Product Highlights

2018-04-16

China Texmatech Co., Ltd.

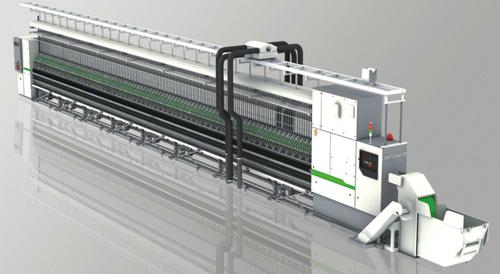

JWF1566 series ring spinning frame

JWF1566 series ring spinning frame is the new generation product to lead the development trends of spinning frame. It is based on JWF1562 series and combined with the fast installation technology, rapid doffing and intelligent spinning expert system. As the upgrade model originated from JWF1562 series, JWF1566 will be the key renovation options for high-end and middle-end customers.

New features:

Integrated center wall and new spindle rail of high precision facilitate to conduct high-speed spinning

With pin hole positioning, the lifting post without adjustment

Pioneering technology of zero adjustment ring rail lifting

New type fast doffing technology, doffing time 2.5 min

Intelligent spinning expert system

JWF1552 series ring spinning frame

JWF1552 series ring spinning frame is the new-generation and high-end short automatic doffing spinning frame independently developed based on JWF1562 long automatic doffing spinning frame platform in responding to the current trend, product status and market demand of spinning frames as well as the requirements of users on high speed, high stability and high reliability. Compared with the traditional short spinning frame, JWF1522 spinning frame inheriting all merits of JWF1562 has a high spindle speed and low energy consumption. With electronic cam lifting technology, rapid doffing technology and automatic bobbin readying unit technology adopted, this spinning frame becomes the first choice of high-end cunstomers by means of its high degree of automation, small land occupation area and extensive variety adaption.

New features:

New type frame

New type of fast doffing technology

Energy and labor saving

Suitable for spinning coarse yarns

Jiangsu Hawk Vision Intelligent Science & Technology Co., Ltd.

Jiangsu Hawk Vision Intelligent Science & Technology Co., Ltd. is specialized in the research and manufacturing of automatic control techniques and optical-electromechanical integration products since 1990. Changzhou Honda is located in Changzhou, which is 160 kilometers away from Shanghai and is one of the most developed manufacturing cities in China. Changzhou Honda is one of the largest and most powerful high-tech enterprise in the textile dyeing control in China.

Since its foundation in 1990.with strong technology and capital strength, Hawk Vision has set up a fundamental research center laboratory on digital textile application techniques. A contingent of outstanding research and development team was brought up, Hawk Vision is keeping a very good cooperative partnership with Tsinghua University - one of the most famous university in China, Chinese Academy of Science (CAS), Hefei, and some well-know domestic dyeing enterprises for developing new digital products. All products are certificated by ISO9001. Hawk Vision also pays attention to protecting intellectual property and business secrets in process of research and development,and then developed intellectual property strategy. Until now, Changzhou Hongda has five invention patents and applications, twenty-one utility patents and applications,one design patent and one software copyright.

By the powerful technology strength and good reputation, Chinese government provide strong support for Hawk Vision. A National Research and Development Center of digital printing and dyeing system technology is set up at Hawk Vision, that for researching National Key Technology R&D; Project. And many research results have already won awards from national dyeing and printing associations. Our products are also recommended by both China Dyeing and Printing Industry Association(CDPIA) and China Textile Engineering Society (CTES). Hawk Vision is the demonstration enterprise of “Integrate IT Application with Industrialization Program” which was awarded by Ministry of Industry and Information Technology of China.

“Hawk Vision Intelligent Integrated Weft/Pattern Straightener” is an initiated internationally leading“full-width scanning pattern/weft straightening technology” of the brand “Hawk Vision” based on its strong European technology background and profound technology research and development ability of Changzhou Hangda. With the full-width scanning over 8,000 detecting points it thoroughly solves deformation of pattern, weft skewing and bowing of textile what the photoelectric weft straightening fails to identifying and straightening, surpasses the value of the photoelectric weft straightening and common image weft straightening. The system has broad adaptability of varieties. In addition to all varieties suitable for the photoelectric weft straightening it is also suitable for yarn-dyed fabric, jacquard cloth, thick and heavy fabric, twill, sanding cloth, knitting, denim, printing fabric etc. what the photoelectric weft straightening fails to identify and straightening thus it largely raises up quality of after-finishing of textile, realizes a revolutionary breakthrough of intelligent pattern/weft straightening of textile and opens a new era of pattern/weft straightening of textile. The equipment has been successfully used in a lot of domestic advanced enterprises and obtained remarkable result. It upgrades marketing competitiveness of enterprise and creates core value for customer.

Hubei Tianmen Textile Machinery Co., Ltd.

Hubei Tianmen Textile Machinery Co., Ltd. is a national hightech enterprise,having decades of history and culture on Drawing Frame development and manufacturing,and known as the title of “Draw Frame Expert” .

The main products of Tianmen company are two major series FA and TM Drawing Frame under “Crane” brand,with original designs and complete intellectual property rights and many national patents, the marketing products include FA305C, FA317A, TMFD81(S), TMFD81L, TMFD83, TM3807S, TM3809Y, TM3811S, TM3813Y, TMFD101L and other models and specifications, which can fulfill various requirements of users.

