地铁站台门门体绝缘方案研究

2018-06-27张俊岭

张俊岭

(中铁第四勘测设计院集团有限公司设备设计研究处,430063,武汉//高级工程师)

地铁乘客在上下车时有可能接触到列车车体或站台门门体。为有效规避乘客触电风险,站台门门体需进行绝缘设计。目前,各地地铁运营部门均按照站台门对地绝缘电阻值不少于0.5 MΩ的标准进行验收。站台门对地绝缘多采用站台门门体的上下立柱连接几个绝缘垫作为技术手段。然而,这是不能绝对保证达到绝缘要求的。而且,站台门门体的安装精度及使用寿命会受到土建及装修等配合工程的相互作用,继而影响到门体的绝缘效果。此外,地铁正式开通运营后,站台门门体在实际运行过程中还会受到空气、温度及湿度变化,以及杂散电流腐蚀等影响,其绝缘阻值也会不断下降。

为切实保障乘客的乘车安全,降低乘客触电风险,有必要提出切实有效且适于推广的地铁站台门门体绝缘方案。

1 站台门门体绝缘方案

1.1 站台门门体结构

在绝缘问题研究初期,曾提出过站台门门体纯由树脂等绝缘材料构筑。这是具备可行性的研究方案。如完全用绝缘材料制作门体,则绝缘效果是超群的,绝对可以满足各地地铁运营部门的电阻值验收标准。但是,地铁站台门还需承受列车进出造成的振动,更要将人、车分界,并对站台边缘起防护作用,其骨架结构也要具有一定的防火隔断功能。目前,全绝缘材料构筑的站台门无法满足这些要求。可见,纯绝缘材料制成站台门门体的方案虽在理论上有可行性,但受限于现有材料技术,无法在实际中应用。

只有以金属构件来作为站台门门体骨架才能满足相应的强度及功能要求。目前,以金属材料作为门体骨架,以绝缘材料作为电阻隔绝层才是最优站台门门体结构方案。

1.2 绝缘材料性能要求

为真正解决站台门门体绝缘的问题,作为金属门体的外装层,绝缘材料需满足以下性能要求:

(1)具有极强的附着力。绝缘材料与门体金属表面必须具有非常强的粘结力。施工完毕后绝缘材料成为门体金属不可分割的一部分,在空气、温度及湿度变化中,以及运营使用过程中不脱层、不断裂。

(2)具有透明的外观。加装绝缘材料后不能影响门体的玻璃隔断效果,以便乘客判断乘车候车时间。

(3)具有极强的耐磨性。由于站台门每天启闭上千次,乘客与门体接触机会也很多,故绝缘材料耐磨性必须相当优异,以保证在实际使用过程中不会因磨损问题而提升触电风险。

(4)具有抗化学腐蚀功能。绝缘材料必须具备抗弱酸碱功能、抗老化及大气腐蚀功能。在正常使用的情况下不会自然降解或因环境变化而变性变质,更能经受保洁人员各种保洁药剂的腐蚀和摩擦。

(5)材料本身具有安全性。绝缘材料应无毒、无刺激性气味,不含有害物质(如铅、镉、六价铬、汞、多溴联苯及多溴二苯醚等有害物质)。

(6)具有防燃烧特性。附着在门体金属表面的绝缘材料,必须满足不燃烧或不成为燃烧催化剂的防火要求。

(7)加装工艺简便、经济。绝缘材料施工最好不需加压加热,也不需使用其它专用设备,以便于推广和日后的维护保养。

1.3 绝缘层实施方案

1.3.1 门体贴膜加装绝缘层方案

门体贴膜加装绝缘层方案中,绝缘层以贴膜加装的方式施工。贴膜技术是操作简便、且透明耐磨的方案。选择合适的材料也能做到无毒无害、抗化学腐蚀、不易燃烧。

但是在实际使用过程中,加装的绝缘膜体极易受到温差和湿度变化的影响,常常会发生脱胶情况,从而影响绝缘效果。

1.3.2 门体喷涂绝缘涂料

在站台门门体表面喷涂绝缘材料同样是操作简便、外观透明的方案;选用优质合理的材料也可满足经济实惠的要求,使门体具有无毒无害、抗化学腐蚀、不易燃烧等性能。

但是,由于采用喷涂方式的涂层厚度极小,在实际使用时,一旦受到外界环境变化和人为摩擦很快就会出现涂层脱落的情况,从而降低绝缘层的绝缘保护效果。

1.3.3 门体涂刷绝缘涂料

在站台门门体涂刷绝缘材料同样具有操作简便、外观透明的特性。合理选用绝缘材料也可满足无毒无害、抗化学腐蚀、不易燃烧的限制条件。而且,采用涂刷方式可大大增加绝缘层的厚度,大幅提高其耐磨性。涂刷层对温度、湿度变化和人为磨损的抗性也远远优于喷涂层。

