Chunfeng Tunnel: The Largest Diameter Shield Tunnel in China

2018-05-10YOUYongfeng511458

YOU Yongfeng( ., ., 511458, , )

1 Project significance

The Chunfeng Tunnel Project is a major transportation project of Shenzhen′s "Going East Strategy". Upon completion, the traffic condition of the existing Chunfeng Elevated Road will be effectively improved, and the traffic congestion in the eastern area, especially in the southeastern of Luohu District, will be greatly alleviated. Using Luohu central cluster as a link and connecting western and eastern clusters together, this project will have a tremendous impetus for promoting the sustainable socioeconomic development in eastern Shenzhen.

2 Project overview

2.1 Engineering design

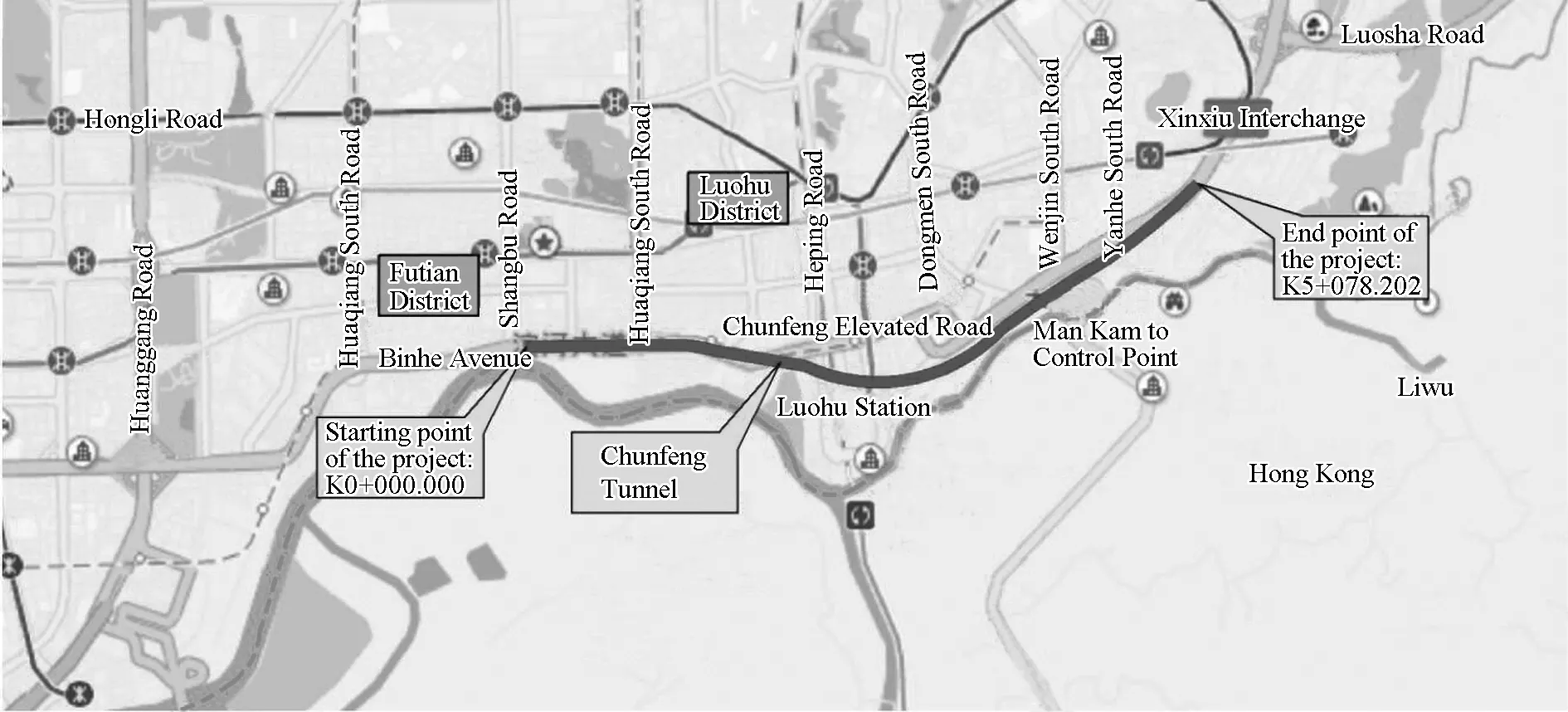

Chunfeng Tunnel is designed in accordance with the technical standards of the urban expressways. A double-layer tunnel with two-way four-lane arrangement, along with an emergency lane on each direction, has been adopted. The design speed limit is 60 km/h. Total length of the route is approximate 5 078 m, where the tunnel length is 4 799 m with a shield section length of 3 603 m and open-cut sections of 456 m long on west end and 740 m long on east end, respectively. An enclosed structure with continuous retaining walls and bored piles will be used at both ends of open-cut tunnel. The maximum depth of excavated foundation pit is 32.3 m. The shield section is to be constructed by using slurry shield method. Refer to Fig. 1 for the layout of Chunfeng Tunnel.

