重型柴油机颗粒物分布规律的试验研究

2018-08-10周小波胡清华苏万华

周小波,胡清华,闫 峰,苏万华

重型柴油机颗粒物分布规律的试验研究

周小波1,2,胡清华1※,闫 峰3,苏万华2

(1. 天津大学计算机科学与技术学院,天津 300350; 2. 天津大学内燃机燃烧学国家重点实验室,天津 300072;3. 中国汽车技术研究中心有限公司,天津 300300)

为了同时控制车用重型柴油机的颗粒物排放质量和数目,该文对稳态工况及瞬态工况下柴油机排放颗粒物分布规律进行了试验研究。试验结果表明:在稳态工况下,随着负荷的增加或者转速的提高,积聚态及核态颗粒物数目浓度、中位直径(count median diameter,CMD)、表面积和质量均呈现增大趋势,且峰值向大粒径方向偏移。在本研究中,稳态工况全工况总颗粒物数目浓度为1.5×106~4.5×106个/cm3,积聚态颗粒物数目浓度为2×106~1×107个/cm3,而核态颗粒物数目浓度为1×107~3×107个/cm3,在总颗粒物数目浓度中占比为65%~96%。全工况当量比均小于0.7,在中低转速,当量比对颗粒物分布影响较为明显,在高转速尤其是大负荷条件下,当量比的影响减弱。在瞬态工况下,颗粒物数目浓度出现了与颗粒物质量类似的排放尖峰现象,浓度峰值达到2×108~7×108个/cm3,比其对应的稳态工况出现的浓度峰值高出1个数量级。而且排放尖峰现象中,积聚态颗粒物数目浓度占主要部分,其峰值浓度比稳态工况要高出2个数量级,此时排放尖峰现象中核态颗粒物数目浓度也出现明显增长。排放尖峰现象对应的粒径主要集中在积聚态颗粒物的50~200 nm范围和核态颗粒物的6~8 nm及20~50 nm范围。这主要是因为当量比在瞬态过程出现了超过临界当量比0.8的情况。研究结果对重型柴油机颗粒物排放控制以及生成机理有重要指导意义,并可为排放后处理器的匹配计算提供数据支持。

柴油机;排气;颗粒;稳态工况;瞬态工况;分布规律;核态和积聚态颗粒

0 引 言

近年来,中国各主要城市均出现了不同程度的雾霾现象。流行病学和毒理学研究表明[1-7],大气中的超细颗粒物(颗粒物粒径D<100 nm)附着大量有毒物质,通过呼吸道进入人体后会对人体呼吸道和心血管等器官造成严重危害,有数据证明其与人类发病率和死亡率有明显关联。中国约有30%的国土面积以及超过8亿人口受到雾霾的影响[8]。同时,颗粒物的辐射效应仅次于二氧化碳(CO2),是造成温室效应的重要原因之一[9]。柴油机排放的微粒直径一般为3 nm~1m,其数目浓度高达10×107~10×109个/cm3,是城市大气中超细颗粒的重要来源。通常,排放微粒按粒径分为核态颗粒物(5 nm<D<50 nm)和积聚态颗粒物(50 nm<D<0.15m),其中积聚态颗粒物主要由不完全燃烧产生的一次碳粒(D为2 nm左右)发生团聚作用并凝结有部分HC和硫酸盐等挥发和半挥发组分形成;核态颗粒物的成因比较复杂,通常认为核态颗粒物是由燃烧室内形成的一次碳粒以及H2SO4或HC等气态前体物成核形成的二次颗粒物,并且其数浓度和粒径分布特征受稀释系统参数(如颗粒在通道内的停留时间、稀释比例、稀释空气的温度和湿度等)影响较大[10-11]。

从2000年开始,随着DPF的推广使用,研究者发现称重式的PM检测方法已经不足以准确反映内燃机颗粒排放水平。因此2001年欧盟组织排放颗粒物测量计划PMP(particle measurement program)开始研究更灵敏和准确的内燃机排放颗粒物检测手段。Giechaskiel等[12-13]于2007年和2010年分别提交轻型车和重型车颗粒数检测方法的最终报告并被PMP采用,这种去除颗粒物中挥发成分后进行颗粒物数量统计的检测颗粒物数量排放的新方法得到了广泛的认可并被列入法规考察范围。自此,颗粒物排放数目和粒径分布成为研究内燃机颗粒物排放特性的新热点。

