基于PWM信号的农用柔性底盘驱动与转向协同控制特性试验

2018-04-11瞿济伟郭康权宋树杰李翊宁

瞿济伟,郭康权,2※,高 华,宋树杰,李翊宁,周 伟

基于PWM信号的农用柔性底盘驱动与转向协同控制特性试验

瞿济伟1,郭康权1,2※,高 华1,宋树杰3,李翊宁1,周 伟1

(1. 西北农林科技大学机械与电子工程学院,杨凌 712100; 2. 陕西省农业装备工程技术研究中心,杨凌 712100; 3. 陕西师范大学食品工程与营养科学学院,西安 710119)

针对四轮独立驱动独立转向的农用柔性底盘驱动转向时需要同时打开和锁紧电磁摩擦锁的矛盾,该文提出一种基于脉冲宽度调制信号(pulse width modulation,PWM)的电磁摩擦锁控制方法来实现偏置转向轴机构的分时步进驱动和转向,并利用自制偏置转向轴试验台,采用双因素试验测试了PWM波频率和占空比对偏置转向轴电磁摩擦锁脉冲锁紧力矩的影响,采用三元二次正交旋转组合试验测试了分时步进驱动和转向时频率、占空比和轮毂电机转速对转向特性的影响。双因素试验结果表明:频率、占空比及其交互作用对脉冲锁紧力矩均有极显著影响(<0.01);在频率4~24 Hz、占空比20%~80%时,锁紧力矩变化范围为6.822~40.046 N·m;旋转组合试验结果表明:频率、占空比、两者交互作用及轮毂电机初始转速对分时步进转向时转向平均角速度均有显著影响(<0.05),转向平均角速度随占空比和轮毂电机初始转速增大而减小,随频率增大而缓慢增大,在频率4~24 Hz、占空比20%~80%、初始转速30~120 r/min时,转向平均角速度变化范围为0~0.514 rad/s。该结论可为农用柔性底盘驱动与转向协同控制提供参考。

农业机械;运输;控制;柔性底盘;PWM技术;偏置转向轴;驱动与转向;协同控制

0 引 言

目前国内温室、农业仓储设施等狭小封闭农业环境急需运动灵活且无污染的动力机械[1-4]。农用柔性底盘是一种四轮独立驱动独立转向电动底盘,该底盘采用轮毂电机的转向轴与轮胎回转平面偏置的偏置转向轴机构,将传统底盘的转向机构和驱动机构合二为一,使柔性底盘灵活地实现直行、横行、斜行及原地回转等运动形式,便于狭小封闭环境运行作业[5-7]。为了使轮毂电机的驱动力矩能够传递到车架,该底盘在偏置转向轴上设置一电磁摩擦锁[8],驱动时锁紧电磁摩擦锁,转向时打开电磁摩擦锁。但是,当需要驱动和转向同时进行时,便出现矛盾。课题组前期主要进行了柔性底盘固定姿势运动的动力学特性[9]及控制策略[10]研究,未涉及驱动与转向同时进行的运动控制。所以解决此矛盾的方法是柔性底盘运动控制中需要研究的重要问题之一。

在农业领域,轮式移动机械转向系统特性对其工作性能有重要影响[11]。目前关于轮式移动机械转向系统的研究主要针对转向灵活性、转向精度及转向稳定性等展开[12-14]。房素素等[15]开发了一种线控液压转向系统,采用电磁比例伺服阀控制转向油缸,保证大动力输出的同时仍具有较好转向灵活性;张闻宇等[16]提出了摩擦轮式拖拉机转向驱动系统,以平行四连杆结构作为驱动机构,减少了转向响应时间。鲁植雄等[17]开发了双通道PID转向控制策略,降低拖拉机线控液压转向跟随误差;张京等[18]基于PID算法设计了转向电机控制策略,提高了农用轮式机器人四轮协同转向控制精度;刘军等[19]将线控转向和GPS/INS组合导航技术结合,并利用转向电机滑模变结构控制提升了系统抗干扰能力。上述底盘很多具有大动力输出,因结构不同研究重点也各不相同。国外也有诸多研究,如文献[20]研究了基于加速度传感器的农业机器人转向模型,实现了惯性导航中转角的获取。Oksanen等[21]研究了4个非对称液压缸引导拖拉机各轮转向的控制策略,实现了无杆转向,使得转向更加轻便;Tabile等[22]设计了一种农业移动机器人,采用转向电机结构并结合GIS技术,提升了其在复杂农业环境的综合工作性能。Ettefagh等[23]基于遗传算法和人工神经网络,对现有的四杆转向机构进行综合优化,减小了转向误差。综上可知,传统底盘的转向控制大多涉及机械、液压助力转向和电机转向[24-27],其转向系统完全独立于驱动系统,不存在转向与驱动协调的矛盾。

本文研究的偏置转向轴机构,转向与驱动动力均源自轮毂电机[28],电磁摩擦锁虽使转向与驱动不能同时刻进行,但为转向与驱动协同进行提供了条件。故本文提出了一种基于脉冲宽度调制信号(pulse width modulation,PWM)的电磁摩擦锁控制方法,使偏置转向轴能够分时步进驱动和步进转向,实现转向与驱动的协同,有望克服上述矛盾。为此,在自制偏置转向轴试验台上搭建测试系统,进行了模拟测试,以期获取偏置转向轴机构驱动与转向协同控制特性参数,为柔性底盘的运动控制提供依据。

1 驱动转向协同控制原理

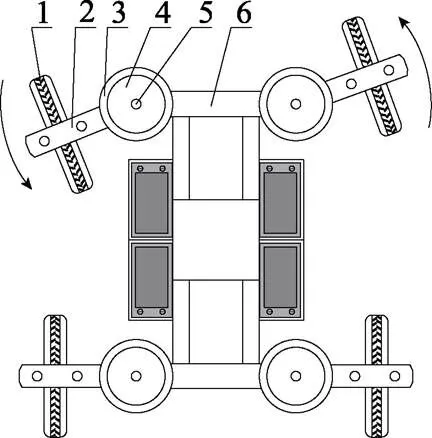

本文研究的农用柔性底盘由4个相对独立的偏置转向轴机构组成[29](图1)。其中电磁摩擦锁定片4、偏置转向轴5及车架6三者固连,动片3与偏置臂2固连。定、动片吸合时,轮毂电机1的驱动力驱动车架6,定、动片释放则使偏置臂2转向。

