The fragmentation of D-shaped casing filled with explosive under eccentric initiation

2018-10-18ZhiweiGuoGuangyanHuangWeiZhuShunshanFeng

Zhi-wei Guo,Guang-yan Huang,Wei Zhu,Shun-shan Feng

State Key Laboratory of Explosion Science and Technology,Beijing Institute of Technology,Beijing 100081,PR China

Keywords:D-shaped casing Eccentric initiation X-ray radiograph technique Fragmentation Numerical simulation

ABSTRACT With the technical development of new warhead designs and improvised explosive device protection,irregular casing filled with explosive has been paid more attention recently.In this paper,we studied the fragmentation of a type of D-shaped casing,which is a common asymmetric casing in the field of warhead design.Based on the radiograph technique,static explosive experiments were conducted with D-shaped casings under four different eccentric initiation ratios to explore their fragmentation.A numerical model was then established to simulate the dynamic response of D-shaped casing filled with explosive.The results of numerical simulation were found to agree well with the experimental data.According to the results of numerical simulation and experimental data,the dynamic responses of D-shaped casing were analyzed.The results of the current work pave way for the innovative design of new warhead and for further studying the dynamic response of asymmetric casing.

1.Introduction

Conventional warheads are usually in axially symmetric shape and their detonation point is on the axis.After initiating the explosive charge in the casing,the shell is broken into fragments that have mostly equal velocity,shape and mass in all radial directions.However,in the recent applications of the casings filled with explosive,sometimes the explosive charge is not initiated on the axis and even the casing itself may not be axially symmetric at all.

Different from the symmetric casings,the explosive loading on the shell of the asymmetric ones is not equal at different azimuth angles,and the circumferential mass and velocity distributions are thus not uniform.Furthermore,the fragments may converge or disperse after initiation[1].For studying the explosion effect and designing the innovative warheads,it is thus necessary to study the fragmentation and fragments distribution of asymmetric casing under internal explosive loading.

Nowadays there are adequate studies on fragmentation process and the velocity distribution of symmetric casings filled with explosive in the field of explosion effect and its application.The fragmentation process and the velocity distribution are also studied adequately,and the corresponding calculating methods are mature.Guangyan Huang studied the fragmentation and velocity axial distribution of fragments of finite-length cylindrical casings by means of X-ray radiograph technique[2,3],which provides reference for further experimental studies.Mafa Wang proposed an empirical model to calculate the fragment velocity circumferential distribution of symmetric casings under eccentric initiation[4].Yuan Li did further research on the velocity distribution of axial symmetric casings based on the analytical and numerical methods[5].Dhote experimentally studied the fragments distribution of a type of axial-enhancement warhead[6],which laid the groundwork for tailoring the fragment profile of aimable warhead.

Due to the variety of asymmetric casings and the complexity of the condition of initiation in the engineering application,a common and basic type of D-shaped casing that is valuable in the design of rotating aimable warhead,explosive formable warhead and the protection of unknown explosive was designed.The D-shaped casing was experimentally studied by X-ray flash photography.Due to practical limitations,it is difficult to obtain the fragment velocity distribution of a full-length casing by the snapshots,and a short casing was designed and tested instead.Moreover,the dynamic response of D-shaped casing was also numerically studied.The numerical results were well consistent with that of experiments.

2.X-ray experiments

2.1.Experimental methods

Fig.1 shows the D-shaped casing tested in the current work,and the picture is overlaid with a schematic illustration.The casing consists of the arc part that is in a semicircle shape and the bottom part that is in a straight-line shape,and the normal thickness of the shell is equal at all positions.In Fig.1,O is the center of the casing,that is,the center of the arc part.

As shown in the figure,the detonation point,which is named as point D,is on the vertical axis of the casing.The eccentric initiation ratio is defined as the ratio of the distance between the detonation point and the center to the radius and denoted as ep.The epranges from 0 to 1.

The casing was made up with a length of 15mm to allow the profile of the fragments to be easily recognized and obtained.In addition,because of the limited length of the D-shaped casing,the detonator cannot be set on the explosive directly.Therefore,a detonation end cap made of nylon was designed,and its schematic is shown in Fig.2.

Fig.3 and Fig.4 demonstrate the setup of the X-ray radiography experiment.The casing was set on a support frame,which is made of corrugated paper and placed on the test platform.In addition,two reference steel spheres with distance of 50 mm were adhered on the support frame to determine the real size of the fragments in the photo.The images of the casing at two moments were both taken on one photo and were analyzed by computer software.There was a protection steel plate between the film and casing,which can prevent the film from the damage caused by fragments and explosive waves.

We have tested one kind of D-shaped casing.The diameter of the casing was 80 mm,the length was 15 mm,and the shell thickness was 2mm.The shell was made of AISI 1045 steel(45#steel in National Standard of the People's Republic of China)and the explosive was Composition B.Since the detonator itself occupies some volume,the eccentric initiation ratio cannot be exactly 0 or 1.So the initiation ratios were set as 1/8,3/8,5/8,and 7/8,respectively.