1.3.4 使用效果比较

广州地铁7号线(一期)和广州地铁6号线(二期)同时开始运营。这2条线站台门绝缘层分别采用了涂刷和喷涂的方式。当6号线(二期)的站台门喷涂层出现部分脱落情况时,7号线(一期)的站台门绝缘涂刷层粘接依旧牢固。检测发现,绝缘涂刷层电阻值高,综合性能极为优异,其表观效果与刚施工完成时高度一致。故选择涂刷绝缘材料的方案为最优方案。

2 施工及运营对绝缘层的影响

2.1 施工对绝缘层的影响

在地铁建设施工过程中,往往会存在多个专业的施工交叉进行,甚至有地面露天施工的情况。施工产生的混凝土碎屑、粉尘及水分等会使门体与大地接触,从而降低绝缘阻值。

为了预防此类问题,建议站台门门体绝缘材料的涂刷工作应在大多数专业施工完成,且站台门门体安装无误的情况下进行。这样可极大规避施工造成的绝缘层损坏风险。

2.2 运营对绝缘层的影响

在地铁开通运营之后,受地铁隧道环境的限制、温度及湿度变化,以及活塞风引起的粉尘会对站台门门体绝缘产生影响[4]。

在地铁运营期间,日常维护清洁所用的清洁剂也会对绝缘层有冲洗、腐蚀作用,进而引起绝缘层电阻值的变化,从而影响其绝缘功能。

针对上述问题,建议采用附着力、耐磨性及抗化学腐蚀等性能更优的绝缘材料[6]。

3 最优方案实例分析

基于上述分析,制定了站台门门体绝缘层最优实施方案。广州地铁7号线一期工程的9个车站站台门采用最优方案,进行了工程化试验。

3.1 新型绝缘涂层材料

在涂刷方案实施中,涂层材料是绝对的重中之重。目前市场上的绝大多数涂层都难以满足金属门体涂层的基本功能要求。为了满足全部功能要求,理论试验阶段设计了涂料新配方,并进行化学合成。经多次试验终于得到了能满足绝缘层全部功能要求的新型绝缘涂层材料。

