Analysis of Process of Microwave Puffing Blueberry Snacks

2018-04-02ZhengXianzheChenKaidiSuXiaolinLiuHanXuHaoWangXiaoruiandHanLingyu

Zheng Xian-zhe, Chen Kai-di, Su Xiao-lin,, Liu Han, Xu Hao, Wang Xiao-rui, and Han Ling-yu

1 College of Engineering, Northeast Agricultural University, Harbin 150030, China

2 Department of Food Engineering, Heilongjiang Vocational College for Nationalities, Harbin 150066, China

Introduction

Blueberry, which is rich in anthocyanins (Liu, 2013),has unique flavor and soft texture.There is only a small variety of blueberry products on the market,due to its intolerance in storage and transportation.The blueberry snacks made by pulp, starch and other materials, under microwave method are novel snack food with crisp taste.

Microwave technology, as a volume heating method(Yanget al., 2008), has puffing effect for the drying of agricultural products (Liet al., 2003) and is proved by Kparuliset al(2005).Fruit and vegetable crisp puffed by microwave technology retains high nutrients (Sun,1996).Therefore, microwave processing method was used in this experiment.Study of Ranet al.(2004)showed that the thickness in the range of 2-6 mm of the material dose not affect the drying rate, but different slice thickness has a significant effect on the temperature.Muet al.(2010) studied on the effects of different processing parameters on the sensory evaluation and texture characteristics of black currant snacks using microwave vacuum technology.Zhenget al.(2012) indicated that the effects of microwave power, vacuum and initial moisture content on the dewatering and structural characteristics of raspberry crisps are significant.The study con firms the existence of the relationship between the volume expansion and the dehydration rate of raspberry snacks (Zhenget al.,2013a).As for the simulation of puffing, Ressinget al.(2007) used finite element method to simulate the temperature distribution of the dough depended on the depth of microwave penetration inside dough in microwave vacuum puffing considering the heat transfer and solid mechanical properties.Liuet al.(2009; 2010) established a mathematic model of microwave vacuum puffed black gallon slices to analyze the volume change of the crisp and the diffusion of internal moisture, the law of temperature transmission.Mu (2011) carried out the multi-physics coupling simulation of expansion of raspberry snacks and the internal pressure gradient and temperature distribution in the process of microwave vacuum puffing.The effects of microwave intensity and initial moisture content on the heat transfer and mechanical properties of puffed snacks are discussed based on above-mentioned studies.These simulations of the puffing process describe the distributions of the temperature and the volume change of materials.However, limited information on analysis of process of microwave puffing blueberry snacks was reported.The aims of this study were to determine the actual value of the internal pressure and temperature of the slices in the process of puffing and obtain the changes of volume based on the amount of water vapor generated inside the snacks.

Materials and Methods

Experimental materials and experimental program

Blueberry pulp provided by Heilong jiang Academy of Agricultural Sciences of Harbin in China was stored at room temperature (25℃).Distilled water was added into the blueberry pulp to adjust its moisture content to setting level.Then mixed the pulp, modified starch (Pregel-A, Tianjin Dingfeng Starch Development Co., Ltd., Tianjin, China) and maltodextrin(Changchun Dihao Food Development Co., Ltd.,Changchun, China) evenly in proportion.The proportion based on the golden section method (Zhenget al., 2013b) at the ratio of starch dough was consisted of blueberry pulp of 32.6 g · 100 g-1, modified starch of 41.7 g · 100 g-1, maltodextrin of 25.7 g · 100 g-1.Finally, the starch dough was prepared to a sheet with a diameter of 18 mm, a thickness of 3 mm and a mass of (5±0.20) g.

Microwave puffing equipment

The microwave workstation (MWS MAN-00074 R1 type, FISO, Quebec, Canada) was employed for puffing blueberry snacks.The equipment consisted of magnetrons installed on the right of the drying chamber and fiber optic sensors which were installed on the top of the drying chamber.Ten intensities of microwave output powers at 0-1 100 W with the interval of 100 W.

