水泵水轮机甩负荷过程流动诱导噪声数值模拟

2018-10-19毛秀丽孙奥冉GiorgioPavesi葛新峰

毛秀丽,孙奥冉,Giorgio Pavesi,郑 源,葛新峰

水泵水轮机甩负荷过程流动诱导噪声数值模拟

毛秀丽1,孙奥冉2,Giorgio Pavesi3,郑 源4,葛新峰4

(1. 西北农林科技大学水利与建筑学院,杨凌 712100;2.安徽省水利水电勘测设计院,合肥 230088;3. 帕多瓦大学工业工程学院,帕多瓦 35131;4. 河海大学水利水电学院,南京 210000)

为研究水泵水轮机甩负荷过程压力脉动特性及其流动诱导噪声,该文基于网格壁面滑行技术和DES湍流模型,对水泵水轮机发电工况下导叶关闭过程进行连续性模拟,并将流场叶片表面压力脉动信号作为声场流动诱导噪声计算声源,通过对压力脉动特性和流动诱导噪声分析得到:导叶进出口处2个无叶区内压力脉动主频位置均在叶频为斯特劳哈尔数等于0.051与1处,导叶出口处频谱值是进口处10倍之上,说明动动干涉对流态的影响强于动静干涉;当尾水管内出现2个反向旋壁涡带时,压力脉动最强烈且其幅值最大。声场分析结果表明外场噪声的主频由压力脉动主频与壳体固有频率综合决定,声压分布具有“∞”形式的指向形态,且各阶叶频处声压分布呈现出明显的对称性,说明叶片噪声辐射具有明显的偶极子特性;在一阶、二阶叶频处,导叶关闭前一半阶段,流量对于外场噪声辐射能力的影响表现为大流量工况下最强,小流量工况下最弱,导叶关闭后一半阶段正好相反。

压力;叶轮;噪声;水泵水轮机;甩负荷过程

0 引 言

抽水蓄能电站机组运行稳定性一直是当下业内研究的热点和难点所在,而机组过渡过程是影响其稳定运行的一个重要因素[1]。尤其近年来新能源的蓬勃发展,抽蓄机组需要更频繁的在水泵和水轮机工况之间切换以满足电网的需求[2]。水泵水轮机在过渡过程中运行时,内部复杂流态可量化表现为压力脉动现象,用以反映机组稳定性[3-4],因而对水泵水轮机过渡过程计算研究意义重大。针对上述问题已有一定研究[5-7],然而前人的工作主要从流场角度分析[8-9],对于机组稳定运行所开展的工作较少,为改善抽蓄机组运行稳定性及控制其诱导噪声辐射水平,本文对水泵水轮机内部压力脉动特性及其引起的流动诱导噪声进行深入研究,以期对抽水蓄能机组过渡过程运行稳定性提供一些技术指导。

国内外学者针对水力机械内部非定常压力脉动及其流动诱导噪声开展了相关工作,Kuethe[10]在其专利中介绍了控制喷气式发动机、压缩机、涡轮机等的噪音和不稳定性;Kato等[11]将流体流动和结构的单向耦合模拟运用到预测五级离心泵外表面辐射噪声中;Jiang等[12]使用平行显式动态有限元模拟了泵结构的振动,阐明了共振噪声产生和传播的机制;Abbot等[13]通过分析一台35 MW水泵水轮机气蚀噪声检测结果,说明了测量的噪声水平应与单元的空化侵蚀速率特性成比例,从而通过噪声量确定空蚀损失;Yang等[14-15]结合计算流体力学与计算声学对离心泵内外场的噪声进行研究,得到截面区域声压峰值和压力脉动峰值位置对应;Opperwall等[16]结合有限元与边界元模型,研究了流体噪声源对液压泵和电机产生的空气噪声影响;王宏光等[17]模拟了轴流泵流场和声场分布,并分析了有泵壳振动影响和无泵壳振动影响下泵壳体边界声场分布;郑源等[18]采用间接边界元法对由叶片旋转偶极子源所引起的外场噪声进行数值计算;司乔瑞[19]分析了离心泵低噪声在水力设计中可优化项等。上述针对水力机械内部压力脉动特性以及流动诱导噪声的研究主要集中于离心泵、轴流泵和混流泵,然而鲜有文章针对水泵水轮机压力脉动特性对流动诱导噪声的影响进行研究,尤其是在过渡过程。

由于试验研究中对水泵水轮机整体内部流场不能做到完全可视化,且在机组长期运行后,磨损使得导叶关闭状态相邻导叶体不能完全贴合接触等原因,数值模拟方法成为研究水泵水轮机甩负荷过程的主要手段。此外,随着高性能计算机的快速发展,计算流体力学技术被广泛应用于各行各业,数值计算模拟研究方法具有省时高效、节约成本、全可视化等优势,使得其成为当下研究水力机械的主要手段,已有大量文献表明CFD数值模拟研究方法的可靠性[19-21]。