1. 轮毂电机驱动轮2. 偏置臂 3. 电磁摩擦锁动片 4. 电磁摩擦锁定片 5. 偏置转向轴 6. 车架

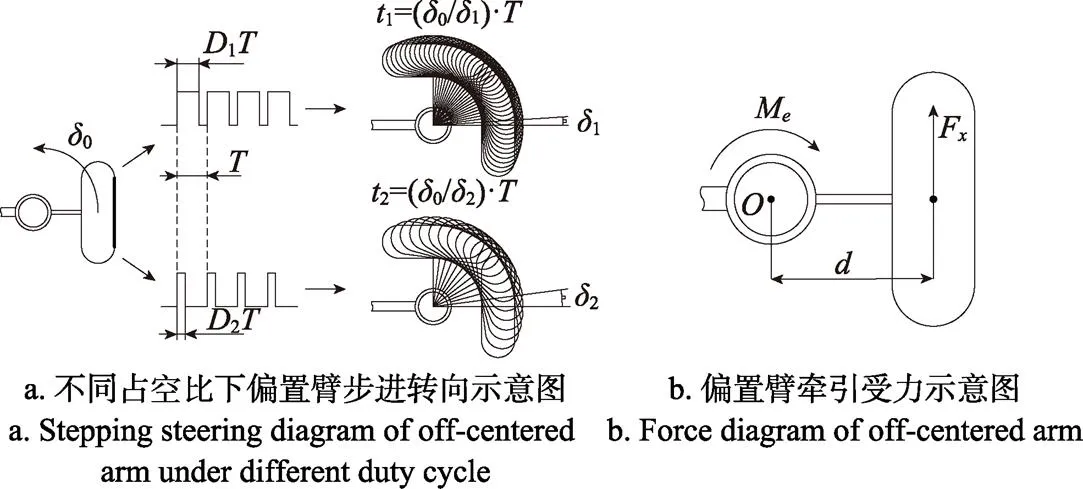

为使驱动与转向协同进行,本文采用电磁摩擦锁不断吸合与释放的方法来实现柔性底盘分时步进驱动与步进转向。PWM信号高电平时电磁摩擦锁吸合,轮毂电机驱动车架;低电平时电磁摩擦锁释放,轮毂电机绕偏置轴转向;在连续PWM信号下,则可实现轮毂电机驱动轮分时步进式驱动与转向。如图2a所示,在PWM频率(周期为)和轮毂电机转速不变时,占空比大时,使偏置转向轴每步转动角度1小,故转到目标角0所需步数多,转向时间1长;占空比小时,使每步转动角度2大,故转到同一角度0所需步数少,转向时间2短。故占空比越小,转向越快。

由以上分析,在轮毂电机转速不变条件下,偏置转向轴驱动转向需满足以下条件:

1)电磁摩擦锁吸合时的锁紧力矩大于轮毂电机对车架的驱动力矩M,才能使轮毂电机的驱动力传递到车架。如图2b所示,轮毂电机驱动时受到地面对轮胎的反作用力F,即

2)频率和占空比的组合应能够使电磁摩擦锁分时释放,才能使轮毂电机绕偏置轴步进转动,进而实现步进转向。

因此,本研究的关键在于探明频率、占空比及轮毂电机转速等参数对电磁摩擦锁锁紧力矩和偏置转向轴机构转向平均角速度的影响规律。

注:δ0为目标角度,(°);D1为较大的占空比,%;D2为较小的占空比,%;δ1代表D1时每步转动角度,(°);δ2代表D2时每步转动角度,(°);t1代表占空比为为D1时转动δ0角度所需时间,s;t2代表占空比为D2时转动δ0角度所需时间,s;T为PWM周期,s; Me为锁紧力矩,N·m;Fx为地面切向反作用力,N; d为偏置距离,m。

2 试验方案

2.1 试验因素及取值范围

通过前期试验发现,影响锁紧力矩的因素有:PWM频率、占空比及电磁摩擦锁驱动电压,其中电磁摩擦锁驱动电压与锁紧力矩呈线性关系[10];影响转向平均角速度的因素有频率、占空比和轮毂电机初始转速。故本试验选取频率、占空比以及轮毂电机初始转速为试验因素。

1)频率:电磁摩擦锁存在吸合响应时间t和释放延迟时间t,因此在一定频率下,电磁摩擦锁对PWM脉冲控制信号宽度的分辨存在一个最小值[30],频率需低于某临界值f,电磁摩擦锁才能出现开关特性[31]。通过测试电磁摩擦锁电流方法获得t与t分别为19.12 ms与12.13 ms。依据式(2)[32]

可计算出频率上限为24 Hz;由于频率低于4 Hz时,释放时转向惯性冲击大,故选取PWM频率4~24 Hz。

2)占空比:通过大量电磁摩擦锁锁紧力矩检测预试验发现,占空比在80%以上,电磁摩擦锁出现一直锁紧状态,无法转向。占空比在20%以下时,电磁摩擦锁锁紧时间太短,无法传递驱动力矩;故选取占空比为20%~80%。

3)轮毂电机初始转速:农用柔性底盘为低速运动底盘,行驶速度在3.6 m/s以内[10],依据运动学公式=2π(为轮毂电机转速,为轮胎半径),3.6 m/s对应的轮毂电机转速为120 r/min,考虑初始转速不可能太低,参考Song等[33]的研究,轮毂电机初始转速取30~120 r/min。