目前,国内外针对柴油机颗粒物数目和粒径分布的研究主要集中在稳态工况下[14-19]。1998年Kittelson等[20]提出典型柴油机稳态工况颗粒物粒径分布、数目、表面积和质量。颗粒物数量和质量浓度基本呈现对数正态分布规律,核态颗粒物占总数量的90%以上,积聚态颗粒物占总质量的比例最大,粗态颗粒物数量较少,其质量约占总质量的5~20%。但是近十几年来随着燃烧理论的发展以及后处理器的使用,粗态颗粒物明显减少,研究者把研究目标主要集中在核态和积聚态颗粒物上。Kazakov等[21]提出碳烟颗粒碰撞理论,认为燃烧温度是决定颗粒物尺寸和分布的主要因素。Desantes等[22]的试验结果显示,积聚态颗粒物与核态颗粒物之间是此消彼长的关系。即积聚态颗粒物如同“海绵体”一样来吸收HC和硫酸盐等挥发和半挥发组分。当积聚态颗粒大幅度增加后,用以促进核态颗粒物生长的组分减少,导致其浓度较低。Shi等[23-24]在稳态工况下系统地研究了颗粒物的物理、化学和形态学特征。

在瞬态工况下,Tan等[25]在轻型柴油机上研究了生物柴油和普通柴油的不同掺混比例在稳态和瞬态工况下对颗粒物数目排放的影响。试验结果表明在稳态工况下,随着生物柴油比例的提高,积聚态颗粒物数目排放减少,核态颗粒物数目增加。在瞬态工况下,扭矩瞬变率增大,总颗粒物数目明显提高;使用生物柴油时,颗粒物数目排放明显高于普通柴油。Wang等[26]研究了在美国瞬态测试循环中转速变化率及扭矩变化率对柴油机颗粒物数目的影响。研究表明在从怠速开始的急加速工况中颗粒物数目会大幅增加。在瞬态工况下,柴油机颗粒物数目及粒径分布特性的研究还比较少,因此,对比分析稳态工况和瞬态工况下柴油机排放颗粒物的生成规律和影响因素具有重大的现实意义和科研价值。

1 试验装置与方法

本文试验台架是无后处理器、满足欧IV法规的试验样机,并通过了中国汽车技术研究中心的认证,主体部分包括某12 L重型柴油机和电力测功机[27],如图1所示。

1.数据采集系统 2. 柴油机 3.IVCT系统 4.高压共轨燃油喷射系统 5.电力测功系统 6.中冷器 7.EGR系统 8.两级涡轮增压系统 9.VGT系统 10.智能控制器 11.瞬时流量计

发动机进气系统部分包括高压级为可变几何截面涡轮(variable geometry turbocharger ,VGT)的两级增压系统、高压废气再循环 (exhaust gas recirculation,EGR)系统和课题组自主研发的进气门晚关系统(IVCT系统)[28]。测试仪器包括高响应的进排放压力传感器、进气流量计、油耗仪、排放采集仪等。试验中使用Cambustion公司的DMS500快速颗粒光谱仪研究分析柴油机瞬态工况颗粒物粒径分布规律,其测量范围是5~1 000 nm,响应时间是100 ms。试验方法参照GB17691中ETC试验规范执行。

2 结果与分析

2.1 稳态工况下颗粒物粒径分布规律

为了研究颗粒物粒径分布规律,稳态试验选取欧洲稳态测试循环(european steady-state cycle,ESC)十三工况作为主要研究工况,并在稳态工况平面内另选了54个工况点以完成全工况颗粒物排放数目脉谱。54个工况点按照转速和扭矩均匀选取,兼顾了转速分布和扭矩分布。

中位直径(count median diameter,CMD)是累积百分比为50%时所对应的粒子直径,直接关系到粒谱特征的判断和表征,是表达颗粒物粒径的重要参数之一。研究表明柴油机排放微粒的粒径分布近似于对数正态分布,CMD用式(1)计算[29]:

式中d是各分级的切割直径,N是分级对应的粒子直径。

2.1.1 负荷对稳态工况颗粒物粒径分布的影响

图2为稳态工况下该发动机为转速1 600 r/min时负荷变化对颗粒物粒径分布、数目浓度、表面积、质量和CMD的影响。图2a为负荷对积聚态颗粒物数目浓度和粒径分布的影响,随着负荷的增大,积聚态颗粒物数目浓度和粒径分布的峰值随之增大,范围处于4×106~8×106个/cm3之间,此时CMD也随之增大,范围在40~50 nm之间。由碳烟颗粒碰撞理论[21]可知,随着负荷的增大,缸内燃烧温度增加,碳烟颗粒之间碰撞的频率提高,颗粒粒径增大,CMD增大。图2b为负荷对核态颗粒物数目浓度和粒径分布的影响。随着负荷的增大,核态颗粒物数目浓度和粒径分布的峰值总体呈现增大趋势,范围处于1×107~2×107个/cm3之间,同时CMD也随之增大,范围在5~9 nm之间,如图2c所示。核态颗粒物的数目浓度相比积聚态颗粒物要高1个量级,如图2d所示,核态颗粒数目浓度在总颗粒数浓度中占比59%~80%,排放颗粒物主要为核态颗粒物。随着负荷的增加,积聚态颗粒物数目浓度呈现增大趋势,其对应的CMD也呈现增大趋势;核态颗粒物数目浓度总体呈现增大趋势,其对应的CMD也呈现增大趋势。