In China, the company holds many patents on drawing frames, especially it holds the unique technology of “Electrical gear setting system, calibrating weight unevenness digitally. No need to change technical gears” and “Electronic Sliver Cutting Device”.

Exhibits: Drawing Frame TMFD81S

Drafting: 3 over 3 double zone curvilinear drafting system with guiding top roller and pressure bar

Driving: Driven by synchronous belts ,short driving route, steady running , power saving and lower noise

Four draft tension: adjustable draft ratios for coiler, front draft , back draft and creel, applicable for various fibers

Adjustment of weight unevenness: Adopting international initiative electronic drafting technology, no need to change technical gear, weight unevenness is adjusted digitally.

Sliver broken while full can :Adopting initiative smart sliver breaking technology, reliable broken rate.

Suction and filter cleaning: Dust filter box located at center behind of machine. This ensures the suction pressure will be balance for 02 deliveries. Upward and downward suction pressure can be separately adjusted. Dust will be automatic cleaned by bar while full can.

Automatic can-changer: Side in-front out, controlled by pneumatic system, 6 empty cans per head at most can be changed continuously which is steady and reliable

Speed control: Controlling speed by inverter

Drawing Frame TMFD81L

Uster UQA short-term auto-leveller, driving and control system are separate for each head, to achieve optimum results

Use programmable logic controller (PLC), touch screen display, controlling motor speed by inverter, etc.

3 over 3 double zone curvilinear draft system with guiding top-roller and pressure bar

Adjustable draft ratios for coiler, front draft, back draft and creel, applicable for various fibers

Available for automatic filter cleaning, automatic can-changer and automatic sliver broken while full can.

Drawing Frame TM3807S

Owning all advantages of Drawing Frame TMFD81S

Min. Front draft zone gauge is 1.5mm, pressure bar location can be adjusted, suitable for pure or blend spinning for processing 12mm-120mm (staple length) fiber

●Delivery can of ¢600mm*1200mm, reduce the sliver joints

Some advantages of Tianmen Drawing frame :

●Unique teeth belt driving system to get below advantages :

To avoide slip ratio .

Machine head without oil leaking out, short driving distance, highest precising.

To save 30%~ 50% power consumption to compare with other drawing frame with gear driving.

Very low noisy, simple maintenance.

●Dust filter box located at center behind of machine. This ensures the suction pressure will be balance for 02 cans. Dust will be automatic clean by bar controlled by air.

●Controlling speed by inverter to allow changing speed at any time, no need to change pulley.

●Material of sliver creel with high quality.

●With electronic sliver breaking device.

Shaoxing Shuifu Textile Equipment Co., Ltd.

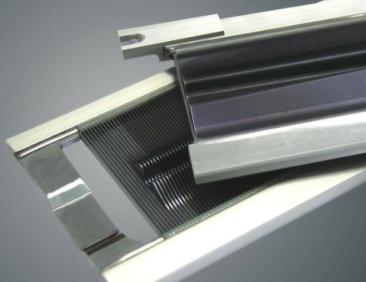

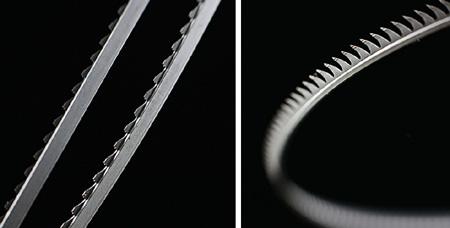

Shaoxing Shuifu Textile Equipment Co., Ltd. is a private enterprise which is professional on producing vary kinds of reeds, which is a administrative council of China textile machinery Association, a vice minister of reeds team in heddle, reeds, dent committee, one of the authority of textile machinery nation standard of reed. She is honored with China Air Jet Profile Reeds Research Center by China Textile Machinery Association in 2015.

Shuifu Company established in 1988 and registered capital of USD 3 million, covers an area of 13,000m2,and its main products are reeds for Air Jet, water Jet, Rapier, Projectile Looms and other special industrial reeds. The annual output is that air-jet reeds are about 90,000 meters, profile dents are 200,000,000 pcs, rapier is 50,000 meters. In order to meet the markets and customers need, Shuifu can maintain and repair the reeds for them, also can provide technical to help them solve the problems. The company is located in Shaoxing PaoJiang Industrial zone (economical developing zone), where is only 210 kilometers from Shanghai PVG airport. The company has rich talent resources and special total advanced equipment, advanced technology to create a useful internal condition. The customers are “god”, the “quality first, service for clients” is the companys tenet, the “going ahead, keeping Innovating” is its spirits, the “contributing to society, exceed ourselves, creating success” is its idea. The company will try its best to make clients 100% satisfied.

Smart Dyeing & Finishing CHTC FONGS Innovations

CHTC Fongs has been committed to the development and manufacturing of dyeing and finishing equipment for more than 50 years. In the past decades, CHTC Fongs devoted to the development of energysaving and emission reduction machines and now it becomes the basic conditions for dyeing factories. Today, we live in a digital era, though in the traditional textile industry, CHTC Fongs has been with the times. Together with its well-known brands: Fongs, Monforts Fongs, Xorella, THEN, Goller, and Monforts, CHTC Fongs dedicated in the development of Smart Dyeing & Finishing and join with the customers to build the intelligent dyeing factory.

