Characterization of ceramic reinforced titanium matrix composites fabricated by spark plasma sintering for anti-ballistic applications

2018-10-18MsekoPopoolFyomi

S.W.Mseko,A.P.I.Popool,O.S.I.Fyomi,b

aDepartment of Chemical,Metallurgical,and Materials Engineering,Tshwane University of Technology,Pretoria,South Africa

bDepartment of Mechanical Engineering,Covenant University,Ota,Nigeria

Keywords:SPS TiB whiskers Hardness Titanium matrix composites Reinforcement

ABSTRACT Titanium has found extensive use in various engineering applications due to its attractive physical,mechanical,and chemical characteristics.However,titanium has relatively low hardness for use as an armour material.ZrB2was incorporated to the Ti matrix to form a Ti-based binary composites.In this study,powder metallurgy techniques were employed to disperse the ceramic particulates throughout the matrix material then consolidated through spark plasma sintering.The composites were densified at 1300oC,pressure of 50 MPa,and holding time of 5 min.The microstructure and phase analysis of the sintered composites was carried out using SEM and XRD,while the hardness was determined using Vickers' microhardness tester.The SEM and XRD results confirmed the presence of the TiB whiskers which renowned with the improving the hardness of titanium.The hardness of the composite with 10 wt%ZrB2showed the highest hardness compared to that obtained for the 5 and 15 wt%ZrB2composites which was 495 and 571Hv respectively.

1.Introduction

The development of advanced materials that out-perform existing materials is an area which is in the fore front of the 4th industrial revolution.Materials such as titanium are one of the most sought-after materials;as it is used in a wide variety of heavy and light engineering applications.The need for lightweight high performance materials sees materials such as aluminium and titanium as the ideal solution for armour.However,the use of aluminium as armour material is limited by its lower strength when compared to titanium([7]:12964).Boyer([2]:22)states that titanium owns exceptional ballistic resistance behaviour and provides a 15-35%reduction in weight compared to aluminium.Although titanium has good ballistic resistance properties,efforts have been made by researchers to enhance its use as armour material([6]:1,[10]:387).Ceramics remain a highly viable option to enhance anti-ballistic properties of titanium.Titanium forms stable TiB whiskers when reinforced with boron-based reinforcements.Studies have proven that TiB whiskers enhance the hardness stiffness of the titanium matrix([11]:43,[12]:243,[14]:152).However,processing of ceramics remains a serious challenge in the materials engineering;this is due to the high melting temperatures and grain coarsening associated with these materials.Spark plasma(SPS)is a state-of-the-art sintering technology,with the capability to fabricate fully dense specimens at significantly low temperatures([13]:320).The unique process parameters associated with this sintering technology are known to provide exception grain size retention when compared to conventional processing techniques([5]:4).However,there is little knowledge in open literature using reinforcement for a titanium matrix composite.This study aims to fabricate a titanium-based composite with enhanced anti-ballistic characteristics through the incorporation of ceramic particulates.

2.Experimental procedure

2.1.Feedstock material

In this study, fine titanium powder supplied by Merck Millipore(with less than 150μm particle size,98%purity)was used as the matrix material.TiB2powder supplied by Merck Millipore was used as the reinforcement material.Figs.1 and 2 are the SEM and XRD images of the feedstock commercially pure titanium(CpTi)and ZrB2.

2.2.Powder mixing

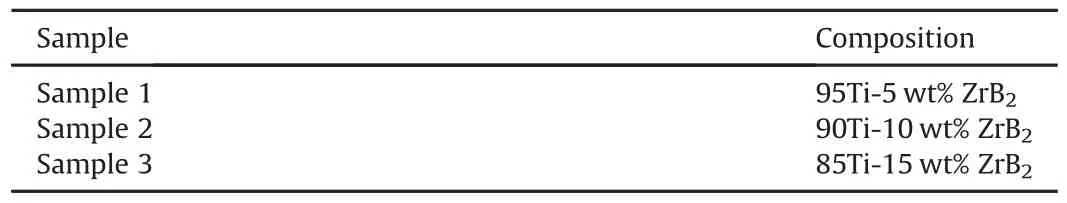

The powder materials were mixed using the PM 400 high energy ball mill at 300 rpm for 8h with 3 agate balls to enhance the mixing kinetics.Three composites were prepared,with reinforcement composition of 5,10,15 wt%ZrB2.Table 1 below,contains a detailed description of the admixed composites.

2.3.Powder consolidation

The admixed samples were then densified using the SPS furnace(HPD5,FCT Systeme GmbH).The admixed powders were densified at a temperature of 1300oC,at an applied load of 50 MPa,5 min dwell time,and heating rate of 100oC/min under a vacuum atmosphere.The sintered products were then prepared for analysis andcharacterization using conventional metallography procedures prior to analysis.

Table 1 Composition of mixed powders.

2.4.Characterization of sintered samples

The microstructure and phase evolution of the sintered samples were investigated using an optical microscope(OPM),scanning electron microscope(SEM),and x-ray diffractometer(XRD).The microhardness of the samples was determined using the Vickers' microhardness tester with an applied load of 100kg.The indentation was carried out at 10 randomly chosen areas on the surface of the sample.

