CHTC FONG’S witnesses SRITEX becoming a benchmark company in Indonesian textile industry

2018-06-28ByGaoHuabin

By Gao Huabin

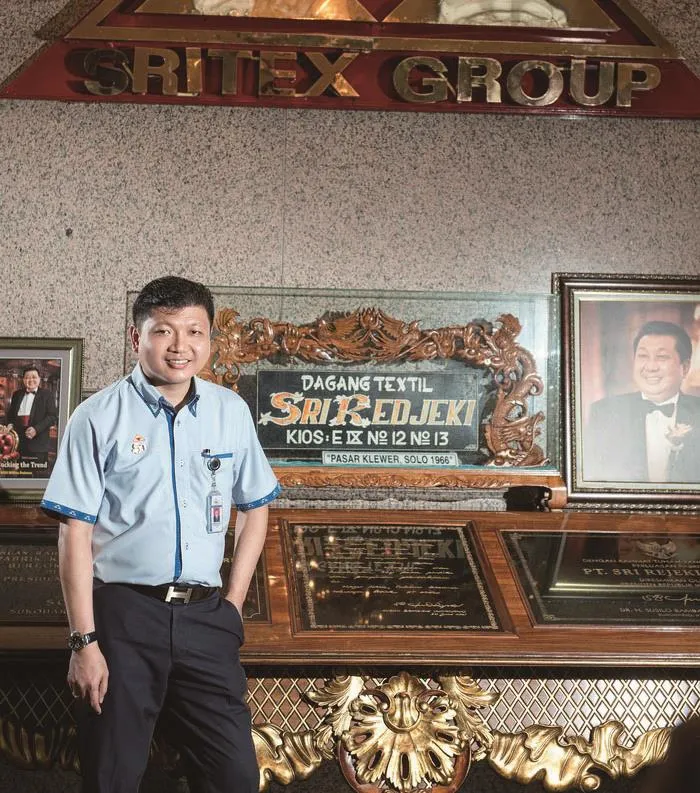

Pak Iwan Setiawan Lukminto, CEO of Sritex Group

PT Sri Rejeki Isman Tbk, better known as Sritex, is the largest integrated vertical–textile garment producer in South East Asia, which is not only benefited from its own efficient operation and management system, but also profited from the advanced machineries of CHTC FONG’S. CHTC FONG’S Group, established in 1963,engaged in producing and providing advanced textile dyeing and finishing equipment for the textile industry.

Since its founding in 1966, Sritex has grown from its humble beginnings with only small trading business in Pasar Klewer, to a company with more than 50,000 employees and established local capabilities to serve the needs of local, regional and global customers. The company has already had four main production units:spinning, weaving, dyeing and finishing, as well as garment, which manufactures yarn, greige, fabrics and apparel that are sold to textile producers and retailers in 55 countries across the globe, with buyers of well-known brands such as H&M, Target, WalMart, Express,Forever 21, New Yorker, Costco. In addition to the fashion clothing,it also specializes in clothing for military, and is appointed by North Atlantic Treaty Organization (NATO) as an official partner to produce military uniforms with high-end specification to more than 35 countries,including Germany, Swedia, Austria and Norway. Nowadays, Sritex entrusts to support nation’s development through production of army forces military uniforms for more than 35 countries.

In total, Sritex has 14 spinning plants (include PT.Sinar Pantja Djaja), 5 weaving plants, 5 dyeing/printing plants and 10 garment plants,occupying an area of 50 ha in Sukoharjo (Central Java). The spinning division is supported by 2,500 machines with more than 530,000 ringspindle and modified machines imported from Asia and Europe. The company’s weaving division has 2,600 weaving machines, producing 120,000,000 meters of greige per year.

The dyeing and printing unit is supported by three continuousdyeing production lines, nine rotary printing machines, 12 jet dyeing machines and nine stenter machines with a total production capacity of 120,000,000 yard per year. The garment division transforms fabric into ready-to-wear clothing. It supported by 6,350 machineries. Production capacity of the division is 16,000,000 pieces of ready to wear garment per year.

To probe into the secret of Sritex’s success, we couldn’t deny its business strategy of “Customer First”.Sritex is good at listening to customers and give the applicable service and solutions, with the strict and measurable international and quality management system ISO 9001 and Environmental management system ISO 14001.

In addition, Sritex has made a huge investment in modern and advanced technology machineries, which is an important asset for business continuity. Sritex possesses complete range of pre-treatment, dyeing and finishing and post treatment machineries covering leading brands of FONG’S, THEN, MONFONG’S and GOLLER. Sritex welcomes every innovation and development steps from Fong’s and finds out new ways to shorten and increase manufacturing efficiency on dyeing and finishing process.

Although Sritex has made success, it still faces some business challenges in efficiency, innovation and environment of dye house, as well as sustainable growth through reliable human capital. Therefore, FONG’S built intense communication with Sritex to deal with the challenges, by improving product stability and technology and deepening interest and participation on Sritex’s requirements, inputs and targets. Meanwhile, Sritex is willing to grow together with Fong’s, giving inputs for Fong’s development to realize mutual sustainable development. Now,the full line of dyeing and finishing machineries of our leading brands Fong’s, Then, Goller and Monfong’s under CHTC Fong’s are all set in the new Sritex Sukoharjo plant and ready to put into production for higher benefits for Sritex.

Sritex believes that textile industry is one of the main drivers for economic development of Indonesia. This industry contributes significantly for foreign exchange earnings and employment, which meets the needs of the domestic clothing, gives a surplus on the trade balance and plays a strategic role on industrialization process. The high demand from domestic market and the increasing world consumption will ensure a bright prospect for the textile industry. On April 21st, 2017, the Indonesian President Joko Widodo inaugurated the expansion of Sritex plant in Sukoharjo District, Central Java Province. In his speech, he highly praised the efforts and achievement that Sritex made for the textile industry in Indonesia. With the good example of Sritex here, he is very sure that the quality of products made in Indonesia is not inferior to those made overseas.

“In the next three years, Sritex will strengthen upstream process by reducing dependency on import material and creating green business and long-term growth. It will take entrepreneurial steps to develop eucalyptus forest industry to supply raw material for rayon production.Availability of self-manufactured raw material will align Indonesia with China and India who have comparative advantages of control of sources for raw materials cotton fiber. Indonesia will be able to control supply sources for raw materials rayon fibre.” Said proudly by Mr. Pak Iwan Setiawan Lukminto, CEO of the Sritex Group.

No matter how far Sritex has to go, CHTC Fong’s is ready to cooperate with her every step of development.

杂志排行

China Textile的其它文章

- Investigation in Guangdong and Shenzhen: New ideas bring new changes

- Investigation on Xinjiang textile industry: From government pushing to self-recycling,entering a new stage of development

- Investigation on standards,testing and quality

- Investigation in Nantong:The Spring of new channels of home textiles is coming

- Look to this age for innovation 2017 Innovative People of the Year in Chinese Textile Industry announced

- China’s textile industry released its first quarter data