The CHTC FONGS Group is proud to present the “one-stop” sustainable solution in dyeing and finishing range of “pre-treatment, dyeing, and posttreatment” at Indo Intertex 2018 in Hall C3, No. 79 Jakarta International Expo – Kemayoran from Apr 4th to Apr 7th. We are looking forward for your visits.

FONGS DYECOWIN High Temperature Dyeing Machine

DYECOWIN is the revolutionary high temperature dyeing machine setting new standards for the industry. It is integrated with the cuttingedge patented technologies to cut down the liquor ratio and to enhance the productivity of the dyeing processes.

Reduce Production Cost

DYECOWIN is a major breakthrough in the long tube machine operating with a much lower running liquor ratio as low as 1:5. The patented fluid distributor at the rear of the machine can effectively adjust the distribution of dyeing liquor according to different fabric types, ensuring an organized fabric stacking pattern.

Optimize the Dyeing Quality

The rollerless design overcomes the tangling problem against conventional machines, avoiding fabric surface defects such as scratch marks and shinning marks caused by unsynchronized motion between nozzles and lifting rollers. Our patented ‘CONJET nozzle technology can ensure the quality of finished products by enabling automatic and precise adjustments of flow volume and nozzle pressure.

Enhance Productivity and Efficiency

The rectangular fabric delivering channel allows fabric to have tension relaxation and a smoother run along the channel, reducing crease marks. This design also favors open width dyeing as no additional process is required. The patented stainless steel storage chamber is capable of increasing the loading capacity. When combined with the use of ‘CONJET nozzle, the sensitive fabric can be run smoothly without scratching and snapping. It assures the surface quality of fabric and minimizes the cycle time.

FONGS TECWIN High Temperature Dyeing Machine

FONGS TECWIN is designed to adopt the ever-changing textile market nowadays. The reliability and applicability is further improved from the last generation.

TECWIN is equipped with several patented designs:

Combined Air & Front Spray Nozzle (Patented & Optional Feature)

If optional blower is equipped, blower will provide highpressure aerodynamic flow in spray nozzle, in order to effectively increase the degree of dye liquor interchange. It is specifically designed for dyeing fabrics that demand high quality.

Front Spray Nozzle (Standard Feature)

It improves the degree of dye liquor interchange before the fabrics entering the main nozzle. The color balance and quality of fabric can then be enhanced.

Liquid Dispersion Storage Chamber

This is a uniquely designed chamber for providing a better liquor dispersion effect.

Dye Liquor Separation Design

The Dye liquor separation is specially designed in TECWIN. With the use of the variable loading storage chamber, the dyeing operation can be performed more smoothly and fabric patterns can be more organized, which eventually

leads to a lower liquor ratio.

Automatic Adjustable Nozzle

Adjustment of nozzle setting is automatically done by means of motor drive system, and hence manual changing of nozzle is not required.

Upper and Lower Overflow Rinsing

Innovative use of upper and lower overflow rinsing systems can deal with various kinds of fabrics.

Lower Overflow Rinsing: This is designed to maintain a pumping operation with low water level and an improved dye liquor separation.

Upper Overflow Rinsing: This is adopted for conventional overflow rinsing function.

THEN AIRFLOW AIRJETWIN Aerodynamic High Temperature Dyeing Machine

AIRJETWIN high temperature airflow dyeing machine, the latest generation of dyeing equipment, is now being offered to fulfill the various requirements of dyeing process nowadays. Through finite element analysis FEA), the airflow and water flow situation is wellanalyzed for design optimization. In addition, by combining different THENS and FONGS product advantages, the entire performance is further enhanced through a holistic design integration.

Single-Blower for Multi-Tube Design

By utilizing single blower with frequency inverter and optimizing pipe network design, the air volumetric flow rate of each tube is evenly distributed.

Integrating Nozzle System

By adjusting various combinations of multiple spraying nozzle and sprayers, the best dyeing performance of a huge variety of fabrics can be achieved.

XY Internal Plaiter

Fabric is capable of being two-way (horizontal and vertical) plaited inside the vessel to organize the fabric stacking

pattern inside the storage chamber. It allows the smooth fabric lifting, enhancing the fabric lifting speed and reducing fabric tangling in the chamber.

Overhead Cleaning System

Effective cleaning is provided through purging to rinse the kier head, ensure no residue color is left.

GOLLER SINTENSA CYCLONE TANDEM High Efficiency Washing Compartment

The newly-designed GOLLER washing compartment - SINTENSA CYCLONE TANDEM reduces fabrics running tension by means of the following two points.

By optimizing fabrics running route. The optimized fabrics running route and the increased cladding intensity of the driven rollers and driven drums can keep the speed of the running fabric in accord with the speed of driven rollers and driven drums, stabilize the processing conditions for fabric in the washing compartment and enhance the accuracy of synchronization so as to facilitate the minimization the running tension of fabric.

By the specially-designed rotor being installed on the driven drum(perforated). The rationale behind is that when the range is running, the rotor can rotates at different speeds under liquor and the high-speed water stirring of rotor can result in low pressure and thus achieving the suction effect of the running fabric. As a result of this, the problem of fabric-slipping can be avoided and the lower running tension can be resulted.

The new generation of GOLLER high efficiency washing compartment - SINTENSA CYCLONE TANDEM is an innovation to the typical washing compartment in large size and in large volume, which can indeed guarantee energysaving, emission reduction and production costssaving and make the open-width washing process for knitted fabric more smooth and efficient.