综上所述,本文将以水泵水轮甩负荷过程作为研究对象,采用CFD数值模拟方法分析其流场压力脉动特性,并以流场数值计算结果叶片表面压力脉动信号作为声场流动诱导噪声的计算声源,进一步研究声场噪声辐射及指向性分布。

1 计算模型及方法

1.1 几何模型和网格划分

如图1a所示为本文研究对象水泵水轮机三维模型图,其包含进水管道、带11个固定导叶的前导叶域、带22个导叶的活动导叶域、带7个后倾式三维叶片的转轮域(转轮进口直径=0.4 m)和出水管道,比转速n=37.2。六面体结构化网格被用于划分整体流道,所有叶片区域均采用O-Block结构,在ICEM中生成5套非结构化网格,通过网格无关性检验后发现当总网格数大于1 200万时,所求得水头波动小于0.45%,为了捕捉到相关量的变化细节,最终划分总网格数为1 400万,其中前导域的网格数500万,活动导叶域395万,转轮域373万[22],图1b所示为部分区域网格图。

图1 水泵水轮机模型与网格

1.2 湍流模型及其边界条件

DES模型是对雷诺时均N-S方程(reynolds averaged navier stokes equations,RANS)模型的修改,其能够对于大涡模拟(large eddy simulation,LES)计算足够精细的区域切换到亚格子尺度公式,然而对于靠近边界区域与湍流长度尺度小于最大网格尺寸的区域,均和RANS模型处理方式相同。因此,DES模型求解计算湍流流动比LES模型需要的计算量少,但比RANS模型或者其他湍流模型更能准确的捕捉流场细节[23]。DES湍流模型具体控制方程见文献[24],其已被成功运用于一系列工程案例,结果表明该模型对流域存在显著分离的模拟计算相对其他模型更为准确[24-26]。因此本文采用计算中选用分离涡模拟(detached eddy simulation,DES)湍流模型[22],借由商业软件 ANSYS CFX 16.1对水泵水轮机甩负荷过程进行数值模拟计算。

进水管道进口设置总压(total pressure),出水管道出口设置为Opening(子选项选择entrainment),流道壁面均设置为无滑移壁面,不同过流部件间设置交界面(GGI),在动静过流部件之间,稳态计算设置冻结转子交界面(FRI),瞬态计算设置瞬态动静交界面(TR/SI)。时间步长采用二阶隐式离散,且步长对应转轮旋转1度,每步循环计算的最大次数为5,主要变量收敛阶级为5阶。同时,为保证准确求解动态特性,数值模拟计算中库朗数要低于3。