Moisture content measurement

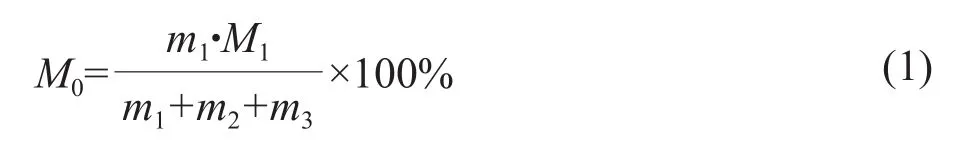

The water content of blueberry pulp was determined by using direct drying (GB 5009.3-2010).A small amount of blueberry pulp was poured into three aluminum boxes, and then placed into a vacuum oven(DHG-9053A, Yiheng Experimental Equipment Co.,Ltd., Shanghai, China).The pulp was dried to constant weight at a temperature of 105℃.The moisture content of berry pulp was calculated according to the ratio of the mass of the removed water to the mass of the pulp.The water content of the dough was calculated by using Eq.(1).

Where,m1was the quality of the blueberry pulp (g),m2was the mass of modified starch (g),m3was the mass of maltodextrin (g),M1was the moisture content of the blueberry pulp (%), andM0was the moisture content of the starch dough (%).

Determination of temperature and pressure

The internal temperature and pressure of the snacks were measured by using two fiber optic sensors connected to the microwave workstation (MWS MAN-00074 R1 type, FISO, Quebec, Canada).The fiber optic sensors were immersed into the center of the snack to measure its temperature and pressure.The same conditions were repeated three times to report the average value.

Determination of amount of water vapor in snacks

The amount of water vapor in the snacks was directly related to the pressure in the snacks.The height of the snacks could be observed through the paper listed height scale in the puffing process with the rotation of the turntable.It could be learnt from the ideal gas state Eq.(2).

Where,Pwas the pressure in the snacks (Pa),ΔVwas the increment of the snacks' volume (m3),nrepresented the amount of water vapor (mol),Rwas the ideal gas constant (8.31441 J · mol-1K-1), andTwas the temperature in the snacks (K).In a closed system,the product of pressure and volume was constant at constant temperature.To improve the accuracy and simplify the solution process, some assumptions were as the followings.The snacks before being puffed were treated as cylinders and ignore the interior air.The puffed snacks were considered as hemispherical,the height of snack was the ball radiusr(mm).The volume increment ΔVof the snacks in MP was considered to be filled with saturated water vapor.The amount of water vapor in the snacks with puffing time was calculated by using Eq.(3).

The meanings of the parameters in the equation were the same as Eq.(2).

Determination of hardness, brittleness and elastic modulus

The hardness of puffed blueberry snacks, defined as the maximum force before the sample underwent crack (Liu, 2013), was measured by a texture analyzer(TA-XT-Plus, Stable Microsystems Ltd., Surrey,UK).The brittleness value referred to the number of crests that occurred, when the anchor was detected in the fragmentation of the crack.The running speed of cylindrical probe was set to 5, 2 and 10 mm · s-1with 2.5 mm diameter, and the pressing distance was 35 mm,and the force threshold was 100 g.The software TEE32 was used to obtain the force-time curve.The hardness and the brittleness of the snacks could be calculated according to these curves.

The stress-strain curves of berry snack subjects stress were obtained according to the force-time curves.The elastic modulus was determined by fitting the linear portion of the curve, between 1/6 and 5/6 of the rupture stress, to a straight line and finding its slope (Ressinget al., 2007).