GOLLER EFFECTA MODUL ANTI-CURL High Performance Washing Compartment

GOLLER EFFECTA MODUL ANTI-CURL is a newly-designed washing compartment which maximizes the flexibility in applications and brings the washing experiences to a brand new level.

By minimizing the occurrence of curling edge and crease marks

EFFECTA MODUL ANTI-CURL is designed particularly for Woven bottom weight and denim with high content of elastic weft processing. The ingenious way of putting the 2 rows of middle support rollers between the row of top rollers and the row of bottom rollers of EFFECTA MODUL ANTI-CURL has substantially shortened the free fabric path in between and thus minimizing the occurrence of curling edge and crease marks. A higher washing efficiency can also be achieved since the extra 2 rows of middle support rollers provide more nips for fabrics during washing process.

By enhancing the compatibility of EFFECTA with different units

EFFECTA MODUL ANTI-CURL is designed specifically for enhancing the compatibility of EFFECTA with different units. It applies the same design principle as the one of SINTENSA CYCLONE TANDEM by incorporating the modular-design intermediated trough with squeezer into the washing compartment - EFFECTA MODUL ANTI-CURL in this case. This modular design has further enhanced the compatibility of EFFECTA with the latest version of Sintensa washing compartment- SINTENSA CYCLONE TANDEM, Oxidator chemical application, swelling, shrinkage and washing compartment and Universa dwelling and washing compartment, etc. With the advancement of applications compatibility, EFFECTA MODUL ANTI-CURL not only complete Gollers product portfolio but also enable Goller to be excelled in every continuous open-width washing occasion.

MONFORTS FONGS MONTEX 6500 AIR FILTRATION OMNI Stenter Frame Range

Advanced Chamber German Design

Proven for Most Homogenous Temperature Distribution

Originate from Monforts Germany developed technology

Montex 6500 Air Filtration Omni (Abbeviation 6500 Omni), is based on the Montex 6500 stenter range in combination of the most advanced heat recovery and air filtration technology to evolve this stenter range into a more advanced environmental friendly machine.

The heat recovery and air filtration device of this 6500 Omni stenter can filter the wax and oil from the exhausted air with high efficient but low energy consumption. The heat recovery is so high which could contribute the textile industry to achieve low carbon release target a step further.

The modular design could allow different space requirement by different textile mills. Also this device run with automatic cleaning function controlled by PLC by running its nozzles along the bar over the top of the filtration units. This will minimize the daily maintenance to the machine.

TwinAir : Monforts patented Twin-Air technology allows top and bottom airflow to be regulated separately. When drying without marking and the most even temperature possible across the fabric. Also, it also could be equipped with Optiscan for Auto-Balance system.

For this standard Nozzle System CAD Stream, its “Lay-onAir”fabric supporting properties in air and with bulking effect through increased volume by its microtumbler effect. Attractive cost/benefit ration with higher evaporation rates. It also provides continuous fabric support even at the chamber transition points.

CAD stream E, suitable to be used with nominal width 260cm or above, the nozzle width could be adjusted to nominal width to 180cm to adapt to narrow fabric width.

CAD stream Slot, combined round and slot nozzles, New slot nozzle design for high-pile and terry cloth fabrics. Also suitable for dyeing processes on the stenter.

Qualitex 750 Programmable logic process controller (PLC). Expandable and adaptable for practically all tasks arising in modern textile finishing. It has Programmable control functions, Operation of the range via panels along the machie, Storage of set-up data sets, Integration of setting values for measureing and control devices, Batch management, Network interfacing, Automatic nozzle pressure control, Prepared for teleservice, Maintenance and two-loop system via touch panels.

This system also run with our developed Monformatic which is control system for technology in combination of treatment processes(drying and heat-setting) to achieve exact maintenance of the dwell time. When the heat-setting point is reached, the fan speed is automatically adjusted. A further contribution to greater cost-effectiveness.

Its function including measurement of the heat absorption of each fabric from the circulation air, determination of exact heat-setting times even with varying parameters such as deviating initial moisture content or reduced circulating air due to clogged filters or fan failure. Besides, the exact determination of the heat-setting point is the reliable basis for optimum speed control and thus for costeffective machine utilization and optimum exhaust air conditions at all times. The payback is energy consumption being under control which always knows the right heat-setting point. This could eliminate the need for allowances and avoid the risk of insufficient heat-setting.

Besides, the system could run with selfdeveloped central processing control software“Q-soft”. This software is for production planning and documentation with a central interface. All process data can be stored in a standardized database(ODBC = Open Data Base Connectivity) where all setpoints and actual values are filed with read and write access for setpoints. Three levels of networking interfacing are possible : Interfacing to your network, Output to a PC with graphic presentation(Monforlogic), Interfacing with a process control system to include machines from other manufacturers as well.

MONFORTS THERMOSTRETCH Skewing Unit

The new ThermoStretch skewing unit from Monforts offers new and improved features for Eco friendly denim finishing avoiding the excessive use of ‘expensive to generate steam that was previously necessary for the cylinder dryers; thereby replacing the need for padding together with steam-operated cylinder dryers.

It also provides a much gentler treatment of the denim fabric during stretching than was previously achievable together with an optimised fabric hand. It also opens the ‘door for stretchable denim applications.

