海带渣与养殖固体废弃物混合发酵产沼气试验

2018-10-10李秀辰张国琛杨福利

李秀辰,李 丰,张国琛,张 倩,杨福利,母 刚

海带渣与养殖固体废弃物混合发酵产沼气试验

李秀辰,李 丰,张国琛,张 倩,杨福利,母 刚

(大连海洋大学辽宁省渔业装备工程技术研究中心,大连,116023)

废弃物的高效和资源化利用是现代渔业发展面临的重要课题。该文以海带渣和养殖固废为原料开展了两相发酵产沼气效果试验研究,探讨了中温条件下(35±1℃)料液TS浓度和接种率对混合水解酸化特性以及厌氧发酵产沼气效果的影响。结果表明,海带渣与养殖固废混合水解酸化过程启动很快,第2天乙酸浓度即达到峰值,5 d后丙酸和丁酸浓度增幅较快,水解酸化过程中甲酸产量相对较低。不同TS浓度(6%、8%和10%)和不同接种率(10%、20%和30%)的料液水解3 d,乙酸的酸化度分别为42.6%、50.0%、49.8%和50.7%、44.3%、40.3%;主要有机酸(乙酸+丁酸+甲酸)的酸化度分别达到61.7%、68.7%、62.2%和69.4%、57.5%、58.0%。料液TS浓度为8%~10%、接种率为10%~20%和pH值为6.0~7.0时,海带渣与养殖固废在中温条件下混合水解2~3 d,即可获得后期发酵产沼气所需的酸化料液。此外,发酵产沼气结果表明,每天按与产沼气接种污泥质量比为1:7~1:9的比例添加酸化料液,在pH值为7.0~8.0和35±1 ℃的条件下厌氧发酵产沼气,产气系统启动很快,而且8~13 d即进入稳定产气阶段,产气率保持在489.4~581.5 mL/gVS,所产沼气中的甲烷体积分数达到82.7%~84.9%,而且料液不会出现酸化现象。海带渣与养殖固废混合水解酸化、批量填料发酵产沼气工艺明显提高了产气效率和系统稳定性。

沼气;甲烷;发酵;混合水解酸化;批量填料发酵;海带渣;养殖固废

0 引 言

海带是大型海洋经济藻类,中国海带养殖年产量近150万t,占世界海带总产量的80%以上[1-2]。海带除直接食用外,亦是重要的工业原料[3-6],目前被广泛用于提取多糖、褐藻酸和碘等高附加值物质[7-9]。由于海带在深加工过程中的利用率只有30%左右,超过50%的残留物为海带渣[10],而这些残渣中仍含有较高的糖类、纤维素和蛋白质等物质[10-12],因此海带渣的资源化利用仍具有重要价值。目前已有利用海带渣提取膳食纤维、制备饲料、肥料和油污吸附材料等的研究探索[13-16];另有利用海带渣发酵制备生物乙醇的研究报道,如明凯利等[17]探讨了干海带渣经过120℃酸、碱处理,在酵母作用下发酵产乙醇的特性,认为比秸秆发酵产乙醇更具优势;Jin等[18]开展了干海带渣发酵产乙醇试验研究,发现经过酸预处理和酶水解,可提高海带渣发酵产乙醇的效率。然而,上述方法仍存在加工成本高、工序复杂、占地空间大和二次污染等局限性,因此,目前大量海带渣仍被作为工业垃圾直接填埋或随加工废水一起排掉。另一方面,随着中国工业化水产养殖的快速发展,大量养殖固废(占投饵量的25%~40%[19])的资源化利用问题,亦成为降低环境污染和环境增值能源开发的重要选择[20-24]。李丰等[25]曾开展了海带渣与养殖固废厌氧发酵产沼气试验探索,发现利用海带渣发酵产沼气具有一定的潜力,而且添加一定比例的养殖固废,可明显提高产效率;但同时发现,海带渣与养殖固废水解较快,采用单相发酵产气容易出现料液过度酸化问题,从而影响产气量和系统稳定性。本文在前期研究的基础上,拟开展海带渣与养殖固废两相厌氧发酵产沼气效果试验研究,探讨料液TS(total solids)浓度和接种率等对海带渣与养殖固废混合水解酸化特性的影响规律以及利用酸化料液发酵产沼气的效果。提出海带渣与养殖固废两相发酵产沼气的合理条件,以期为中国渔业废弃物的低成本和资源化利用提供相关技术参考。

