调制比对磁控溅射法生长DLC/WSx多层膜微结构和力学性能的影响

2018-08-24郑晓华林玲玲常新新王贡启杨芳儿

郑晓华,林玲玲,常新新,王贡启,杨芳儿

调制比对磁控溅射法生长DLC/WS多层膜微结构和力学性能的影响

郑晓华,林玲玲,常新新,王贡启,杨芳儿

(浙江工业大学 材料科学与工程学院,杭州 310014)

采用磁控溅射法在200 ℃Si(100)基体上交替沉积WS和类金刚石碳膜(DLC)制备不同调制比的DLC/WS多层膜(周期为10 nm)。利用扫描电镜(SEM)、能谱仪(EDS)、X射线衍射仪(XRD)、X射线光电子谱(XPS)等手段分析调制比对多层膜成分、微观结构及界面的影响。利用薄膜应力测试仪、纳米压痕仪、涂层附着力划痕仪和球盘式摩擦磨损试验机等测试多层膜的力学性能及大气中的摩擦磨损性能。结果表明:DLC/WS多层膜结构致密而平整,界面强化效应明显,膜中WS均为非晶结构。随着调制比增大,多层膜的(S)/(W)由0.77增大至1.08,硬度先降低后升高,膜内压应力逐渐减小,结合力先增大后减小,摩擦因数由0.307降至0.171,磨损率逐渐上升。调制比为1:39的多层膜性能最优,硬度可达11.4 GPa,磨损率低至1.17×10−15 m3∙N−1∙m−1,显著优于纯WS薄膜的。

WS2;类金刚石碳;多层膜;调制比;显微组织;摩擦;磨损

过渡族金属硫化物(MS)由于其特殊的六方层状结构,层与层之间的剪切强度很低,使其拥有优异的润滑特性[1−2]。其中,WS2因其在真空环境下摩擦因数低、工作温度高、耐磨性能好等优点而被广泛应用于机械加工和航天航空等领域中[3−4]。然而,纯WS2薄膜结构疏松,其硬度及承载能力有限,且在潮湿环境中易潮解和氧化形成WO3,致使润滑性能急剧下 降[5−6]。

研究表明,在WS2薄膜中掺入单质金属如Ti[7−8],Ag[9]、Cr[10]、Ni[11−12]等元素,可以改善薄膜的抗氧化性和耐磨性;而在WS2薄膜中添加非金属元素如C、N以及化合物[13−17]制成复合薄膜,其硬度、弹性模量、耐磨性等也得到了明显提升,如WU等[18]采用磁控溅射和脉冲激光沉积技术制备了WC/DLC/WS2纳米复合膜(Diamond like carbon,DLC),发现复合膜主要呈非晶结构,表面平整致密,具有很好的摩擦学性能和环境适应性。此外,纳米多层化亦是薄膜性能改良的有效方法之一[19−22],由于纳米多层膜的界面强化效应有助于提高薄膜的硬度、韧性、耐磨性和抗氧化性能,特别是在软硬交替的多层膜体系中。ZHU等[23]采用磁控溅射和低温离子渗硫复合技术制备了WS2/MoS2多层膜,发现WS2和MoS2之间产生交互作用,提高薄膜致密度,增强抗氧化性,并且多层膜较纯WS2膜具有较低的摩擦系数和较优的耐磨性。GONG等[24]采用等离子体化学气相沉积和中频脉冲非平衡磁控溅射相结合的方法制备了类石墨烯/MoS2复合多层膜,发现具有分层结构的纳米多层膜摩擦学性能较好,在潮湿空气中可达到超滑(摩擦因数约0.004)。杨芳儿等[25−26]制备了不同层厚比和不同调制周期的WS/a-C多层膜,发现多层膜结构致密,表面平整,其硬度、结合力以及在大气中的耐磨性有所改善。刘京京等[27]制备了CrA1N/WS2纳米多层膜,发现六方结构的WS2在CrA1N的模板作用下会转变为B1-NaCl型面心立方结构并与CrA1N层发生共格外延生长,使薄膜的力学性能和耐磨性得到强化。WATANABE等[28]采用磁控溅射法制备了WS2/MoS2纳米多层膜,结果表明多层膜具有超晶格结构,与单一薄膜相比,表现出良好的力学性能以及较长的使用寿命;XU等[29]对MoS2/Mo-S-C纳米多层膜的研究发现,所制备的多层膜中MoS2呈现出明显的(002)晶面择优生长,并且多界面设计可以改变相邻子层的结构,使薄膜的韧性和耐磨性得到很大改善。

鉴于类金刚石碳膜(DLC)的高硬度、在大气环境中的优异摩擦学性能[30−31]以及纳米多层界面效应对薄膜性能的有益作用,本文作者尝试构筑DLC/WS纳米多层膜,通过研究不同调制比DLC/WS纳米多层膜的成分、结构、力学和摩擦磨损性能,阐明DLC膜层与WS膜层之间的作用机理,为理解DLC/WS纳米多层膜的性能奠定理论和实验基础,也为进一步提升WS2薄膜在大气环境中的耐磨性,拓展其应用范围提供实验依据和新思路。