颗粒物毒性与颗粒物表面积密切相关[30-31]。假设颗粒物均为球形规则体,根据颗粒物数目浓度和粒径分布,可以得到颗粒物表面积分布,如图2e与图2f所示。随着负荷的增加,积聚态颗粒物表面积增加,对应峰值在5×1010~18×1010nm2/cm3之间,核态颗粒物表面积随负荷增加整体呈现增大趋势,其对应峰值在1×109~7×109nm2/cm3之间,比积聚态颗粒物表面积峰值低1~2个量级。而且,相比颗粒物数目浓度,颗粒物表面积和粒径分布对应的峰值无论是积聚态还是核态均往大粒径方向偏离。由于颗粒物密度无法测量且形状不规则,此处假设颗粒物密度均匀,核态与积聚态密度一致,且均为球形规则体。图2g与图2h为负荷对积聚态和核态颗粒物质量和粒径分布的影响。颗粒物质量和粒径的分布规律与颗粒物数目浓度和粒径的分布规律有明显区别,随着负荷的增加,积聚态颗粒物质量呈明显增加趋势,对应峰值在1×104~4×104ng/m3之间,核态颗粒物质量与粒径分布随负荷增加整体呈现增大趋势,其对应峰值在20~80 ng/m3之间,比积聚态颗粒物质量低2~3个数量级。相比颗粒物数目浓度和表面积分布,颗粒物质量和粒径分布的对应峰值无论是积聚态还是核态均往大粒径方向偏离。

图2 稳态工况下负荷对颗粒物分布的影响

2.1.2 转速对稳态工况下颗粒物粒径分布的影响

图3为稳态工况下50%负荷时转速变化(1 300、1 600和1 900 r/min)对颗粒物粒径与数目浓度分布、表面积、质量和CMD的影响。图3a为转速对积聚态颗粒物数目浓度和粒径分布的影响,随着转速的提高,积聚态颗粒物数目浓度和粒径分布的峰值随之增大,范围处于5×106~8×106个/cm3之间,此时CMD也随之增大,范围在37~47 nm之间。图3b为转速对核态颗粒物数目浓度和粒径分布的影响,随着转速的提高,核态颗粒物数目浓度和粒径分布的峰值随之增大,范围处于1×107~2×107个/cm3之间,同时CMD也随之增大,范围在6~8.5 nm之间,如图3c所示。核态颗粒物的数目浓度相比积聚态颗粒物要高1个量级,如图3d所示,在总颗粒物数目中,核态颗粒物占比在64%~75%之间。这主要是由于随着转速的上升,燃烧过程中的实际混合时间减少,在缸内局部缺氧条件下,更易导致碳烟颗粒生成量的增加,这些颗粒以积聚态为主;而核态颗粒物其成核作用受排放温度影响较大,随着转速的提高,排放温度从670 K增大到780 K,核态颗粒物数目浓度随着转速的提高而增大,且CMD也随之增大。因此随着转速的提高,积聚态颗粒物数目浓度上升,其对应的CMD也增大;核态颗粒物数目浓度呈现增大趋势,其对应的CMD也呈现增大趋势,排放颗粒物主要为核态颗粒物,且随转速提高而增加。

颗粒物表面积分布如图3e与图3f所示。颗粒物表面积和粒径分布规律与颗粒物数目和粒径分布规律一致,随着转速的提高,积聚态颗粒物表面积明显增加,对应峰值在6×1010~16×1010nm2/cm3之间,跨度较大;核态颗粒物表面积随转速增加而增大,其对应峰值在2×109~6×109nm2/cm3之间,比积聚态颗粒物表面积峰值低1~2个量级。而且,相比颗粒物数目浓度,颗粒物表面积和粒径分布对应峰值无论是积聚态还是核态均往大粒径方向偏离。

图3g与图3h为转速对积聚态和核态颗粒物质量与粒径分布的影响。随着转速的增加,积聚态颗粒物质量呈明显增加趋势,对应峰值在7×106~30×106ng/cm3之间,核态颗粒物质量随转速增加而增大,其对应峰值在2×104~9×104ng/cm3之间,比积聚态颗粒物质量峰值低2个量级以上。相比颗粒物数目浓度和表面积分布,颗粒物质量分布对应峰值无论是积聚态还是核态均往大粒径方向偏离。因此,大粒径颗粒物是颗粒物质量的主要来源,且积聚态颗粒物远大于核态颗粒物。

