激光淬火及熔覆技术提高柑橘枝粉碎机65Mn钢锤片耐磨性

2018-09-03黄永俊李明震李善军张衍林

孟 亮,李 雄,黄永俊,万 强,李明震,李善军,张衍林

激光淬火及熔覆技术提高柑橘枝粉碎机65Mn钢锤片耐磨性

孟 亮,李 雄,黄永俊,万 强,李明震,李善军,张衍林※

(华中农业大学工学院,武汉 430070)

为了提高柑橘枝粉碎机锤片的摩擦性能,该文主要通过多面激光淬火及激光熔覆技术强化65Mn钢锤片表面。采用金相显微镜、显微硬度计、摩擦磨损试验机等探究激光处理后65Mn钢组织对其显微硬度及摩擦性能的影响。试验结果表明:经激光淬火处理后65Mn钢主要由完全淬火区、不完全淬火区、热影响区及基体组成,经激光熔覆处理后65Mn钢主要由熔覆区、完全淬火区、不完全淬火区、热影响区及基体组成;65Mn钢经激光淬火处理后,其显微硬度最高可达619.8 HV0.1;65Mn钢经激光熔覆处理后,其显微硬度最高可达1 038.4 HV0.1;65Mn钢经水淬-中温回火处理后,其平均显微硬度为585.6 HV0.1;激光淬火处理后65Mn钢表面出现磨粒磨损机制,平均摩擦系数为0.40;65Mn钢经激光熔覆Ni60+35%WC后熔覆层表面出现磨粒磨损机制,平均摩擦系数为0.36;水淬-中温回火热处理后65Mn钢表面出现粘着磨损机制,平均摩擦系数为0.41;由此可见,65Mn钢锤片经激光熔覆处理后摩擦性能较好。该研究可为锤片耐磨性提升提供参考。

农业机械;显微组织;淬火;激光熔覆;显微硬度;摩擦性能

0 引 言

由于65Mn具有良好的摩擦性能以及较好的经济性,使得65Mn钢成为很多刀具及工程机械耐磨工件的首选材料。65Mn钢锤片作为柑橘枝粉碎机上的关键工作部件,易于出现磨损进而影响柑橘枝粉碎机工作效率。为进一步提高65Mn钢耐磨工件使用寿命,相关学者采用了一些新的工艺方法提高65Mn钢耐磨工件的使用寿命,王宏立等[1]对65Mn钢表面进行激光淬火,试验对象为65Mn钢板,试验方法采用预热处理后的单道激光淬火和激光熔凝,试验表明:经激光淬火处理后试样表面组织为细密的针状马氏体,显微硬度较常规处理有较大提高,试样拥有较好摩擦性能且磨损机制为磨粒磨损和黏着磨损。袁晓明等[2]对65Mn钢旋耕刀表面进行渗铬-淬火-中温回火热处理工艺,试验表明:处理过的旋耕刀能达到典型的表硬内韧特点,摩擦性能较传统工艺处理试样得到了较大提高。黄永俊等[3]对农机用65Mn钢刀具进行预热处理-激光强化,试验对象为65Mn钢板,试验方法采用激光淬火时单道扫描,试验表明:激光淬火处理后硬化区的显微硬度要高于激光熔凝硬化区显微硬度,正火预热处理后激光强化组织显微硬度要高于淬火-中温回火预热处理后激光强化组织的显微硬度。由于金属复合涂层具有较高的硬度、较优的摩擦性能以及良好的化学稳定性,使得其在磨损部件中的应用得到越来越多的关注[4-12]。

激光表面强化技术具有冷却速度快、自动化程度高及易于选区加工等特点,因此在工件表面改性方面得到了广泛的应用。单道激光处理为农机用65Mn钢在农机部件组织改善和耐磨性提升方面提供一定的科学依据,但其试验方法与实际应用需求存在一定差异;本文选择粉碎机65Mn钢锤片作为试验对象,采用多面激光淬火和激光熔覆处理对锤片进行表面强化,研究不同工艺处理后试样显微组织及摩擦性能。

1 试验材料及方法

1.1 试验材料

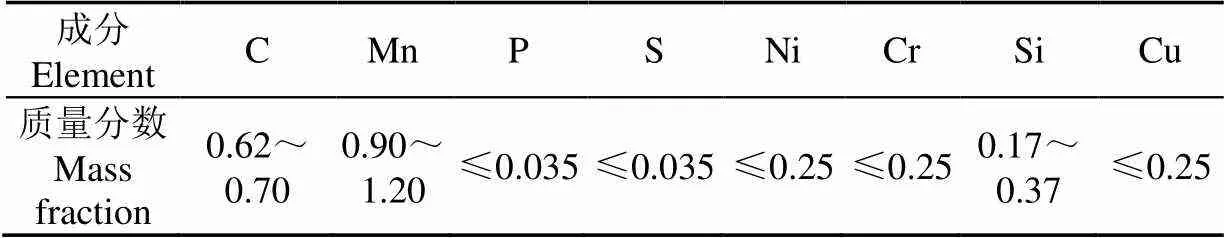

激光淬火、激光熔覆及普通热处理试验所采取的基材均为65Mn钢锤片,试验前对试样表面除锈除油并清洗洁净,试样尺寸为90 mm×60 mm×12 mm,其组织成分如表1所示。激光熔覆涂层材料为WC/Ni60(碳化钨与镍60)合金粉末,其中WC(碳化钨)的质量分数为35%。