Data processing

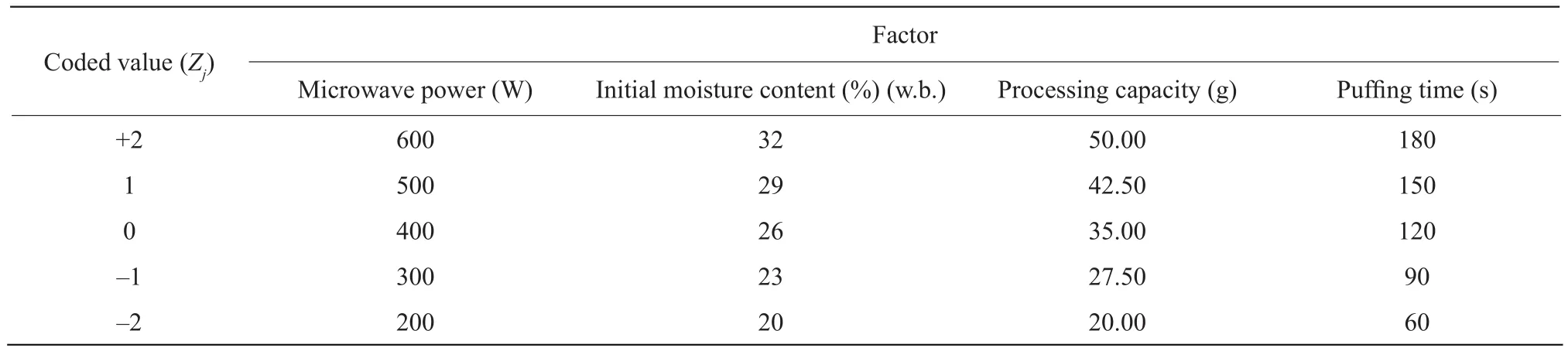

Sigma Plot (Ver12.5) was used to establish regression models of temperature and pressure over time.Design Expert (Ver8.0.6) was used to design the four-factor five-level center combination experiment.Factor level and coded level are shown in Table 1.