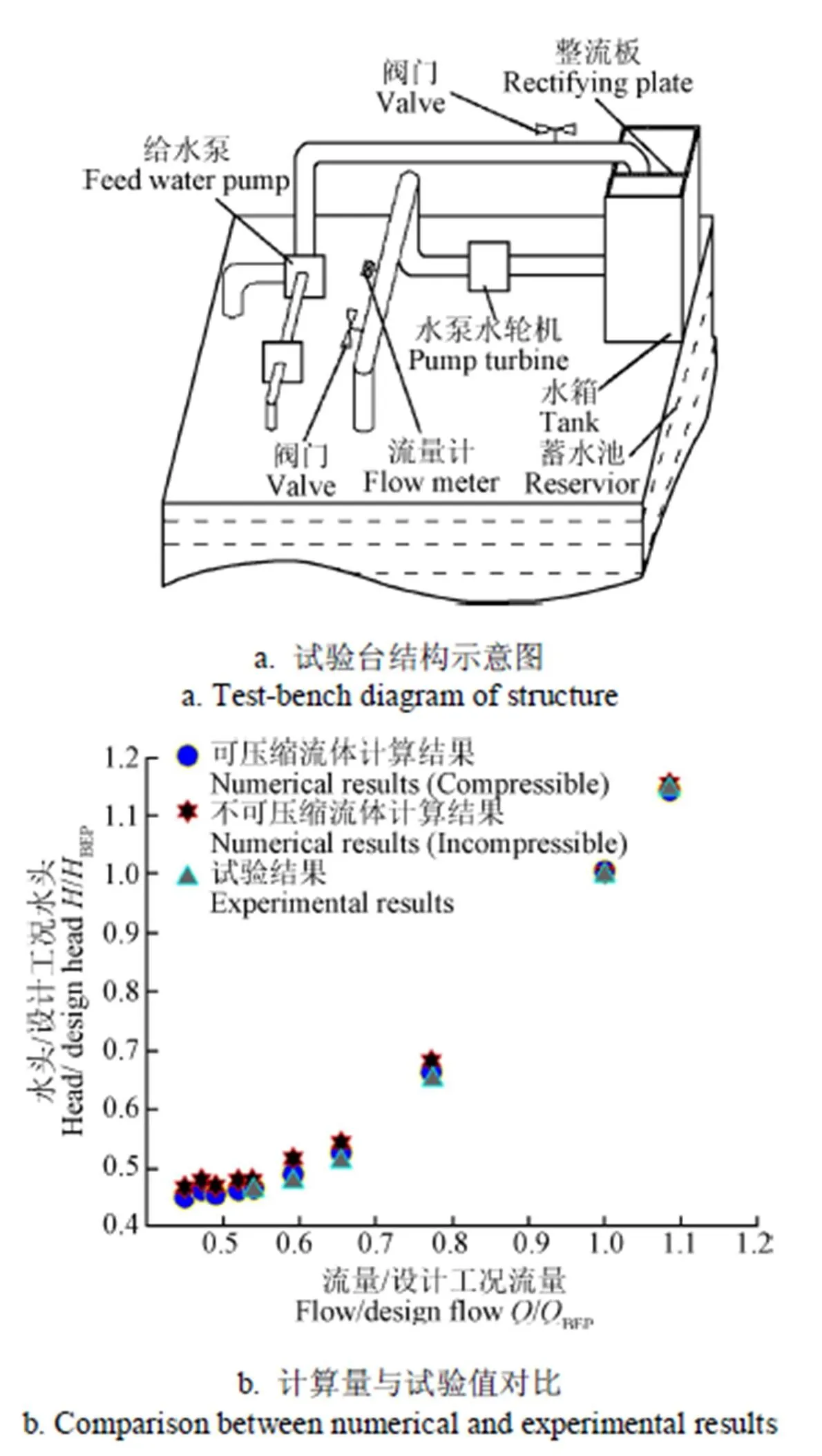

模型试验在意大利帕多瓦大学工业工程系开式旋转机械试验台(OTF)上完成,图2a所示为试验台结构[27],该试验台按照国际标准IEC60041与IEC60193,针对水力机械性能及瞬态特性测试而设计模型验证结果如图2b所示,基于ISO标准的定转速工况系列计算结果与试验结果对比用于验证模型,相关量测量遵循IEC标准,仪器校准均在现场完成[22]。可以看出考虑流体弱可压缩性得,到的计算结果与试验值更符合,水头计算值与试验值吻合较好,设计工况附近误差约为0.2%,部分负荷工况下误差低于3.3%(图2b),说明本文所涉及的计算模型及方法可较为准确的预测水泵水轮机的外特性,为下文研究水泵水轮机内部压力脉动特性提供了保证。