表1 65Mn钢基体成分组成(质量分数)

1.2 试验方法

本试验采用设备为GS-HL-5000型激光器(武汉高斯激光设备有限公司,功率5 kW,波长10.6m)及SX2-5-12型电炉(武汉亚华电炉有限公司,额度功率5 kW,额定电压220 V,额定温度1 000 ℃)。试验方法采用多面激光淬火和激光熔覆处理。激光淬火时采用功率为2.5 kW,扫描速度为300 mm/min。激光熔覆时采用功率为3.2 kW,扫描速度为350 mm/min,送粉速度为15~20 g/min。普通热处理采用水淬-中温回火工艺,其试验参数为:淬火温度为790 ℃,时间20 min;中温回火温度为350 ℃,时间25 min。试样经激光淬火及激光熔覆后,沿垂直于扫描速度方向截取一部分制作金相样品,使用体积分数为10%的硝酸酒精溶液对金相样品进行腐蚀。试样经普通热处理后,在试样任意部位截取部分制作金相样品,并利用10%的硝酸酒精溶液对金相样品进行腐蚀。通过MJ30型金相显微镜(广州市明美光电技术有限公司,像素2000万)分析金相试样的显微组织结构,利用HV-1000B型数字显微硬度计(烟台华银试验仪器有限公司,最小检测单位0.25m)测量金相试样各部分显微硬度,加载压力为0.981 N,压力保持时间为15 s。将表面改性后的试样制作成15 mm×15 mm×4 mm标准试样块,在MS-T-3001型摩擦磨损试验机(兰州华汇仪器科技有限公司,加载精度0.1 g)进行磨损试验,磨头材料为Si3N4,试验时间20 min,载荷500 g,旋转速度50 r/min,摩擦温度0 ℃。锤片实际运行工况下磨损主要集中于4个顶角相邻端面,因此为提升锤片摩擦性能,本文对锤片4个顶角相邻5个端面全部进行激光淬火及激光熔覆,如图1所示,热处理范围尺寸为60 mm×15 mm、12 mm× 15 mm、60 mm×12 mm。

图1 65Mn钢锤片激光处理部位示意图

2 试验结果与分析

2.1 激光淬火处理后65Mn组织分析

图2为65Mn钢经激光淬火处理后显微组织的低倍截面形貌及各温度区间显微组织结构。

图2 激光淬火处理后样品显微组织

如图2a所示,65Mn钢经激光淬火处理后由表及里显微组织由完全淬火区、不完全淬火区、热影响区及基体组成。如图2b所示,由于激光加工时工作区域较小且激光能量密度较大,导致其加热和冷却速率极快,所以经激光淬火后65Mn钢表层完全淬火区组织为针状马氏体+少量残余奥氏体,残余奥氏体分布在针状马氏体之间。如图2c所示,不完全淬火区组织为铁素体+回火屈氏体,回火屈氏体分布在铁素体之间;回火屈氏体是由于多面激光淬火造成,具体来说是进行另一面加工时,由于热流因素影响,进而相当于对前一次组织进行回火。热影响区组织为片层状珠光体+粒状珠光体,如图2d所示,片层状珠光体的量少于基体内片层状珠光体。