1 实验

采用磁控溅射法交替溅射WS2靶和石墨靶,在Si(100)基体上沉积DLC/WS多层膜,通过控制基体在WS2靶和石墨靶上方的停留时间,获得调制周期约为10 nm、调制比DLC/WSx(单个周期内DLC膜和WS膜的厚度之比)分别为1:39、1:19、1:9、3:20、1:4(分别编号为样品2~6)的DLC/WS多层膜,薄膜总厚度约为500 nm(50个周期),且先沉积WS层。镀膜前先将抛光的基体(单晶硅片,P型,á100ñ晶向)放入体积分数为10%氢氟酸溶液中清洗5min,再分别用丙酮和无水乙醇各清洗15min,烘干后装入JPG−450型真空镀膜机,腔体内的本底真空度为1.5×10−3Pa,随后采用如下条件进行溅射:靶基距70 mm,溅射气压0.6 Pa,偏压−50 V,基体温度200 ℃,WS2靶功率60 W,石墨靶功率65 W。另外,在相同工艺条件下制备了厚度约为500 nm的纯WS膜(样品1)和DLC膜(样品7),以便进行对比分析。

采用型号为Bruker D8 Advance的Х射线衍射仪(XRD)分析多层膜的晶体结构,Cu靶K射线(=0.154 056 nm),步长0.033 (°)/s,扫描角度6°~63°。用型号为∑IGMA的蔡司场发射扫描电镜(SEM)观察DLC/WS多层膜磨损前后的表面形貌,并用电镜自带的能谱仪(EDS)分析多层膜的化学成分。采用型号为AXIS ULTRA DLD的X射线光电子能谱仪(XPS)测定元素的光电子谱,激发源为Al靶K单色辐射(=1486.7 eV),功率为45 W,步长50 meV,通能20 eV,所得谱线在XPSPEAK软件中用Shirley法扣除背底,然后用洛伦兹−高斯函数进行拟合。采用型号为LabRAM HR UV的激光拉曼光谱仪对DLC膜样品的拉曼光谱进行分析,激光波长为632.8 nm,所得谱线用线性插值法扣除背底,用洛伦兹−高斯函数进行拟合。采用型号为SuPro FST 150的薄膜应力测试仪[32]测量基体镀膜前后曲率半径的变化,从而计算出多层膜内应力,硅基体的弹性模量为190 GPa,泊松比为0.2。采用型号为Nano Indenter G200的纳米压痕仪及连续刚度法测量薄膜的硬度,压入深度约为50 nm。采用型号为WS−2005的涂层附着力划痕仪[33]测定多层膜与基体间的结合力,加载速率100 N/min,最大载荷100 N,划痕长度4 mm,划痕速度4 mm/min。采用型号为WTM−1E的球盘式摩擦试验机测试薄膜在大气中(相对湿度约45%)的摩擦学性能,球试样为直径3 mm的GCr15钢球(62HRC),盘试样为薄膜样品,试验载荷0.5 N,相对滑动速度0.105 m/s,测试时长10 min。采用型号为Dektak3的台阶仪测量薄膜表面磨痕的截面轮廓并计算磨损体积,然后依据滑行距离、法向载荷和磨损体积计算出多层膜的磨损率。

2 结果与讨论

2.1 薄膜的S、W摩尔比与结构

众所周知,磁控溅射制备的WS膜,其S、W摩尔比一般小于2,这是因为离子辐射、选择性溅射、WS2靶材中S元素和W元素的溅射产额差异、高沉积温度、低沉积气压等[34−35]诸多因素均能降低薄膜的(S)/(W)。图1所示为能谱(EDS)分析法测得的薄膜(S)/(W),可见纯WS膜的(S)/(W)最高(为1.36),而多层膜(样品2~6)的(S)/(W)远低于纯WS膜且随着调制比的增大而增大。这说明DLC膜层在WS膜中的插入显著降低WS膜的(S)/(W),本文作者推测这可能是由于S元素与Si的亲和力优于DLC膜,而W元素则相反,从而导致DLC膜表面对W元素的吸附作用高于S元素,致使多层膜的(S)/(W)较低。另外,较厚的DLC膜层可有效抵挡高能粒子对WS层的轰击,抑制S元素的挥发,继而降低S元素损失,因而WS层的(S)/(W)随DLC层膜厚的增加而增加。