2.2.Analysis of experimental results

The experimental results are shown in Fig.5.The fragments of the casing were clearly divided in to two parts,and referred to as the arc part and the bottom part.It can be seen that the arc part broke seriously while the bottom part has relatively less fractures.Only if the eccentric ratio was 5/8,there appeared an obvious fracture in the bottom part.

For the arc part,it can be seen that the number of the fragments were increasing but the fragments size were generally decreasing.The max length,which is defined as feature length,of each fragment was measured based on the X-ray photograph.The feature length obtained from the X-ray photo was used to describe the size changes of fragments.The feature lengths distribution of fragments was hereafter obtained and shown in Fig.6.As shown in the figure,when the eccentric ratio was 1/8,the percentage of the fragments whose feature length was lower than 5mm was 66.7%,and that of the fragments whose feature length ranged from 5-10 mm was 26%.However,when the eccentric ratio was 3/8,the percentage of the fragments whose feature length was between 5 and 10 mm increased to 58.6%,which indicated that the fragments became larger with increasing eccentric ratios.The maximum of feature lengths was up to 15.7mm when the eccentric ratio became 7/8.Furthermore,the percentage of the fragments with relatively large feature length(more than 5mm)was nearly 80%.

According to the experimental results,it is considered that when the eccentric ratio is small,the detonation wave will firstly impact on the bottom part of the shell and reflect a detonation wave with larger pressure.Then the reflected detonation wave will chase after the original detonation wave and impact on the arc part.The velocity of the shell of arc part is thus larger,which leads to higher tensile stress and more fractures in the shell.However,when the eccentric ratio is relatively larger,the shell of arc part near the initiation point is adequately accelerated and fragments easier.The early fragmentation leads to leakage of explosive products and the generation of the unloading wave in the shell,which reduce the tensile stress in the shell.So the fragments near the detonation point becomes larger.

As for the bottom part,by measuring the length of bottom part in the X-ray photos in these tests,it can be seen that the length of bottom part ranged from 82 to 86 mm.It was implied that the bottom part did not deform under the explosive loading.And it is therefore obtained that the direction of the fragment velocity does not influence by the condition of initiation,which is in consistence with the results of the studies on symmetric casings[2,5].

3.Numerical simulation model

3.1.Establishment of numerical model

Based on the Autodyn numerical simulation software,numerical model that was same as the experimental configuration was established,which consists of casings filled with explosive and detonation end cap.The geometric model was shown in Fig.7.

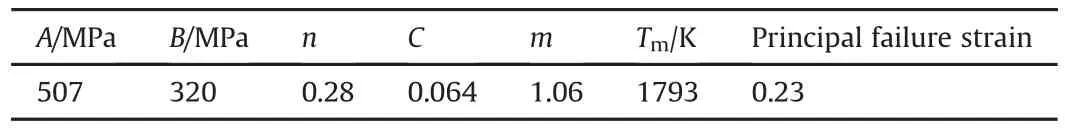

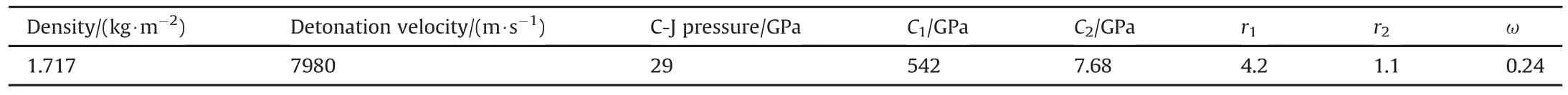

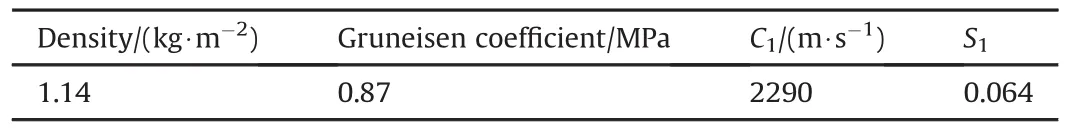

The material of shell is AISI 1045(45#steel in the National Standard of People Republic of China),which can be described by JC constitutive model[7]in Autodyn.Besides,the failure and fracture of the shell of casing were described by the plastic strainfailure criterion[7].The model parameters of the shell were shown in Table 1.The equation of state of the Composition B was described by JWL model,which can be directly used from Autodyn material data base,and its parameters are shown in Table 2.For being consistent with the experimental specimens,the material of the detonation end cap was set as Nylon,and it can be directly obtained from the Autodyn material database.The parameters are shown in Table 3.

Table 1 The model parameters of the shell[7].

For avoiding the excessively distortion of the mesh in simulation of explosion,which was often accompanied by ultra-high speed and extreme deformation,SPH method was utilized to simulate the explosion.