图3 稳态工况下转速对颗粒物分布的影响

2.1.3 稳态工况颗粒物分布

为完成全工况颗粒物排放数目脉谱,稳态试验包括十三工况及其他54个工况。图4为稳态工况下全工况平面内总颗粒物数目浓度(图4a)、核态颗粒物数目浓度(图4b)、积聚态颗粒物数目浓度(图4c)及当量比分布规律(图4d)。其中总颗粒物数目浓度在1.5×107~4.5×107个/cm3,积聚态颗粒物数目浓度为2×106~1×107个/cm3,核态颗粒物数目浓度为1×107~3×107个/cm3,在总颗粒物数目浓度中占比65%~96%。从整个稳态工况平面可以看出,全工况当量比均小于0.7,在中低转速,当量比对颗粒物分布影响较为明显,而在高转速尤其是大负荷条件下,当量比的影响减弱。

图4 稳态工况下颗粒物数目浓度及对应的当量比分布

2.2 瞬态测试循环的颗粒物分布

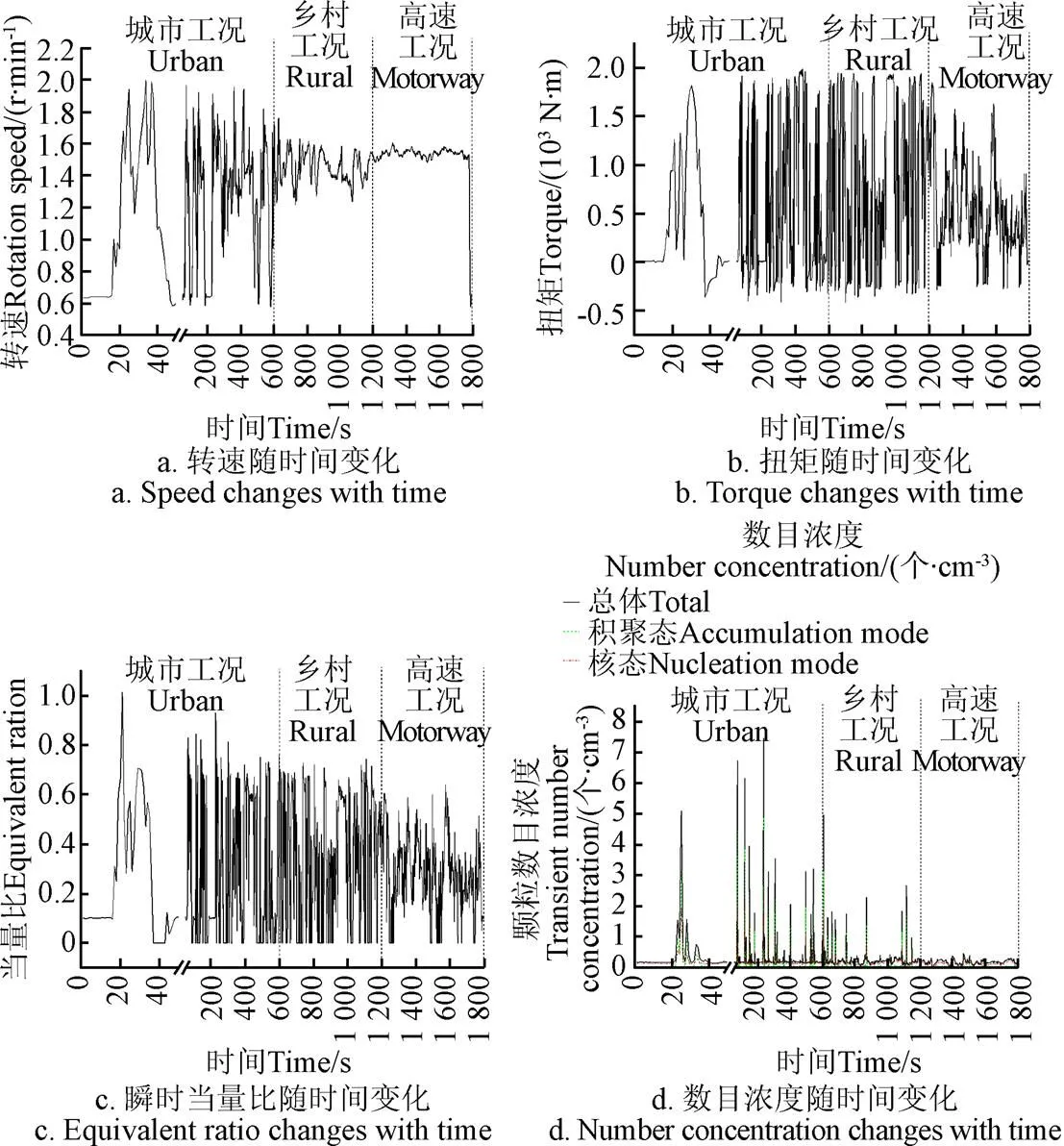

本文按照欧洲瞬态测试循环(ETC)完成,瞬态控制策略参考文献[27]。图5为在ETC瞬态测试循环中转速和扭矩、当量比变化趋势和颗粒物分布规律,包括总颗粒物数目浓度、核态颗粒物数目浓度和积聚态颗粒物数目浓度。从颗粒物数目浓度来看,瞬态工况下出现了与颗粒物质量类似的排放尖峰现象,数目浓度峰值甚至达到了2×108~7×108个/cm3,比其对应的稳态工况出现的浓度峰值高出1个数量级。而且排放尖峰现象中,积聚态颗粒物占主要部分,这与稳态工况有很大不同,其数目浓度峰值比稳态工况要高出2个数量级,从稳态工况的2×106~1×107个/cm3跨越式增长到1×108~8×108个/cm3;此时排放尖峰现象中核态颗粒物数目浓度也出现明显的增长,其数目浓度峰值从稳态工况的1×107~3×107个/cm3增长到3×107~3×108个/cm3。排放尖峰现象主要是因为当量比在瞬态过程出现了对应的峰值,稳态工况下当量比没有超过0.7,但是排放尖峰对应的工况出现了超过临界当量比0.8的情况[27]。

图5 瞬态工况下颗粒物分布

在城市道路工况中,排放尖峰出现12次,总颗粒物数目浓度峰值为2×108~8×108个/cm3,积聚态颗粒物数目浓度峰值为1×108~5×108个/cm3,核聚态颗粒物数目浓度峰值为3×107~3×108个/cm3;在乡村道路工况中,排放尖峰出现8次,总颗粒物数目浓度峰值明显低于城市道路工况,为1×108~3×108个/cm3,积聚态颗粒物数目浓度峰值为1×108~2×108个/cm3,核聚态颗粒物数目浓度峰值为3×107~1×108个/cm3;在高速道路工况中,排放尖峰没有出现,总颗粒物数目浓度、积聚态颗粒物数目浓度、核聚态颗粒物数目浓度与稳态工况颗粒物粒径分布规律相当。图6为在ETC瞬态测试循环中颗粒物粒径分布的频谱图,更准确地反应了各个颗粒物粒径对应的颗粒物数目浓度。