图1 薄膜的S、W摩尔比

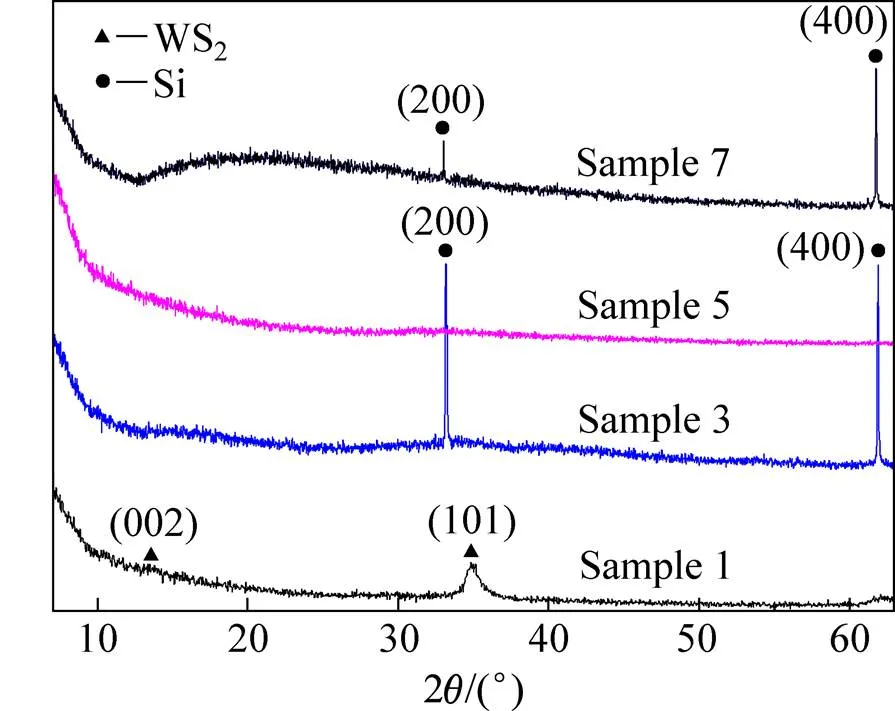

由薄膜的XRD谱(见图2)可知,纯WS膜在2≈34°处出现了明显的WS2(101)衍射峰,2≈14°处的WS2(002)衍射峰极其微弱,而多层膜均未出现与WS2相相关的衍射峰,这表明多层膜中的WS均为非晶(或微晶)结构,即DLC层的插入显著降低WS2相的结晶度。此外,所有多层膜和DLC膜中均未出现石墨和金刚石相的衍射峰,说明碳膜也以非晶或微晶的形式存在。DLC膜的拉曼光谱分析表明,其谱线由位于1331 cm−1的D峰和位于1530 cm−1的G峰叠加而成,其D/G(D峰与G峰的强度之比)为1.45。