Results

Changes of internal pressure and temperature inside berry snacks

Effects of microwave intensity on pressure and temperature inside berry snacks

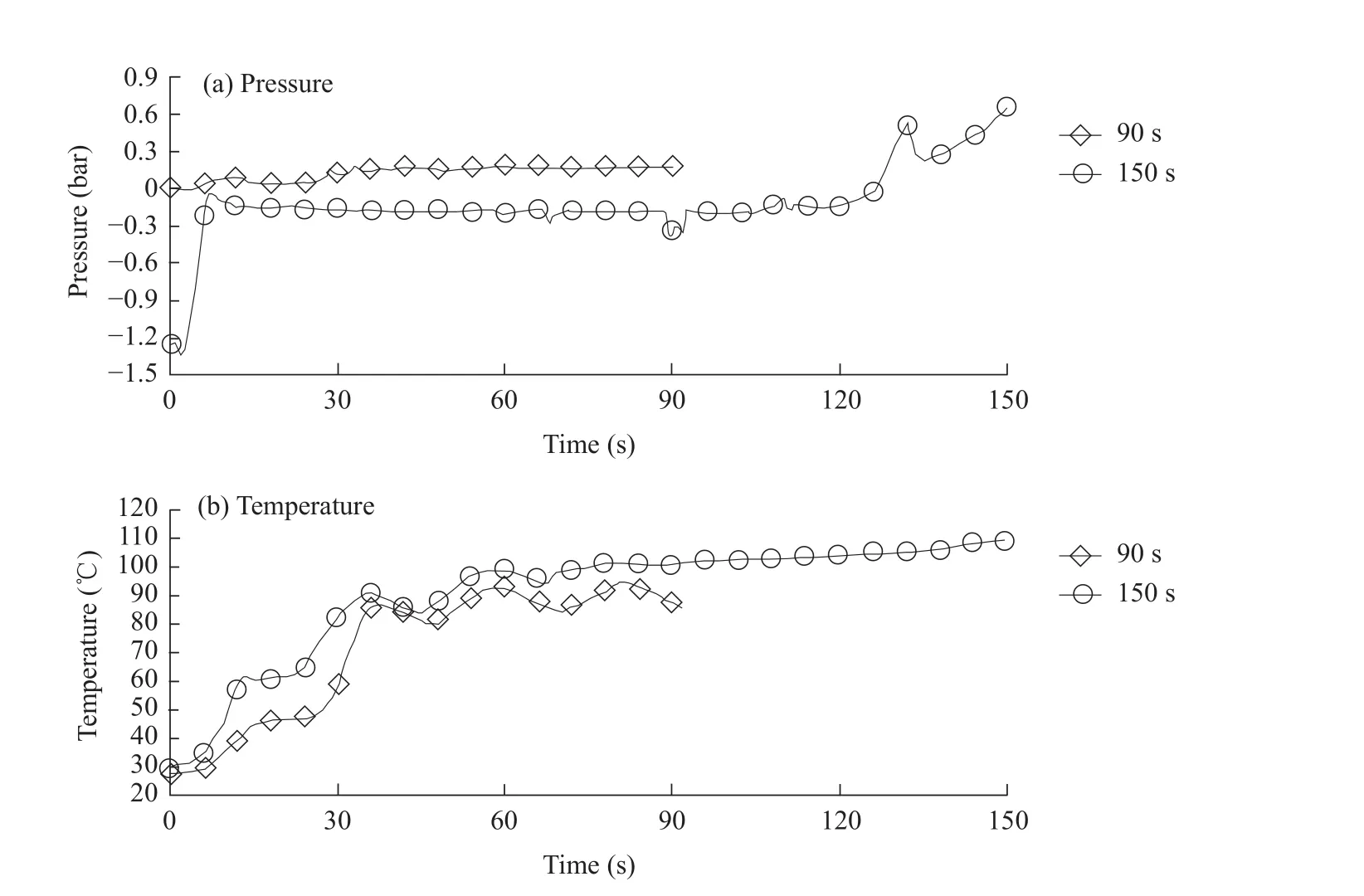

Fig.1 depicted the changes in internal pressure and temperature over time under different microwave intensities at the initial moisture content of 23% (w.b.)and puffing time of 150 s.In the early puffing stage,there was few changes in pressure and temperature inside the berry snacks.With the accumulation of microwave energy, the pressure and temperature in the slices increased rapidly for the puffing time of 1 min.The greater the microwave intensity resulted in the more evaporation of moisture in berry slabs.But in the end of the process, the pressure of the snacks tended to similar trends under different microwave intensities.

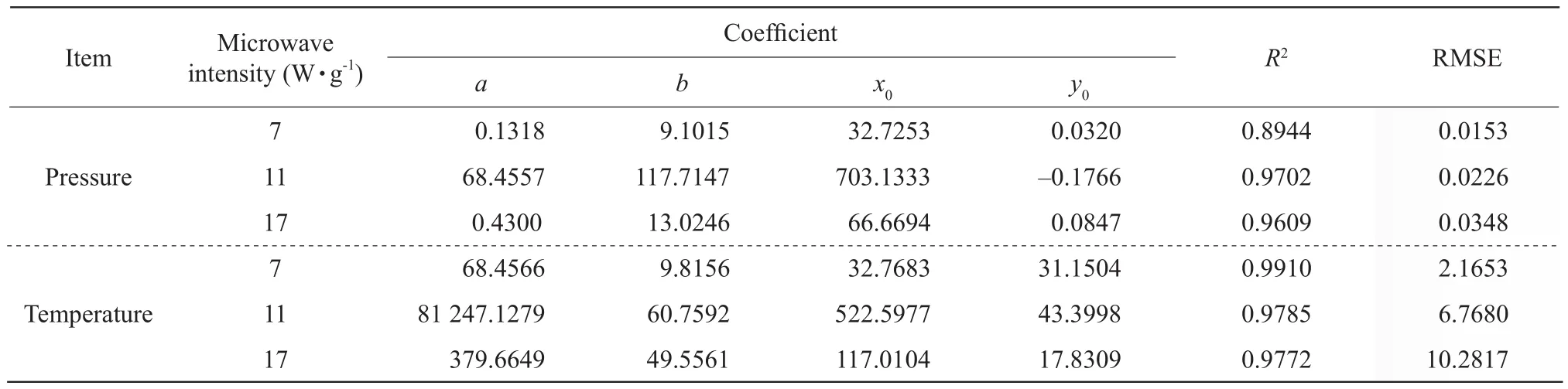

There was a regression equation of pressure and temperature over time.The precision of the model was determined by the determination coefficientR2and the root mean square error (RMSE) (Chenet al., 2013).The model with higherR2and lower RMSE was chosen as the most suitable regression model.

The trend of the internal pressure and temperature of the snacks were simulated under different microwave intensities at the initial moisture content of 23% (w.b.)and the expansion time of 150 s.Several models were selected to fit the pressure-time and temperature-time curves, and Eq.(4) was the most suitable model by comparingR2and RMSE of different models.

In this model, the fitting of pressure and temperature with time was higher, and the related statistical parameters and values are shown in Table 2.

Changes of pressure and temperature under different initial water contents Fig.2 showed the changes of the pressure and temperature in the process of the snacks with initial moisture content at the microwave intensity of 11 W · g-1and puffing time of 120 s.As shown in Fig.2(a), the pressure of the snacks was inversely proportional to the initial moisture content at the beginning.The pressure inside the snacks increased slowly at low initial moisture content.However, the pressure of the snacks increased rapidly at high initial moisture content.In the late stage of the puffing process, the internal pressure of the snacks increased with the increase of initial moisture content.Because the high dielectric constant of water, the higher initial moisture content of the snacks resulted in the higher dissipation of the microwave energy, which contributed to raise temperature of snacks as shown in Fig.2(b).