2.2 试验方法及装置

2.2.1 电磁摩擦锁锁紧力矩检测

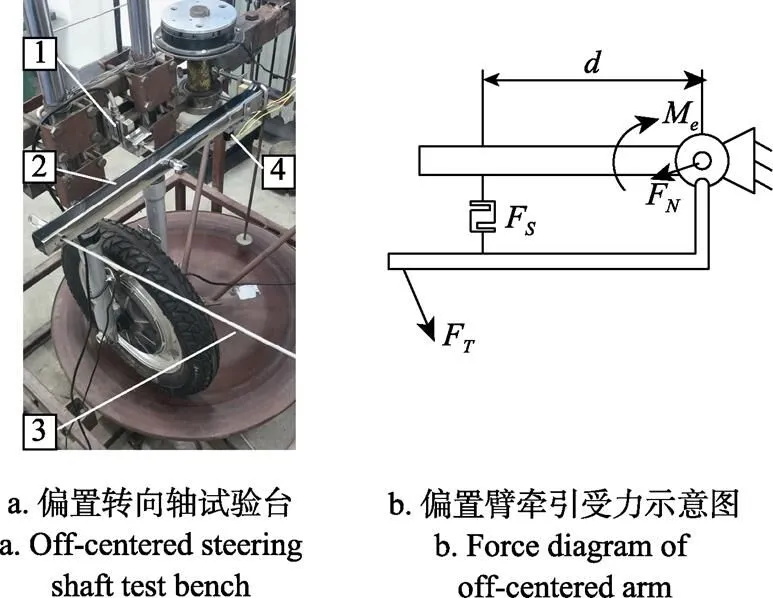

若以轮毂电机为动力检测锁紧力矩,只能测出轮毂电机对车架的驱动力矩,由式(1)知,而此驱动力矩会小于锁紧力矩,故要测出锁紧力矩特性,必须用外在动力为牵引才可测出锁紧力矩峰值,故本文以液压升降台为动力牵引。偏置转向轴机构控制系统如图3所示,中央控制器输出PWM信号给PWM触发开关模块,开关模块输出矩形脉冲电压作用于电磁摩擦锁,使电磁摩擦锁处于间歇吸合工作状态;然后启动液压升降台匀速牵引图4a所示的钢丝绳,使其匀速水平拉动自制偏置转向轴试验台[9]上“L”形杠杆2的牵引端转动,杠杆中间通过力传感器1(TJL-1,蚌埠天光传感器公司,0~500 N,灵敏度1.33 mV/V)垂直拉动偏置臂(图4a),牵引过程中车轮等的阻力被校正清除。试验中偏置臂最大转动角度40°,转动速度约0.1 rad/s。用研华工控机(610H,研华科技公司)及数据采集卡(USB7648B,中泰研创科技公司)采集数据,测得牵引力F,得到电磁摩擦锁锁紧力矩M(图4b)。

图3 偏置转向轴机构控制系统简图

1.力传感器 2.“L”形杠杆 3.钢丝绳 4.多圈电位器

1.Force sensor 2.“L”shaped lever 3.Wirerope 4. Multi turn potentiometer

注:F为钢丝绳拉力,N;F为力传感器拉力,N;F为支持力,N;M为锁紧力矩,N·m;为偏置距离,m。

Note:Fis pulling force of wirerope,N;Fis pulling force of force sensor, N;Fis support force, N;Mrepresents tightening torque, N·m;is off-centered distance, m.

图4 试验台实物图与偏置臂牵引受力分析图

Fig.4 Object of test bench and force diagram of off-centered arm

2.2.2 转向平均角速度检测

采用偏置转向轴试验台,以轮毂电机为动力进行单轮转向测试,检测PWM信号控制下偏置转向轴的转向平均角速度特性。如图5所示,启动偏置轴试验台的轮毂电机和水平转盘,依据转速传感器1、2(D046,龙戈电子,0~1 000 r/min)显示的转速,通过控制器调节水平转盘与轮毂电机同速,因水平转盘与轮毂电机的接触处到各自回转中心距离相等,故切线速度相同,模拟出匀速直线行驶状态。在此状态下,由控制器给轮毂电机一方向盘信号,使其相对水平转盘加速,使偏置臂转动,转向目标角度为30°。精密多圈电位器(22HP-10,日本SAKAE公司,0~5 kΩ)检测偏置臂转动角度,数据采集系统的时钟获取转向时间,进而计算出转向平均角速度。

1. 转速传感器1 2. 转盘电机 3. 转速传感器2 4. 水平转盘 5. 制动盘 6. 多圈电位器 7. 支架

2.3 试验设计

设计了双因素五水平试验测试频率和占空比对锁紧力矩的影响,频率取4、9、14、19、24 Hz,占空比取20%、35%、50%、65%、80%,各5水平、共25组试验,每组重复5次取均值。

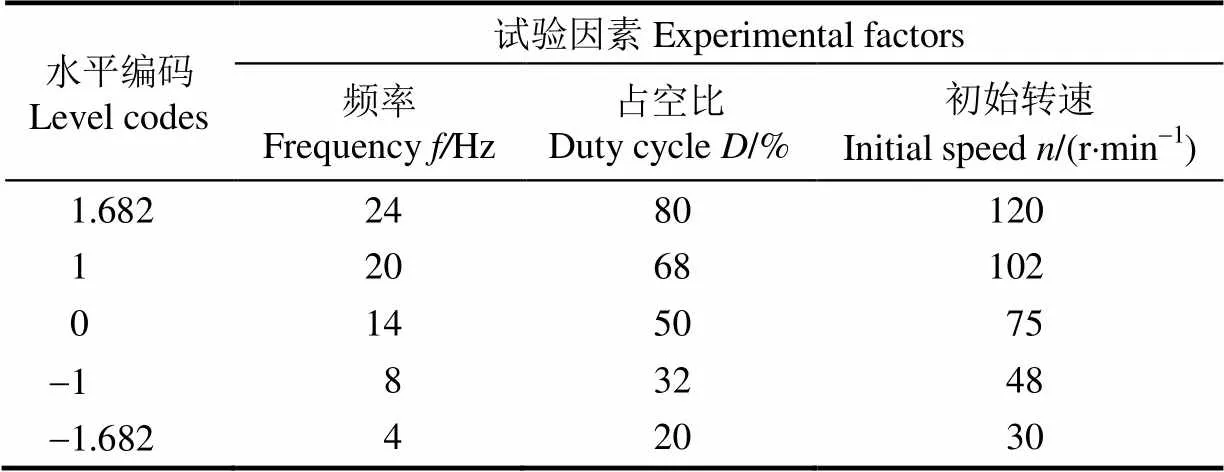

设计了三元二次正交旋转组合试验测试频率、占空比和轮毂电机转速对转向平均角速度的影响,其因素水平编码如表1所示。共20组试验,每组重复5次取均值。

表1 试验因素与水平编码

3 结果与分析

3.1 电磁摩擦锁锁紧力矩测试结果分析

3.1.1 试验结果方差分析

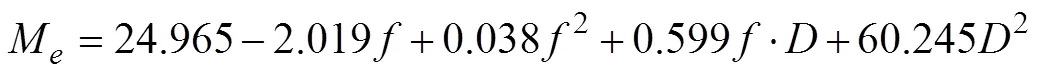

利用SPSS软件进行进行方差分析的结果如表2所示。频率、占空比以及两者交互作用皆对锁紧力矩有极显著影响(<0.01)。同时可以判断占空比频率以及频率和占空比交互作用对锁紧力矩影响程度排序为:。