图2 薄膜的XRD谱

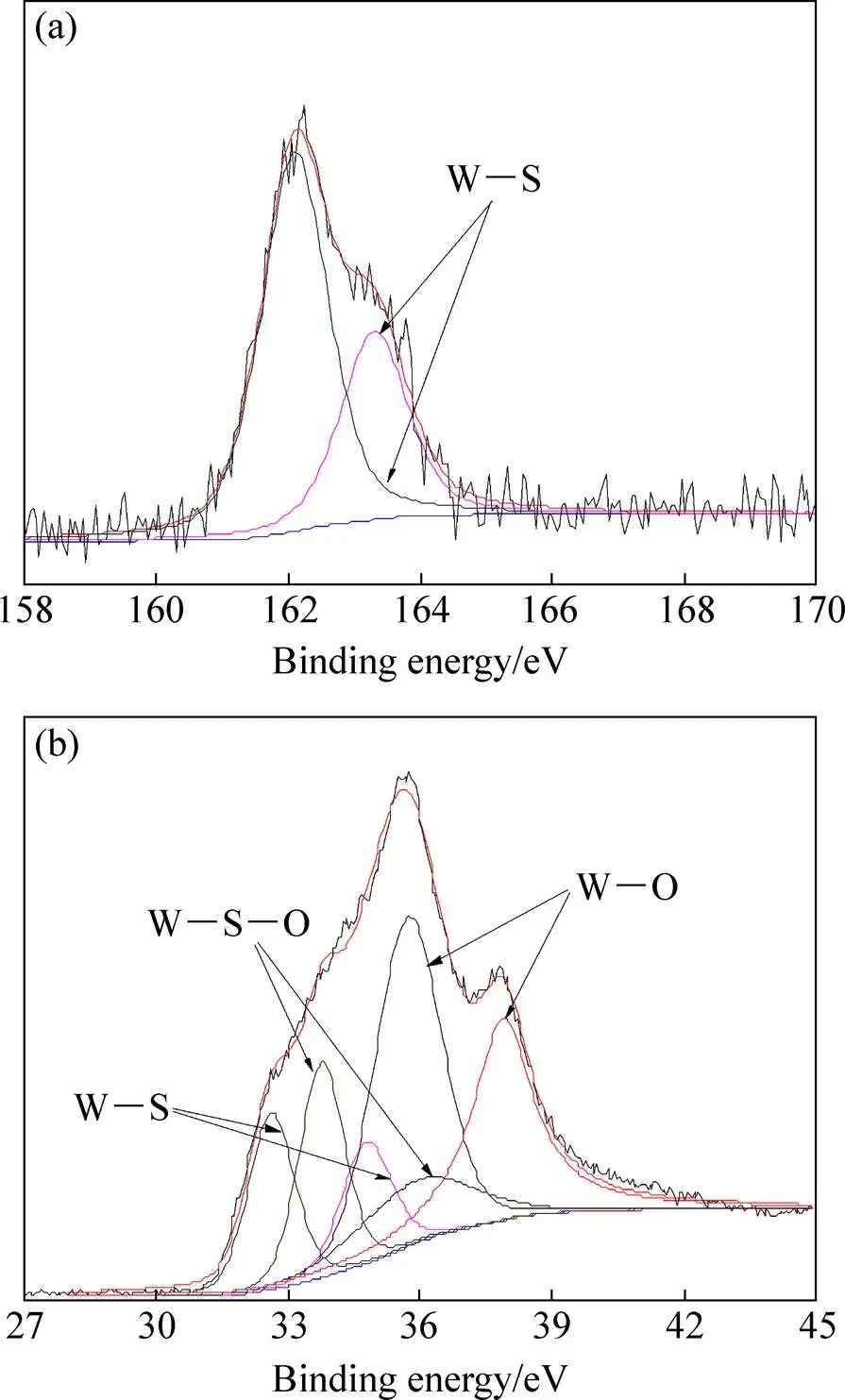

采用XPS技术对多层膜样品2的价键结构进行分析。图3所示为经过30s氩离子刻蚀后样品2的S2p和W4f XPS谱图及拟合结果,多层膜中的S元素主要以WS2((162.0±0.1) eV、(163.2±0.1) eV)的形式存在(见图3(a)),而W元素主要以WS2((32.6±0.1) eV、(34.8±0.1) eV)、WSO((33.8±0.2) eV、(35.9±0.2) eV)和WO3((35.7±0.2) eV、(37.9±0.2) eV)的形式存在(见图3(b)),其中,WSO是WS2发生部分氧化的产物,WO3则是薄膜长时间暴露大气后的完全氧化产物。可见,多层膜中的W元素和S元素主要以WS2相的形式存在,无单质W或单质S。样品2的C1s谱图信噪比很低,这是因为DLC膜厚度很小(约0.25 nm),刻蚀之后已被完全清除,从而难以判断膜中是否形成WC相。事实上,样品2刻蚀前的C1s和W4f谱图中未发现W—C键对应的结合能峰(283.5和32.0 eV),因而可以断定多层膜中未形成WC相。

图4(a1)~(a4)所示为薄膜的SEM像。从图4(a1)中可知,纯WS膜表面由“小颗粒”状物质聚集而成,“小颗粒”的尺寸约10~50 nm,结构较为疏松,这种结构易在大气中发生潮解氧化。而多层膜样品表面与纯DLC膜类似(见图4(a2)~(a4)),致密而平整,表现为无特征膜形式。图4(b1)~(b4)所示为薄膜横截面的SEM像。从图4(b1)中可以看到,纯WS膜底部组织致密,上部呈疏松柱状结构生长,与文献[26]的结果一致。从图4(b2)和(b3)中可以看到,多层膜与基体结合良好,结构致密,表面比纯WS膜光滑得多,调制比为3:20样品的层状几何结构明显(见图4(b3))。可见,多层结构设计以及DLC层的引入,能够有效抑制WS膜的柱状生长、降低表面粗糙度、提高薄膜致密度,从而有利于抑制其吸潮氧化。

图3 多层膜样品2表面各元素的结合能

2.2 薄膜的力学性能

图5所示为薄膜硬度实测值和多层膜的理论混合硬度计算值。其中,DLC/WS多层膜的理论混合硬度采用下式计算[36]:

composite=(WSx/total)×WSx+(DLC/total)×DLC(1)

式中:WSx、DLC分别为单个多层周期中WS和DLC膜的厚度;WSx、DLC分别为WS和DLC单层膜的硬度,也即相同参数条件下制备的WS和DLC膜硬度值(1.2 GPa和19.8 GPa),composite为纳米多层膜的理论混合硬度。

图4 薄膜的表面与横截面的SEM像

图5 薄膜硬度和多层膜的理论混合硬度

由图5可知,多层膜的硬度随着调制比的增大先降低后升高,并显著高于其理论混合硬度值,这一方面说明多层膜的硬度服从复合材料混合法则,另一方面说明多层膜内出现了明显的多层界面强化效应;小调制比多层膜内的界面强化效应十分强烈,比调制周期为50 nm的WS/a-C多层膜[37]中观察到的要强烈得多。这是由于多层膜相邻两层材料的晶格常数不同,晶格常数较小的受到拉应力,晶格常数较大的受到压应力,从而在多层膜的生长方向上形成了交变应力 场[38],导致多层膜硬度升高。此外,硬质相DLC与基质WS2剪切应力不同,位错运动需要更大能量,从而使多层膜硬度变大。再者,多层膜相邻两层的相不一样,使材料生长状况交替改变,阻碍位错运动。