(a) Plan layout

(b) ProfileFig. 1 Layout of Chunfeng Tunnel

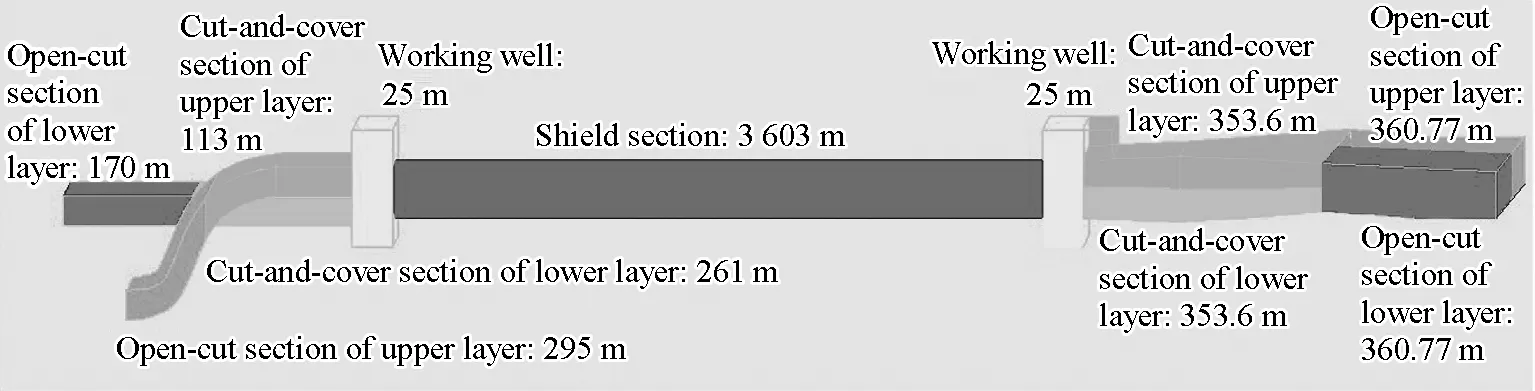

The buried depth of tunnel shield section varies from 6.1 m (0.40D) at the west end of tunnel to a maximum depth of 46.2 m, where the tunnel section is below Luohu Railway Station. The tunnel is adjacent to Shenzhen River and Buji River, and the maximum water/soil pressure at the bottom of the shield section is 0.6 MPa. The shield section is designed as a single-hole tunnel, as shown in Fig. 2(a). The inner diameter of the tunnel is 13.9 m and the outer diameter is 15.2 m. Auxiliary tunnel facilities include evacuation stairs, cable passage, drainage ditch and ventilation flue as shown in Fig. 2(b).

(a) Single-hole shield section

2.2 Engineering geology and hydrogeology

Fig. 3 Geological profile of tunnel

3 Project difficulties and engineering solutions

3.1 Difficulties and challenges

Chunfeng Tunnel is the largest diameter (cutterhead diameter: 15.80 m) slurry shield tunnel in China. It is the first transport tunnel using shield technology and the first single-hole with double-layer tunnel in City of Shenzhen. The project is located in the coastal area with relative complex geological and hydrological environment, and the tunnel passes through a long distance of inhomogeneous rock strata and multiple fractured zones.