1 材料与方法

1.1 试验材料

海带渣:海带提取岩藻聚糖硫酸酯后的残渣。海带提取多糖过程为:粉碎→酶解(果胶酶和纤维素酶)→浸泡提取→剩余海带渣。将新鲜海带渣封袋包装,保存在-18℃的冰箱中备用。

种污泥:取自大连东泰产业废弃物处理有限公司的餐厨垃圾厌氧发酵产沼气系统,系统发酵温度为35±1℃,pH值为7.5±2。种污泥用棕色玻璃容器密封保存于4℃的冰箱中备用。

养殖固废:取自大连市某石斑鱼循环水养殖系统中沉淀池的底部,清除石块等异物,用棕色玻璃容器密封保存于4℃的冰箱中备用。

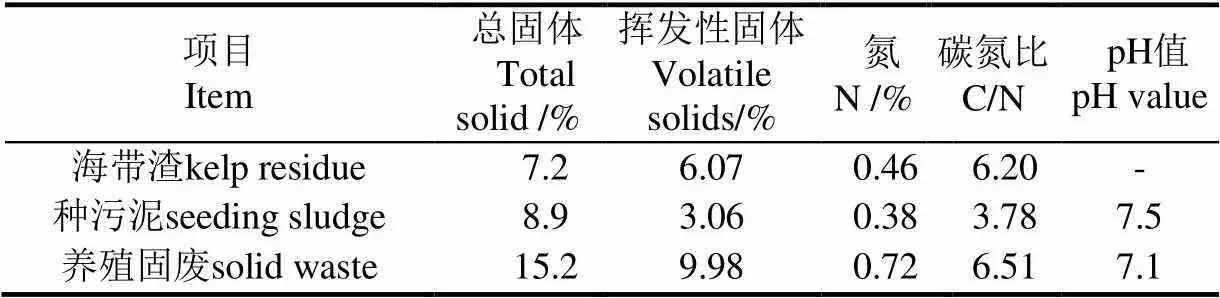

海带渣、种污泥和养殖固废的主要特性指标分别见表1。

表1 海带渣、种污泥和养殖固废的主要成分

1.2 试验仪器与设备

试验系统:海带渣与养殖固废混合水解酸化和厌氧发酵产沼气系统同文献[26]。

其他仪器设备:紫外可见分光光度计(UV-7504)、气相色谱仪(GC9890)、高效液相色谱仪(日立L-2000)、台式高速冷冻离心机(TGL-16M)、电热鼓风干燥箱(101A-3)、箱式电阻炉(SX2-4-10)、精密电子天平(MP1100b)和pH计(PHS-3E)等。

1.3 试验方法

1.3.1 接种污泥驯化

水解酸化接种污泥驯化:取种污泥于发酵瓶中,按种污泥质量分数的30%加入海带渣和养殖固废,其中海带渣与养殖固废的混合质量比为4:3(前期试验结果),用1~3 mol/L的HCl调节pH值至5.0~7.0,在温度为(35±1)℃的条件下培养驯化,直到系统不产气为止,制得水解酸化接种污泥。

产甲烷接种污泥驯化:取种污泥于发酵瓶中,按种污泥质量分数的1%加入海带渣与养殖固废(二者质量比同上),用1 mol/L的NaHCO3调节pH值至7.0~8.0,每天按照上述质量比连续添加海带渣和养殖固废,在温度为(35±1)℃的条件下驯化20 d,制得产甲烷接种菌种。

1.3.2 厌氧水解酸化试验

1)不同料液TS浓度水解酸化试验:将海带渣与养殖固废按照质量比4:3混合,加蒸馏水调节料液TS浓度分别为6%、8%和10%,按与海带渣质量比1:10的比例加入水解酸化接种污泥,用1 mol/L的HCl和NaOH将料液的pH值调至7.0,在温度为(35±1)℃条件下水解酸化。每个试验组设置2个平行样,每24 h取样测定VFA(volatile fatty acids)及其主要组分的浓度、料液pH值和SCOD(soluble chemical oxygen demand)浓度等指标,试验持续8 d。

2)不同接种率水解酸化试验:将海带渣与养殖固废按照质量比4:3混合,加蒸馏水调节料液TS浓度为8%,分别按与海带渣质量分数为10%、20%和30%的比例加入水解酸化接种污泥。其他方法同上。