3.Results and discussion

3.1.Microstructure and phase characterization

The OM micrographs depict the formation of needle-like TiB whiskers for all composites(see Fig.3(a)-(c)).There is more prominent formation of TiB whiskers in 85Ti-15wt%ZrB2(see Fig.3(c))when compared to the composites with lower reinforcement compositions.Fig.3(a)shows a few un-diffused ceramic phases which can be seen by the black spots.The microstructure of the composites showed a decrease in grain sizewithan increase incomposition.This phenomenon was also evident in the studies conducted by Chaudhury et al.([3]:759)and Kumar,Rao,and Selvaraj([8]:59).This phenomenon is attributed to the evolution of TiB2toTiB which leads to grain refinement.

Fig.3(a)and(c)and Fig.4(a)and(c)shows two distinctive regions:one is the dominant light and grey,which confirm the presence of titanium,while the darker boride-rich phase is randomly distributed in the form of needle-like microstructures and irregular shaped microstructure.The images also show the presence of white-like phase,which is less distinctive compared to the other two prominent phases,the white-coloured phase occurs along the grain boundaries,this phase is also observed in the XRD results as(Zr1-x,Tix)O2phase.The conditions for the formation of srilankite(Zr1-x,TixO2),and its role in phase equilibrium studies,are still uncertain.Previous studies have been carried out with the aim of fabricating(Zr1-x,Tix)O2species from through the mechanical alloying of TiO2and ZrO2([4]:153,[9]:181).The formation of this phase in this study is attributed to the interstitial oxygen present in the feedstock powders as an impurity.An even dispersion of the reinforcement particulates(phases)throughout the matrix can be observed from the images.This is attributed to the efficient mixing and blending kinetics associated with the planetary ball mill.The SEM images for all three composites show that the presence of the ceramic phase is not only by needle-like structures,TiB is also present in other irregular shapes.The images also depict grain refinement with an increase in reinforcement for three composites.This phenomenon was also observed on the OM micrographs.

The metallographically prepared samples were analysed for phases.The XRD spectra of the composites is depicted in Fig.5.The spectra show thatα-Ti is the most prominent phase for all three composites,this was also observed in the XRD spectra of the unsintered CpTi powder.The results also depict the detection of the cubicβ-Ti phase for all three composites:theβphase was detected at 2θangles of approximately 40 and 54ofor sample 4;40,54,and 70ofor sample 5;70ofor sample 3.The formation of theβphase is due to the evolution of theαphase during the sintering process([1]:844).The evolution of theαphase is due to the thermomechanical processes of applied pressure and the joule heating effect associated with SPS([13]:320).The observation also confirms the transformation of all the boron species(ZrB2)into TiB in the resultant composites matrix.The patterns also showed that there is no presence of Ti3B4,which was a possible intermediate phase in the matrix.

3.2.Microhardness

The microhardness of the composites was presented in Fig.6.As expected,the hardness of the composite with the least reinforcement composition was relatively lower compared to the other two composites;from the SEM images it was observed that sample 1 had the fewest TiB whiskers formed.Sample 2 showed a highest hardness of 595Hv,which is higher than 571Hv obtained for the sample 3.This is attributed to the relatively lower densification expected at high reinforcement compositions.Relative density was listed as one the physical properties that have significant effect on hardness in the work carried out by Huang and Chen([7]:12951).The OM results of sample 3(see Fig.3)showed high contents of the white-like(Zr1-x,Tix)O2phase,the low hardness might be due to its high content compared to sample 1 and 2.However no studies were found in literature to support this postulation.

4.Conclusions

SPS is an effective technique that can be used to fabricate Ti-ZrB2binary composites at relatively low sintering temperatures.The methodology used in this study was effective in inducing dispersion strengthening effect on the composites;as all the composites showed an improvement in hardness due to the dispersion of the ceramic particulates throughout the matrix material.TiB was readily fabricated through in-situ reaction of Ti and B species,this resulted in the formation of good interfacial bonding between the Ti matrix and the TiB reinforcement phase.The good interfacial bonds between the titanium matrix and the boride based reinforcements will lead to the enhancement of the anti-ballistic properties of titanium.

Acknowledgement

This material is based upon work supported financially by the National Research Foundation.The authors also acknowledge the support from the the Tshwane University of Technology,Pretoria,South Africa which helped to accomplish this work.

杂志排行

Defence Technology的其它文章

- Overview of Al-based nanoenergetic ingredients for solid rocket propulsion

- Implications of fine water mist environment on the post-detonation processes of a PE4 explosive charge in a semi-confined blast chamber

- Systematic research on the performance of self-designed microwave plasma reactor for CVD high quality diamond

- cis-1,3,4,6-Tetranitrooctahydroimidazo-[4,5-d]imidazole(BCHMX)as a part of explosive mixtures

- Joining and machining of(ZrB2-SiC)and(Cf-SiC)based composites

- Structural evolution,optoelectrical and corrosion properties of electrodeposited WO3integration on Zn-TiO2electrolyte for defence super application