图6 瞬态工况颗粒物粒径分布频谱图

为了方便分析,把城市道路工况、乡村道路工况和高速道路工况的前50 s对应的颗粒物粒径分布频谱图放大,与整个测试循环并列展示。

从整个测试循环可以发现,在颗粒物粒径大于200 nm时,3个道路工况并没有明显区别。在颗粒物粒径50~200 nm内,数目浓度峰值达到1×108个/cm3以上的情况(即图中白色区域)主要集中在城市道路工况(12次)和乡村道路工况(8次),高速道路工况没有,这也就是前面讨论的瞬态排放尖峰中的积聚态颗粒物。城市道路工况对应的数目浓度峰值达到1×108个/cm3以上的情况(即图中白色区域)持续时间长,大多超过10 s,而乡村道路工况对应的数目浓度峰值达到1×108个/cm3以上的情况(即图中白色区域)持续时间较短,大多在5 s以内。颗粒物粒径在20~50 nm时,城市道路工况和乡村道路工况出现排放尖峰的时刻,该粒径段也出现了数目浓度峰值达到1×108个/cm3以上的情况(即图中白色区域)。颗粒物粒径小于20 nm时,城市道路工况中数目浓度峰值达到1×108个/cm3以上的情况(即图中白色区域)很少,而乡村道路工况和高速道路工况较多,且数目浓度峰值均出现在颗粒物粒径为6~8 nm时。因此,在瞬态工况下排放尖峰现象对应的粒径主要集中在积聚态颗粒物的50~200 nm范围和核态颗粒物的6~8 nm及20~50 nm范围。

3 结 论

本文对稳态工况及瞬态工况下柴油机排放颗粒物粒径分布规律分别进行了分析,结果如下:

1)在稳态工况下,随着负荷的增加,积聚态颗粒物数目浓度呈现上升趋势,其对应的CMD也呈现增大趋势,积聚态颗粒物表面积和质量均呈现增大趋势且峰值向大粒径方向偏移;核态颗粒物数目浓度总体呈现增大趋势,其对应的CMD也呈现增大趋势,核态颗粒物表面积和质量均呈现增大趋势且峰值向大粒径方向偏移。

2)随着转速的提高,积聚态颗粒物数目浓度上升,其对应的CMD呈现增大趋势,积聚态颗粒物表面积和质量均呈现增大趋势且峰值向大粒径方向偏移;核态颗粒物数目浓度呈现增大趋势,其对应的CMD呈现增大趋势,核态颗粒物表面积和质量均呈现增大趋势且峰值向大粒径方向偏移。