图2 模型试验

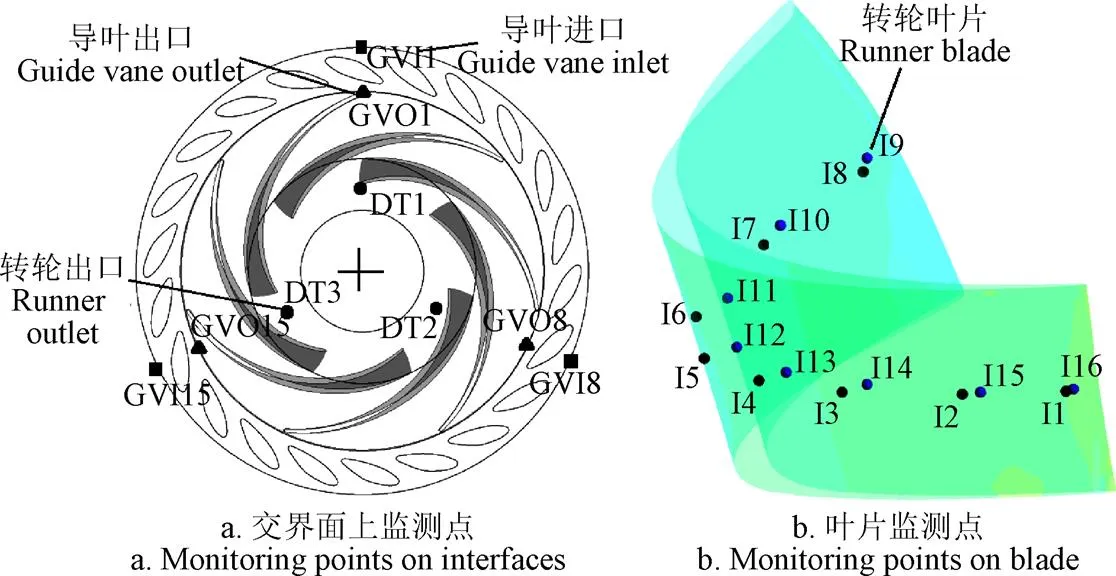

1.3 监测点位置

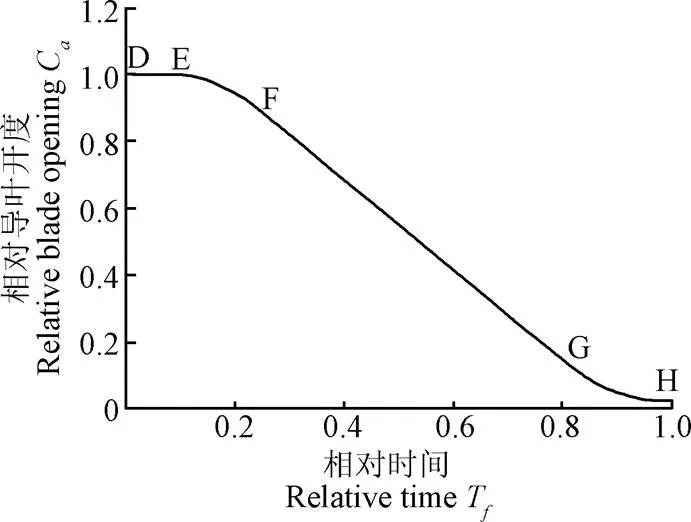

导叶运动遵循如图3所示的关闭规律,其中、是二次函数段是线性函数段,横坐标T代表相对时间,纵坐标C表示相对导叶开度。水泵水轮机甩负荷过程导叶运动引起网格扭曲变形,网格正交性降低导致数值模拟真实性降低,导叶大幅度运动产生负网格引起计算报错停止,若采用重画网格等形式解决上述问题,则导叶运动过程会出现间歇性,与电站实际情况不符。因此本文基于网格壁面滑行技术[22],在整个计算过程中,为保证数值模拟的真实性,任一时刻网格质量为初始网格质量的60%以上。本文在进行流动诱导噪声分析时,是通过非定常计算得到的压力脉动信号作为声源。为更好的获取水泵水轮机内各处压力脉动信息,本文在模型内设置了相应的监测点,部分监测点位置如图4所示,用于采集压力信号以分析流场压力脉动特性,以及作为声场流动诱导噪声研究的声源。

图3 导叶关闭规律

图4 部分监测点位置图

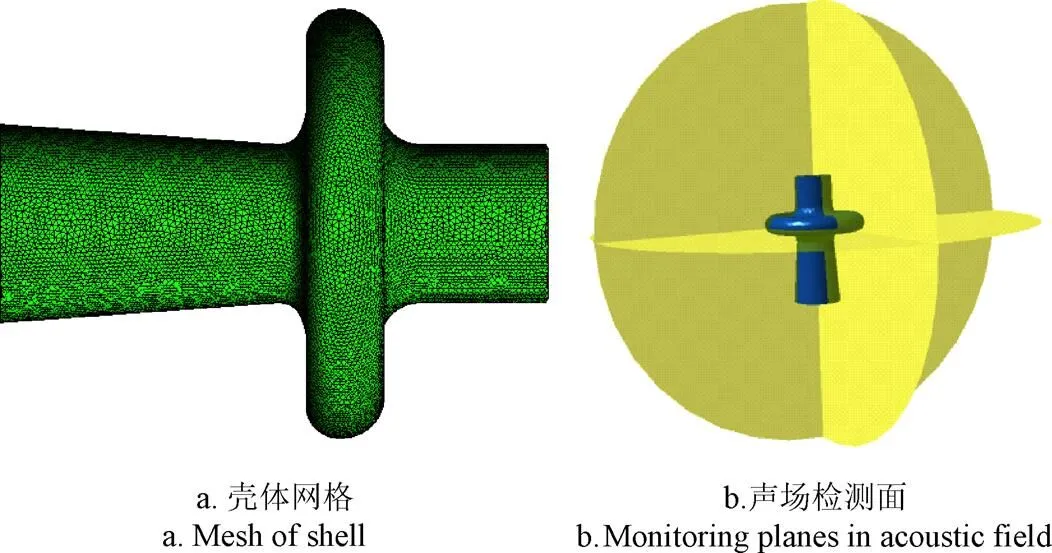

1.4 声场计算模型

声学边界元法基于波动方程可以很好的对复杂腔体内的声场进行数值计算,对低频噪声求解时具有明显的优势,水泵水轮机在实际运行过程中的声学计算空间并非完全封闭,因此本文采用间接声学边界元法进行噪声数值计算,其是指将计算流体力学和计算声学求解相结合,且对离散格式、湍流模型及边界条件的要求均较低[18],从本质上讲间接法是Lighthill声类比法,控制方程如式(1)所示。