利用SPSS软件进行回归分析,首先将各因素的二次项以及交互项转换为一次项,即将非线性回归转换为线性回归,得出线性回归方程后再转为非线性方程[34]。本文用逐步回归方式,得到回归模型如式(3)所示,决定系数2=0.955,可见拟合相关程度较高,可用于预测电磁摩擦锁锁紧力矩在不同PWM波频率和占空比下的变化情况。

表2 电磁摩擦锁锁紧力矩试验结果方差分析

3.1.2 频率和占空比对锁紧力矩的影响

试验过程中,不同频率与不同占空比组合下的电磁摩擦锁锁紧力矩及转角动态变化趋势相似。举其中一例如图6a所示,在频率4 Hz、占空比50%的PWM控制下,用液压升降台牵引偏置臂转动,电磁摩擦锁锁紧力矩呈脉冲状态,偏置转向轴转角呈阶梯式增大。脉冲峰值保持在30 N·m上下。

不同频率与占空比下锁紧力矩峰值变化如图6b所示。占空比在20%~80%范围内,锁紧力矩随着占空比的增大而增大。在占空比为80%时,电磁摩擦锁锁紧力矩峰值基本不随频率变化,保持在40 N·m上下;当占空比65%~35%时,锁紧力矩先随频率增大而下降;当占空比为20%时,锁紧力矩随频率增大下降到一定值后,接近不变。

总体上看,24 V额定电压下,在频率4~24 Hz、占空比20%~80%时,锁紧力矩变化范围为6.822~ 40.046 N·m,由图6可知,通过改变频率和占空比组合,可实现锁紧力矩与轮毂电机驱动力矩的匹配并使偏置臂步进转向。