2.2 激光熔覆处理后65Mn组织分析

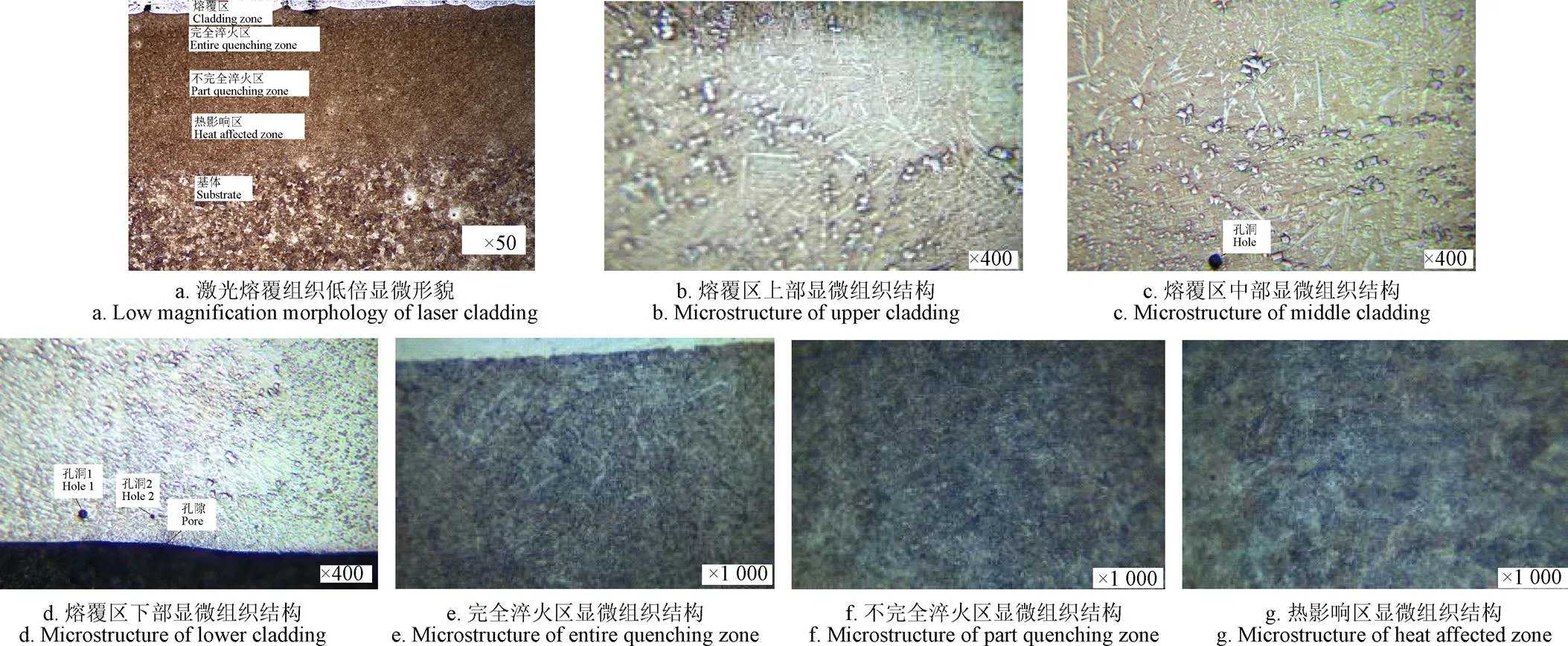

图3为65Mn钢经激光熔覆处理后显微组织的低倍截面形貌及各温度区间显微组织结构。

如图3a所示,65Mn钢经激光熔覆处理后由表及里显微组织由熔覆区、完全淬火区、不完全淬火区、热影响区及基体组成。由于熔覆区各部位温度场分布不同并且受到热流因素的影响,导致熔覆区组织分为上、中、下3层。如图3b所示,熔覆区上部显微组织主要为树枝状共晶组织,同时存在熔解WC。由于熔覆层上部散热渠道相对较多,既可以通过基体散热也可通过与外界进行散热,此处温度梯度最低,结晶速度最大,/比值趋于零,以至于熔覆区上部出现生长方向多向性的树枝晶[13]。熔覆区中部组织为共晶组织,由图3c可知,熔覆区中部晶枝大小相对于上部晶枝较粗,主要是此处晶枝相较于上部散热慢。由图3d可知,熔覆区下部显微组织为共晶组织,熔覆区与基体结合部位有一条白亮带,白亮带宽度大约为1~2m,白亮带靠近熔覆区附近组织主要由等轴晶及树状晶组成,由于熔覆区下部与基体交界处温度梯度值较小,结晶速度较大,液体与固体间存在正温度梯度,使得垂直于白亮带方向具有较优的散热条件,导致此区域组织沿白亮带垂直方向生长[14],同时可观察到熔覆区中出现气孔及熔覆区与基体结合处出现孔隙,造成此现象可能是由于WC含量过高,导致WC与Ni基二者热膨胀系数差异增大,进而产生气孔或裂纹[15-19]。完全淬火区显微组织为针状马氏体+少量残余奥氏体,且组织较为细密,如图3e所示。由图3f可知,不完全淬火区组织为粒状珠光体,主要是由马氏体经高温回火获得。由图3g可知,热影响区组织为片层状珠光体+少量粒状珠光体。

图3 激光熔覆处理后样品显微组织结构

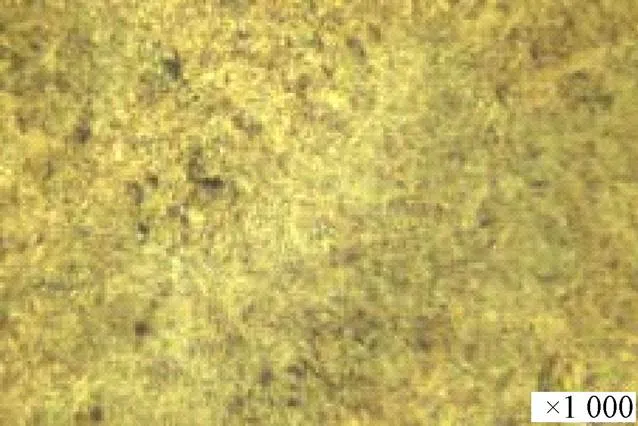

2.3 水淬-中温回火处理后65Mn组织分析

图4为65Mn钢经水淬-中温回火处理后显微组织结构。如图4所示,65Mn钢经水淬-中温回火处理后显微组织为针状马氏体。在水淬-中温回火处理中,65Mn钢经790 ℃高温加热后致使组织转变为奥氏体,在快速冷却的条件下组织转变为针状马氏体。