图5 声场壳体网格及监测面布置

2 计算结果分析

2.1 流场计算结果分析

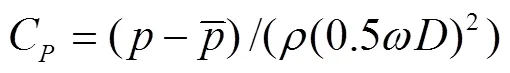

为了量化分析数值模拟计算得到压力信号,定义压力系数C如式(2)来表征压力脉动特性。

图6所示为活动导叶域进口面监测点GVI1、GVI8及GVI15在导叶关闭过程中压力脉动变化情况,可以看出各监测点压力系数具有一致的变化趋势和近似相等的脉动幅值范围。导叶持续关闭使喉部直径逐渐减小引起法向过流面积减小,导致部分水流被阻挡在导叶前而无法通过,前导叶域和活动导叶域之间积聚大量的流体使得该无叶区压力值呈现增长趋势(图6a),且压力脉动幅值随着时间减小。图6b是图6a在相对时间区间T=0.98到1之间的放大窗口,各监测点压力脉动幅值范围偏差说明在接近导叶关闭点时,导叶进口前无叶区内流动并非对称。

图6 活动导叶进口压力脉动特性

与导叶进口处压力变化趋势相反,活动导叶出口处压力随着时间减小(图7a),压力脉动幅值范围在T=0.8之前呈现缩小趋势,在最后20%导叶关闭阶段(T=0.8到T=1)其幅值范围持续增长。从图6和图7可以看出导叶出口处压力系数脉动幅值范围是对应导叶进口处的2倍以上,主要原因是转轮旋转使得该无叶区水流具有周向速度,另一方面是因为活动导叶和转轮之间产生较强的动干涉影响流态。此外,导叶出口处压力信号具有明显的周期性,图7b是图7a在区间T=0.98到T=1之间的放大窗口,与图6b不同之处在于各监测点压力脉动幅值在相同范围内,垂直连续线段示意监测点GVO1压力周期特性。

图7 活动导叶出口压力脉动特性

图8所示为无叶区内压力脉动频谱图,可以看出2个无叶区内压力功率谱密度(power spectral density, PSD)主频位置均在叶频=0.051与=1处,且各监测点在叶频处所对应频谱幅值明显高于其他频率对应频谱值,从而说明叶频所对应声场的能量在流动诱导噪声频谱中占主导作用,因此后文在对水泵水轮机进行流动诱导噪声计算时将主要针对叶频及其倍频进行求解。导叶出口处频谱值是进口处的10倍之上,由于活动导叶进口位置流态主要受动静干涉影响,而活动导叶出口位置流态主要受动动干涉影响,说明动动干涉对流场的影响要强于动静干涉。

转轮出口流态相对复杂,监测点压力系数变化趋势可分为3个阶段:导叶关闭前50%(T=0到T=0.64)阶段模型内部流场相对稳定,流量减少引起尾水管内环绕内壁面B逐渐形成空腔环域(图9),转轮出口压力系数呈增长趋势(图10a);当T=0.67时内壁面B附近出现反向回流且其旋向与转轮转向相反(图9),尾水管内流道被分成3个区域(I-出流区,II-空腔区,III-回流区),同时反向回流区向尾水管外壁面A扩散,至T=0.8尾水管内空腔区域消失,因该阶段尾水管内存在两个反向旋壁涡带,监测点DT1、DT2及DT3压力脉动加剧且幅值较大,表现出极不稳定的脉动特性(图10a);由于导叶关闭最后阶段入流量小,回流区域延伸占据三分之二尾水管流道。为更清楚观察尾水管进口监测点压力脉动情况,图10b是图10a区间T=0.98至T=1的放大图。

图8 无叶区压力脉动频域特性

图9 尾水管压力分布及流线图

图10 转轮出口压力脉动特性

2.2 声场计算结果分析

水力机械流动诱导噪声指向性分布在各个方向上的趋势基本相同,且其趋势不随流量的变化而改变[18],因此选取面分析外场噪声,研究一阶到三阶叶频处噪声指向性分布和辐射水平。从图11a可以看出叶片表面偶极子声源对应的声场云图具有明显的类似“∞”的指向形态,且各阶叶频处,声压的分布在面上呈现出明显的对称性,上述指向性分布具有对称性证明叶片噪声辐射具有明显的偶极子特性。

注:BPF是叶频,Hz。

图11a所示为0.5BEP时一阶叶频声压云图,可以看出声压扩散形状与模型结构相关,在近似轴向流动方向和近似轴向流动的法向方向声压分布是对称衰减的,且模型所在位置声压幅值最大,声压幅值随着与模型距离的增加而减小。此外,最大声压值位于尾水管内,图11a中尾水管内剑齿状区域对应图9(T=0.64)出流区。