3)稳态工况全工况平面内总颗粒物数目浓度为1.5×107~4.5×107个/cm3,积聚态颗粒物数目浓度为2×106~1×107个/cm3,核态颗粒物数目浓度为1×107~3×107个/cm3,且在总颗粒物数目浓度中占比65%~96%之间,因此在稳态工况下,核态颗粒物数目是总颗粒物数目的主要来源。全工况当量比均小于0.7,在中低转速当量比对颗粒物分布影响较为明显,而在高转速尤其是大负荷条件下,当量比的影响减弱。

4)在瞬态工况下,颗粒物数目浓度出现了与颗粒物质量类似的排放尖峰现象,浓度峰值达到2×108~7×108个/cm3,比其对应的稳态工况出现的浓度峰值高出1个数量级。而且排放尖峰现象中,积聚态颗粒物数目浓度占主要部分,其峰值浓度比稳态工况要高出2个数量级,从稳态工况的2×106~1×107个/cm3跨越式增长到1×108~8×108个/cm3;排放尖峰现象中核态颗粒物数目浓度也出现明显的增长,其峰值浓度从稳态工况的1×107~3×107个/cm3增长到3×107~3×108个/cm3。排放尖峰现象对应的粒径主要集中在积聚态颗粒物的50~200 nm范围和核态颗粒物的6~8 nm及20~50 nm范围。

[1] Lamarche B, Moorjani S, Cantin B, et al. Small, dense low-density lipoprotein particles as a predictor of the risk of ischemic heart disease in men: prospective results from the Qué bec Cardiovascular Study[J]. Circulation, 1997, 95(1): 69-75.

[2] Wasko M K, Goodman S B. Emperor’s new clothes: Is particle disease really infected particle disease?[J]. Journal of Orthopaedic Research, 2016, 34(9): 1497-1504.

[3] 冯仲科,毛海颖,李虹. 环首都圈植被分布与可吸入颗粒物的空间相关性[J]. 农业工程学报,2015,31(1):220-227.

Feng Zhongke, Mao Haiying, Li Hong. Spatial correlation between vegetation distribution and respirable particulate matter around capital region[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(1): 220-227. (in Chinese with English abstract)

[4] Suzuki S, Nishikawa A, Kuwana M, et al. Inflammatory myopathy with anti-signal recognition particle antibodies: case series of 100 patients[J]. Orphanet journal of rare diseases, 2015, 10(1): 61.

[5] 张延峰,宋崇林,成存玉,等. 车用柴油机排放颗粒物中有机组分和无机组分的分析[J]. 燃烧科学与技术,2004,10(3):197-201.

Zhang Yanfeng, Song Zonglin, Cheng Cuiyu, et al. Analysis of the organic and inorganic components in the emission particulates from diesel engine[J]. Journal of Combustion Science & Technology, 2004, 10(3): 197-201. (in Chinese with English abstract)

[6] Stewart Goldman M D, Turner C D, Jr D P, et al. Katsouyanni K, Touloumi G, Spix C. Short-term effects of ambient sulphur dioxide and particulate matter on mortality in 12 European cities: results from times series data from the APHEA project[J]. British Medical Journal, 1997, 314(7095): 1658-1653.

[7] 李林,周启星. 不同粒径大气颗粒物与死亡终点关系的流行病学研究回顾[J]. 环境与职业医学,2015,32(2):168-174.

Li Lin, Zhou Qixing. Size-fractionated atmospheric particulate matters and mortality: An epidemiological review[J]. Journal of Environmental & Occupational Medicine, 2015, 32(2): 168-174. (in Chinese with English abstract)

[8] 郝斌. 不同燃料对柴油机排放颗粒物的影响研究[D]. 天津:天津大学,2014.

Hao Bin. Effect of Fuel Identity on the Exhaust Particles from Diesel Engine[D]. Tianjin: Tianjin University, 2014. (in Chinese with English abstract)

[9] 梅德清,赵翔,王书龙,等. 柴油机排放颗粒物的热重特性分析[J]. 农业工程学报,2013,29(16):50-56.

Mei Deqing, Zhao Xiang, Wang Shulong, et al. Thermogravimetric characteristics analysis of particulate matter of emission of divided diesel[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(16): 50-56. (in Chinese with English abstract)

[10] 王强. 乙烯预混火焰中碳烟微观形貌、纳观结构及氧化特性研究[D]. 天津:天津大学,2015.

Wang Qiang. Studies on the Morphology, Nanostructure and Oxidation Reactivity of Soot in a C2H4/O2/Ar Premixed Flame[D]. Tianjin: Tianjin University, 2015. (in Chinese with English abstract)

[11] 于文斌. 基于混合与化学反应协同作用的混合燃烧控制策略的研究[D]. 天津:天津大学,2012.

Yu Wenbin. Research on Hybrid Combustion Control Strategy Based on Interaction of Mixing and Chemical Factors[D]. Tianjin: Tianjin University, 2012. (in Chinese with English abstract)

[12] Giechaskiel B, Carriero M, Martini G, et al. Heavy Duty Particle Measurement Programme (PMP): Exploratory Work for the Definition of the Test Protocol[J]. Sae International Journal of Engines, 2009, 2(1): 1528-1546.