Table 1 Experimental values and coded level

Fig.1 Changes of pressure and temperature in snacks of different microwave intensities [initial moisture content of 23%(w.b.), expansion time of 150 s]

Table 2 Statistical parameters and values of coefficients specific to Eq.(4) for different microwave intensities

Fig.2 Changes of pressure and temperature in snacks of different initial water contents (microwave intensity of 11 W · g-1,puffing time of 120 s)

Changes of pressure and temperature of snack with puffing time

As shown in Fig.3, the changes of pressure and temperature with puffing time at microwave intensity of 11 W · g-1and the initial moisture content of 29%(w.b.).The changes of pressure and temperature were non-significant with puffing time.

Changes of amount of water vapor and volume expansion of snacks

Amount of water vapor and volume of snacks with microwave intensity

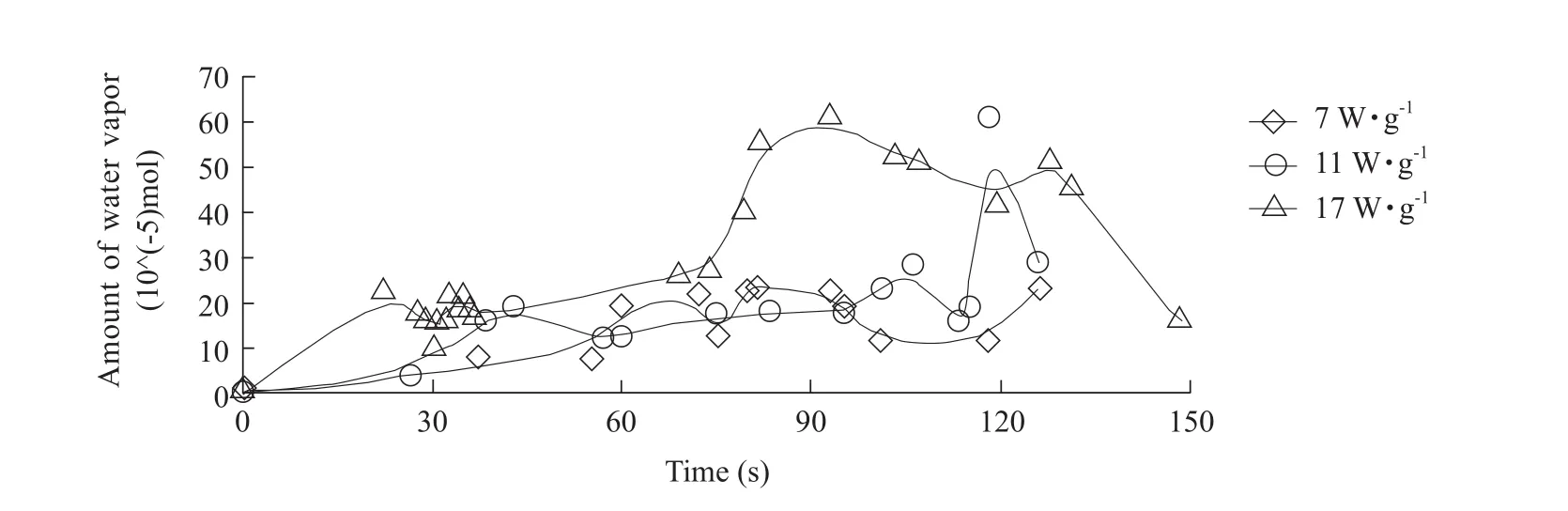

Change of the volume of water vapor in the snacks is shown in Fig.4, under different microwave intensities at the initial moisture content of 23% (w.b.) and the expansion time of 150 s.Points represented the actual experiment value, dotted line represented the trend.As the amount of water vapor in the snacks was directly related to the pressure within the snacks, so the change in the amount of water vapor was similar to the change in pressure.The amount of water vapor in snacks was closely related to the volume of snacks, the more water vapor in the snacks, the greater the volume of the berry snacks.Volume of water vapor and volume of snacks with different initial water contents

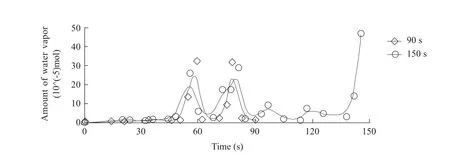

Fig.5 showed the change of the volume of water vapor under different initial water contents at the microwave intensity of 11 W · g-1and the puf fing time of 120 s.The volume of water vapor in the snacks of high moisture content was little at the beginning of the puffing process.With the rotation of turntable in the microwave workstation, microwave penetration depth showed cyclical changes, so the amount of water vapor and volume of berry snacks.