图6所示为薄膜的内应力和结合力变化趋势。从图6(a)中可以发现,样品5多层膜样品呈现拉应力,而其他多层膜样品为压应力(用负值显示),幅值低于纯WS膜和DLC膜且随着调制比的增大而减小。研究表明,薄膜内应力主要源于薄膜生长过程中的非平衡性、薄膜特有的微观结构以及不同材料的热膨胀系数差异[39]。纳米多层结构以及DLC层的引入可以使薄膜形成复杂的界面结构,抑制WS晶粒的柱状生长,从总体上改善界面间热膨胀系数的差异和结构错配度,从而降低内应力。另外,界面强化效应增强,会阻碍位错的产生和增殖,进而为内应力释放提供更大的空间。从图6(b)中可以发现,随着调制比增大,薄膜结合力先增大后减小(4号多层膜例外),这是由于少量的DLC就能阻断WS膜层的柱状生长,使薄膜变得平整致密,从而提高结合力。随着DLC层厚度进一步增大,多层膜界面强化效应减弱,层间滑动阻力减小且更易于出现层间分离,致使结合力下降。至于多层膜5号样品的内应力和4号样品的结合力出现反常的具体原因,需要进一步深入研究。

图6 薄膜的内应力和结合力

2.3 薄膜的摩擦磨损性能

图7所示为薄膜在大气环境(相对湿度(RH)45%)中摩擦测试后的SEM像。从图7中可以看出,纯WS膜(见图7(a))表面磨痕宽度较大,犁沟数量众多,这与其硬度低、耐磨性能差等因素相关。样品2(见图7(b))的表面磨痕宽度较小,仅有少量磨屑粘附于磨斑两边,薄膜未被磨穿;样品4(见图7(c))磨损严重,膜层脱落严重,磨斑两边磨屑尺寸较大,Si基底大面积裸露,这与薄膜的结合力差,在摩擦过程中极易发生剥落结果相符;而纯DLC膜(见图7(d))表面基本完好,只有少量磨屑。

图8(a)所示为薄膜在大气环境中的平均摩擦因数。由图8(a)可知,纯WS膜的摩擦因数最低(0.138),而多层膜的摩擦因数随调制比的增大出现逐渐降低的趋势。这是由于多层膜的摩擦因数不仅与薄膜的剪切强度有关,也与多层膜中润滑相WS2的含量和S/W比、致密度、表面粗糙度等因素有关。随着调制比增大,多层膜的界面强化效应逐渐减弱,薄膜的剪切强度下降,因而多层膜的剪切阻力降低,此外,WS层中S、W摩尔比增大也有利于降低摩擦因数。图8(b)所示为薄膜在大气环境中(相对湿度45%)的磨损率,多层膜的磨损率低于纯WS膜,并且随着调制比增加磨损率逐渐增大(样品4的除外),导致这一结果的原因与薄膜的结构、硬度和结合力等因素相关。本文作者认为,样品2的结构致密、硬度和结合力较高,因而磨损率较低,约为1.17×10−15 m3∙N−1∙m−1;而样品4由于结合力低,容易从基体上剥落,加上硬度也较低,因此,样品很快被磨穿,出现如图7(c)所示的磨损形貌。

图7 薄膜在大气中(相对湿度45%)摩擦测试后的磨痕形貌

图8 薄膜在大气(相对湿度45%)环境中的摩擦因数和磨损率

3 结论

1) 多层结构设计以及DLC层的引入可显著降低WS膜层的S和W的摩尔比,有效抑制WS膜层的柱状生长,并诱导强烈的界面强化效应,大幅度提高薄膜硬度,且WS膜层为非晶结构。

2) 多层结构有利于降低薄膜内应力,显著提高薄膜的耐磨性能,而大气环境中的摩擦因数高于纯WS薄膜的。调制比为1:39的多层膜性能最优,其硬度可达11.4 GPa,磨损率低至1.17×10−15 m3∙N−1∙m−1。

[1] SPALVINS T. Coatings for wear and lubrication[J]. Thin solid Films, 1978, 53(3): 285−300.

[2] HILTON M R, FLEISCHAUER P D. Applications of solid lubricant films in spacecraft[J]. Surface and Coatings Technology, 1992, 54/55: 435−441.

[3] SIMMONDS M C, SAVAN A, SWYGENHOVEN H V, PFLUGER E, MIKHAILOV S. Structural, morphological, chemical and tribological investigations of sputter deposited MoS/metal multilayer coatings[J]. Surface and Coatings Technology, 1998, 108/109: 340−344.