图4 水淬-中温回火处理后样品显微组织结构

2.4 显微硬度

图5为不同工艺处理后65Mn钢横截面显微硬度分布。由图5可知,经激光淬火处理后65Mn钢截面硬度随着距表面距离的增加,显微硬度总体呈现缓慢下降、急剧下降、缓慢下降、稳定的趋势。经激光熔覆处理后65Mn钢截面硬度随着距表面距离的增加,显微硬度总体呈现缓慢上升、缓慢下降、急剧下降、缓慢下降、稳定的趋势。根据显微硬度变化趋势,可将界面硬度区域划分为高显微硬度区、急剧下降过渡区、缓降过渡区及低显微硬度区,与此对应硬化区、不完全淬火区、热影响区及基体。对于激光淬火而言,硬化区为完全淬火区,而激光熔覆硬化区则包含熔覆区及完全淬火区。对于激光淬火而言:其硬化区深度大约为0.8 mm;不完全淬火区深度较窄,大约为0.2 mm;热影响区深度大约为1.2 mm。对于激光熔覆而言:其硬化区深度大约为1.2 mm;不完全淬火区深度较窄,大约为0.2 mm;热影响区深度大约为1.0 mm。

注:QZ为硬化区,PQZ为不完全淬火区,HAZ为热影响区,SUB为基体。

由图5可知,硬化区经激光淬火处理后65Mn钢组织的显微硬度最高可达619.8 HV0.1,主要是因为在急热、急冷的情况下会导致碳原子来不及扩散致使珠光体转变为含碳量较高的奥氏体,冷却后得到高碳马氏体,硬度略高于水淬-中温回火热处理后65Mn钢组织的平均显微硬度585.6 HV0.1。

由图5可以看出经激光熔覆处理后试样显微硬度先呈现增长的趋势后呈现下降的趋势,出现这种情况是因为在进行激光熔覆时,由于激光能量较高导致熔覆区表层合金元素烧损以至于熔覆区表面处硬度稍低于亚表层,随着距表层距离增加,显微硬度会逐渐降至65Mn钢基体硬度,冶金结合(白亮带)区域硬度稍低于熔覆区硬度而高于基体,是由于熔池中存在对流作用,基体中的Fe等元素会扩散进入熔池进而稀释熔覆区使得显微硬度降低,同时熔覆区中的合金元素向基体扩散,由于固溶强化作用使得冶金结合区域显微硬度高于基体。对于经激光熔覆处理后的65Mn钢而言,在高硬度的硬化区中,其显微硬度可达到1 038.4 HV0.1,显微硬度相对于经水淬-中温回火热处理后65Mn钢平均显微硬度提高了近1.77倍。从图5还可以看出,激光熔覆处理后硬化区的显微硬度远高于激光淬火处理后硬化区的显微硬度,一方面是复合合金粉末中WC的含量较高,另一方面是由于激光能量密度较高以及扫描速度较低使得WC颗粒较大程度的熔解,进而使快速凝固后析出的碳化物强化相数量也得到相应的提高,激光熔覆过程中熔池的凝固速率极快,进而细化组织,从而起到强化表面的作用[20-27]。

3 材料的摩擦性能

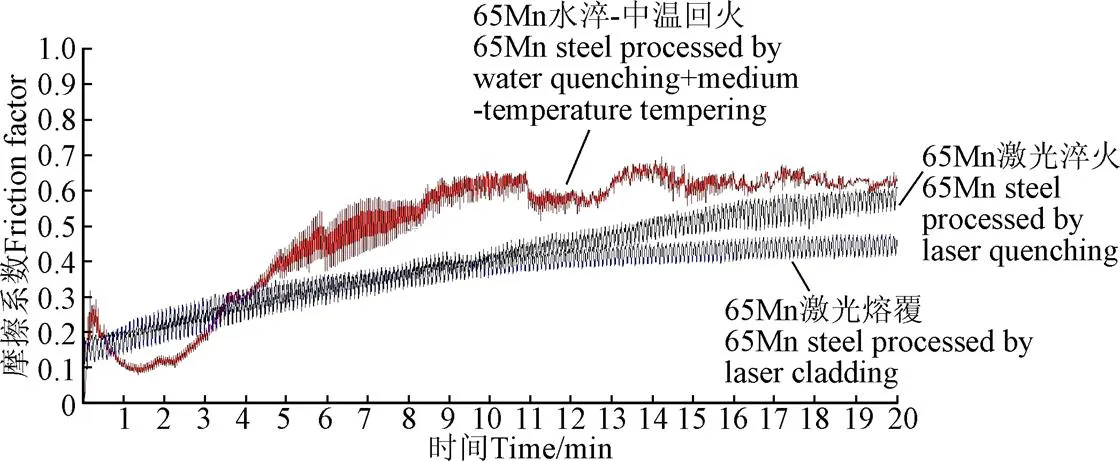

图6为表面改性及普通热处理后试样在干摩擦过程中摩擦系数与时间变化曲线。由图6可知,试样在摩擦过程初始阶段中摩擦系数迅速增加,随着时间的增加,摩擦系数缓慢增加,最终稳定在某一范围内。经激光淬火处理后的65Mn钢在整个摩擦过程中摩擦系数随时间的波动程度相对于水淬-中温回火热处理较为平缓,平均摩擦系数为0.40。经水淬-中温回火热处理后65Mn钢在整个摩擦过程中摩擦系数随时间波动幅度较大,主要原因是由于热处理过程中降温不均匀导致65Mn钢表面软硬不一,进而在摩擦磨损过程中磨损表面附着较多粘着物,平均摩擦系数为0.41。而经激光熔覆处理后65Mn钢在整个摩擦过程中摩擦系数随时间波动最平稳,说明熔覆层的摩擦性能较好,平均摩擦系数为0.36。从图6还可以看出,在摩擦磨损过程后期,摩擦系数随时间略有增加,是由于试样表面与磨粒接触面积逐渐增加,进而加大塑性变形程度及磨损程度,致使试样表面粗糙度增加,所以摩擦系数略有上升。