1.3.3厌氧发酵产气试验

取水解酸化料液30g,分别按酸化料液与接种污泥质量比为1:5、1:7和1:9的比例加入产甲烷接种污泥,混合混匀,用1~3 mol/L的NaOH和HCI将混合液的pH值调至7.0~8.0,在温度为(35±1)℃条件下进行厌氧发酵产沼气试验。每24 h取样测定系统产气量、生物气体中甲烷含量、料液pH值和COD浓度等指标,同时每天定量添加水解酸化料液30 g,进行批量填料发酵产气试验。

1.4 指标测定方法

料液TS和VS分别用称质量法测定[27];SCOD浓度和pH值分别用重铬酸钾法和酸度计测定[28];VFA浓度和VFA主要组分浓度测定分别用比色法和高效液相色谱分析法测定[28];沼气中的甲烷体积分数采用GC9890气相色谱测定。

2 结果与分析

2.1 混合水解酸化

图1为不同TS浓度条件下,海带渣与养殖固废混合水解酸化试验结果。由图1可知,水解前期,3种TS浓度的料液中均有少量甲酸产生,5 d后甲酸产量增加较明显,分别在第6~7天达到峰值1 536.8、1 335.0和2 174.2 mg/L。料液TS浓度越高,甲酸浓度相对较高,但是与同条件下的乙酸浓度比较,3种TS浓度的料液中甲酸产量明显较低。另由图1可知,水解开始后,各料液中的乙酸浓度均显著增加,第2天分别达到5 910.5、7 533.5和8 720.6 mg/L的峰值,4 d后乙酸浓度明显下降,第8天时分别降至1 642.0、1 892.9和2 069.2 mg/L。水解过程中,料液TS浓度高,乙酸产亦比较高。由图1还可看出,TS浓度为6%和8%的料液在水解开始后均有一定量的丁酸产生,而TS浓度为10%的料液水解第2天后有少量丁酸产生,5 d后各料液中的丁酸浓度明显增加,第6~7天峰值分别达到5 517.3、3 757.9和5 030.5 mg/L。此外,水解开始后,各料液中均有少量的丙酸产生,5 d后丙酸浓度增幅明显(见图1),第8天时分别达到3 730.9、4 993.0和6 367.3 mg/L,料液TS浓度高,丙酸产量相对较高。

分析试验结果,海带渣与养殖固废混合水解酸化过程启动很快,前3 d乙酸是主要的VFA组分,后期丙酸和丁酸产量较高,水解酸化过程中甲酸浓度相对较低。因为在水解前期,料液的pH值相对较高(见图1d),有利于产乙酸微生物的代谢[29-30],料液中的有机质被迅速水解转化成乙酸;但是随着酸化时间延长,其他酸化菌将乙酸转化成H2和CO2(结果未示出)和甲酸等[31],致使乙酸浓度随之降低;另一方面,由于水解初期料液中H2的分压力较低,产生的丙酸相对容易转化为乙酸[31],而随着H2的分压力升高,丙酸转化为乙酸的难度加大,同时随着水解后期有机酸的积累,料液pH值降低(见图1d),产丙酸菌活性增加[30-32],致使丙酸产量提高;此外,水解后期偏酸性的料液(pH值为5.48~5.95)使丁酸浓度增加,这与张波等[30]的研究结果基本一致。

另由试验结果发现,料液TS浓度对海带渣与养殖固废混合水解有机酸产量及其组分等有较大影响。水解过程中,TS浓度为6%的料液有机酸产量明显低于其他2种料液;水解后期,TS浓度高的料液丙酸产量越高;水解3 d中,3种TS浓度的料液中乙酸的平均酸化度(乙酸浓度/SCOD浓度)[33]分别为42.6%、50.0%和49.8%;对后期厌氧发酵产沼气比较有利的3种有机酸(乙酸+丁酸+甲酸)的酸化度分别达到61.7%、68.7%和62.2%。综合考虑水解VFA组分特性与产量以及料液pH值波动等因素,选取料液TS浓度为8%~10%,pH值为6.0~7.0,在中温条件下水解2~3 d, 对海带藻渣和养殖固废混合水解酸化和保证后期发酵产沼气比较有利。

注:甲乙丁/SCOD 为甲酸、乙酸和丙酸的总酸化度,即:水解酸化料液中甲酸、乙酸和丁酸的质量和与SCOD质量之比;乙/SCOD 为乙酸的酸化度,即:水解酸化料液中乙酸的质量与SCOD的质量比。