3.2.Numerical simulation results

The numerical simulation results of D-shaped casings under eccentric initiation with eccentric ratios of 1/8 and 7/8 are shown in Fig.8.Determining the position of fragments with max velocity in axial direction is of great importance,because those are the fragments recognized from the X-ray photos,which makes observing the fragmentation of the shell possible.As shown in the side view,it can be seen that when the eccentric ratio is 1/8,the maximum fragment velocities of arc part appeared in the nearly the middle position,while it appeared in the right side with bigger eccentric ratio.Because when the eccentric ratio was small,the detonation wave transmitted a long way to the top of the arc part.And thus the rarefaction wave generated from two end effected on the detonation wave.So the detonation wave near to middle position in axial direction had the highest pressure.However,when the eccentric ratio was large,the detonation point is very near to the top of the arc part,which made the shell driven adequately.In addition,the detonation end cap further reduce the effects of the rarefaction wave from that side.As for the bottom part,the effect was just the opposite.

Figs.9 and 10 shows the comparison between the numerical and experimental results.It can been seen that the numerical resultsagree with experiments in terms of rarefaction wave effects,divisions of fragments regions and the profiles of fragments.

Table 2 Parameters of EOS of composition B.

Table 3 Parameters of model of Nylon.

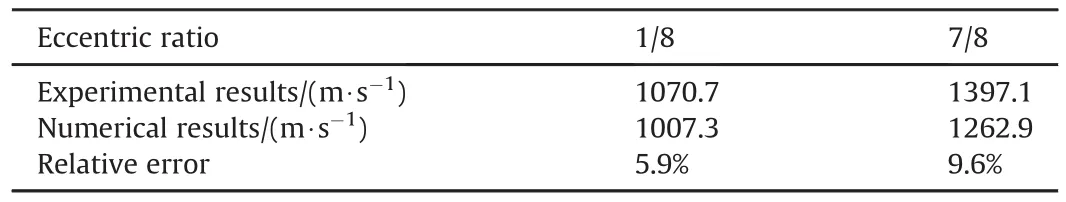

For quantitatively validate the numerical model,the average velocity of the bottom part of the D-shaped casing was compared because the fragment velocities of the bottom part was vertical,which can remove the error generated by parallel photogrammetry.The average velocities of the D-shaped casings from the experiments was obtained by measuring the distance between the fragments profiles obtained at two times.The average velocities from numerical model can be directly obtained.The velocities comparison between the experimental and numerical results are listed in Table 4.According to the comparison,it can be obtained that the relative errors between the numerical model and experiments are all not more than 10%,which means that the numerical model has enough accuracy to simulate the dynamic response of the D-shaped casing under eccentric initiation.

Based on the fragments analysis module of Autodyn,fragmentation of the D-shaped casing under internal explosive loading was then obtained.We just analyzed the fragments that had max velocity.The probabilities of fragments with different mass of the arc part of D-shaped casing were therefore obtained and shown in Fig.11.It is seen that when the eccentric ratio was small,the shell in the arc part was more likely to break in to small fragments(less than 0.5g).With the increase of eccentric ratio,the fragments were likely to become larger,which was consistent with experimental results.

4.Conclusion and discussion

In this paper,a series of experimental and numerical studies were conducted to obtain the dynamic response of D-shaped casings under the explosive loading with eccentric initiation.The fragments size circumferential distribution was obtained by X-ray radiophotograph technique.And a numerical model was established based on the specimen to analyze the dynamic response of D-shaped casing in detail.The results in this work can provide decent methods and data for further researches on the asymmetriccasings filled with explosive and corresponding engineering design.In summary,the conclusions are as follows:

Table 4 Comparison of the average velocity of the bottom part between the experimental and numerical results.

(1)A kind of D-shaped casing was designed.And a detonation end cap for short casing filled with explosive was designed to make eccentric initiation possible.

(2)According to the X-ray experiments,the fragmentation of D-shaped casing under eccentric initiation was obtained.The experimental results shows that the shell far away from the detonation point,which suffered impact of detonation wave with higher pressure,is more likely to break into small fragments.

(3)Based on the experiments,a numerical model was established to analyze the fragmentation of the D-shaped casing in detail.The mass distribution of fragments was obtained,and the results agreed well with the experimental results.

Acknowledgements

This work is supported by the National Natural Science Foundation of China[grant number 11772059];the National Key Research and Development Program of China[grant number 2017yfc0822300];the 111 Project[grant number G20012017001];and the Foundation of State Key Laboratory of Explosion Science and Technology of China[grant number KFJJ13-1Z].

杂志排行

Defence Technology的其它文章

- Overview of Al-based nanoenergetic ingredients for solid rocket propulsion

- Implications of fine water mist environment on the post-detonation processes of a PE4 explosive charge in a semi-confined blast chamber

- Systematic research on the performance of self-designed microwave plasma reactor for CVD high quality diamond

- cis-1,3,4,6-Tetranitrooctahydroimidazo-[4,5-d]imidazole(BCHMX)as a part of explosive mixtures

- Joining and machining of(ZrB2-SiC)and(Cf-SiC)based composites

- Structural evolution,optoelectrical and corrosion properties of electrodeposited WO3integration on Zn-TiO2electrolyte for defence super application