National Standard of China—Industrial Linear Alkylbenzene

2018-10-22

Foreword

This standard is drafted in accordance with the rules given in the GB/T 1.1-2009. It was issued on 29 Dec. 2017,and implemented on 1 Jul. 2018.

This standard replaces the GB/T 5177-2008 Industrial lineal alkylbenzene. The following deviations have been made with respect to the GB/T 5177-2008.

——The addition of the request for content of lineal alkylbenzene;

——The addition of the analytical method for the determination of lineal alkylbenzene.

This standard was proposed by China National Light Industry Council.

This standard was under the jurisdiction of National Technical Committee 272 on Surfactant and Detergent of Standardization Administration of China.

This standard was drafted by SINOPEC Jinling petrochemical corporation, Productivity promotion center of surfactants and detergents, China research institute of daily chemical industry.

The drafters of this standard are Huang Aizhong,Wang Wanxu, Li Xiaohui.

The previous editions of this standard are as follows:

— GB/T 5177.1-1993, GB/T 5177.2-5177.4-1985, GB/T 5177.5-2002;

— GB/T 5177-2008.

Scope

This standard specifies the technical requirements, test methods, inspection rules, labeling, packaging, transport,storage of industrial lineal alkyl benzene product.

This standard is applicable to industrial lineal alkylbenzene products manufactured by dehydrogenation process and cracking process, and typically used in the production of synthetic detergent.

Normative references

The following referenced documents are indispensable for the application of this document. For dated references,only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

GB/T 614 Chemical reagent—General method for the determination of refractive index;

GB/T 1884 Crude petroleum and liquid petroleum products—Laboratory determination of density—Hydrometer method;

GB/T 6536 Standard test method for distillation of petroleum products at atmospheric pressure;

GB/T 6682 Water for analytical laboratory use—Specification and test methods;

GB/T 11275 Surface active agents—Determination of water content;

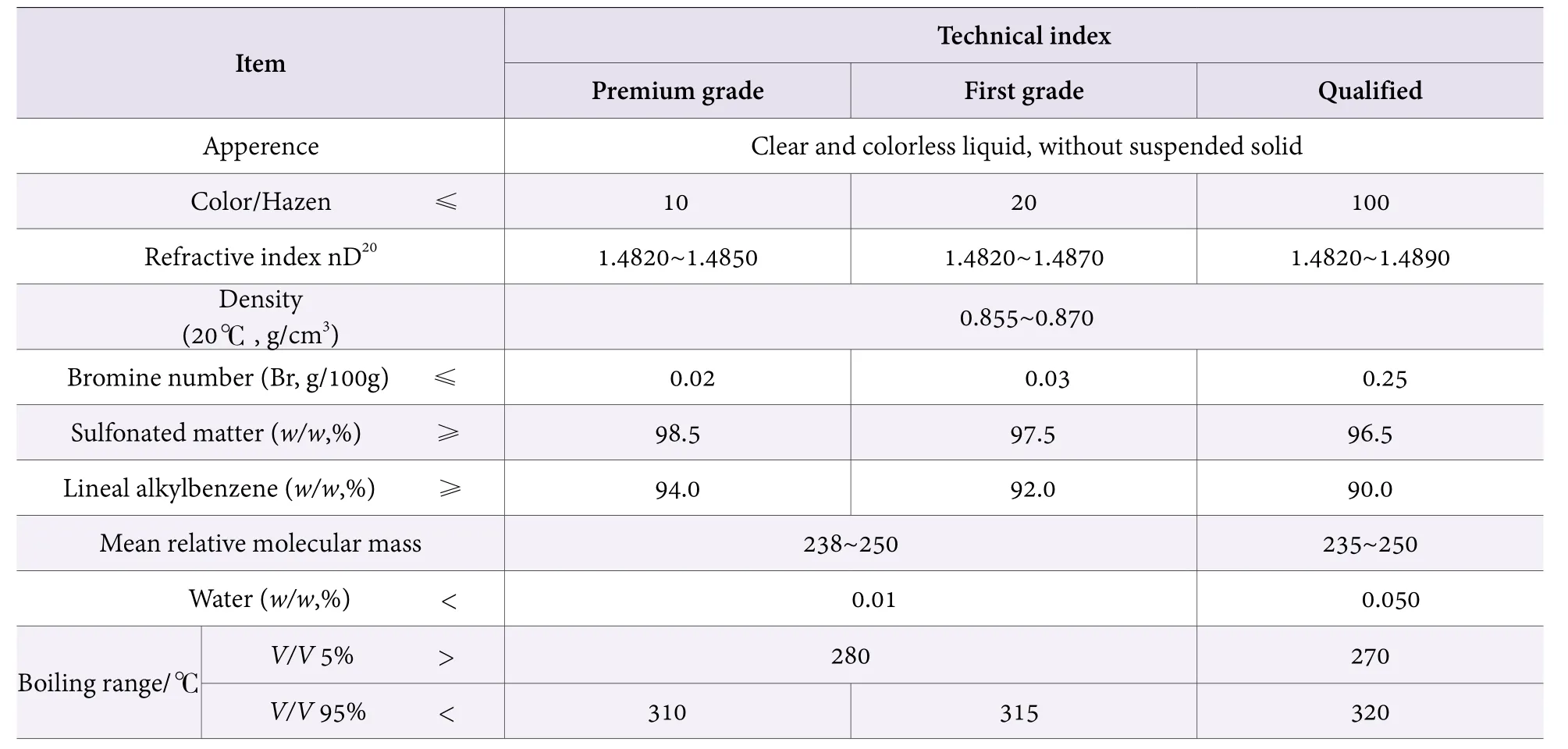

Table 1. Specification of industrial lineal alkylbenzene

GB/T 15818 Test method for biodegradability of surfactants.