[4] 周 磊, 尹桂林, 王玉东, 余 震, 何丹农. 反应溅射WS2/MoS2/C复合薄膜的摩擦磨损性能[J]. 中国有色金属学报, 2010, 20(3): 483−487. ZHOU Lei, YIN Gui-lin, WANG Yu-dong, YU Zhen, HE Dan-nong. Tribological and wear properties of reaction-sputtered WS2/MoS2/C composite films[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 483−487.

[5] 王均安, 于德洋, 欧阳锦林. 二硫化钼溅射膜在潮湿空气中贮存后润滑性能的退化与失效机理[J]. 摩擦学学报, 1994(1): 25−32. WANG Jun-an, YU De-yang, OUYANG Jin-lin. Study on the mechanism of lubrication degradation and failure of MoS2sputtered films stored in the moist air[J]. Tribology, 1994(1): 25−32.

[6] 尹桂林, 黄平华, 余 震, 何丹农, 涂江平. MoS2/WS2共溅射复合薄膜的微结构及其摩擦磨损性能研究[J]. 摩擦学学报, 2007(1): 41−44. YIN Gui-lin, HUANG Ping-hua, YU Zhen, HE Dan-nong, TU Jiang-ping. Microstructure and tribological properties of Co-sputtered MoS2/WS2composite films[J]. Tribology, 2007(1): 41−44.

[7] SCHARF T W, RAJENDRAN A, BANERJEE R, SEQUEDA F. Growth, structure and friction behavior of titanium doped tungsten disulphide (Ti-WS2) nanocomposite thin films[J]. Thin Solid films, 2009, 517(19): 5666−5675.

[8] BANERJEE T, CHATTOPADHYAY A K. Structural, mechanical and tribological properties of WS2-Ti composite coating with and without hard under layer of TiN[J]. Surface and Coatings Technology, 2014, 258: 849−860.

[9] XU Shu-sheng, GAO Xiao-ming, HU Ming, SUN Jia-yi, WANG De-sheng, ZHOU Feng, WENG Li-jun, LIU Wei-min. Morphology evolution of Ag alloyed WS2films and the significantly enhanced mechanical and tribological properties[J]. Surface and Coatings Technology, 2014, 238: 197−206.

[10] DEEPTHI B, BARSHILIA H C, RAJAM K S, KONCHADY M S, PAI D M. Structure, morphology and chemical composition of sputter deposited nanostructured Cr-WS2solid lubricant[J]. Surface and Coatings Technology, 2010, 205(2): 565−574.

[11] XU Shu-sheng, GAO Xiao-ming, HU Ming, SUN Jia-yi, JIANG Dong, ZHOU Feng, LIU Wei-min Liu, WENG Li-jun. Nanostructured WS2-Ni composite films for improved oxidation, resistance and tribological performance[J]. Applied Surface Science, 2014, 288: 15−25.

[12] 杜广煜, 巴德纯, 王晓光. Ti/Ni过渡层对WS2薄膜摩擦学性能影响[J]. 摩擦学学报, 2009(2): 146−151. DU Guang-yu, BA De-chun, WANG Xiao-guang. Effects of Ti/Ni transition layers on frictional behavior of tungsten disulfide thin film[J]. Tribology, 2009(2): 146−151.

[13] NYBERG H, SUNDBERG J, SARHAMMAR E, GUSTAVSSON F, KUBART T, NYBERG T, JANSSON U, JACOBSON S. Extreme friction reductions during initial running-in of W-S-C-Ti low-friction coating[J]. Wear, 2013, 302(1): 987−997.

[14] 宋玉波, 代明江, 余志明, 韦春贝, 侯惠君, 林松盛. WS2-C固体润滑薄膜的制备及其摩擦磨损性能[J]. 材料研究与应用, 2010(4): 530−533. SONG Yu-bo, DAI Ming-jiang, YU Zhi-ming, WEI Chun-bei, HOU Hui-jun, LIN Song-sheng. Preparation and tribological properties of WS2-C solid lubrication films[J]. Materials Research and Application, 2010(4): 530−533.

[15] 王 松, 岳 文, 李星亮, 姚 克, 方 鹏. 超低摩擦WS2/W-DLC固体润滑薄膜的制备与性能[J]. 材料热处理学报, 2016(2): 159−163. WANG Song, YUE Wen, LI Xing-liang, YAO Ke, FANG Peng. Fabrication, microstructure and properties of super-low friction WS2/W-DLC solid lubrication film[J]. Transactions of Materials and Heat Treatment, 2016(2): 159−163.

[16] ZHU Li-na, WANG Cheng-biao, WANG Hai-dou, XU Bin-shi, ZHUANG Da-ming, LIU Jia-jun, LI Gou-lu. Tribological properties of WS2composite film prepared by a twostep method[J]. Vacuum, 2010, 85: 16−21.