综合分析图11b、11c、11d不同流量下模型外声场在一阶、二阶及三阶叶频处指向性分布,可以看出声压极小值位于0°和180°附近,极大值位于90°附近,且极大值的位置在尾水管附近,主要原因是尾水管内水流一方面受到转轮旋转影响,具有一定的周向速度生成带旋流,另一方面因为流量减小,尾水管内水流不足以补充空腔位置,加剧了涡流的形成。图8b所示一阶叶频辐射水平,其声压值明显高于二阶叶频和三阶叶频,分析原因可能是壳体结构的某阶固有频率与一阶叶频相近,导致流体与壳体之间产生共振,从而使得噪声辐射水平较大。该现象从另一角度说明流动诱导噪声的主,频由压力脉动主频和壳体固有频率综合决定,在设计模型时需重点考虑该问题,尽可能的避免叶频与壳体固有频率接近。此外,流量从BEP减小至0.5BEP的过程中,一阶叶频声压级逐渐减小;而随着导叶继续关闭(0.5BEP至0.02BEP阶段),声压级反而增长。

噪声在二阶叶频处辐射水平如图11c所示,二阶叶频处不同流量下外声场指向性分布与尾水管内流场变化相互对应,经历如下3个阶段:流量从BEP减小至0.6BEP的过程中,二阶叶频声压级随流量的减小而减小,声压幅值在流量大于0.5BEP变化较小,BEP处声压级是0.6BEP处的1.5倍;在流量为0.6BEP时,声场分布在XY面上接近于圆形,说明此时外场噪声不同方位上的辐射能力差异不大,对应于尾水管流场从0.6BEP至0.4BEP空腔区域形成回旋流(图9),二阶叶频处声压级增大;在尾水管出流区和回流区空间缩小阶段时,声压级减小,当流量进一步减小不足以填充该空环区时,声压级出现增长趋势(0.3BEP至0.02BEP)。图11d中三阶叶频处流量从BEP减小至0.7BEP的过程声压级变化不大,导叶继续关闭至0.5BEP阶段声压级有明显的降低,在后50%导叶关闭过程中,三阶叶频处声压级出现较为紊乱的发展趋势。

3 结 论

本文基于DES湍流模型和动网格理论对某电站可逆式水泵水轮机模型发电工况下导叶关闭过程进行连续性模拟,通过分析流场与声场计算结果得到以下结论:导叶进出口处2个无叶区内压力脉动主频位置均在叶频为斯特劳哈尔数等于0.051 与1处,且导叶出口处频谱值是进口处的10倍之上,说明动动干涉对流场的影响要强于动静干涉。转轮出口监测点压力脉动特性与尾水管内流场变化的3个阶段相对应(第一阶段:相对时间T=0到T=0.64;第二阶段:T=0.64到T=0.8;第三阶段T=0.8到T=1),当尾水管内出现2个反向旋壁涡带时(T=0.67),压力脉动最强烈且其幅值最大。在导叶持续关闭的过程中,外场噪声的主频由压力脉动主频与壳体固有频率综合决定,且各阶(1、2、3阶)叶频处声压指向性分布和辐射水平分别反映出流场压力脉动特性。叶片表面偶极子声源对应的声场云图具有明显的类似“∞”的指向形态,且各阶叶频处声压的分布呈现出明显的对称性,说明叶片噪声辐射具有明显的偶极子特性。在1阶、2阶叶频处,流动诱导噪声声压分布整体表现为:导叶关闭前50%阶段,流量对于外场噪声辐射能力的影响表现为大流量工况下较强(设计工况流量BEP到0.6BEP),小流量工况下较弱(0.6BEP到0.4BEP),导叶关闭后50%阶段正好相反,从而说明改善水泵水轮机内部压力脉动情况是降低流动诱导噪声辐射水平的重要手段。

[1] 李君,王磊,廖伟丽. 可逆式水泵水轮机“S”形区域内部流场特性分析[J]. 农业工程学报,2014,30(15):106-113.

Li Jun, Wang Lei, Liao Weili. Internal flow characteristics analysis on S-shaped region of reversible pump-turbine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(15): 106-113. (in Chinese with English abstract)

[2] Deane J P, Gallachóir B P Ó, Mckeogh E J. Techno- economic review of existing and new pumped hydro energy storage plant[J]. Renewable & Sustainable Energy Reviews, 2010, 14(4): 1293-1302.

[3] Sun H, Xiao R, Liu W, et al. Analysis of S characteristics and pressure pulsations in a pump-turbine with misaligned guide vanes[J]. Journal of Fluids Engineering, 2013, 135(5): 511011.

[4] Liu J, Liu S, Wu Y, et al. Numerical investigation of the hump characteristic of a pump–turbine based on an improved cavitation model[J]. Computers & Fluids, 2012, 68: 105-111.

[5] Mao X, Monte A D, Benini E, et al. Numerical study on the internal flow field of a reversible turbine during continuous guide vane closing[J]. Energies, 2017, 10(7): 988.

[6] Li D, Gong R, Wang H, et al. Analysis of vorticity dynamics for hump characteristics of a pump turbine model[J]. Journal of Mechanical Science & Technology, 2016, 30(8): 3641-3650.

[7] Liu D M, Zheng J S, Wen G Z, et al. Numerical simulation on the “S” characteristics and pressure fluctuation of reduced pump-turbine at start-up condition[J]. 2012, 15(6): 062034.