The construction site of this project is in the old area of City of Shenzhen. The construction area is narrow and the surrounding environment is very complex. There are many existing buildings, lots of underground pipelines, and numerous traffic flows. All the above have made this project the most difficult and highest risk project among the same type of projects in the world. Therefore, to complete this project requires very high engineering design capability and many innovations of construction technology on the tunnel structure. Its characteristics and difficulties are summarized as follows:

(1)Largest shield diameter: It adopts slurry shield with the largest shield diameter in China, 15.80 m.

(2)Difficult and complex: The shield machine in this project has to pass through 3 603 m continuously in a single application, and crosses the very complex strata consisting of soft layer underlaid by hard layer, inhomogeneous soft and hard layers and full-section hard rock, etc. The tunnel excavation volume is huge and the transport distance is quite long. The tunnel has a wide variation in burying depth, and a small turning curve(radius = 750 m only), high water pressure, and very high construction technical requirements. These factors will induce a series of difficulties and challenges for shield tunneling.

(3)Very high risk: The tunnel is to be constructed in a prosperous and busy region of the city. It is under 25 buildings of Shenzhen Customs and Frontier Inspection Station and 5 bridges. Furthermore, additional 187 buildings will be affected by this project. The potential ground settlement must be considered in design and must be strictly controlled during the construction to eliminate the safety risk of these existing buildings. In addition, the underground tunnel will pass through multiple important transportation facilities, such as, Metro Line 9, Line 1, Shenzhen Railway Station, Guangzhou-Shenzhen Railway and Chunfeng Elevated Road.

(4)New/High technology: A series of new and high technologies, such as, BIM building information model and road traffic simulation, are applied to this project to provide technical support for the safety, quality and efficiency of the project.

3.2 Design and construction solutions

(1)Conducting research and study on the tunneling model test using super-large section shield in continuous hard rock and fractured zones; optimizing cutter design and carrying out comprehensive measures to enhance geological forecast; selecting experienced manufacturers through international bidding and procurement procedure; performing expert argumentation on key issues; taking advantage of the rich experience provided by China Railway Tunnel Group in construction and accurate recognition of geological conditions; integrating with the shield manufacturer to improve the shield design and performance reliability and to achieve quality monitoring on entire manufacturing process.

(2)When tunneling in unfavorable geological strata, such as, long-distance hard rock, 11 fractured zones, shallow burying depth and high water pressure, lots of risks and challenges can be encountered, for example, tool wearing out, high-frequency tool replacement, mud cake on cutter, working face instability, etc. Innovative design is required to develop and renovate the shield equipment to have special functions, i.e. cutter replacement under normal pressure, soft and hard cutter exchange, main bearing shaft expansion, cutter wearing protection, cutter condition detection system, anti-mud cake flushing system and advance geological forecast system.

(3)The quality assessment has to be conducted in advance for all existing buildings, bridges, metros, operating railways and pipelines within the tunnel construction zone. Pre-reinforcement has been used to ensure the safety and stability of existing structures during shield tunneling based on the assessment and structural conditions. For the fractured zones being prone to collapse, all strata above the tunnel will be grouted and reinforced to improve their stability. At the same time, according to surface monitoring data, tunneling parameters will be continuously adjusted to control the shield posture and so as to advance the shield steadily.

(4)Develop BIM information platform for the entire tunnel, establish a management system related to quality, safety, progress and cost of construction, give full play to the advantages of modern architectural intelligence software to provide technical support for the project. At the same time, the road traffic simulation system, safety animations system and safety control & monitoring system have been adopted to provide an overall management guide line and a strong construction backup for building an intelligent underground tunnel successfully.

4 Construction duration

The project started on February 23rd, 2017 and is scheduled to be completed and opened on January 19th, 2021.

5 Project participants

The project adopts the general contract mode, with China Railway Group Limited and China Railway Tunnel Group Co., Ltd. taking overall responsibility for the implementation of the general contract.