3.2 偏置转向轴机构转向平均角速度测试结果分析

3.2.1 旋转组合试验结果及分析

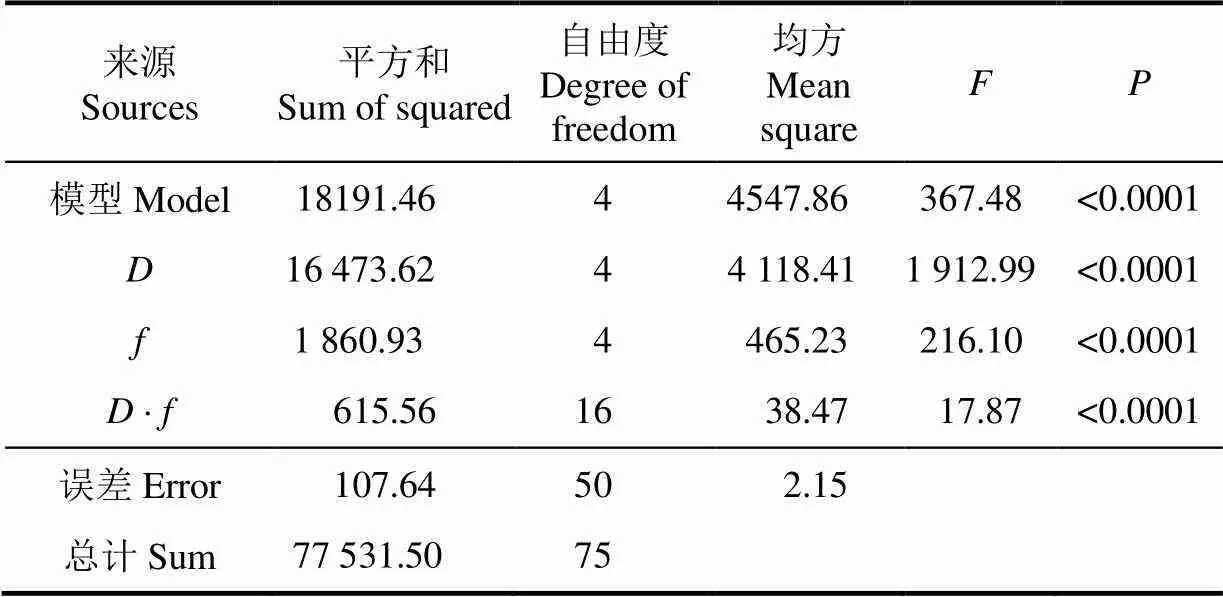

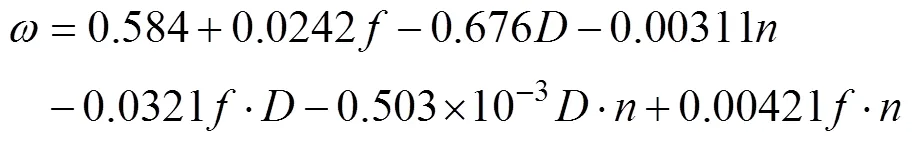

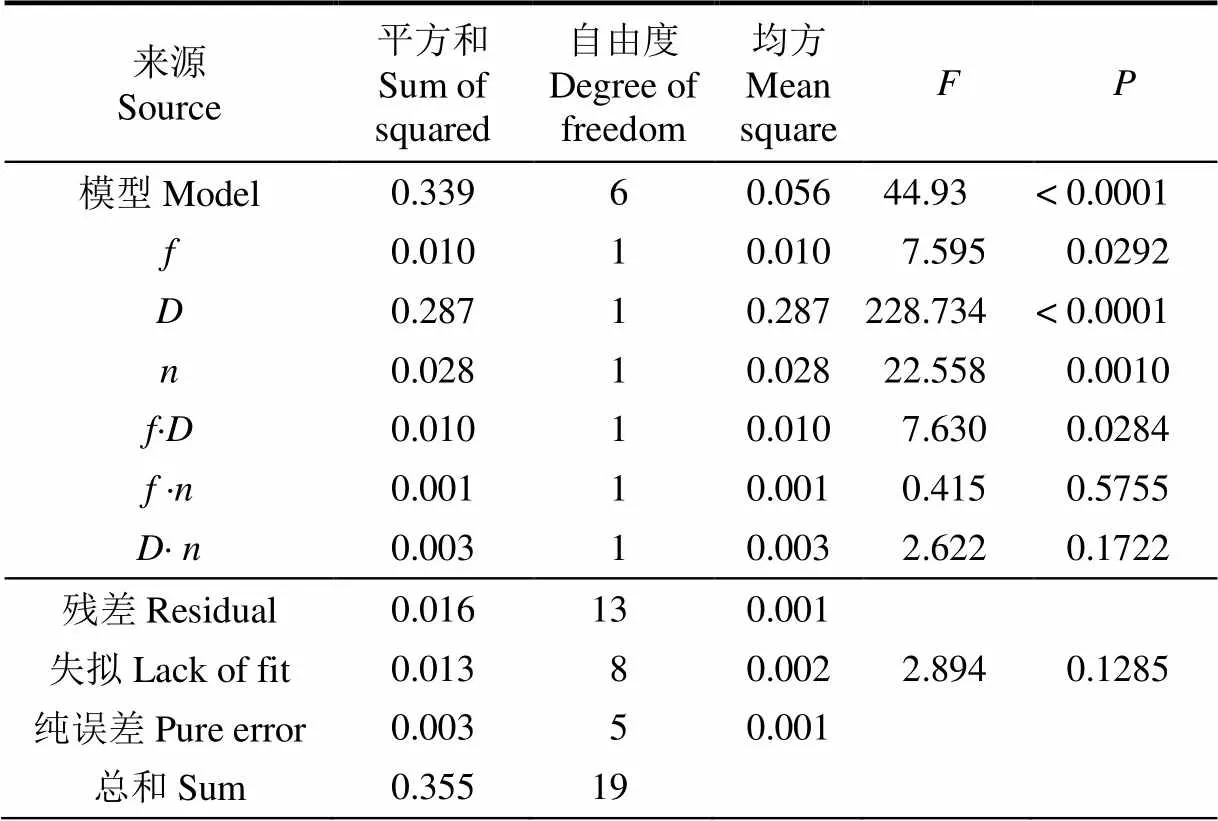

转向过程中,通过获取转角从0~30°所用时间,计算出平均转向角速度如表3所示。通过Design expert对表3的试验结果进行三元二次回归分析,建立转向平均角速度与各个试验因素的回归模型方程为

回归模型的方差分析如表4所示,由表4可知回归模型是极显著的(P<0.01);且失拟项不显著(P>0.05),信噪比为25.255,大于4,可见模型较好,能够用来预测偏置转向轴机构转向平均角速度在不同频率、占空比及轮毂电机初始转速时的变化情况。

表3 转向平均角速度旋转组合试验方案及结果

同时由表4可看到,对于转向平均角速度,占空比、初始转速的影响均极显著(<0.01),频率、频率与占空比交互作用影响显著(<0.05),其他交互作用的影响不显著(>0.05),各因素对转向平均角速度影响的主次顺序为:占空比、初始转速、频率与占空比的交互作用、频率。

表4 转向平均角速度回归模型方差分析

3.2.2 单因素影响分析

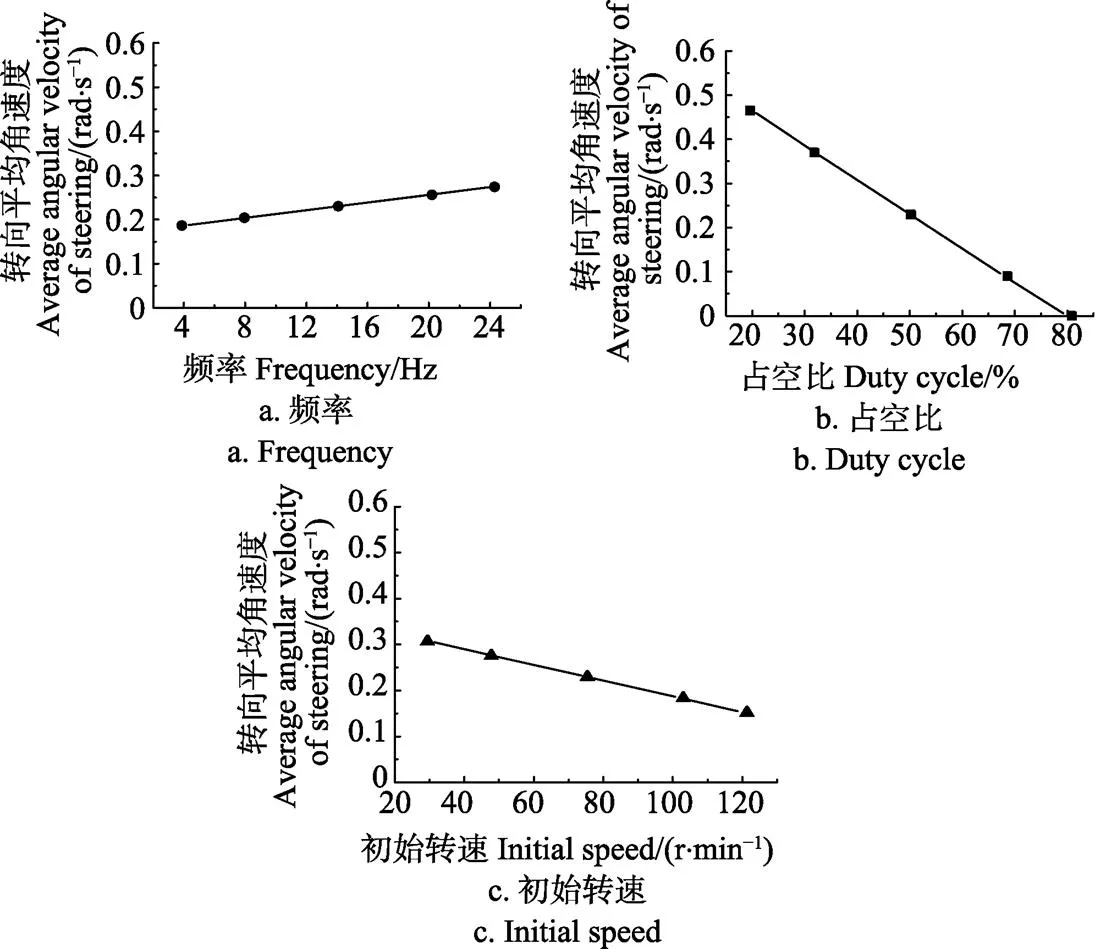

式(4)回归模型中,将频率、占空比以及轮毂电机初始转速三因素中任两者定于编码中的0水平,便可观察到单因素对转向平均角速度的影响趋势。采用此法得到单因素对转向平均角速度影响的关系式为:

