上的温度分布

图11分别描绘了2种送风方式下堆垛中心高度方向的温度分布。从图中可以看出:2种送风方式下堆垛中心处温度变化趋势存在较大的差异。在竖壁贴附送风方式下,货物区中心线处的温度分布比较集中,主要处于273~273.4 K。而在冷风直吹的送风方式下,由于堆垛上部区域温度较高,导致货物区温度分布范围为272.8~274.4 K。主要是由于顶部射流对气流有较强的卷吸作用,使得换热后温度较高的气流向上运动形成的。

a. 竖壁贴附送风方式a. Vertical wall attached air supplyb. 冷风机直吹送风方式b. Cooling fan direct blowing air supply

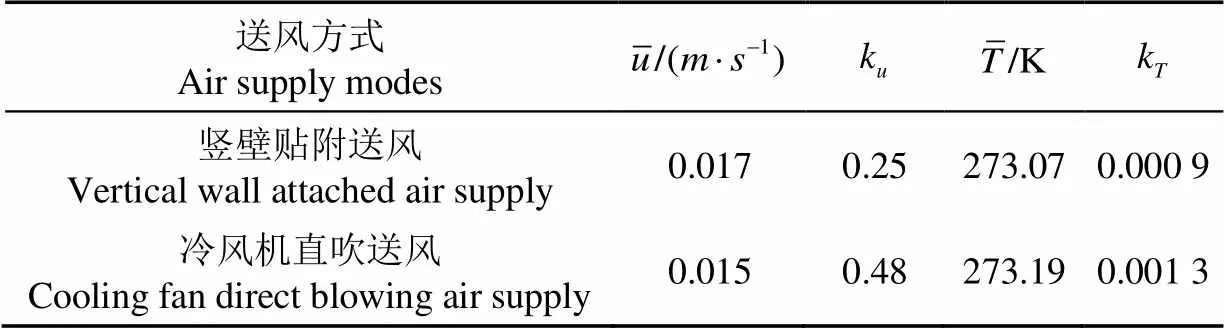

3 气流组织的评价

根据通风(空调)的目的,可以从3个方面来描述和评价气流组织:送风的有效性、污染物排除的有效性及热舒适性等相关的参数。对于冷藏库而言,货物所处的温度场、速度场以及换热的有效性应为关注重点。因此,本文选用能量利用系数和不均匀系数对2种送风方式进行综合评价。

3.1 能量利用系数

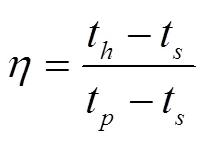

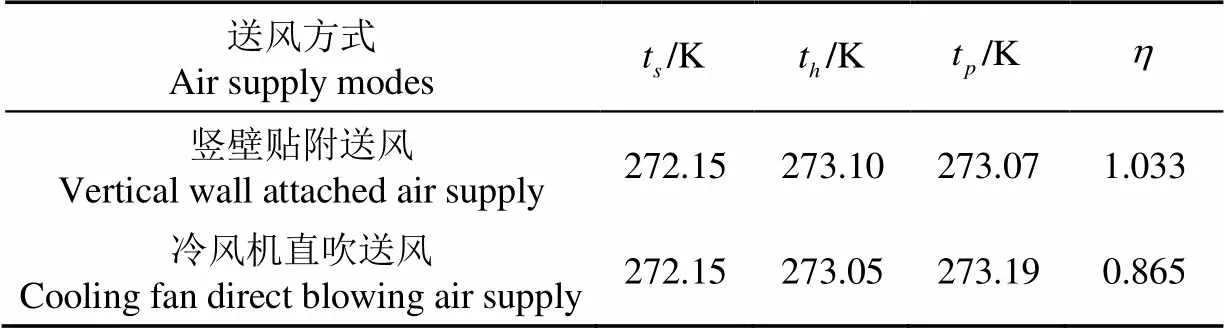

不同送风方式下库内热量移除的有效性,可以用能量利用系数来评价[23-24],其定义如下

表2 两种送风方式下的能量利用系数

注:t为送风温度,t回风温度,t货物区平均温度,能量利用系数。

Note:tis the supply air temperature,tis the return air temperature,tis the average temperature of the cargo area,is the energy utilization coefficient.