图2 接种率对混合水解酸化特性及pH值的影响

图2为不同接种率条件下,海带渣与养殖固废混合水解试验结果。由图2看出,水解期间,3种料液均有一定量的甲酸产生,但是甲酸浓度比较低,水解8d,甲酸的平均浓度分别为1 059.6、1 122.3和1 170.6 mg/L。另由图2可知,水解开始后,不同接种率的料液中乙酸浓度均显著增加,第2天分别达到峰值(7 533.5、7 052.5和6 840.4 mg/L),之后出现不同幅度的下降,其中接种率为30%的料液乙酸产量下降最为明显,第3天时该料液中乙酸浓度已降至2 762.8 mg/L,可见接种率愈高,乙酸产量较低。由图2还可看出,接种率为10%的料液在水解开始后即有丁酸产生(见图2a),第7天达到峰值(3 757.9 mg/L);而接种率为20%和30%的料液,水解3 d后丁酸浓度增加比较显著,分别在第6天达到峰值(4 018.8和4 543.9 mg/L)。此外,在水解前期,各料液中均有一定的丙酸产生,5 d后丙酸产量明显增加,水解期间各料液中的丙酸平均浓度分别为2 651.0、2 752.4和2 819.0 mg/L,接种率越高,丙酸产量相对较高。

由图2d结果看出,水解酸化第1天,不同接种率的料液的pH值迅速降至5.91~6.04,这是因为海带渣和养殖固废颗粒迅速水解酸化产生了大量有机酸,导致pH值迅速降低。另外,水解酸化1~4 d中,接种率为10%的料液pH值波动较小,期间乙酸产量也较高,之后pH值出现波动性降低,料液中的丙酸和丁酸浓度随之增加。此外,水解酸化2 d后,接种率为20%和30%的料液的pH值出现显著下降,其中后者下降更加明显,期间乙酸浓度降幅也最大;第4~6天2种料液的pH值一直维持在较低水平(5.69~5.72),该阶段料液中的丙酸和丁酸浓度明显增加。可见,接种率越高,水解过程中pH值下降越快,因为接种率高,菌种含量多,酸化底物的酸化速率越大[33]。

结果表明,不同接种率条件下,海带渣和养殖固废混合水解前期均属乙酸型水解过程,后期为丁酸和丙酸型水解,而且接种率越高,水解乙酸产量越低,产丁酸和丙酸优势更明显。因为水解酸化是一个微生物生长代谢的过程,接种微生物的含量直接决定水解酸化原料的降解速率和酸化产物的种类[31-33]。在本试验条件下,水解酸化3 d,3种料液中乙酸的平均酸化度分别为50.7%、44.3%和40.3%;3酸(乙酸+丁酸+甲酸)的平均酸化度分别为69.4%、57.5%和58.0%。综合考虑水解产酸特性,海带渣和养殖固废混合水解酸化时,当接种率为10%~20%,料液pH值为6.0~7.0,水解2~3 d,可获得后期发酵产沼气所需的酸化料液。

2.2 厌氧发酵产沼气试验

图3为海带渣与养殖固废的混合水解酸化料液厌氧发酵产沼气的试验结果。由图3a看出,厌氧发酵产气系统启动后,不同接种比例的料液日产气量均呈上升趋势,其中接种比例为1:9的料液日产气量增幅最为明显,第8天时达到峰值730 mL/d, 之后日产气量保持在625~690 mL/d之间;接种比例为1:5和1:7的料液分别在第17和13天达到产气高峰(690 和685 mL/d)。可见接种比例越高,产气系统启动越快,而且达到产气高峰的时间越短。由图3a还可看出,系统运行13 d后,3种料液均进入稳定产气阶段,而且日产气量非常接近。表明在该阶段,接种比例对日产气量的影响不显著。

由图3b可知,产气系统启动后,不同接种比例的料液的累积产气量几乎均呈线性递增趋势,而且7 d后累积产气量增幅更为明显,系统运行18 d时,3种料液的累积产气量分别为8 960、9 565和11 020 mL,平均VS产气率分别达到470.6、489.4和581.5 mL/g。可见,接种比例高的料液,累积产气量和产气率均相对较高。

此外发现,系统启动后,3种料液所产生沼气的甲烷含量均呈递增趋势(见图3c)。第13天时,甲烷体积分数分别由第2天的12.4%、20.8%和24.8%增至74.0%、82.4%和83.3%,之后各试验组甲烷含量趋于稳定,平均体积分数分别为77.1%、82.6%和84.9%,表明在该阶段甲烷菌已很好地适应了发酵料液环境,并且进入稳定生长时期,其中接种量分别为1:7和1:9的发酵料液所产生物气体中甲烷含量较高。