图7为根据式(5)绘制出的单因素曲线,频率在4~24 Hz时,转向平均角速度随着频率的增加而呈现缓慢增加趋势,且总体变化幅度在0.1 rad/s左右。故底盘工作中适当增加频率可以增大偏置转向轴机构转向平均角速度。

图7 单因素对平均角速度的影响

由图7b看到,占空比在20%~80%时,随着占空比的增大,偏置转向轴机构转向平均角速度呈现快速减小的趋势,且占空比为80%时,转向平均角速度为0,说明此时偏置转向轴已无法转动;当占空比为20%时,转向平均角速度为0.465 rad/s,此时锁紧力矩很小,不能传递驱动力。可见占空比的有效范围在20%~80%以内,工作时占空比可尽量在此范围的中间值附近选择。

由图7c,轮毂电机初始转速在30~120 r/min时,随着转速增大,转向平均角速度呈减小趋势,总体变化幅度在0.15 rad/s左右。可见柔性底盘的前进速度对转向平均角速度有一定的限制作用。

总体上看,频率在4~24 Hz内,占空比在20%~ 80%内,轮毂电机初始转速在30~120 r/min内时,偏置转向轴机构转向平均角速度的变化范围为0~0.514 rad/s,且调节频率和占空比,可适应偏置臂的不同步进转向速度需求。

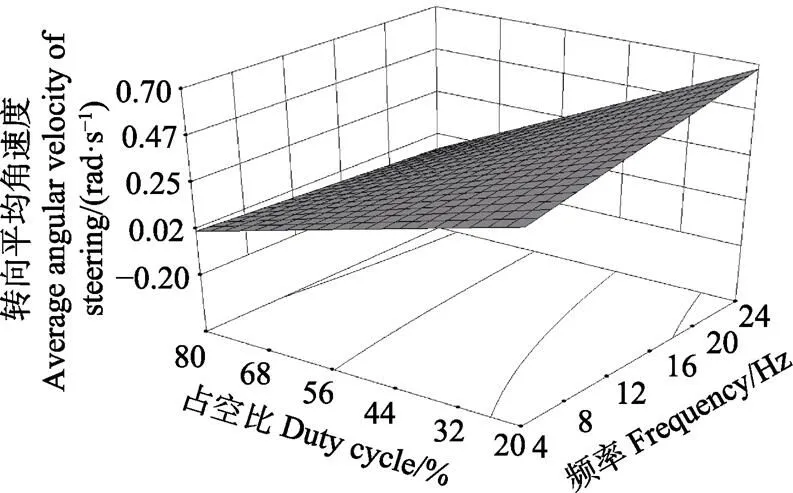

3.2.3 频率与占空比交互作用影响分析

频率和占空比的交互作用对转向平均角速度的影响显著,故利用Design expert做出偏置转向轴机构平均角速度关于频率和占空比的响应曲面(图8),可直观观察频率和占空比耦合作用对于转向平均角速度的影响。由图8可知,占空比较小越趋近于20%时,随着频率增大转向平均角速度缓慢增大;当占空比越趋近于80%时,转向平均角速度随着频率的增大而缓慢降低。

图8 频率和占空比的响应曲面

综上可知,PWM控制电磁摩擦锁间歇吸合,实现了轮毂电机分时步进驱动与转向,且通过改变PWM频率和占空比,可满足不同驱动力矩和转向速度的需求,克服了驱动与转向不能同时进行的矛盾。

4 结 论

本文利用PWM信号控制电磁摩擦锁的方法,解决了偏置转向轴机构驱动与转向不能同时进行的矛盾,通过对该方法下锁紧力矩与转向平均角速度特性的研究,得出以下结论:

1)PWM信号频率、占空比及其交互作用对电磁摩擦锁锁紧力矩均有显著影响(<0.05);在频率4~24 Hz、占空比20%~80%时,锁紧力矩范围为6.822~ 40.046 N·m。

2)PWM信号占空比、轮毂电机初始转速对转向平均角速度影响极显著(<0.01);频率、频率和占空比交互作用对转向平均角速度影响显著(<0.05);占空比影响效应最明显;在频率4~24 Hz,占空比20%~ 80%、初始转速30~120 r/min时,转向平均角速度变化范围为0~0.514 rad/s;且转向平均角速度随占空比增大而快速减小,随初始转速增大而减小,随频率增大而缓慢增大。

[1] 齐飞,魏晓明,张跃峰. 中国设施园艺装备技术发展现状与未来研究方向[J]. 农业工程学报,2017,33(24):1-9. Qi Fei, Wei Xiaoming, Zhang Yuefeng. Development status and future research emphase on greenhouse horticultural equipment and its relative technology in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(24): 1-9. (in Chinese with English abstract)

[2] 刘继展. 温室采摘机器人技术研究进展分析[J]. 农业机械学报,2017,48(12):1-18. Liu Jizhan. Research progress analysis of robotic harvesting technologies in greenhouse[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(12): 1-18. (in Chinese with English abstract)

[3] 邹福星,李建平,何相逸,等. 电动自走式温室水体修复植物收获机设计与试验[J]. 农业机械学报,2016,47(6):61-66. Zou Fuxing, Li Jianping, He Xiangyi, et al. Design and experiment of self-propelled water body restoration plants harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(6): 61-66. (in Chinese with English abstract)

[4] 管春松,胡桧,陈永生,等. 温室用小型电动拖拉机研究[J]. 中国农机化学报,2015,36(2):67-69. Guan Chunsong, Hu Hui, Chen Yongsheng, et al. Study on small electric tractors for greenhouse[J]. Journal of Chinese Agricultural Mechanization, 2015,36(2): 67-69. (in Chinese with English abstract)

[5] 梅娜,郭康权,路敌,等. 柔性底盘驱动控制系统设计[J].农机化研究,2010,32(4):112-113,122. Mei Na, Guo Kangquan, Lu Di, et al. Flexible chassis design driven control system[J]. Journal of Agricultural Mechanization Research, 2010,32(4): 112-113, 122. (in Chinese with English abstract)

[6] 路敌,郭康权. 柔性底盘的转向运动模型[J]. 农机化研究,2011,33(4):219-222. Lu Di, Guo Kangquan. Divertical motion model of flexible chassis[J]. Journal of Agricultural Mechanization Research, 2011,33(4): 219-222. (in Chinese with English abstract)

[7] 杨露,郭康权,丁新民. 基于电桥电路的温室作业柔性底盘转向控制系统的设计[J]. 农机化研究,2013,35(9):151-155. Yang Lu, Guo Kangquan, Ding Xinmin. The steering control system design of flexible chassis for conservatory work based on bridge circuit[J]. Journal of Agricultural Mechanization Research, 2013,35(9): 151-155. (in Chinese with English abstract)

[8] 西北农林科技大学. 一种车辆辅助转向装置:2007100176441[P]. 2007-09-05.