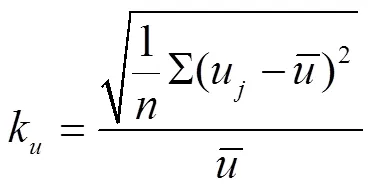

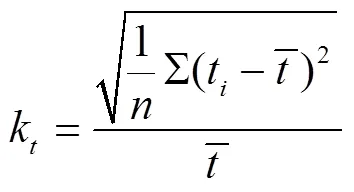

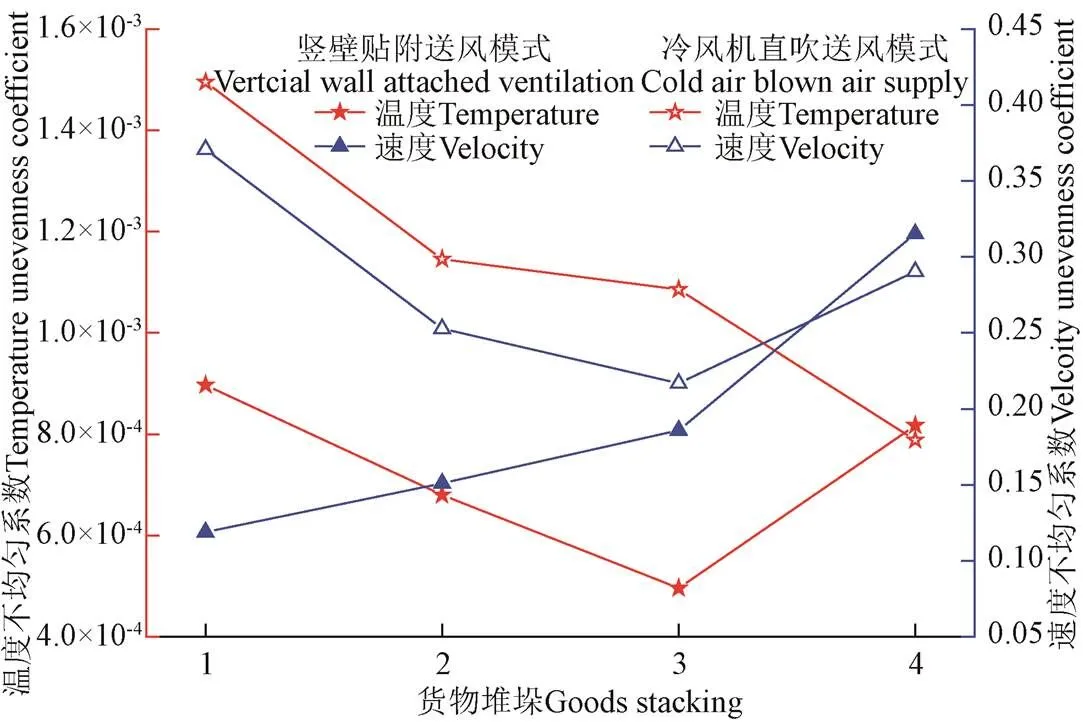

3.2 不均匀系数

冷藏库内气流组织的均匀性对果蔬的贮藏品质有着重要的影响,为此引用“不均匀系数”指标对冷藏库内的气流组织进行评价。

图12 堆垛测点分布示意图

Fig 12 Distribution diagram of stacking measurement points

图13 两种送风方式下不均匀系数的对比

表3 两种送风方式下的不均匀系数

4 结 论

本文以某苹果冷藏库为研究对象,采用数值模拟的方式,研究了竖壁贴附送风方式下冷藏库内流场的分布特性。通过与冷风机直吹送风方式的对比,证明了竖壁贴附送风模式可以形成更为均匀的速度场和温度场,并能够有效地提高送风的能量利用率。其详细结论如下:

[1]Chourasia M K, Goswami T K. Steady state CFD modeling of airflow, heat transfer and moisture loss in a commercial potato cold store[J]. International Journal of Refrigeration, 2007, 30(4): 672-689.

[2]Ho S H, Rosario L, Rahman M M. Numerical simulation of temperature and velocity in a refrigerated warehouse[J]. International Journal of Refrigeration, 2010, 33(5): 1015-1025.

[3]Tapsoba M, Moureh J, Flick D. Airflow patterns in a slot-ventilated enclosure partially loaded with empty slotted boxes[J]. International Journal of Heat and Fluid Flow, 2007, 28(5): 963-977.

[4]Akdemir S, Ozturk S, Edis F O, et al. CFD modelling of two different cold stores ambient factors[J]. IERI Procedia, 2013(5): 28-40.

[5]Moureh J, Flick D. Airflow characteristics within a slot-ventilated enclosure[J]. International Journal of Heat and Fluid Flow, 2005, 26(1): 12-24.