图3 水解酸化料液批量填料发酵产气特性

由图3d还可看出,系统启动5 d中,3种料液的pH值呈现波动性增加趋势,分别由初始的7.31、7.36和7.52,增至第5天的7.60、7.63和7.67,这与该阶段产气细菌处于适应期,系统产气相对不稳定有关;系统运行第6~11天中,各料液pH值相对比较稳定,其中接种量为1:9的料液pH值相对较高,与该阶段料液的产气量比较一致;系统运行11~12 d期间,接种比例为1:5和1:7的料液的pH值出现了一定下降,但是进入稳定产气阶段后,各料液的pH值均趋于稳定,分别保持在7.56、7.53和7.57左右,对甲烷菌生长比较有利[34]。系统运行期间,3种料液均未出现酸化现象。

3 结 论

1)水解酸化结果表明,海带渣与养殖固废混合水解酸化过程启动很快,第2天乙酸浓度即达到峰值,5 d后丙酸和丁酸浓度增幅较快,水解酸化过程中甲酸产量相对较低。水解3 d,乙酸和主要有机酸的酸化度分别达到40.3%~50.7%和57.5%~69.4%。当料液TS浓度为8%~10%、污泥接种率在10%~20%、料液pH值为6.0~7.0时,在(35±1)℃的条件下水解酸化2~3 d,即可获得后期厌氧发酵产沼气所需要的水解酸化料液。

2)厌氧发酵产沼气结果证明,水解酸化料液厌氧发酵产沼气系统启动后,日产气量和生物气体中甲烷含量提升很快,且接种比例高的料液,产气效率较高,进入稳定产气所需的时间也较短;13 d后接种比例对产气效果的影响已不显著。当接种比例为1:7~1:9、料液pH值为7.0~8.0,在(35±1)℃的条件下,批量填料发酵产沼气时,8~13 d可进入稳定产气阶段,产气率达到489.4~581.5 mL/g,所产生物气体中甲烷体积分数在80%以上,且系统可保持持续稳定产气。

3)试验结果显示,海带渣与养殖固废两相厌氧发酵系统的日产气量和甲烷含量高于单相厌氧发酵系统。因此,海带渣与养殖固废混合水解酸化、批量填料厌氧发酵产沼气的工艺模式,明显提高了产气效率和系统稳定性。

[1] 农业部渔业渔政管理局. 中国渔业统计年鉴[M].北京:中国农业出版社,2017.

[2] 岳昊,孙英泽,胡婧,等.中国海带产业及国际贸易情况分析[J]. 农业贸易展望,2013(9):65-74.Yue Hao, Sun Yingze, Hu Jing, et al. Industry and international trade ofin China[J]. Agricultural Outlook, 2013(9): 65-74. (in Chinese with English abstract).

[3] 宋武林. 海带的主要功能及加工利用研究现状[J]. 渔业研究,2016,38(1):81-86.Song Wulin. Research on the primary functions and utilization of[J]. Journal of Fisheries Research, 2016,38(1): 81-86. (in Chinese with English abstract).

[4] Anbuchezhian R, Karuppiah V, Li Z. Prospect of Marine Algae for Production of Industrially Important Chemicals[M]. In: Das D. (eds) Algal Biorefinery: An Integrated Approach. Cham: Springer International Publishing, 2015.

[5] Stefan Kraan. Mass-cultivation of carbohydrate rich macroalgae, a possible solution for sustainable biofuel production[J]. Mitigation and Adaptation Strategies for Global Change, 2013, 18(1): 27-46.

[6] Adams J M M, Bleathman G,Thomas D, et al. The effect of mechanical pre-processing and different drying methodologies on bioethanol production using the brown macroalga(Hudson) JV[J]. Journal of Applied Phycology, 2017, 29(5): 2463-2469.

[7] 任丹丹,李景娟,李佰磊,等. 海带岩藻黄素对油脂氧化的抑制作用研究[J],大连海洋大学学报,2012,27(6):564-566.Ren Dandan, Li Jingjuan, Li Bailei, et al. Antioxidative activity to lipids by fucoxanthin from kelp[J]. Journal of Dalian Ocean University, 2012, 27(6): 564-566. (in Chinese with English abstract).