[17] DAI Ming-jiang, WEI Chun-bei, ZHOU Ke-song, ZHU Min, HOU Hui-jun, LIN Song-sheng, TONG Xin. Properties of W/DLC/W-S-C composite films fabricated by magnetron sputtering[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(9): 3002−3011.

[18] WU J H, RIGNEY D A, FALK M L, SANDERS J H, VOEVODIN A A, ZABINSKI J S. Tribological behavior of WC/DLC/WS2 nanocomposite coatings[J]. Surface and Coatings Technology, 2004, 188/189: 605−611.

[19] LI J L, WANG Y X, WAND L P. Structure and protective effect of A1N/Al multilayered coatings on NdFeB by magnetron sputtering[J]. Thin Solid Films, 2014, 68(4): 87−93.

[20] WANG Tao, ZHANG Guo-jun, JIANG Bai-ling. Comparison in mechanical and tribological properties of CrTiAlMoN and CrTiAlN nano-multilayer coatings deposited by magnetron sputtering[J]. Applied Surface Science, 2016, 363: 217−224.

[21] 李 琪, 代明江, 韦春贝, 侯惠君, 林松盛. 钛合金表面MoS2-Ti/Cu-Ni-In多层固体润滑膜的制备及其抗微动磨损性能[J]. 表面技术, 2017(1): 111−117. LI Qi, DAI Ming-jiang, WEI Chun-bei, HOU Hui-jun, LIN Song-sheng. Preparation and anti-fretting wear resistance of MoS2-Ti/Cu-Ni-In multilayer solid lubrication film on titanium alloy surface[J]. Surface Technology, 2017(1): 111−117.

[22] XU Zhao-ying, ZHENG Y J, JANG F, LENG Y X, SUN Hong, HUANG Nan. The microstructure and mechanical properties of multilayer diamond-like carbon films with different modulation ratios[J]. Applied Surface Science, 2013, 264: 207−212.

[23] ZHU Li-na, WANG Cheng-biao, WANG Hai-dou, XU Bin-shi, ZHUANG Da-ming, LIU Jia-jun, LI Guo-lu. Microstructure and tribological properties of WS2/MoS2multilayer films[J]. Applied Surface Science, 2012, 258: 1944−1948.

[24] GONG Zhen-bin, JIA Xiao-long, MA Wei, ZHANG Bin, ZHANG Jun-yan. Hierarchical structure graphitic- like/MoS2film as superlubricity material[J]. Applied Surface Science, 2017, 413: 381−386.

[25] YANG Fang-er, LU Ye, ZHANG Rong, ZHANG Xiang-hua, ZHENG Xiao-hua. Microstructure and tribological properties of WS/a-C multilayer films with various layer thickness ratios in different environments[J]. Surface and Coatings Technology, 2017, 309: 187−194.

[26] 杨芳儿, 史玉龙, 章 荣, 沈淑康, 鲁 叶, 郑晓华. 不同调制周期WS/a-C多层膜的组织结构及摩擦学特性[J]. 中国有色金属学报, 2016, 26(1): 96−102. YANG Fang-er, SHI Yu-long, ZHANG Rong, SHEN Shu-kang, LU Ye, ZHENG Xiao-hua. Microstructure and tribological properties of WS/a-C multilayer films with various modulation periods[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 96−102.

[27] 刘京京, 李 伟, 孟 佳, 刘 平, 张 柯, 马凤仓, 刘新宽, 陈小红, 何代华. CrAlN/WS2纳米多层膜的微观结构和力学性能研究[J]. 功能材料, 2016(12): 12118−12123. LIU Jing-jing, LI Wei, MENG Jia, LIU Ping, MA Feng-cang, LIU Xin-kuan, CHEN Xiao-hong, HE Dai-hua. Study on microstructure and mechanical properties of CrA1N/WS2nanomultilayered films[J]. Journal of Functional Materials, 2016(12): 12118−12123.

[28] WATANABE S, NOSHIRO J, MIYAKE S. Friction properties of WS2/MoS2multilayer films under vacuum environment[J]. Surface and Coatings Technology, 2004, 188/189: 644−648.

[29] XU Jiao, HE Teng-fei, CHAI Li-qiang, QIAO Li, WANG Peng, LIU Wei-ming. Growth and characteristics of self-assembled MoS2/Mo-S-C nano period multilayers for enhanced tribological performance. Scientific Reports, 2016, 6: 25378.

[30] VETTER J. 60 years of DLC coatings: historical highlights and technical review of cathodic arc processes to synthesize various DLC types, and their evolution for industrial applications[J]. Surface and Coatings Technology, 2014, 257: 213−240.

[31] MASUKO M, ONO T, AOKI S, SUZUKI A, ITO H. Friction and wear characteristics of DLC coatings with different hydrogen content lubricated with several Mo-containing compounds and their related compounds[J]. Tribology International, 2015, 82: 350−357.