The ThermoStretch unit also continues to be available as a ‘long stretch unit but without conditioning/heating properties for the fabric.

Monforts has in depth “knowhow” in high speed processing ranges for denim finishing with the “double rubber” twin compressive shrinking unit working in tandem for working speeds even above 80 metres / minute.

The larger fabric content of the ThermoStretch unit in combination with the “double rubber” twin compressive shrinking unit ensures minimum residual shrinkage values and highest production speeds which could not be achieved before.

In the denim industry, this concept is making a significant contribution to higher productivity and lower energy consumption and the company has references in Vietnam and Mexico.

Denim technologists will be at the exhibition to offer detailed advice to visitors on the latest denim finishing processes.

Monforts will also highlight its texCoat coating processes and finishing of technical textiles, especially airbag materials at the show.

Monforts is the only manufacturer that can offer completely integrated coating lines from a single source with the coating machine tailored to the subsequent Monforts drying technology.

The Monforts system has the shortest fabric path from the coating unit into the stenter and offers all variations of coating application systems, such as knife over air, knife over roller, magnetic knife or printing head.

All of these options are also available in wider widths, with the engineering from a single source.

Changshu Textile Machinery Works Co., Ltd.

Changshu Textile Machinery Works Co., Ltd. is the specialized factory in China of producing series Dobby, Cam motion and Jacquard used on various kind of looms. It is the high-tech enterprise in Jiangsu Province. The products have been identified as and the provincial hightech products as its enrolling mark of “Chang-fang”, which is the famous trademark in Jiangsu. The products are well sold in Chinese mainland markets and are also exported to areas in Japan, Korean, Brazil and India etc.

Changshu Textile Machinery Works Co., Ltd. is located in the fertile land of fish and rice in the south of China. The company faces Shanghai on the east. Suzhou on the south as well as the Yangtze River on the north. It is only 1500 meters away from the Changshu-hefei Expressway and is convenient to its traffic communication.

The company was established in 1970, and its comprehensive strength is becoming stronger and stronger results to its leading position in the industry by carrying out the rolling technological transformation. The NC machines, the precision checking and testing device were all imported from the foreign companies. The professional technicians make up more than 30% of the total workers and staffs, our annually outputs are 100,000 sets high quality shedding devices. The main products such as the high-speed electronic Dobby, the high-performance electrical Jacquard and the high-speed positive Cam Motion Device, are warmly welcomed by domestic and foreign customers. The company has already gained ISO9001 Quality Guaranteed System Certificate and ISO14000 Environmental Management System Certificate, is the provincial CAD application and ERP application demonstration enterprise. The company is established with the provincial technical centre and the provincial textile machinery engineering centre, has a number of core technology and patents, is the developing and manufacturing base of the scientific& technical innovation and the novel shedding device. The company has already get into the main specialized industry in the world of producing shedding device.

Exhibits:

TYPE D2655B HIGHSPEED ELECTRONICALLY CONTROLLED ROTARY DOBBY

Type of shedding: double lift, full clear open

Type of reversing: positive lever reversing

Mount method: in low position (left and right side)

Practical speed for looms: ≤ 550 rpm (depending on the weave)

Pitch: 12 mm

Lifting units: 16, 20

Highness of shedding: 50 - 145 mm

Pattern controlling method: electronic

Endless wefts: ≤ 12,800

Lubrication: impeller pump of bath lubrication

Use: Suitable for the high-speed rapier looms, and air-jet looms

TYPE D2869 HIGHSPEED ELECTRONICALLY CONTROLLED ROTARY DOBBY

Technique parameters:

Type of shedding: double lift, full clear open

Type of reversing: positive lever reversing

Mount method: in high position

Max.speed for looms: 650 rpm(depending on the weave)

Pitch:12 mm

Lifting units:16

Suitable reed width:150 - 360 cm

Pattern controlling method:electronic

Endless wefts:12,800

Lubrication: impeller pump oil bath lubrication

Use:Suitable for foreign and domestic advanced air-jet and water-jet looms such as Series HJ, Series JW, Series ZW etc.

Features:

It adopts rotary principle to ensure absolutely clear and stable shedding also under maximum loading and speed.

High reliability and stability running behavior thanks to spiral bevel and complementary cams as well as all joints are needle and ball bearings.

Due to the impeller pump oil bath lubrication and a bigger oil filter,the maintenance of this Dobby is reduced to a lower level.

Pattern design software and a portable data transmitter (optional) are provided, convenient to change the patterns.

Use the integrated heald reversing cover and reinforced heald reversing frame to improve the performance and stability of the whole machine.

TYPE GT561T/H TUCKING-IN DEVICE

The type GT561 tucking-in device is mounted onto the rapier and projectile looms for weaving ture selvedges.

It can automatically cut off the weft yarn and hook the yarn end into the cloth fell.weaving the yarn end into the selvedge through the beating up to form neat selvedge. This device has the features of simple, stable low noise, small power and convenient maintenance.