[13] Giechaskiel B, Dilara P, Sandbach E, et al. Particle measurement programme (PMP) light-duty inter-laboratory exercise: comparison of different particle number measurement systems[J]. Measurement Science & Technology, 2008, 19(9): 44-46.

[14] Benajes J, García A, Monsalve-Serrano J, et al. Gaseous emissions and particle size distribution of dual-mode dual-fuel diesel-gasoline concept from low to full load[J]. Applied Thermal Engineering, 2017, 120: 138-149.

[15] Barrios C C, Domínguez-Sáez A, Martín C, et al. Effects of animal fat based biodiesel on a TDI diesel engine performance, combustion characteristics and particle number and size distribution emissions[J]. Fuel, 2014, 117: 618-623.

[16] Barrios C C, Martin C, Dominguez-Saez A, et al. Effects of the addition of oxygenated fuels as additives on combustion characteristics and particle number and size distribution emissions of a TDI diesel engine[J]. Fuel, 2014, 132: 93-100.

[17] 王忠,孙波,赵洋,等. 小型非道路柴油机排气管内颗粒的粒径分布与氧化特性[J]. 农业工程学报,2016,32(10):41-46.

Wang Zhong, Sun Bo, Zhao Yang, et al. Characteristics of particle coagulation and oxidation in exhaust pipe of diesel engine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016. (in Chinese with English abstract)

[18] 李新令,黄震,王嘉松,等. 柴油机排气颗粒浓度和粒径分布特征试验研究[J]. 内燃机学报,2007,25(2):113-117.

Li Xinling, Huang Zhen, Wang Jiasong, et al. Investigation on concentrations and size distribution characteristic of particles from diesel engine[J]. Transactions of Csice, 2007, 25(2): 113-117. (in Chinese with English abstract)

[19] 孟建,刘军恒,孙平,等. 双极荷电凝并降低柴油机颗粒排放数量的试验研究[J]. 农业工程学报,2017,33(14):78-84.

Meng Jian, Liu Junheng, Sun Ping, et al. Experimental research on decreasing particles emission number of diesel engine by bipolar charged coagulation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(14): 78-84. (in Chinese with English abstract)

[20] Kittelson D B. Engines and nanoparticles: a review[J]. Journal of Aerosol Science, 1998, 29(5/6): 575-588.

[21] Kazakov A, Foster D E. Modeling of soot formation during di diesel combustion using a multi-step phenomenological model[J]. Sae Technical Papers, 1998.

[22] Desantes J M, Bermúdez V, García J M, et al. Effects of current engine strategies on the exhaust aerosol particle size distribution from a Heavy-Duty Diesel Engine[J]. Journal of Aerosol Science, 2005, 36(10): 1251-1276.

[23] Shi J P, Khan A A, Harrison R M. Measurements of ultrafine particle concentration and size distribution in the urban atmosphere[J]. Science of the Total Environment, 1999, 235(1/2/3): 51-64.

[24] Shi J P, Evans D E, Khan A A, et al. Sources and concentrationof nanoparticles (<10 nm diameter) in the urban atmosphere[J]. Atmospheric Environment, 2001, 35(7): 1193-1202.

[25] Tan P Q, Ruan S S, Hu Z Y, et al. Particle number emissions from a light-duty diesel engine with biodiesel fuels under transient-state operating conditions[J]. Applied Energy, 2014, 113(113): 22-31.

[26] Wang Jian, John Storey, Norberto Domingo, et al. Studies of diesel engine particle emissions during transient operations using an engine exhaust particle sizer[J]. Aerosol Science and Technology, 2006, 40(11): 1002-1015.

[27] Xiaobo Zhou, Erxi Liu, Dezeng Sun, Wanhua Su, Study on transient emission spikes reduction of a heavy-duty diesel engine equipped with a variable intake valve closing timing mechanism and a two-stage turbocharger[J]. International Journal of Engine Research, 2018(13): 146808741774883.

[28] 战强. 重型柴油机可变气门系统的开发及实验研究[D]. 天津:天津大学,2013.

Zhan Qiang. Design of The Variable Valve Timing System for Heavy Duty Diesel Engine and Its Experimental Study [D]. Tianjin: Tianjin University, 2013. (in Chinese with English abstract)

[29] 刘志华,葛蕴珊,丁艳,等. 柴油机和 LNG 发动机排放颗粒物粒径分布特性研究[J]. 内燃机学报,2009,27(6):518-522.