[6]杜子峥,谢晶,朱进林. 数值模拟技术预测风机两种摆放方式对冷库堆垛货物的影响[J]. 食品与机械,2015,31(3):145-149. Du Zizheng, Xie Jing, Zhu Jinlin. Effects of two different fans arrangement on stacking cargo in cold store based on numerical simulation[J]. Food and Machinery, 2015, 31(3): 145-149. (in Chinese with English abstract)

[7]刘晓菲,南晓红. 装设均匀送风管道对冷藏库气流流场特性的改善[J]. 农业工程学报,2016,32(1):91-96. Liu Xiaofei, Nan Xiaohong. Improvement on characteristics of air flow field in cold storage with uniform air supply duct[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(1): 91-96. (in Chinese with English abstract)

[8]Thanh V T, Van Brecht A. Vranken E. Modelling of three-dimensional air temperature distributions in porous media[J]. Biosystems Engineering, 2007, 96(3): 345-360.

[9]Ambaw A, Bessemans N, Gruyters W. Analysis of the spatiotemporal temperature fluctuations inside an apple cool store in response to energy use concerns[J]. International Journal of Refrigeration, 2016, 66: 156-168.

[10]陈宝明,刘芳,云和明. 多孔介质自然对流传热传质[M]. 北京:科学出版社,2016.

[11]Antohe B V, Lage J L. A general two-equation macroscopic turbulence model for incompressible flow in porous media[J]. International Journal of Heat and Mass Transfer, 1997, 40(13): 3013-3024.

[12]Nakayama A, Kuwahara F. A Macroscopic turbulence model for flow in a porous medium[J]. Journal of Fluids Engineering, 1999, 121(2): 427-433.

[13]冯坤旋,南晓红,杨巧银. 果蔬冷库进货期间货物温度稳定性的影响因素[J]. 农业工程学报,2015,31(20):294-300. Feng Kunxuan, Nan Xiaohong, Yang Qiaoyin, et al. Factors on goods temperature stability in fruits & vegetables cold storage during the loading process[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(20): 294-300. (in Chinese with English abstract)

[14]Ansys Fluent, User’s Guide Southpointe[M]. ANSYS Inc, 2015.

[15]杨昭,徐晓丽,李喜宏. 保鲜库三维非稳态流场模拟及实验[J]. 天津大学学报,2007,40(2):157-162. Yang Zhao, Xu Xiaoli, Li Xihong. Simulation and Experiment on the unsteady 3D flow field of cool store[J]. Journal of Tianjin University, 2007, 40(2): 157-162. (in Chinese with English abstract)

[16]Lisowa H, Wujec M, Lis T. Influence of temperature and variety on the thermal properties of apples[J]. International Agrophysics, 2002, 16(1): 43-52.

[17]Delele M A, Schenk A, Tijskens E, et al. Optimization of the humidification of cold stores by pressurized water atomizers based on a multiscale CFD model[J]. Journal of Food Engineering, 2009, 91(2): 228-239.

[18]Hoang H M, Duret S, Flick D, et al. Preliminary study of airflow and heat transfer in a cold room filled with apple pallets: Comparison between two modelling approaches and experimental results[J]. Applied Thermal Engineering, 2015, 76: 367-381.

[19]Cheng Y, Niu J, Liu X, et al. Experimental and numerical investigations on stratified air distribution systems with special configuration. Thermal comfort and energy saving[J]. Energy and Buildings, 2013, 64(5): 154-161.

[20]王烨. 封闭腔内湍流自然对流换热及工程应用[M]. 北京:科学出版社,2015.

[21]尹海国. 条缝型送风口竖壁贴附射流气流组织设计方法研究[D]. 西安:西安建筑科技大学,2012. Yin Haiguo. Study on Design Procedures of Air Distribution by Air Curtain Ventilation with A Linear Slot Diffuser[D]. Xi’an: Xi´an University of Architecture and Technology, 2012. (in Chinese with English abstract)

[22]谢晶,瞿晓华,徐世琼. 冷藏库内气体流场数值模拟与验证[J]. 农业工程学报,2005,21(2):11-16. Xie Jing, Qu Xiaohua, Xu Shiqiong. Numerical simulation and verification of air flow in cold-store[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2005, 21(2): 11-16. (in Chinese with English abstract)

[23]Rhee K, Shin M, Choi S. Thermal uniformity in an open plan room with an active chilled beam system and conventional air distribution systems[J]. Energy and Buildings, 2015, 93: 236-248.