Mounting method: in high position (one in each side and one in middle)

Width of selvedge zone: 11 mm

Suitable speed for looms: 430 r/min (T) 500 r/min (H)

Suitable range: can be widely used on various kind of domestic and imported looms such as looms of FAST, TP500, TP600, XINGLONG, GTM, GTM-AS, GA733-AS, GA737A, THEMA-II, SM92, M93, KT566, GA731, GA747 series etc.; (the-detail connection methods according to the looms type.tuck-in device is at your option. )

TYPE JL2410 HIGH SPEED ELECTRONIC JACQUARD

Technique parameters:

Type of shedding: double lift, full clear open

Pattern controlling method:electronic (independent CFJC300 controlling, the max. storage of single pattern is 256 MB)

Lifting needles: 5,736, 6,144, 6,912, 8,448, 9,216

Maximum speed for looms: 550 rpm (according to the actual weave technology)

Suitable reed width: 1,900 - 4,600 mm

Longtitudinal lifting packs: 24

Application:

Suitable for various kind of shuttleless loom (air-jet, rapier and projectile) to weave fabrics of the towel, the furniture and the curtain etc.

Features:

Adopts oil bath conjugate cam to drive; The concentric shaft guarantees the shed has a symmetrical and balanced movement.

Different shedding time satisfies different width requirements of looms. There are hundreds of sheds can be selected.

The new controlling system adopts LINUX platform, it is more stable and more convenient, makes the possibility of the computer virus infection fell into the lowest.USB interface to replace the traditional hard disk, data transfer is more safety.

Softwares function can be expanded by means of upgrading the software.

S1353 POSITIVE CAM MOTION DEVICE

Technique parameters:

Type: positive conjugate cam

Mounting method: in low position

Cam numbers: 4 - 10

Pitch: 12 mm

Shed: 56 - 135 mm

Lubrication: active lubrication of gear pump

Separation method: special separation with spanner

Fabrics to be woven: plain, twill, satin and fabrics that cycles within 4, 5, 6 wefts.

Suitable reed width: 150 - 460 cm

Suitable looms: foreign and domestic air-jet looms, such as RF10, JAT610/710, ZAX/ZAX-E etc., and rapier looms, such as GTM series, GTM series, FAST series, THEME series etc.

Features:

The design of high precision conjugate cam and the optimization design for the devices structure implements the stable running at high speed.

The handle type device makes the cam completely separate from the swing-arm, easy for changing the cams variety, so the structure is simple and reasonable.

The precision helical bevel gear drive makes the loom has low noise, low vibration and lighter load.

The ratio of different fabrics are carried out by replacing the pairing-helical bevel gear.

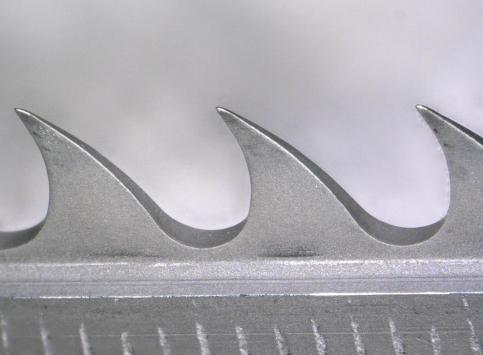

Guangshan White Shark Card Clothing Co., Ltd.

Guangshan White Shark Card Clothing Co., Ltd. was founded in 1962, which is the largest manufacturing base for metallic card clothing in china. As the HIGH-TECH Enterprise, it has passed the approval of ISO9000 with self-support right for imports and exports.

In the upcoming exhibition, the company will heavily introduce card clothing of “Jintran” surface strengthening treatment, which has the advantages of super durability, protecting fiber, reducing cotton knot, strong corrosion resistance, as well as no running-in period and so on.

Super durability. It adopts nanoscale wearresisting material to increase surface strengthening treatment through special technique, to form 0.003-0.005mm protective layer on the surface of the cloth. Experimental testing data shows that tooth hardness of cloth could increase to 1100-1300HV from 860HV, and the durability has been improved a lot. Meanwhile, the surface of cloth is smooth, with roughness Ra reaching to 0.15μm, friction coefficient μ <0.20, as well as service life reaching more than twice of European clothing. Processing volume of cotton fiber could reach 1800 - 2000 tons.

Protecting fiber. Through the process of bevel gear, the clothing has circular-arc edge, conical tooth tip, rounded and sooth body. Under a magnifying glass of Keans 200 times, the tooth tip is like 6μm drop, which can relax the impact on fiber and reduce the cutting injury to fiber, with short fiber rate down 0.5 - 1 percentage point (equal to save raw material 5 - 10 kg/ton).

Reducing cotton knot. Compared with the ordinary clothing, this card clothing has better performance with less tooth top area, sharp tooth tip, as well as improved puncture carding function, with removal rate of cotton knot up 90%.

Strong corrosion resistance. It has excellent corrosion resistance with the combination between new anti-corrosion technology and special process. The multiple corrosion tests of salt mist, moist heat and acid show that the corrosion form of card clothing is not obvious, which can be naked in normal environment without any protective measures.

No running-in period. In the production process, it adopts special technology of cone gear, wear resistance and corrosion resistance, without treatment in the late process. There is no running-in period in the service.

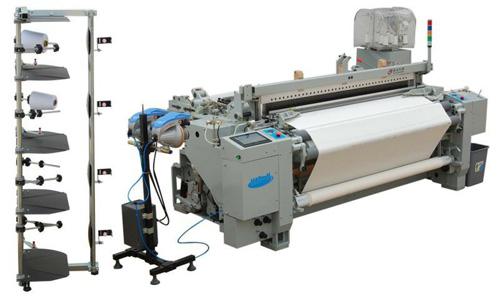

Qingdao Haijia Machinery Co., Ltd.