3.1.1 涂层材料的基本性能技术参数

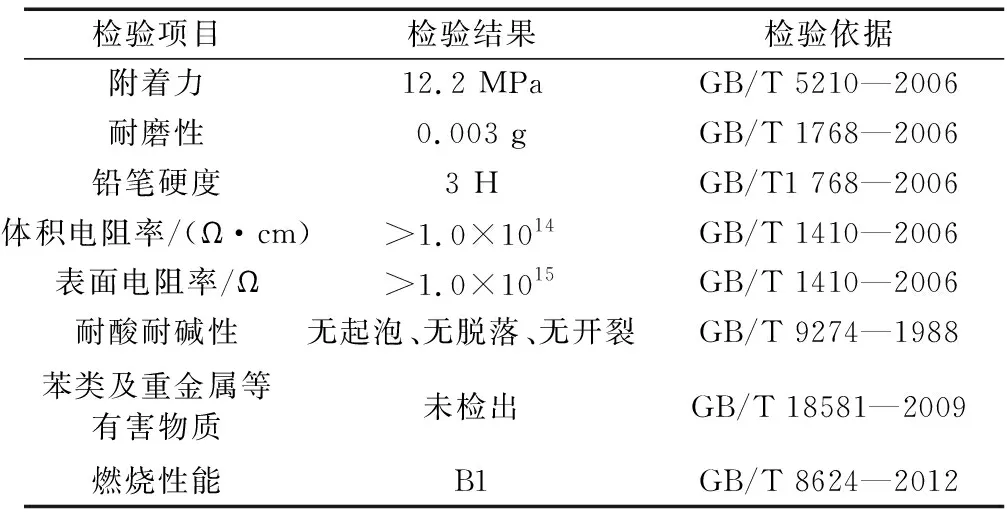

绝缘涂层材料主要化学成分为纳米有机硅,其合成固化后技术参数如表1所示。

表1 涂层材料参数表

3.1.2 涂层材料特殊性能分析

新型绝缘涂层材料除了要满足基本性能要求,作为站台门涂层还应满足特殊性能要求。

(1)附着力:涂层附着力为12.2 MPa,即粘结力达到122 kg/cm2,所以涂层在正常的运营使用过程中不会脱落,与金属门体粘结为一体。

(2)耐磨性:涂层耐磨性指数为0.003 G。该指数测试时采用500 G橡胶砂轮以50 r/min转速运转10 min后再计算磨损量的测试方式。而绝缘涂层在实际使用时一般只有乘客触碰或衣物摩擦。可见,新型绝缘涂层材料耐磨性能优异,完全满足站台门门体绝缘层的耐磨性需求。

(3)电阻率:由表1可知,新型绝缘涂层材料体积电阻率及表面电阻率都很高,其性能优异,完全满足绝缘性需求。

(4)燃烧性能:新型绝缘涂层材料的燃烧性能为B1级。现场燃烧试验结果显示,该涂层材料涂装在金属表面以后,能达到不燃效果。

3.2 工程化试验

在方案的实践效果工程化试验中,进行了站台门门体(包括安全门每侧24个活动门、端门及应急门等)可触部分基层处理,门体待涂刷部分的表面清洁后,采用新型绝缘材料对每个站内的站台门门体金属外露不锈钢表面部分进行涂刷。

充分考虑到乘客上下车、候车等待等触及可能性,涂刷区域覆盖了从滑动门立柱不锈钢包板及门楣,到端头门立柱不锈钢包板外露于站台侧部分,再到滑动门、端门与应急门轨道侧可与人体接触的金属部分。

整个施工过程中,施工工艺简洁快速。用丙酮或酒精将门体金属表面清洗干净后,再用细羊毛刷将涂料轻轻地均匀涂在金属表面即可。工期短,也不需要专业设备,其施工过程快速而高效。

施工过后,涂层均匀透亮,质感饱满,丝毫不影响乘客观感和地铁运营的日常使用,且使站台门门体具备反光效果,起到了美化作用。

在工程化试验中,门体绝缘涂层有效减少了门体表面的泄漏电流,增加了门体绝缘电阻。地铁运营1 a之后,绝缘层的电阻值均大于100 MΩ,绝缘性能较刚加装完成时保持一致;绝缘层没有任何损坏,更没有脱层起皮现象,其外观效果与刚施工完一样透亮。

3.3 工程化试验结论

工程试验证明,新的绝缘涂层技术已具备优异的性能,不仅克服了传统金属表面绝缘层(涂层或贴膜)的附着力低、耐磨性差、易损坏、难以施工及不透明不美观等弊病,而且不需对站台门结构作任何更改,不影响金属外观及质感,施工简便、工期短。因此,可进行工程化推广。现广州地铁9号线、13号线、4号线南延线及知识城支线已全部采用该新型绝缘涂层技术,实施效果良好。

4 结语

地铁站台门门体绝缘失效问题一直是地铁建设的工程隐患。本文对现行地铁站台门门体的各种绝缘方案进行综合比较,着眼于规避乘客上下车触电风险,并结合工程方案实施后的客观效果,提出站台门门体涂刷绝缘材料的绝缘改进方案,旨在建设更安全、经济、便捷高效的城市轨道交通体系。

[1] 中华人民共和国住房和城乡建设部. 地铁设计规范:GB 50157—2013[S].北京:中国计划出版社,2003: 126.

[2] 饶美婉.城市轨道交通站台门新型整体式绝缘设计方案[J].城市轨道交通研究,2016(3): 27.

[3] 王凯,倪少权,陈钉均,等.地铁运营模式在城际铁路的应用研究 [J].交通运输工程与信息学报,2016(2): 2.

[4] 陈韶章.地下铁道站台屏蔽门系统[M].北京:科学出版社,2005.

[5] 孙增田,李华,程强.屏蔽门接轨保护及绝缘保护必要性分析[J].城市轨道交通研究,2006(8): 44.

[6] 叶宏,凌人. 屏蔽门门体绝缘及站台绝缘的探讨[J]. 现代城市轨道交通,2012(6):27.

(收稿日期:2017-12-19)

(Continued from Commentary)

science and technology of high-speed trains, the introduction stage of high-speed train manufacturing technologies, the digestion, absorption and innovation stage of the imported technologies, and the researching and manufacturing stage of China Standard EMU trains.