[9] 宋树杰,瞿济伟,李翊宁,等. 农用车底盘偏置转向轴驱动轮运动与动力特性试验[J]. 农业工程学报,2015,31(23):28-34. Song Shujie, Qu Jiwei, Li Yining, et al. Experiment on movement and dynamic property of driving wheel with offset steering shaft for agricultural vehicle[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(23): 28-34. (in Chinese with English abstract)

[10] 宋树杰. 农用柔性底盘的运动特性与控制策略研究[D]. 杨凌:西北农林科技大学,2017. Song Shujie. Research on Kinematical Features and control strategy of Agricultural Flexible Chassis[D]. Yangling: Northwest A&F University, 2017. (in Chinese with English abstract)

[11] 刘岭,闫光荣,雷毅,等. 基于改进粒子群算法的车辆转向梯形机构优化[J]. 农业工程学报,2013,29(10):76-82. Liu Ling, Yan Guangrong, Lei Yi, et al. Optimization design of steering trapezoid mechanism based on an improved particle swarm optimization[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(10): 76-82. (in Chinese with English abstract)

[12] 乔建璐,范英,晋民杰,等. 四轮转向车辆转向特性研究[J].中北大学学报(自然科学版),2017,38(4):458-465. Qiao Jianlu, Fan Ying, Jin Minjie, et al. Study on the steering characteristics of four wheel steering vehicle[J].Journal of North University of China (Natural Science Edition), 2017, 38(4): 458-465. (in Chinese with English abstract)

[13] Ye Y, He L, Zhang Q. Steering control strategies for a four- wheel-independent-steering bin managing robot[J]. IFAC Papers On Line, 2016, 49(16): 39-44.

[14] Gat G, Gan-Mor S, Degani A. Stable and robust vehicle steering control using an overhead guide in greenhouse tasks[J]. Computers & Electronics in Agriculture, 2016, 121: 234-244.

[15] 房素素,鲁植雄,王增才,等. 拖拉机线控液压转向系统设计及样车性能试验[J]. 农业工程学报,2017,33(10):86-93. Fang Susu, Lu Zhixiong, Wang Zengcai, et al. Design and prototype performance experiments of steering-by-wire hydraulic pressure system of tractor[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(10): 86-93. (in Chinese with English abstract)

[16] 张闻宇,丁幼春,王磊,等. 拖拉机自动导航摩擦轮式转向驱动系统设计与试验[J]. 农业机械学报,2017,48(6):32-40. Zhang Wenyu, Ding Youchun, Wang Lei, et al. Design and experiment on automatic steering control system of friction drive for tractor[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(6): 32-40. (in Chinese with English abstract)

[17] 鲁植雄,龚佳慧,鲁杨,等. 拖拉机线控液压转向系统的双通道PID控制仿真与试验[J]. 农业工程学报,2016,32(6):101-106. Lu Zhixiong, Gong Jiahui, Lu Yang, et al. Simulation and experiment of dual channel PID control for hydraulic steer by wire system of tractor[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(6): 101-106. (in Chinese with English abstract)

[18] 张京,陈度,王书茂,等. 农用轮式机器人四轮独立转向驱动控制系统设计与试验[J]. 农业工程学报,2015,31(18):63-70. Zhang Jing, Chen Du, Wang Shumao, et al. Design and experiment of four-wheel independent steering driving and control system for agricultural wheeled robot[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(18): 63-70. (in Chinese with English abstract)

[19] 刘军,袁俊,蔡骏宇,等. 基于GPS/INS和线控转向的农业机械自动驾驶系统[J]. 农业工程学报,2016,32(1):46-53. Liu Jun, Yuan Jun, Cai Junyu, et al. Autopilot system of agricultural vehicles based on GPS/INS and steer-by-wire[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(1): 46-53. (in Chinese with English abstract)

[20] Zhao S, Zhang Z B, Jeong H Y, et al. A turning model of agricultural robot based on acceleration sensor[J]. IFAC Papers On Line, 2016, 49(16): 445-450.

[21] Oksanen T, Linkolehto R. Control of four wheel steering using independent actuators[J]. Ifac Proceedings Volumes, 2013, 46(18): 159-163.

[22] Tabile R. Design of the mechatronic architecture of an agricultural mobile robot[J]. IFAC Proceedings Volumes, 2010, 43(18): 717-724.

[23] Ettefagh M M, Javash M S. Optimal synthesis of four-bar steering mechanism using AIS and genetic algorithms[J]. Journal of Mechanical Science & Technology, 2014, 28(6): 2351-2362.

[24] Nam K, Fujimoto H, Hori Y. Lateral stability control of in-wheel-motor-driven electric vehicles based on sideslip angle estimation using lateral tire force sensors[J]. IEEE Transactions on Vehicular Technology, 2012, 61(5): 1972-1985.

[25] Wang R,Wang J. Tire–road friction coefficient and tire cornering stiffness estimation based on longitudinal tire force difference generation[J]. Control Engineering Practice, 2013, 21(1): 65-75.