图6 摩擦系数与时间关系

不同工艺强化后试样磨损形貌图如图7所示。由图7a可知,经激光淬火处理后的65Mn钢表面犁沟较浅,属于磨粒磨损机制。由图7b可知,经水淬-中温回火热处理后65Mn钢表面犁沟深浅不一,属于粘着磨损机制。由图7c可知,经激光熔覆处理后65Mn钢熔覆区表面出现了剥落及较浅犁沟,磨损机制为磨粒磨损,造成此现象主要有两方面原因,一是在循环法向载荷及剪切应力作用下使熔覆区局部发生剥落,二是熔覆区中WC硬质颗粒分布较广,在磨损过程中WC颗粒阻碍Si3N4磨粒对基体的磨削[28-30]。

图7 摩擦磨损高倍形貌

经激光强化后65Mn钢,试样表面硬度与磨头表面硬度相差较小,试样表面会形成较浅的犁沟,提高了65Mn钢的摩擦性能。

4 结 论

1)经激光淬火处理后65Mn钢由表及里显微组织依次为针状马氏体+少量残余奥氏体、铁素体+回火屈氏体、片层状珠光体+粒状珠光体、片层状珠光体+铁素体。经激光熔覆处理后65Mn钢由表及里显微组织依次为共晶组织、针状马氏体+少量残余奥氏体、粒状珠光体、片层状珠光体+粒状珠光体、片层状珠光体+铁素体。经水淬-中温回火处理后65Mn钢显微组织为针状马氏体。

2)经激光淬火处理后65Mn钢显微硬度最高可达619.8 HV0.1,经激光熔覆处理后65Mn钢显微硬度最高可达1 038.4 HV0.1,经水淬-中温回火处理后65Mn钢平均显微硬度为585.6 HV0.1。在高硬度的硬化区中,65Mn钢锤片经激光熔覆处理后显微硬度最高。

3)经激光淬火处理后65Mn钢平均摩擦系数为0.40,属于磨粒磨损机制。经激光熔覆处理后65Mn钢平均摩擦系数为0.36,属于磨粒磨损机制。经水淬-中温回火处理后65Mn钢平均摩擦系数为0.41,属于粘着磨损机制。65Mn钢锤片经激光熔覆处理后,平均摩擦系数最低。

65Mn钢锤片经激光处理尤其是激光熔覆处理后摩擦性能较好,且工艺简单,满足了锤片表硬心韧的性能要求。该研究为锤片耐磨性提升提供了科学依据,对实际生产应用有一定指导意义。

[1] 王宏立,张伟,申玉军,等. 激光淬火65Mn钢表面摩擦磨损性能研究[J]. 应用激光,2015(6):652-656.

Wang Hongli, Zhang Wei, Shen Yujun, et al. Study on friction and wear properties of laser quenched 65Mn steel[J]. Journal of Applied Lasers, 2015(6): 652-656. (in Chinese with English abstract)

[2] 袁晓明,王宏宇,赵玉凤,等. 大耕深旋耕刀的制造工艺及其耐磨性[J]. 扬州大学学报:自然科学版,2012,15(1):33-37.

Yuan Xiaoming, Wang Hongyu, Zhao Yufeng, et al. Manufacturing process and wear resistance of deep-tillage rotary blade[J]. Journal of Yangzhou University: Natural Science Edition, 2012, 15(1): 33-37. (in Chinese with English abstract)

[3] 黄永俊,张国忠. 农机用65Mn钢预热处理后激光强化组织及性能[J]. 农业工程学报,2015,31(1):53-57.

Huang Yongjun, Zhang Guozhong. Microstructure and property of 65Mn steel preheated by laser strengthening[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(1): 53-57. (in Chinese with English abstract)

[4] 曾维华,刘洪喜,王传琦,等. 工艺参数对不锈钢表面激光熔覆Ni基涂层组织及耐腐蚀性能的影响[J]. 材料工程,2012(8):24-29.

Zeng Weihua, Liu Hongxi, Wang Chuanqi, et al. Effects of technological parameters on microstructure and corrosion resistance of laser cladding Ni-based coating on stainless steel surface[J]. Journal of Materials Engineering, 2012(8): 24-29. (in Chinese with English abstract)

[5] 李美艳,韩彬,王勇,等. B4C和Ti含量对激光熔覆Fe-Cr-Ni-Si系合金涂层结构及性能影响[J]. 中国激光,2013,40(12):12030081-12030085.

Li Meiyan, Han Bin, Wang Yong, et al. Effect of B4C and Ti contents on structure and property of laser cladding Fe-Cr-Ni-Si alloy coatings[J].Chinese Journal of Lasers, 2013, 40(12): 12030081-12030085. (in Chinese with English abstract)

[6] 储训,马援东. 铸铁、铸钢激光表面改性材料及工艺研究[J]. 农业工程学报,2001,17(4):22-25.