[8] 刘淇,孙霞,赵玲. 鲜海带加工中甘露醇、碘及主要金属元素含量变化[J].海洋渔业,2014,36(1):73-77.Liu Qi, Sun Xia, Zhao Ling. The content changes of mannitoliodine and main metal elements in the fresh Laminaria japonica processing[J]. Marine Fisheries, 2014, 36(1): 73-77. (in Chinese with English abstract).

[9] Bernd H A, Rehm M, Fata M. Alginate production from marine macroalgae, with emphasis on kelp farming[J]. Alginates and Their Biomedical Applications. In Springer Series in Biomaterials Science and Engineering, 2018(11) 27-66.

[10] 张俊杰,段蕊,许可,等. 海带工业中海带渣应用的研究及展望[J]. 水产科学,2010,29(10):620-623.Zhang Junjie, Duan Rui, Xu Ke, et al. Status and development of dealginate residues in kelp industry[J], Fisheries Science, 2010, 29(10): 620-623. (in Chinese with English abstract).

[11] Feng X, Meng X, Zhao J,et al. Extraction and preparation of cellulose nanocrystals from dealginate kelp residue: Structures and morphological characterization[J]. Cellulose, 2015, 22(3): 1763-1772.

[12] 卢茳虹,林宗毅,崔春,等. 柠檬酸提取海带渣中多糖及其抗氧化活性与结构的研究[J].食品工业科技,2012,33(23):93-96.Lu Jianghong,Lin Zongyi,Cui Chun, et al. The extraction of polysaccharide from Laminaria japonica residue by citric acid and study on antioxidant activitiesand structural characteristics[J]. Science and Technology in Food Industry, 2012, 33(23):93-96. (in Chinese with English abstract).

[13] 周楠,马杰,张淑平,等. 海带渣生产有机肥的工艺研究[J]. 化学工程与装备. 2011(3):11-13.Zhou Nan, Ma Jie, Zhang Shuping, et al. Study on the technology of kelp residue in organic fertilizer production[J]. Chemical Engineering& Equipment, 2011 (3): 11-13. (in Chinese with English abstract).

[14] 彭素晓,常志强,马骊,等. 海带渣添加比例及其酶解产物对凡纳滨对虾生长、消化和非特异性免疫力的影响[J]. 动物营养学报,2017,29(7):2587-2596.Peng Suxiao, Chang Zhiqiang, Ma Li, et alEffects of kelp meal adding proportion and its enzymatic hydrolysates on growth digestion and non-specific immunity of[J]. Chinese Journal of Animal Nutrition, 2017, 29(7): 2587-2596. (in Chinese with English abstract).

[15] 李莎,张国琛,李秀辰,等. 挤压膨化与改性处理海带渣的油污吸附特性试验[J].大连海洋大学学报,2014,29(4):413-419. Li Sha,Zhang Guochen, Li Xiuchen, et al. Oilabsorbing property of kelpresidues extruded and modifiedby stearic acid[J]. Journal of Dalian Ocean University, 2014, 29(4): 413-419. (in Chinese with English abstract).

[16] Yu L L , Browning J F, Burdette C Q, et al. Development of a kelp powder () Standard Reference Material[J]. Analytical and Bioanalytical Chemistry, 2018, 410(4): 1265-127.

[17] 明凯利,张梅,王树春,等. 利用海带渣生产燃料乙醇的初步研究[J]. 化工进展,2013,32(3):570-574.Ming Kaili, Zhang Mei, Wang Shuchun, et al. A preliminary study on production of fuel ethanol from kelp residue [J]. Chemical Industry and Engineering Progress, 2013, 32(3): 570-574. (in Chinese with English abstract).

[18] Jin T, Wang H, Wang J, et al.Ethanol production from kelp slag hydrolysates using genetically engineered. Journal of Applied Phycology, 2015, 27(3): 1327-1336.

[19] Timmons M B, Ebeling J M, Wheaton F W. Recirculating Aquaculture System[M]. New York: USDA-CSREES NRAC Publication, 2001.

[20] 李秀辰,李俐俐,张国琛,等.养殖固体废弃物作碳源的海水养殖废水反硝化净化效果[J].农业工程学报,2010,26(4):275-279.Li Xiuchen, Li Lili, Zhang Guochen, et al. Denitrification of wastewater with external carbon source of solid wastes in recirculating marine culture system[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(4): 275-279. (in Chinese with English abstract).