Haijia company is the largest water jet and air jet loom manufacturer in Qingdao China. Since two decades ago, Haijia has been only focusing on researching water jet and air jet loom, and now more than 82,000 sets machine are running successfully in the market, with market share ranked No 1 for 12 consecutive years.

Haijia Machinery has made great efforts in product development and promotion. It has launched 300 series (851 series & 873 series), 400 series (408, 410 and 412 series), and 8100 series, among which 8100 series is the latest one produced after October, 2016, and will be promoted in technology.

In the upcoming exhibition, Haijia Machinery will exhibit HJ-8100 series water jet looms and HJA-N air jet looms.

HJ-8100 series water jet looms

Recommend reasons:

It adopts integrated design of wall board with more optimized design in the frame part, to make the frame more stable, more efficient and better in fabric quality.

Its optimized beating-up designing makes beating-up more stable and suitable for the fabric with high-density and higher speed.

The top speed can reach 1,400 RPM.

The highest weft density can be up to 82 shuttles/cm (208 per inch) for 75D fabric.

Technical parameters:

Nominal reed space covers 150, 170, 190, 210, 230, 280, 300, 320, 340 and 360.

The effective width is divided into standard width of 0 - -500 mm, and optional width of 0 - -700 mm.

The quantity of nozzle covers single nozzle, double nozzles, three nozzles and four nozzles.

The openings ways include plain, cam, dobby and jacquard way.

Beating-up method: four-barrel beating-up(strengthened solid beating-up axis for the standard, and six-barrel beating-up for the optional).

Mechanical ceramic scissors; photoelectric weft-finder

Warp beam diameter: ∮800 mm, ∮1,000 mm(optional).

HJA-N series air jet looms

Recommend reasons:

High efficiency, energy conservation, and strong adaptability

Technical parameters:

Nominal reed space covers 150, 170, 190, 210, 230, 280, 300, 320, 340 and 360.

The effective width is divided into standard width of 0 - -500 mm, and optional width of 0 --700 mm.

The quantity of nozzle covers double nozzles, four nozzles and six nozzles.

The openings ways include plain, cam, dobby and jacquard way.

Beating-up method: four-barrel beating-up, sixbarrel beating-up (optional).

Mechanical ceramic scissors; photoelectric weft-finder

Warp beam diameter: ∮800 mm, ∮1,000 mm(optional).

Jiangyin Huafang New Technology& Science Research Co., Ltd.

Main exhibits to be promoted in Indonesia:

Spinning: HFJ Compact Spinning Device HF series intelligent doffing system

Weaving: HF988C/HF988D Intelligent Sectional Warping Machine HF928B High Speed Automatic Sectional Warping Machine

HFJ Compact Spinning Device

Main Structure features

Four-roller system, lattice apron are of positive drive.

Negative pressure system adopt main blower with general air duct and filter net to avoid dirtying workshop.

Modular design, 6 spindles or 8 spindles in one unit.

Well-designed negative pressure distribution ensures consistency of airflow at each suction nozzle.

The optimization designed suction nozzle on profiled tube, good for fiber compact.

Inverter control for both energy-saving and pressure adjusting for different yarn count spinning demands.

Smoothly moving of the yarn is guaranteed by tension device of the lattice apron (patent product of H-FANG).

Closed-loop control on negative pressure guarantee stable pressure during spinning. (For option)

Auto-cotton stripping device available. (For option)

JEF1562JM-1200, JWF1536B-1008, JEF1530-1008, JWF1520-1104, EJM178-108, ZJ1598-1008, ZINSER351-1680, LR9/AXL-1824, ZINSER71-1200, LR60/AXL-1824, RX220 RX240-1008, RY5-960, ZINSER360-1008, G33-1200, G32-1440, K44-1008.

Lattice apron:

One of the drafting units of the national industry standard of grid circle;

The weave, styling and cutting lines designed and manufactured by H-fang, can provide customers with a variety of high quality grid rings.

HF series intelligent doffing system

Suitable for the full automatic doffing spinning tube, automatic conveying pipe, automatic intubation. Replace manual operation, improve production efficiency, reduce production costs and reduce labor intensity.

Features:

The conveying system (patent) adopts imported steel strip, which has no deformation, fast and stable transportation and low noise.

The use of PLC, frequency converter, servo system, touch screen and other electrical system precision control, complete function, easy operation, low failure rate, easy maintenance and maintenance;

Performance:

Doffing system works once spinning bobbins is full.

Doffing time is 3 minutes, cycle working of doffing and spinning, no artificial standby time.

100% of donning and drawing rate.

Ratio of yarn and staying is 97%, increase around 8%-15% productivity

Warping Machine:— To ensure the perfect beam quality and highest production efficiency

HF988C/HF988D Intelligent Sectional Warping Machine

Machine is preparatory to weaving lines of wool textile, trademark fabric, heavy twist synthetic fiber filament fabric, yarn dyed fabric, natural silk fabric, towel and special industrial fabric. It can work with water-jet, air-jet, rapier and gripper loom.