Product formula

The formula of industrial lineal alkylbenzene is R-C6H5(R is an alkyl group with average carbon number of 12)

Specification

Physico-chemical specifications of industrial lineal alkylbenzene

Physico-chemical specifications of industrial lineal alkylbenzene shall conform to specifications in Table 1.The industrial lineal alkylbenzene product manufactured through dehydrogenation process shall not be less than the index of first grade.

Biodegradability

The 7 day primary biodegradation of sodium alkylbenzene sulfonate, produced by industrial lineal alkylbenzene, after sulfonation and nuetrilization, shall not less than 90%.

Test method

Unless otherwise specified, during the analysis, use only reagents of recognized analytical grade and only water confined to the grade 3 in GB/T 6682.

Appearance

Visual inspection. Put the sample in beaker or glass bottle, visually identify the appearance at 25℃.

Color

Determine in accordance with Annex A.

Refractive index

Determine in accordance with GB/T 614.

Density

Determine in accordance with GB/T 1884.

Bromine number

Determine in accordance with Annex B.

Sulfonated matter

Determine in accordance with Annex C.

Mean relative molecular mass

Determine in accordance with Annex D.

Water

Determine in accordance with GB/T 11275.

Boiling range

Determine in accordance with GB/T 6536.

Biodegradability

Determine in accordance with GB/T 15818.

lineal alkyl benzene

Determine in accordance with Annex E.

Inspection rules

Inspection classification and items

1) Type inspection

Type inspection shall cover all the items in Table 1. Type inspection shall be conducted under following situations:

a) Any change or abnormality in raw materials,production processes, manufacturing equipment and production management (including personnel quality)that may affect the quality of the products.

b) Type inspection shall be conducted once a year under regular production, or when the lineal alkylbenzene content less than 92.0%.

c) Resume production after long-time shutdown.

d) Big differences between the results of routine inspection and the latest type inspection.

e) Requested by quality supervision organizations or national management authority.

2) Routine inspection

Routine inspection shall cover all the items in Table 1.

Batch and sampling

1) Batch

Industrial lineal alkylbenzene products shall be delivered and inspected in batch. The product with the same specification and same batch number forms one delivery lot.

The products can leave the factory only if they’ve been deemed qualified as specified in this standard and the Certificate of Analysis has been issued by the quality control department of the factory. The Certificate of Analysis shall include the following items: name of manufacturer,product name, brand trade mark, standard code, quality grade, lot number, batch size, quality index, production date, etc.

The consignee shall complete acceptance inspection based on the Certificate of Analysis. If necessary, conduct sampling and inspection or arbitration within a month according to sampling rules.

2) Sampling

Based on the number of tank(truckload, shipload)or barrel, when batch size greater than 1, determine the sample size according to Table 2 for truckload or shipload product, and according to Table 3 for barreled product,and sample randomLy from the batch.

For tank with uniform cross section, take out the sample liquid equally and respectively in the depth of the 1/6,1/2, 5/6 of the liquid level, combine each proportion and make the entire sample.

For the train tank and truck tank, sampling at the depth of half level.

Table 2. Batch Quantity and Sample Size for truckload or shipload product

Table 3. Batch Quantity and Sample Size for barreled product

During sampling, take out totally 3 kg of sample, from each sampling package equally, and fill into 3 clean and dry bottles with stopper. Properly seal and label the bottle with product name, grade, lot number, manufacturer name, sampling date and the name of sampling person. Both consignor and consignee keep one bottle for inspection,the third one shall be kept by consignor for arbitration if necessary. The sample shall be kept in dark place and storage time shall not exceed one month.

Decision rules

The inspection results shall be rounded off according to the technical requirements to determine whether the product is qualified or not. In cases of at least one unqualified item found in the results, resampling from a double sample size is necessary for the reinspection test of unqualified item. The batch can be deemed unqualified as the reinspection results do not conform to this standard.

Arbitration

If the inspection results of consignor and consignee are differ from each other, and agreement cannot be reached by two parties through negotiation, two parties may request arbitration inspection. The result of the arbitration inspection shall prevail.

Labeling, packaging, delivery and storage

Labeling

1)The label on the packaging barrel shall be legible and straight, declaring:

a) Product name, trademark, grade and standard code;

b) Production date or lot number;

c) Net weight and gross weight;

d) Warnings (Avoid water and damp, etc.);

e) Name, address and contact number of manufacturer.

The patterns and words on the label shall be clear,without decolorization, water-proof and oil- proof.

Packaging

The industrial lineal alkylbenzene shall be packed with special tank (truck or ship) which do not affect the quality of product, or clean container with enough strength and non-corrosion.

Leave appropriate margin when filling the products into the container according to environmental temperature.Seal well. The net weight shall conform to the nominal mass.

Delivery

The product shall be properly covered during delivering. Avoid sunlight, moist and rain. Load and unload appropriately, prevent from damage.

Storage

The product shall be stored in a dry and clean storehouse with sealed side up. If storage in open air is inevitable,cover the container to avoid sun exposure, moist, rain and package damage.

杂志排行

China Detergent & Cosmetics的其它文章

- Tmall Global Encourages Italian Beauty Brands to Enter the Chinese Market

- China Acid-based Surfactant Forum 2018 Held in Changsha

- JD.Com Will Admit Unilever into Its Warehousing, Logistics Networks

- BASF to Establish $10b Site in Guangdong

- Major Industry Events

- China’s makeup supplier Beukay Cosmetics Sets Its Sights on International Markets