[24]Michal Krajčík, Angela Simone, Bjarne W. Air distribution and ventilation effectiveness in an occupied room heated by warm air[J]. Energy and Buildings, 2012, 55: 94-101.

[25]Zhang Y, Liu J, Pei J. Performance evaluation of different air distribution systems in an aircraft cabin mockup[J]. Aerospace Science and Technology, 2017, 70: 359-366.

[26]Li A G, Liu Z J, et al. Reduced-scale model study of ventilation for large space of generatrix floor in Hohhot underground hydropower station[J]. Energy and Buildings, 2011, 43(4): 1003-1010.

Improvement on characteristics of air flow field in cold storage with vertical wall attached ventilation

Bai Tongtong, Nan Xiaohong※, Jin Baohong, Chu Zhengpeng

(710055)

During the storage of fruits and vegetables, the uniformity of air distribution inside the cold storage store is crucial to affect both the storage quality of fruits or vegetables and energy efficiency of supply air. In the traditional cooling fan direct blowing air supply mode, some local air velocities and temperatures are easily to be larger than those required for cargo area, which would greatly reduce the uniformity of air distribution and the storage quality of fruits and vegetables. Therefore, the reasonable airflow organization is critical to the air distribution of the cold storage and must be carefully considered. In order to improve the uniformity of indoor air distribution, the study introduced the vertical wall attached ventilation which originated applied for indoor climate control of public buildings. To investigate the flow characteristics of the vertical wall attached ventilation, a three-dimensional SSTsolution model was established to study the distribution characteristics of the flow field and the cooling effect of the stored cargo. According to the practical array of the stored apples, the cargo area was regarded briefly as porous medium zone. In order to ensure the accuracy of the numerical calculation and the rationality of the mathematical model, grid independence verification and experimental verification were carried out. The accuracy of numerical calculation was studied by comparison with some accepted correlations and the rationality of the mathematical model was proved. The velocity distribution and temperature distribution of typical sections were monitored to illustrate the air flow pattern and temperature distribution characteristics under the vertical wall attached ventilation mode. Meanwhile, compared with the traditional air supply by cooling fan for direct blowing, it was clarified that the vertical wall attached ventilation could form a more uniformly temperature distribution and velocity distribution on the monitoring section and monitoring line. However, the air distribution of monitoring section and monitoring line could not fully reflect the overall temperature and velocity distribution inside the cold storage. Furthermore, the air distribution evaluation index was introduced and calculated in order to fully understand the temperature distribution characteristics of the studied cold storage room. First of all, in order to reflect the uniformity of air distribution, the non-uniformity coefficient of temperature and non-uniformity of velocity were introduced. According to the temperature and velocity values of 40 measuring points in each stack, the velocity non-uniformity coefficient and temperature non-uniformity coefficient were calculated under two air distribution modes. It was manifested that the vertical wall attached ventilation enabled non-uniformity coefficient of temperature and non-uniformity of velocity to decrease by 31% and 47%, respectively at the same air supply flow rate and temperature. Secondly, to evaluate the energy utilization of the air supply, the energy utilization efficiency of the two modes was calculated from monitoring air supply temperature, air return temperature and average temperature in the cargo area. It was indicated that the vertical wall attached ventilation made the energy utilization increase by 19% due to the more sufficient heat exchange between the air and cargo. Since the vertical wall attached ventilation can form a more uniform air distribution under a higher energy utilization rate, it can effectively improve indoor air distribution characteristics and well meet the storage requirements of fruits and vegetables.

flow field; cold storage store; vertical wall attached ventilation; numerical simulation; non-uniformity coefficient; energy efficiency

白通通,南晓红,金宝红,初正鹏. 竖壁贴附送风改善冷藏库内流场特性[J]. 农业工程学报,2019,35(22):331-337. doi:10.11975/j.issn.1002-6819.2019.22.039 http://www.tcsae.org

Bai Tongtong, Nan Xiaohong, Jin Baohong, Chu Zhengpeng. Improvement on characteristics of air flow field in cold storage with vertical wall attached ventilation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(22): 331-337. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.22.039 http://www.tcsae.org

2019-04-14

2019-10-05

陕西省自然科学基础研究计划项目(2018JM3038)

白通通,研究方向为冷藏库内气流组织的数值模拟。Email:1910686979@qq.com

南晓红,教授,博士,主要从事制冷技术领域的科研与教学工作。Email:nanxh@xauat.edu.cn

10.11975/j.issn.1002-6819.2019.22.039

TB61+1

A

1002-6819(2019)-22-0331-07