[8] Hasmatuchi V, Roth S, Botero F, et al. High-speed flow visualization in a pump-turbine under off-design operating conditions[C]// 25th IAHR Symposium on Hydraulic Machinery and Systems, 2010: 012059.

[9] Xiao Y X, Sun D G, Wang Z W, et al. Numerical analysis of unsteady flow behaviour and pressure pulsation in pump turbine with misaligned guide vanes[C]// 26th IAHR Symposium on Hydraulic Machinery and Systems. 2012, v 15, n PART3.

[10] Kuethe A. Control of noise and instabilities in jet engines, compressors, turbines, heat exchange and the like:US3776363 [P/OL]. (1973-04-12) [2018-06-30]. http://www.freepatentsonline.com/3776363.html.

[11] Kato C, Yoshimura S, Yamade Y, et al. Prediction of the noise from a multi-stage centrifugal pump[C]// ASME 2005 Fluids Engineering Division Summer Meeting, 2005: 1273-1280.

[12] Jiang Y Y, Yoshimura S, Imai R, et al. Quantitative evaluation of flow-induced structural vibration and noise in turbomachinery by full-scale weakly coupled simulation[J]. Journal of Fluids & Structures, 2007, 23(4): 531-544.

[13] Abbot P A, Walsh J, Halas R. Cavitation noise investigation of a pump-turbine[C]// Waterpower. ASCE, 2015: 2031-2040.

[14] Yang J, Yuan S, Yuan J, et al. Numerical and experimental study on flow-induced noise at blade-passing frequency in centrifugal pumps[J]. Chinese Journal of Mechanical Engineering, 2014, 27(3): 606-614.

[15] 袁寿其,薛菲,袁建平,等. 离心泵压力脉动对流动噪声影响的试验研究[J]. 排灌机械,2009,27(5):287-290.

Yuan Shouqi, Xue Fei, Yuan Jianping, et al. Experimental study on impact of pressure fluctuation on flow-noise in centrifugal pump[J]. Drainage and Irrigation Machinery, 2009, 27(5): 287-290. (in Chinese with English abstract)

[16] Opperwall T, Vacca A. A combined FEM/BEM model and experimental investigation into the effects of fluid-borne noise sources on the air-borne noise generated by hydraulic pumps and motors[J]. Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science, 2014, 228(3): 457-471.

[17] 王宏光,徐小龙,杨爱玲,等. 轴流泵流动噪声数值模拟[J]. 排灌机械工程学报,2011,29(3):199-203.

Wang Hongguang, Xu Xiaolong, Yang Ailing, et al. Numerical simulation of flow noise in axial-flow pump[J]. Drainage and Irrigation Machinery, 2011, 29(3): 199-203. (in Chinese with English abstract)

[18] 郑源,陈宇杰,毛秀丽,等. 混流泵压力脉动特性及其对流动诱导噪声的影响[J]. 农业工程学报,2015,31(23):67-73.

Zheng Yuan, Chen Yujie, Mao Xiuli, et al. Pressure pulsation characteristics and its impact on flow-induced noise in mixed-flow pump[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(23): 67-73. (in Chinese with English abstract)

[19] 司乔瑞. 离心泵低噪声水力设计及动静干涉机理研究研究[D]. 镇江:江苏大学,2014.

Si Qiaorui. Investigation on Hydraulic Design of Centrifugal Pumps with Low Noise and Mechanism of Rotor-Stator Interaction[D]. Zhenjiang: Jiangsu University, 2014. (in Chinese with English abstract)

[20] Zhao X, Xiao Y, Wang Z, et al. Numerical analysis of non-axisymmetric flow characteristic for a pump-turbine impeller at pump off-design condition[J]. Renewable Energy, 2018, 115: 1075-1085.

[21] Li D, Wang H, Qin Y, et al. Numerical simulation of hysteresis characteristic in the hump region of a pump-turbine model[J]. Renewable Energy, 2018, 115: 433-447.

[22] Mao X, Giorgio P, Zheng Y. Francis-type reversible turbine field investigation during fast closure of wicket gates[J]. Journal of Fluids Engineering, 2018, 140(6): 061103.

[23] Spalart P R. Detached-eddy simulation[J]. Annual Review of Fluid Mechanics, 2009, 41(1): 181-202.

[24] Minakov A V, Engineer D V P, Litvinover I V, et al. Vortex ropes in draft tube of a laboratory Kaplan hydroturbine at low load: an experimental and LES scrutiny of RANS and DES computational models[J]. Journal of Hydraulic Research, 2017(1): 1-18.

[25] Xu H, Wray T, Agarwal R K. Application of a new DES model based on wray-agarwal turbulence model for simulation of wall-bounded flows with separation[C]// Aiaa Fluid Dynamics Conference, 2017.