Chu Xun, Ma Yuandong. Material and technology research on surface of cast iron and cast steel by laser cladding[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2001, 17(4): 22-25. (in Chinese with English abstract)

[7] 刘秀波,乔世杰,翟永杰,等. TA2合金激光熔覆自润滑复合涂层组织与摩擦学性能[J]. 摩擦学学报,2017,37(1):75-82. Liu Xiubo, Qiao Shijie, Zhai Yongjie, et al. Microstructure and tribological properties of laser cladding self-lubricating anti-wear composite coatings on TA2alloy[J]. Tribology, 2017, 37(1): 75-82. (in Chinese with English abstract)

[8] 张松,张春华,吴维㞵,等. TiC/Ti复合材料激光熔覆层的冲击磨粒磨损性能[J]. 金属学报,2002,38(10):1100-1104.

Zhang Song, Zhang Chunhua, Wu Weitao, et al. Impact abrasive behavior of TiC / Ti composite layer by laser cladding[J]. Acta Metallurgica Sinica, 2002, 38(10): 1100-1104. (in Chinese with English abstract)

[9] 赵树国,李成龙. 激光熔覆工艺参数对CBN膜层裂纹率的影响[J]. 中国表面工程,2015,28(6):119-126.

Zhao Shuguo, Li Chenglong. Relationship between crack rate of CBN coating and parameters of laser cladding[J]. Chinese Surface Engineering, 2015, 28(6): 119-126. (in Chinese with English abstract)

[10] 刘洪喜,董涛,张晓伟,等. 激光熔覆制备WC/Co50/Al硬质合金涂层刀具的微观结构及切削性能[J]. 中国激光,2017,44(8):08020021-08020029.

Liu Hongxi, Dong Tao, Zhang Xiaowei, et al. Microstructure and cutting performance of WC/Co50/Al cemented carbide coated tools fabricated by laser cladding process[J]. Chinese Journal of Lasers, 2017, 44(8): 08020021-08020029. (in Chinese with English abstract)

[11] 王璐,胡树兵,单炜涛,等. 激光熔覆NiCrMn-WC复合涂层的组织与耐磨性[J]. 中国有色金属学报,2014,24(1):145-151.

Wang Lu, Hu Shubing, Shan Weitao, et al. Microstructure and wear resistance of laser cladding NiCrMn-WC composite coatings[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 145-151. (in Chinese with English abstract)

[12] 赵建国,李建昌,郝建军,等. 氮弧熔覆TiCN/Fe金属陶瓷涂层对农业刀具耐磨性的影响[J]. 农业工程学报,2013,29(3):84-89.

Zhao Jianguo, Li Jianchang, Hao Jianjun, et al. Influence of TiCN/Fe metal ceramic coating by reaction nitrogen arc cladding on wear resistance of agricultural tools[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(3): 84-89. (in Chinese with English abstract)

[13] 袁庆龙,冯旭东,曹晶晶,等. 激光熔覆镍基合金涂层微观组织研究[J]. 中国激光,2010,37(8):2116-2120.

Yuan Qinglong, Feng Xudong, Cao Jingjing, et al. Research on microstructure of Ni-based alloy coating by laser cladding[J]. Chinese Journal of Lasers, 2010, 37(8): 2116-2120. (in Chinese with English abstract)

[14] 何宜柱,斯松华,徐锟,等. Cr3C2对激光熔覆钴基合金涂层组织与性能的影响[J]. 中国激光,2004,31(9):1143-1148.

He Yizhu, Si Songhua, Xu Kun, et al. Effect of Cr3C2particles on microstructure and corrosion-wear resistance of laser cladding Co-based alloy coating[J]. Chinese Journal of Lasers, 2004, 31(9): 1143-1148. (in Chinese with English abstract)

[15] 路程. 激光熔覆Ni基球形WC复合涂层的组织与性能研究[D]. 广州:华南理工大学,2012.

Lu Cheng. Microstructure and Performance of Ni-based Spherical WC Composite Coating by Laser Cladding[D]. Guangzhou: South China University of Technology, 2012. (in Chinese with English abstract)

[16] 戎磊,黄坚,李铸国,等. 激光熔覆WC颗粒增强Ni基合金涂层的组织与性能[J]. 中国表面工程,2010,23(6):41-44.

Rong Lei, Huang Jian, Li Zhuguo, et al. Microstructure and property of laser cladding Ni-based coating reinforced by WC particles[J]. China Surface Engineering, 2010, 23(6): 41-44. (in Chinese with English abstract)

[17] 周圣丰,戴晓琴,郑海忠. 激光熔覆与激光感应复合熔覆WC-Ni60A 涂层的结构与性能特征[J]. 机械工程学报,2012,48(7):115-118.

Zhou Shengfeng, Dai Xiaoqin, Zheng Haizhong. Characteristics on structure and properties of WC-Ni60A coatings by laser cladding and laser-induction hybrid cladding[J]. Journal of Mechanical Engineering, 2012, 48(7): 115-118. (in Chinese with English abstract)

[18] 高原,王成磊,黄家强,等. 高频感应熔覆Ni60合金组织及耐磨性能研究[J]. 稀有金属材料与工程,2011,40(增刊2):309-312.