[21] 李平,罗国芝,谭洪新. 循环水养殖系统固体废弃物厌氧消化处理技术与分析[J]. 渔业现代化,2009,36(6):16-19. Li Ping,Luo Guozhi, Tan Hongxin. Analysis of anaerobic digestion of waste solids derived from recirculating aquaculture system[J]. Fishery Modernization,2009, 36(6): 16-19. (in Chinese with English abstract).

[22] Lanari D, Franci C. Biogas production from solid wastes removed from fish farm effluents[J]. Aquatic Living Resources, 1998, 11(4): 289-295.

[23] Gebauer R. Mesophilic anaerobic treatment of sludge from saline fish farm effluents with biogas production[J]. Bioresource Technology, 2004, 93(2): 155-167.

[24] Gebauer R, Ekebrokk B. Mesophilic anaerobic treatment of sludge from salmon smolthatching[J]. Bioresource Technology, 2006 (97): 2389-2401.

[25] 李丰. 海带藻渣与养殖固废联合厌氧发酵制取沼气主要工艺试验研究[D]. 大连:大连海洋大学,2013.Li Feng. Study on the Technology and Process of Biogas Production by Kelp Residue and Aquaculture WasteCombined Anaerobic Fermentation[D]. Dalian: Dalian Ocean University, 2013. (in Chinese with English abstract).

[26] 李秀辰,张国琛,孙文,等. 不同预处理和发酵条件对浒苔沼气产率的影响[J].农业工程学报,2012,28(19):200-206.Li Xiuchen, Zhang Guochen, Sun Wen, et al. Biogas yield ofunder different pretreatment and anaerobicfermentation conditions[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(19): 200-206. (in Chinese with English abstract).

[27] 袁振宏,吴创之,马隆龙. 生物质能利用原理与技术[M].北京:化学工业出版社,2005.

[28] 任南琪,王爱杰. 厌氧生物技术原理与应用[M]. 北京:化学工业出版社,2004.

[29] 王忠江,李文哲,石铁,等. 温度和料液浓度对牛粪高浓度厌氧水解酸化的影响[J]. 农业工程学报,2008,24(11):212-216.Wang Zhongjiang, Li Wenzhe, Shi Tie, et al. Effects of temperature and liquor concentration on the high-concentration anaerobic hydrolysis and acidogenesis of dairy manure[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2008, 24(11): 212-216. (in Chinese with English abstract).

[30] 张波,史红钻,张丽丽. pH对厨余废物两相厌氧消化中水解和酸化过程的影响[J].环境科学学报,2005,25(5):665-669.Zhang Bo, Shi Hongzuan, Zhang Lili. The influence of pH on hydrolysis and acidogenesis of kitchen wastes in two-phase anaerobic digestion[J]. ActaScientiae Circumstantiae, 2005, 25(5): 665-669. (in Chinese with English abstract).

[31] 任南琪,王爱杰,马放.产酸发酵微生物生理生态学[M].北京:科学出版社,2005.

[32] 贺静,邓雅月,李凛,等. 废弃食用油脂两相厌氧发酵酸化条件优化[J]. 农业工程学报,2015, 31(19): 247-253.He Jing, Deng Yayue, Li Lin, et al. Process optimization of wasted edible oil hydrolytic acidification in two-phase anaerobic digestion[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(19): 247-253. (in Chinese with English abstract).

[33] 谭文英,许勇. 餐厨垃圾水解酸化性能的研究[J]. 安徽农业科学,2014,42(33):11832-11835,11838.Tan wenying,Xu Yong. Research on hydrolysis and acidification performance of food waste[J]. Journal of Anhui Agr. Sci. 2014, 42(33): 11832-11835,11838. (in Chinese with English abstract).

[34] 泮进明,张瑜,朱宝宁,等. 食品废物两相高温半干法厌氧发酵生产沼气初步研究[J]. 农业工程学报,2008,24(7):199-203. Pan Jinming, Zhang Yu, Zhu Baoning, et al. Biogas production from food waste by two-stage semi-dry-thermophilic anaerobic digestion[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(7): 199-203. (in Chinese with English abstract).