HF988C Intelligent Sectional Warping Machine

Main technical data:

working width: 2,300 - 5,600 mm or customize

beam diameter:φ 800/1,000/1,250 mm

Max winding speed: 800 m/min

Max beaming speed: 200 m/min

beaming tension accuracy: ≤ ±2%

briakeing distance: ≤ 3 m (500 m/min)

drum cylinder diameter: 1,000 mm

drum cone taper: 1 : 8 (φ800mm)

1 : 6 or 1 : 8 (φ1,000 mm)

HF988D Intelligent Sectional Warping Machine

Brake system: using a hydraulic disc brake

Guide rail: two high-precision linear guide rail, the inside of the support gear, to ensure the perfect wire and strip

Upper and lower tail shaft holder: electric adjustment

Claping and closing: Joint tooth structure

Oil waxing device: infinitely variable speed control of oil wax quantity

HF928B High Speed Automatic Sectional Warping Machine

This machine has wide application scope. Its modular structure and multiple optional devices make it suitable for any kind of spun yarn and industrial filament, especially suitable for high-capacity and wide-width beam with high winding tension requirement.

HF 928B ensures high-quality warp yarn and flexible production.

Technical parameter:

Working width: 2,300 - 5,600 mm

Beam diameter: 800/1,000/1,250 mm

Max winding speed: 1,000 m/min

Max beaming speed: 300 m/min

Braking distance: <= 2 m (800 m/min), <= 1 m(500 m/min)

Max section width: 800 mm

Max winding tension: 800 N

Max beaming tension: 15,000 N

Section poisoning accuracy: <= 0.01 (mm)

Section traverse accuracy: <= 0.01%

In the Indonesian market, nearly 30 units are sold in batches and divided warping machines, covering the subdivision of yarn dyed fabrics, towels, home textiles, fishing nets and so on.

Huafang adhering to the enterprise concept of“create value for customers”, serving the majority of Indonesian customers with high quality and efficient service values, has been widely praised by customers, and has laid a solid foundation for Indonesia to expand the Indonesian market.

Geron Card Clothing (Jiangsu) Co., Ltd.

Geron Card Clothing (Jiangsu) Co., Ltd. is a leading carding accessories company including research, manufacturing and marketing, enjoying the world biggest card clothing research center with high technology and biggest production capacity, with two factories in Nantong City and Baiyin City respectively.

The group company named Geron Co., Ltd. has been listed in stock in Shenzhen Stock Exchange in 2014. Geron starts a new chapter as the first listed textile accessories company in China. And the company will help you find the optimal and complete card clothing solution.

Blue diamond

Main features:

Sliver and Yarn quality shall achieve same level with any

other world brand.

Service life for pure cotton shall be more than 1000 tons, and chemical fiber 1200 tons in normal condition.

Blue diamond realizes soft carding, drastically reducing fiber damage, and SFC reduced by around 20%.

Double teeth cylinder wire

Main features:

Double teeth cylinder wire can increase 15%- 30% sliver speed according to different carding conditions and greatly improve the production. But quality are the same as before.

Wuxi Hongyuan Electromechanical Technology Co., Ltd.

HY-7 HIGH SPEED DRAW TEXTRURING MACHINE SERIES

HY-7 applies single-Shaft and single-motor direct driving system, simplify structure and easy for maintenance. Use a new fully-enclosed primary heat to reduce the energy consumption.

HY-7DV and HY-7S are used for ply-yarns, de-torque yarns, also can produce S twist and Z twist yarn. For these two types, A and B side can be operated completely independently, enable to produce high quality, multi-type, multi-specification yarns to meet the requirement of a most dynamic market. HY-7DV is used for polyester yarn and HY-7S for polyamide yarns.

HY-7(LC) can produce polyester with Spandex covering yarn, expanding the machine usage.

Yantai S&S; Science and Technology Application Engineering Co., Ltd.

Yantai S&S; Science and Technology Application Engineering Co., Ltd. will exhibit S&S; Series of Electronic Jacquard System Engineering.

Series of Jacquard Adaptive for looms - Air Jet, water Jet, Rapier, Projectile Looms

Weaving Products: Label, Tie, Furnishings, Curtain, Sofa Cloth, Bed Cloth, Towel, Carpet, Velvet, Garment Fabric, Lining Fabric, Saree, Silk Fabrics and so on. Advantageous Features:

Low-power axial-flow fans ensure stable working condition to electric system.

High efficiency

With the most concise shedding mechanism, and crank direct drive pulling mechanism.

Fully-sealed and highly-reliable electric control system

High speed and low torque are more suitable for making large and heavy design fabrics.

The most concise shedding mechanism and the fewest parts offer easy maintenance and the cost is also much lowered.

Chain Driving shedding system. Standard parts, with efficiency as high as 96%. The bearig capacity and life of self-lubricating chain is 5 times of common chain.

With a good mechanical property, the casting wallboard makes the vibration decreased, noise reduced and lifetime extended.

Hollow type of core parts, with light inertia which is specialized for speed and heavy pattern.

Adoptig elastic diaphragm which is freemaintainance, low inertia, high elasticity, high torque and no noise.

杂志排行

China Textile的其它文章

- Textile industry is expected to enjoy steady development this year

- 数据

- Sharing product info on intimate level key to retail future

- To attract plus size shoppers,speak directly & authentically to her

- INDA’s Professional Development Center offers new comprehensive Absorbent Hygiene Products Training Course

- Intertextile Shanghai Home Textiles–Spring Edition in March to satisfy growing demand for finished products in China