Gao Yuan, Wang Chenglei, Huang Jiaqiang, et al. Microstructure and wear resistance of Ni60 layer prepared by high-frequency induction cladding[J]. Rare Metal Materials and Engineering, 2011, 40(Supp.2): 309-312. (in Chinese with English abstract)

[19] 周野飞,高士友,王京京. 激光熔覆高碳铁基合金组织性能研究[J]. 中国激光,2013,40(12):3-5.

Zhou Yefei, Gao Shiyou, Wang Jingjing. Microstructure- property of laser cladding high carbon Fe-based alloy[J]. Chinese Journal of Lasers, 2013, 40(12): 3-5. (in Chinese with English abstract)

[20] 张攀,张伟,于鹤龙,等. 感应熔覆铁基合金涂层的显微组织与性能[J]. 中国表面工程,2016,29(1):41-45.

Zhang Pan, Zhang Wei, Yu Helong, et al. Microstructure and properties of Fe-based alloy coatings synthesized by induction cladding[J]. China Surface Engineering, 2016, 29(1): 41-45. (in Chinese with English abstract)

[21] 屈平,马跃进,赵建国,等. 适宜碳化钨含量提高Ti(C,N)-WC涂层耐磨耐蚀性[J]. 农业工程学报,2014,30(16):35-40.

Qu Ping, Ma Yuejin, Zhao Jianguo, et al. Appropriate WC content improving wear and corrosion resistance of Ti(C, N)-WC coating[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(16): 35-40. (in Chinese with English abstract)

[22] 郭国林,张娜,王俊杰,等. Q235钢氩弧熔覆铁基合金涂层的耐磨性研究[J]. 铸造技术,2012,33(6):675-676.

Guo Guolin, Zhang Na, Wang Junjie, et al. Investigation on wear resistance of Fe-based alloy coating prepared by argon arc cladding on Q235[J]. Foundry Technology, 2012, 33(6): 675-676. (in Chinese with English abstract)

[23] 郝建军,马跃进,李建昌,等. 氩弧熔覆原位合成Ni基耐磨层在犁铧上的应用[J]. 农业工程学报,2006,22(12):118-120.

Hao Jianjun, Ma Yuejin, Li Jianchang, et al. Application of in-situ synthesis of nickel-based anti-abrasion coating by argon-arc cladding on plowshare[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006, 22(12): 118-120. (in Chinese with English abstract)

[24] 江少群,王刚,陈超文. WC增强Fe基合金熔覆层的组织与湿砂磨损特性[J]. 中国表面工程,2015,28(1):37-41.

Jiang Shaoqun, Wang Gang, Chen Chaowen. Microstructure and wet sand abrasion resistance of Fe-based alloy clad coatings reinforced with WC[J]. China Surface Engineering, 2015, 28(1): 37-41. (in Chinese with English abstract)

[25] 张国栋,李莉,刘念,等. 打壳锤头等离子堆焊镍基涂层组织和性能[J]. 机械工程学报,2014,50(20):71-76.

Zhang Guodong, Li Li, Liu Nian, et al. Structure and properties of nickel-based surfacing on crust breaker deposited by plasma arc welding[J]. Journal of Mechanical Engineering, 2014, 50(20): 71-76. (in Chinese with English abstract)

[26] 韩照坤,樊云飞,赵建国,等. 深松铲NiWC喷焊层耐磨性研究[J]. 河北农业大学学报,2015,38(1):110-117.

Han Zhaokun, Fan Yunfei, Zhao Jianguo, et al. Study on wear-ability of deep-shovel with NiWC coating[J]. Journal of Agricultural University of Hebei, 2015, 38(1): 110-117. (in Chinese with English abstract)

[27] 孙耀宁. 激光熔覆TiC增强Ti基复合涂层的组织与性能[J]. 应用激光,2008,28(4):282-286.

Sun Yaoning. Microstructure and properties of laser clad TiC reinforced Ti matrix composite coatings[J]. Application Laser, 2008, 28(4): 282-286. (in Chinese with English abstract)

[28] 陈希章,胡科,袁其兵. 激光熔敷原位合成WC增强铁基复合涂层的组织和性能[J]. 中国表面工程,2016,29(4):118-122.

Chen Xizhang, Hu Ke, Yuan Qibing. Microstructure and performance of WC reinforced Fe-based composite coating synthesized in-situ produced by laser cladding[J]. China Surface Engineering, 2016, 29(4): 118-122. (in Chinese with English abstract)

[29] 曹熙,王文健,刘启跃,等. 激光离散淬火对轮轨材料磨损与损伤性能的影响[J]. 中国表面工程,2016,29(5):72-79.

Cao Xi, Wang Wenjian, Liu Qiyue, et al. Effects of laser dispersed quenching on wear and damage performances of wheel/rail materials[J]. China Surface Engineering, 2016, 29(5): 72-79. (in Chinese with English abstract)

[30] 赵建国,李建昌,王安,等. 喷焊余温淬火改善深松铲尖铁基涂层耐磨性[J]. 农业工程学报,2018,34(3):65-71.