[26] 卓桂荣,陈辛波,余卓平,等. 全方位线控四轮转向电动汽车设计[J]. 机械设计,2005(2):29-32. Zhuo Guirong, Chen Xinbo, Yu Zhuoping, et al. Design of an omnidirectional wire controlled four wheels steering electric car[J]. Journal of Machine Design, 2005(2): 29-32. (in Chinese with English abstract)

[27] 来鑫,陈辛波,武晓俊,等. 四轮独立驱动与转向电动车辆运动控制系统及控制策略研究[J]. 汽车工程学报,2015 (5):334-340. Lai Xin, Chen Xinbo, Wu Xiaojun, et al. Study on motion control systems and algorithms for four-wheel independent driving and steering electric vehicles[J]. Chinese Journal of Automotive Engineering, 2015(5): 334-340. (in Chinese with English abstract)

[28] 李翊宁,周伟,宋树杰,等. 温室作业用柔性底盘试验样机的设计[J]. 农业工程学报,2017,33(19):41-50. Li Yining, Zhou Wei, Song Shujie, et al. Design of experimental prototype of flexible chassis used in greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(19): 41-50. (in Chinese with English abstract)

[29] 西北农林科技大学.一种电动车辆驱动底盘:2009100210653[P]. 2009-07-15.

[30] 田静. 高速开关阀PWM控制电路的开发[J]. 中国民航大学学报, 2003, 21(6):26-30. Tian Jing. Developing PWM signal genevator for high speed on-off valve[J]. Journal of Civil Aviation University of China, 2003, 21(6): 26-30. (in Chinese with English abstract)

[31] 王琼,吴惠,夏光,等. 基于PWM控制模式的高速开关阀开关特性分析及优化[J]. 合肥工业大学学报:自然科学版,2016,39(9):1199-1204. Wang Qiong, Wu Hui, Xia Guang, et al. Analysis and optimization of switching characteristics of high speed on-off solenoid valve based on PWM control mode[J]. Journal of Hefei University of Technology(Natural Science), 2016, 39(9): 1199-1204. (in Chinese with English abstract)

[32] Zhuo G, Wang H. Modeling and simulation of high speed on-off valve based on AMESim[C]// International Conference on Electrical and Control Engineering. IEEE, 2011: 2342-2346.

[33] Song S, Li Y, Qu J, et al. Design and test of flexible chassis automatic tracking steering system[J]. International Journal of Agricultural & Biological Engineering, 2017, 10(5): 45-54.

[34] 葛宜元. 试验设计方法与Design-Expert软件应用[M]. 哈尔滨:哈尔滨工业大学出版社,2015.

Experiments on collaborative control characteristics of driving and steering for agricultural flexible chassis based on PWMsignal

Qu Jiwei1, Guo Kangquan1,2※, Gao Hua1, Song Shujie3, Li Yining1, Zhou Wei1

(1.712100,; 2.712100,; 3.710119,

Electromagnetic friction lock is an important part of agricultural flexible chassis. When it is closed, flexible chassis will be driven forward, and will steer when opened. In engineering practice, flexible chassis needs to steer while advancing. Therefore, there is conflict between the opening and the closing of electromagnetic friction lock when the 2 motions need to be carried out at the same time. In order to solve this problem, a method based on pulse width modulation (PWM) technology was proposed to control the opening and the closing in this paper. The opening was achieved during low level of PWM wave, while the closing was achieved during high level of PWM wave. In this way, flexible chassis can be driven forward during steering. Further, some experiments were conducted to investigate the influences of PWM frequency and duty cycle on driving and steering performance of flexible chassis. Firstly, based on off-centered steering shaft test bench, two-factor experiments were performed to study the effects of frequency and duty cycle on pulse tightening torque, using a traction device which was composed of a lever and a force sensor. Then tightening torque was calculated from force sensor measurement and arm length value. Secondly, for the purpose of examining the characteristics of time-sharing steering related with the influence of frequency, duty cycle and initial speed of electric wheel, a quadratic orthogonal regression experiment was conducted on off-centered steering shaft test bench. In this test, steering motion was simulated by controlling the speed of horizontal turntable of test bench and electric wheel. Average steering angular velocity was taken as the evaluating indicator of steering characteristics, and it can be attained by measuring the steering time due to the same target angle of steering. Afterwards, results of two-factor experiment showed that frequency, duty cycle and their interaction had highly significant influences on tightening torque (P<0.01). In the process of rotation, the curve of tightening torque showed a pulse change, and the rotation angle of steering arm displayed a step-like rise. When frequency was 4-24 Hz and duty cycle was 20%-80%, the tightening torque of off-centered steering shaft varied from 6.822 to 40.046 N·m. The tightening torque declined as frequency increased when duty cycle was 20%-80% except a few duty cycles. Meanwhile, for the frequency ranging from 4 to 24 Hz, tightening torque rose with the increasing of duty cycle. Then regression analysis was carried out according to the results and a regression model was presented. Results of quadratic orthogonal regression experiment illustrated that the average steering angular velocity was remarkably influenced by the PWM frequency, duty cycle and their interaction as well as the initial rotation speed of in-wheel motor (IWM) (P<0.05). With the increment of duty cycle and the initial speed of IWM, the steering average angular velocity decreased rapidly but slowly increased with the increasing of frequency. When the frequency was 4-24 Hz and the duty cycle was 20%-80%, and the initial speed of IWM was 30-120 r/min, the average steering angular velocity varied from 0 to 0.514 rad/s. Therefore, through changing the PWM frequency, duty cycle and the initial speed of IWM, the process of pulse-driven and time-sharing steering for flexible chassis is able to be well achieved, and these results can provide a basis for cooperative control of flexible chassis.

agricultural machinery; transportation; control; flexible chassis; pulse width modulation; off-centered steering shaft; driving and steering; cooperative control

瞿济伟,郭康权,高 华,宋树杰,李翊宁,周 伟. 基于PWM信号的农用柔性底盘驱动与转向协同控制特性试验[J]. 农业工程学报,2018,34(7):75-81. doi:10.11975/j.issn.1002-6819.2018.07.010 http://www.tcsae.org

Qu Jiwei, Guo Kangquan, Gao Hua, Song Shujie, Li Yining, Zhou Wei. Experiments on collaborative characteristics of driving and steering for agricultural flexible chassis based on PWM signal[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(7): 75-81. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.07.010 http://www.tcsae.org

2017-12-20

2018-03-05

国家自然科学基金资助项目(51375401)

瞿济伟,湖北利川人,博士生,主要从事智能农业装备技术研究。Email:qujiwei_mail@foxmail.com

郭康权,陕西西安人,教授,博士生导师,主要从事智能农业装备技术研究。Email:jdgkq@nwsuaf.edu.cn

10.11975/j.issn.1002-6819.2018.07.010

S229+.1;U463.1

A

1002-6819(2018)-07-0075-07