[32] 张国炳, 郝一龙, 田大宇, 刘诗美, 王铁松, 武国英. 多晶硅薄膜应力特性研究[J]. 半导体学报, 1999, 6: 24−28. ZHANG Guo-bing, HAO Yi-long, TIAN Da-yu, LIU Shi-mei, WANG Tie-song, WU Guo-ying. Residual stress properties of polysilicon thin film[J]. Chinese Journal of Semiconductors, 1999, 6: 24−28.

[33] 王春明. 掺杂纳米SiC的硫化物等离子喷涂复合涂层摩擦学性能研究[D]. 南京: 东南大学, 2006: 17−20. WANG Chun-ming. The tribology of plasma sprayed sulphide with added nano-sic composite coating[D]. Nanjing: Southeast University, 2006: 17−20.

[34] BAKER M A, GILMORE R, LENARDI C, GISSLER W. XPS investigation of preferential sputtering of S from MoS2and determination of MoSstoichionmetry from Mo and S peak positions[J]. Applied Surface Science, 1999, 150: 255−262.

[35] ZHANG Xiao-ling, LAUWERENS W, HE Jia-wen, CELIS J P. Structure and growth of basal and random oriented MoScoatings deposited by magnetron sputtering[J]. Journal of Vacuum Science and Technology, 2003, 21: 416−421.

[36] KIM H S. On the rule of mixtures for the hardness of particle reinforced composites[J]. Materials Science and Engineering, 2000, 289: 30−33.

[37] 郑晓华, 章 荣, 史玉龙, 沈靖枫, 李 昂, 杨芳儿. 不同层厚比WS/a-C多层膜的组织结构及摩擦学特性[J]. 真空科学与技术学报, 2016, 36(6): 659−665. ZHENG Xiao-hua, ZHANG Rong, SHI Yu-long, SHEN Jing-feng, LI Ang, YANG Fang-er. Microstructure and tribological properties of WS/a-C multilayer films with various layer thickness ratio[J]. Journal of Vacuum Science and Technology, 2016, 36(6): 659−665.

[38] KATO M, MORI T, SCHWARTZ L H. Hardening by spinodal modulated structure[J]. Acta Metallurgica, 1980, 28(3): 285−290.

[39] 徐可为, 高润生, 陈 瑾. 沉积方式与基体材料对TiN薄膜内应力的影响[J]. 真空科学与技术学报, 1993(2): 108−115. XU Ke-wei, GAO Run-sheng, CHEN Jin. Effects of deposition and substrate on the evolution of internal stress in TiN films[J]. Journal of Vacuum Science and Technology, 1993(2): 108−115.

Effect of modulation ratio on microstructure and mechanical properties of DLC/WSmultilayer films by magnetron sputtering

ZHENG Xiao-hua, LIN Ling-ling, CHANG Xin-xin, WANG Gong-qi, YANG Fang-er

(College of materials science and engineering, Zhejiang University of Technology, Hangzhou 310014, China)

The DLC/WSmultilayer films with various modulation ratios and modulation period of 10 nm were layer-by-layerdeposited on Si(100) substrates by magnetron sputtering method at 200 ℃. The effects of modulation ratio on the chemical composition, microstructure and interface of the films were characterized by means of scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDS), X-ray diffractometry (XRD) and X-ray photoelectron spectroscopy (XPS). The mechanical properties and tribological properties in atmosphere of the films were evaluated by residual stress tester, nano-indentation tester, scratch tester and ball-on-disc tribotester. The results show that DLC/WSmultilayers are compact and smooth, the strengthening of interfacial effect is remarkable and WSphase is defined as amorphous structure. As the modulation ratio increasing, the molar ratio of S and W increases from 0.77 to 1.08, the hardness decreases first and then increases while the compressive stress decreases in the film gradually, the adhesion to substrate increases first and then decreases, the friction coefficient decreases from 0.307 to 0.171, and the wear rate increases. Compared with pure WSfilm, DLC/WSmultilayer films have much better mechanical properties, and the film with modulation ratio of 1:39 has the best performance, its hardness is 11.4 GPa and its wear rate is of 1.17×10−15 m3∙N−1∙m−1.

WS2; diamond like carbon; multilayer; modulation ratio; microstructure; friction; wear

Project(LY15E010007) supported by Zhejiang Provincial Natural Science Foundation of China

2017-06-16;

2018-01-12

YANG Fang-er; Tel: +86-571-88320479; E-mail: yfe1230@163.com

10.19476/j.ysxb.1004.0609.2018.07.09

1004-0609(2018)-07-1343-08

TH117

A

浙江省自然科学基金资助项目(LY15E010007)

2017-06-16;

2018-01-12

杨芳儿,教授级高工;电话:0571-88320479;E-mail:yfe1230@163.com

(编辑 李艳红)