Zhao Jianguo, Li Jianchang, Wang An, et al. Improvement of wear resistance of deep-shovel tip with Fe-based alloy coating by flame spray welding residual temperature quenching[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2018, 34(3): 65-71. (in Chinese with English abstract)

Improvement on wear resistance of citrus twig grinding hammer of 65Mn steel by laser quenching and laser cladding

Meng Liang, Li Xiong, Huang Yongjun, Wan Qiang, Li Mingzhen, Li Shanjun, Zhang Yanlin※

(,,430070,)

In order to improve the wear resistance of the citrus twig grinding hammer, the multiple surfaces of the 65Mn steel hammer are strengthened by laser quenching and laser cladding. The metallographic microscope, microhardness tester and friction tester are used to study the effect of laser treated 65Mn steel on its microhardness and friction property. The main equipment used in this experiment is GS-HL-5000 fiber laser and SX2-5-12 type electric furnace. The power used for laser quenching is 2.5 kW and the scanning speed is 300 mm/min. For laser cladding, the power is 3.2 kW, the scanning speed is 350 mm/min, and the powder feeding speed is 15-20 g/min. Ordinary heat treatment uses water quenching and medium-temperature tempering process, and the test parameters are: With the quenching temperature of 790 °C, the time is 20 min; with the tempering temperature of 350 °C, the time is 25 min. After the laser quenching and laser cladding of the sample, a part of the metallographic sample is cut perpendicular to the scanning speed. The metallographic sample is etched by using 10% solution of nitric acid (volume fraction), and the metallographic sample is analyzed by the metallographic microscope. The loading pressure of digital microhardness tester is set to 0.981 N for 15 s pressure-keeping time. The friction experiment is implemented by MS-T-3001 friction tester with Si3N4grinding head, time of 20 min, 500 g loading, spindle speed of 50 r/min and 0 ℃ testing temperature. The results show that 65Mn steel, processed by laser quenching, is composed of entire quenching zone, part quenching zone, heat affected zone and substrate with its microstructure sequences as acicular martensite + retained austenite, ferrite + tempered troostite, lamellar pearlite + granular pearlite, lamellar pearlite + ferrite from the surface to the center. The 65Mn steel, processed by laser cladding, is composed of cladding zone, entire quenching zone, part quenching zone, heat affected zone and substrate with its microstructure sequences as eutectic structure, acicular martensite + retained austenite, granular pearlite, lamellar pearlite + granular pearlite, lamellar pearlite + ferrite from the surface to the center. The microstructure of 65Mn steel processed by water quenching and medium-temperature tempering is acicular martensite. The maximum microhardness of 65Mn steel processed by laser quenching is 619.8 HV0.1while the average microhardness of 65Mn steel processed by water quenching and medium-temperature tempering is 585.6 HV0.1.The surface microhardness of 65Mn steel processed by laser quenching is slightly higher than that by water quenching and medium-temperature tempering, because the surface of 65Mn steel with laser quenching is prone to form a layer of high carbon martensite. The maximum microhardness of 65Mn steel processed by laser cladding is 1 038.4 HV0.1, far more higher than the other 2 kinds of processing ways, because not only the content of WC (tungsten carbide) in composite alloy powder is high and also the higher laser energy density and the lower scanning speed can melt the WC particles to a large extent, increasing the number of carbide strengthening phase precipitated by rapid solidification. Abrasive wear mechanism appears on the surface of 65Mn steel by laser quenching, and the average friction coefficient is 0.40. Adhesive wear mechanism appears on the surface of 65Mn steel by water quenching and medium-temperature tempering, and the average friction coefficient is 0.41. The mechanism of surface abrasive wear appears on the surface of cladding layer, when the 65Mn steel is treated by laser cladding with Ni60 + 35% WC, and the average friction coefficient is 0.36, and the wear resistance is better. Based on the above results, the surface hardness of the laser-treated 65Mn steel increases substantially and the wear resistance increases significantly. This study provides a reference for extending the service life of the hammer.

agricultural machinery; microstructure; quenching; laser cladding; microhardness; friction property

10.11975/j.issn.1002-6819.2018.17.008

TG174.44

A

1002-6819(2018)-17-0054-07

2018-02-05

2018-06-06

现代农业(柑橘)产业技术体系建设专项资金项目(CARS-26);中央高校基本科研业务费专项基金(2662015PY144);国家重点研发计划(2017YFD0202001、2017YFD0701400)

孟 亮,高级工程师,博士生,研究方向为现代农业装备设计。 Email:4662078@qq.com

张衍林,教授,博士生导师,研究方向为柑橘生产机械化和生物质能装备研究。Email:zhangyl@mail.hzau.edu.cn

孟 亮,李 雄,黄永俊,万 强,李明震,李善军,张衍林. 激光淬火及熔覆技术提高柑橘枝粉碎机65Mn钢锤片耐磨性[J]. 农业工程学报,2018,34(17):54-60. doi:10.11975/j.issn.1002-6819.2018.17.008 http://www.tcsae.org

Meng Liang, Li Xiong, Huang Yongjun, Wan Qiang, Li Mingzhen, Li Shanjun, Zhang Yanlin. Improvement on wear resistance of citrus twig grinding hammer of 65Mn steel by laser quenching and laser cladding[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(17): 54-60. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.17.008 http://www.tcsae.org