Biogas yield by mixed anaerobic fermentation of kelp residue and aquaculture solid waste

Li Xiuchen, Li Feng, Zhang Guochen, Zhang Qian, Yang Fuli, Mu Gang

(116023,)

Above50% of kelp in weight is left as residue during kelp processing, and 25%-40% of the feed in aquaculture is converted to solid waste. Efficient and cost-effective utilization of kelp residue and aquaculture solid waste is vital for sustainable development of modern fisheries. Experimental studies on biogas yield from two-phase fermentation of kelp residue and aquaculture solid waste were carried out in the condition of (35±1) ℃ medium temperature. The effects of TS concentration and inoculation rate on mixing hydrolytic acidification characteristics of kelp residue and aquaculture solid waste were studied, and sequentially the biogas yield property from acidified liquor in a batch-adding manner was studied as well. Concentrations of VFA (volatile fatty acids) and their main components, COD (chemical oxygen demand), pH value, and so on were measured during mixing hydrolytic acidification process. Accordingly, the items including daily biogas yield, methane content in the biogas, and pH value were recorded during the fermentation process. Results showed that the mixing hydrolytic acidification process of kelp residue and aquaculture solid waste was fast. The highest concentration of acetic acid was measured on the 2ndday of hydrolyzing, while the concentration of propionate acid and butyric acid increased relatively quickly after 5 days’ hydrolyzing. Formicacid production during the mixing hydrolytic acidification process was relatively lower. With TS concentration of 6%, 8% and 10%, the acidifying degree of acetic acid and main organic acids (acetic acid + butyric acid + formicacid) reached 42.6%, 50.0%, 49.8% and 61.7%, 68.7%, 62.2%, respectively. Additionally, with inoculation rate of 10%, 20% and 30% for mixing hydrolytic acidification, the acidifying degree of the acetic acid and main organic acids were 50.7%, 44.3%, 40.3% and 69.4%, 57.5%, 58.0%, respectively, after 3 days’ hydrolyzing. It was accordingly known that desired acidified liquor could be obtained for further fermentation and biogas production by mixing hydrolytic acidification of kelp residue and aquaculture solid waste at (35±1) ℃ in 2-3 d if TS concentration, inoculation rate and pH value were kept at 8%-10%, 10%-20%, and 7.0-8.0, respectively. Furthermore, the fermentation of acidified liquor demonstrated that the biogas production process started quickly and kept an increasing biogas yield and methane content by batch-adding of acidified liquor and with the quantity ratios of acidified liquor to the inoculation methanogenic sludge of 1:5, 1:7 and 1:9. There was a measureable increase in pH value of liquor during the first 5 days and a little fluctuation in pH value in the ratios of 1:5 and 1:7 during the 11th-12thday, but stable pH value was found after 13 days. Relatively higher daily biogas yield and earlier peak of biogas yield were measured in the liquor of 1:9, followed by the liquor of 1:7 and 1:5. After the fermentation of 13 days, the quantity ratio of acidified liquor to the inoculation methanogenic sludge had no significant influence on the daily biogas yield and methane content in the biogas. Comparatively, with the quantity ratios of acidified liquor to the inoculation methanogenic sludge of 1:7 and 1:9, the biogas production efficiency could reach 489.4-581.5 mL/gVS and the methane content in the biogas reached 82.7%-84.9% after 8-13 days fermentation at (35±1) ℃ and pH value of 6.0-7.0. No excessive accumulation of VFA was observed during the fermentation process of the acidified liquor. Therefore higher efficiency and stability of biogas production may be achieved by mixing hydrolytic acidification and batch-adding fermentation of kelp residue and aquaculture solid waste.

biogas; methane; fermentation; co-hydrolytic acidification; batch-adding fermentation; kelp residue; aquaculture solid waste.

10.11975/j.issn.1002-6819.2018.18.028

X512

A

1002-6819(2018)-18-0228-07

2018-05-16

2018-07-12

辽宁省创新团队项目(LT2016018);辽宁省科技攻关项目(201304)

李秀辰,博士,教授,主要从事渔业节能减排技术研究。

Email:lxc@dlou.edu.cn

李秀辰,李 丰,张国琛,张 倩,杨福利,母 刚. 海带渣与养殖固体废弃物混合发酵产沼气试验[J]. 农业工程学报,2018,34(18):228-234. doi:10.11975/j.issn.1002-6819.2018.18.028 http://www.tcsae.org

Li Xiuchen, Li Feng, Zhang Guochen, Zhang Qian, Yang Fuli, Mu Gang. Biogas yield by mixed anaerobic fermentation of kelp residue and aquaculture solid waste[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(18): 228-234. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2018.18.028 http://www.tcsae.org