The first stage started in "The 8th Five-year Plan" period. During "The 9th Five-Year Plan" period, researching and manufacturing of the high-speed train core components and overall-technology researching of high-speed trains were completed and the core technologies of high speed trains were mastered. On the basis of the above scientific research results, the developing, testing and verifying tasks of the whole high-speed train were carried out during "The 10th Five-year Plan" period. At this stage, the core technologies of high-speed trains grew out of nothing. Its landmark achievements were "China′s Star" and "Pioneer" EMU trains. On September 10, 2002, the highest test speed of "Pioneer" EMU train reached 292.0 km/h. On November 27, 2002, 2M+3T short-marshalling of "China′s Star" EMU train reached the highest test speed of 321.5 km/h. On December 20, 2002, 2M+9T long-marshalling of "China′s Star" EMU train reached the maximum test speed of 305.9 km/h. On the basis of the successful development of the "Pioneer" EMU train, the development of power-distributed high-speed EMU trains of 300 km/h in China was started.

Tackling key problems in science and technology at the first stage cultivated a complete talent team of China in all respects of high speed trains′ theoretical researching, high speed trains′ designing, manufacturing, inspecting and testing etc. At the technical level, the core technologies′ being mastered laid a foundation for the industrialization of the key components of AC drive traction system, computer-control braking system, high-speed gearbox, aluminum-alloy vehicle body, dense coupler, air spring and etc. Meanwhile, all kinds of detect equipment were founded, making detection technology reach the world′s advanced level.

The second stage that started in 2003 introduced high-speed train manufacturing technologies. Thus, the localization of the high-speed trains of "Harmony" CRH1, 2, 3, 5 series was realized, significantly improving railway transportation capacity and passengers′ travel quality, making manufacturing enterprise′s manufacturing ability, level and quality control have a qualitative leap and forming the localization capacity and the industrialization structure. Meanwhile, more comprehensive and deepening understandings for standards, technology, maintenance and application of high-speed trains were achieved. The problems existing at this stage were as follows. The core technologies were controlled by foreign investors, which were enslaved to others. The EMU train models of different technical platforms were too many. There were more than 20 models and the technical platforms and the standard systems were not uniform. For the development of EMU trains, there was lack of perfect top-level designs.

The third stage is the stage of digestion, absorption and innovation for the imported technologies. Its landmark achievements were "Harmony" CRH380 series high-speed trains that were successfully developed in 2010. The deficiencies of the second stage had been improved somewhat at this stage.

The fourth stage, that is, the researching and manufacturing stage of China Standard EMU trains, was begun in 2012. This stage based on the forward design, got rid of the situation of core technologies′ being enslaved to others, set up the standard system of China′s high speed trains, and founded the completely independent technology platforms of China′s high-speed trains. It was the milestone of China′s high-speed train technology development. Its landmark achievement was that "Renaissance" high-speed EMU train with the highest operating speed of 350 km/h commenced commercial operation.

The great significance of developing China Standard EMU trains is as follows. Firstly, China′s EMU sustaining innovation technology platform has been founded. Secondly, the technical standard systems of EMU which adapts to our country′s situation have been formed. Thirdly, China has had the intellectual property rights of high-speed trains. Fourthly, the world-class "producing-studying-researching-applying" innovation teams have been cultivated. Thus, China′s high-speed train technique level′s continuously lying in the world′s advanced rank would be ensured.

Currently, high speed train technologies and its new-type trains are constantly emerging all over the world. For example, there are Germany′s fourth generation Velaro-D high-speed train and the ICE 4 high-speed train, France′s fourth generation new-type AGV high-speed train that adopts permanent-magnet motor traction and is distributed-power, and Japan′s Shinkansen E5, E6 high-speed trains, etc. China is now speeding up to develop China′s new generation intelligent high-speed rail trains, and they will be put into trial operation on Beijing-Zhangjiakou high-speed railway line that will be opened in 2019. We must continue to innovate in the technical aspects of high-speed trains. Only this can ensure that we continue to be in the first square team to keep up with the world′s advanced level and to achieve the higher goal of leading technology.

(This paper is the summary of the author′s keynote speech at "2018 Urban Rail Transit Development Forum and The Academic Forum of 20th anniversary ofUrbanMassTransitMagazine′s Starting Publication" on the May 17, 2018.)