[26] Hui S, Xiao R, Wang F, et al. Analysis of the pump-turbine S characteristics using the detached eddy simulation method[J]. Chinese Journal of Mechanical Engineering, 2015, 28(1): 115-122.

[27] 阳君,袁寿其,Pavesi Giorgio,等. 水泵水轮机泵工况下近设计点驼峰现象的流动机理研究[J]. 机械工程学报,2016,52(24):170-178.

Yang Jun, Yuan Shouqi, Pavesi Giorgio, et al. Study of hump instability phenomena in pump turbine at large partial flow conditions on pump mode[J].Journal of Mechanical Engineering, 2016, 52(24): 170-178. (in Chinese with English abstract)

Simulation of flow induced noise in process of pump-turbine load rejection

Mao Xiuli1, Sun Aoran2, Giorgio Pavesi3, Zheng Yuan4, Ge Xinfeng4

(1.712100; 2.230088,; 3.35131,; 4.210000)

The grid market is redistributed with significantly increase of the exploitation of unpredictable renewable energy, such as wind and solar energy sources, however, the ways of electricity generation by both wind and solar energy depend on environment which is extremely unstable. For the sake of balancing electricity generated by renewable energy, pumped storage power stations are experiencing a thriving process. As the core of pumped storage power station, the stable operation of the pump turbine is extremely important, especially for pump-turbine working at transient conditions. In order to study pressure fluctuating characteristics and its' influence on flow-induced noise, a continuous unsteady simulation was carried out in pump-turbine guide vane closing process under generating mode. In this article, wall sliding mesh was used to realize guide vane continuous motion, which ensured that the mesh quality at any moment was larger than 60% compared with the initial mesh quality, meanwhile, DES turbulent model was adopted in all calculations due to its good performance in many industrial cases. The whole pump-turbine model was meshed with structured mesh by commercial software ICEM, and five different mesh sizes were used in mesh sensitivity validation, with the size of 14 million selected finally. On the other hand, a test was performed by the team of Giorgio Pavesi to prove this model in open test facility in Padova University, the entire model validation was carried out according to ISO standards, and relative parameters were measured based on IEC standards. Commercial software ANYSYS CFX 16.2 was used to realize all simulating calculations with 8 computer cores, one month was taken to finish this calculation. The flow field calculating results were analyzed in frequency and time-frequency domains, including mass flow, pressure, and torque et al., in the meantime, the pressure on the surfaces of blades was regarded as flow-induced noise source to study sound field. The solution obtained from flow field illustrates that pressure fluctuating amplitudes at guide vane outlet is more than twice compared to the relative value at guide vane inlet location, the main reason is flow in the vaneless space that is close to runner is affected by rotor-rotor interaction. In addition, pressure pulsations at runner outlet arrive at peaks when two vortexes appear in draft tube with two different rotating directions. As for frequency domain characteristics, both strauhal number=0.051 and=1 are captured, whereas the spectrum of those pressure fluctuations that are close to guide vane outlet is 10 times of the relative value at guide vane inlet, which explains that rotor-rotor interaction has a stronger influence on flow field than rotor-stator interaction. Some rules are found by analyzing flow-induced noise in sound field, the analysis illustrates that flow-induced noise radiation level is related to both pressure fluctuating and shell natural frequency captured in exterior acoustic field, the shape of sound distribution is like “∞” and sound level distributions in different directions and faces are symmetrical, this explains that the blade noise radiation has obvious dipole characteristics. Furthermore, at the first and second-order blade passage frequencies, the effect of flow rate on the radiation performance of noise is stronger under larger flow conditions during guide vane closure, which becomes weaker under smaller flow conditions in the first half of the guide vane closure, as for the second half phase of guide vane closure, the results are exactly opposite to the previous phenomena. Moreover, flow-induced noise radiation is consistent with fluid characteristics during pump-turbine load rejection. Consequently, to improve pressure fluctuating characteristics can reduce flow-induced noise.

pressure; impellers; noises; pump-turbine; load rejection process

10.11975/j.issn.1002-6819.2018.20.007

TK734

A

1002-6819(2018)-20-0052-07

2018-04-17

2018-07-30

国家公派留学项目(No. 201506710011)

毛秀丽,讲师,从事水力机械及其系统研究。Email:maoxl@nwafu.edu.cn

毛秀丽,孙奥冉,Giorgio Pavesi,郑 源,葛新峰. 水泵水轮机甩负荷过程流动诱导噪声数值模拟[J]. 农业工程学报,2018,34(20):52-58. doi:10.11975/j.issn.1002-6819.2018.20.007 http://www.tcsae.org

Mao Xiuli, Sun Aoran, Giorgio Pavesi, Zheng Yuan, Ge Xinfeng. Simulation of flow induced noise in process of pump-turbine load rejection[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(20): 52-58. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.20.007 http://www.tcsae.org