Liu Zhihua, Ge Yunshan, Ding Yan, et al. The size distribution characteristic of PM emitted from diesel engine and LNG engine[J]. Transactions of Csice, 2009. (in Chinese with English abstract)

[30] Ibald-Mulli A, Wichmann H E, Kreyling W, et al. Epidemiological evidence on health effects of ultrafine particles. J Aerosol Med, 2002, 15: 189-201

[31] Oberdöster G, Utell M J. Ultrafine particles in the urban air: To the respiratory track and beyond. Environ Health Perspec, 2002, 110 A: 440-441.

Experimental study on particle distribution of exhaust emission of heavy-duty diesel engine

Zhou Xiaobo1,2, Hu Qinghua1※, Yan Feng3, Su Wanhua2

(1.300350,; 2.300072,; 3.,300300,)

In recent years, smog has emerged in most of major cities in China. Epidemiological and toxicological studies showed that the ultrafine particles in the atmosphere adhere to a large number of toxic substances, which can cause serious harm to human respiratory and cardiovascular and other organs after they enter the human body through the respiratory tract. and the data indicated that it had a significant correlation with human morbidity and mortality. Particulate emissions from diesel engines are an important source of ultrafine particles in urban atmosphere. The researchers found that the weighing method of particulate matter detection cannot accurately reflect the emission levels of internal combustion engines. This new method for measuring the number of particulate matter emissions after removing volatile matter from the method has been widely recognized and included in the scope of regulatory investigation. However, there are few studies on the number and size distribution of particles in the transient process of diesel engine. In order to simultaneously control the quality and quantity of particulate matter emitted from heavy duty diesel engines, the particle distribution of exhaust particulates from diesel engines under steady and transient conditions was studied. The test bench is a 12 L heavy duty diesel engine and an electric dynamometer. The test bench is a prototype with no post-processor and meets the Euro IV regulations. It has been certified by China Automotive Technology Research Center (CATRC). The engine intake system consists of a two-stage turbocharging system with variable geometry section turbine (VGT), a high-pressure EGR system and an intake valve late closing system (IVCT system, which is developed by the research group independently). Cambustion DMS500 fast particle spectrometer was used to analyze the particle size distribution of diesel engine under transient conditions. The experimental results showed that, in the steady state, with the increase of load or speed, the concentration of accumulated particles showed an upward trend, corresponding to the increase of count median diameter (CMD), the surface area and mass of accumulated particles showed an increasing trend, and the peak value shifted to the direction of large particle size. In this study, the total number concentration of particles during the steady state is 1.5×106-4.5×106/cm3, and accumulation mode particle was 2×106-1×107/cm3, nucleation mode particle was 1×107-3×107/cm3which account for 65%-96%. In the steady state, the number of nucleation mode particles is the main source of the total number of particles. The equivalent ratio of all steady state conditions is less than 0.7. The effect of equivalent ratio on particle distribution is obvious at middle and low rotational speed, but weakens at high rotational speed, especially at high load. The European Transient Cycle (ETC) was used for the transient test. In transient condition, the spikes also appear in the number concentration of particles which similar to that of quality of particulate matter, and the number concentration peak even reaches 2×108-7×108/cm3, which is 2 orders of magnitude higher than that of the corresponding steady state operation. The number concentration of nucleation mode particle increases significantly in the spikes, but the proportion of the number concentration of nucleation mode particle in the total particles is reduced. The number concentration of accumulation mode particle is the main part of the spikes which is different from the steady state condition. The particle size peak is mainly concentrated in the 50-200 nm range at accumulation mode, the 6-8 nm and 20-50 nm at nucleation mode, this mainly because that the equivalent ratio in the transient process appears to exceed the critical equivalent ratio of 0.8 working conditions. The equivalent ratio does not exceed 0.7 in steady state operation, but the condition corresponding to the emission peak appears to exceed the critical equivalent ratio 0.8. The results are of great significance for particulate emission control and generation mechanism of heavy-duty diesel engine, and can provide data support for matching calculation of post-exhaust processor.

diesel engineers; exhaust gas; particulate matter; steady state condition; transient condition; distribution function; nucleation and accumulation mode

周小波,胡清华,闫 峰,苏万华. 重型柴油机颗粒物分布规律的试验研究[J]. 农业工程学报,2018,34(13):62-69.doi:10.11975/j.issn.1002-6819.2018.13.008 http://www.tcsae.org

Zhou Xiaobo, Hu Qinghua, Yan Feng, Su Wanhua. Experimental study on particle distribution of exhaust emission of heavy-duty diesel engine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(13): 62-69. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.13.008 http://www.tcsae.org

2018-03-26

2018-06-06

周小波,博士后,主要研究柴油机排放控制及自动驾驶。 Email:xiaobo_zhou@tju.edu.cn

胡清华,教授,博士生导师。主要研究不确定性建模和多模态学习等。Email:huqinghua@tju.edu.cn

10.11975/j.issn.1002-6819.2018.13.008

TK421+.5

A

1002-6819(2018)-13-0062-08