Fig.3 Changes of pressure and temperature in snacks of different expansion time [microwave intensity of 11 W · g-1, initial moisture content of 29% (w.b.)]

Fig.4 Water vapor volume of substance in snacks of different microwave intensities [initial moisture content of 23% (w.b.) ,expansion time of 150 s]

Fig.5 Water vapor volume of substance in snacks of different initial water content (microwave intensity of 11 W · g-1, puffing time of 120 s)

Enough puffing time was helpful for volume expansion of snacks at proper microwave intensity and initial moisture content in microwave puffing.As shown in Fig.6, the puffing time had no significant impact on the amount of water vapor at the microwave intensity of 11 W · g-1and the initial moisture content of 29% (w.b.).

Fig.6 Water vapor amount of substance in snacks of different expansion time (microwave intensity of 11 W · g-1, initial moisture content of 29% (w.b.))

Discussion

From the results, it could be seen that in the initial stage of the expansion, there were few changes in pressure, temperature, volume of water vapor and volume of snacks.The reasons could be that in the initial stage of volume expansion of berry snacks,temperature and vapor water raised, due to absorption of microwave energy within snacks.No significant effect of microwave intensities on the internal pressure and the temperature of the berry snacks was observed in the initial stage.A small amount of water vapor in the snacks caused the radial extension; therefore, few changes of the volume occurred in the drying stage(Hanet al., 2006).The accumulation of microwave energy in berry snacks caused the evaporation of liquid water inside the snacks, which contributed to improving the internal pressure, expanding the volume and forming the porous structure.

The depth of the microwave penetration inside material had positive relation to the absorption.The more absorption of microwave energy inside berry snacks resulted in more amounts of water evaporation to form fine pores of the interior.During the experiment, it could be clearly observed when the snacks were close to the waveguide, the volume was significantly increased.The pressure, temperature, volume of water vapor and volume of snacks increased rapidly for the puffing time of 1 min.This could be explained that with the accumulation of microwave energy absorbed by the snacks, a large number of water had been vaporized, resulting in a sharp increase in the pressure inside the snacks.Large amounts of water vapor could also lead to an increase in the volume of berry snacks.

With the reduction of moisture inside berry snacks,the ability of the snacks to absorb microwave energy decreased, which resulted in the decrease of the amount of water vapor.After the water vapor was lost,its original volume left pores.As a result, the volume of the snacks expanded.

It was difficult to form a stable structure in the highly initial moisture content or low microwave intensity.When the initial moisture content was low or the microwave intensity was high, the moisture in the snacks was removed to form a stable structure in a short time.It was necessary to make appropriate choices of the initial moisture content and microwave intensity in order to obtain a good puffing effect.

Conclusions

In the initial stage of microwave puffing, the moisture inside the berry snacks absorbed microwave energy to increase the temperature and the moisture evaporation.Porous structure appeared and the volume of the berry snacks rose, due to the vaporization of the liquid water.In the end of the puffing process, the moisture content in the slices had been greatly reduced leading to a large number of pores in the snacks till constant.

(1) In the initial stage of microwave puffing, the internal pressure and temperature of the snacks was proportional to the microwave intensity and inversely proportional to the initial moisture content.In later stage, the pressure increased rapidly with the generation of the water vapor.Finally, the pressure inside the snacks achieved 0.3-0.6 bar under high microwave intensity and moderate initial moisture content.

(2) The volume of the snacks was directly related to the amount of water vapor.In the beginning, less amount of water vapor in the snacks was diffucult to change the volume of the berry snacks.With the accumulation of microwave energy inside slices, a large amount of water vapor increased rapidly the volume of the berry snacks.

Chen J K, Lin H T, Li H,et al.2013.Modeling and optimization of microwave vacuum drying of pleurotus eryngii slices.Chinese Journal of Vacuum Science and Technology, 12(33): 1184-1190.

Han Q H, Li S J, Ma J W,et al.2006.Microwave vacuum drying and puffing characteristics of apple snacks.Journal of Agricultural Mechanization, 37(8): 155-158, 167.

Kparulis M, Kpauehnert S, Leikpaer M,et al.2005.Influence of energy input and initial moisture on physical properties of microwave-vacuum dried strawberries.European Food Research and Technology, 221(6): 803-808.

Li Y Z, Zheng S X, Luo S C,et al.2003.Process characteristics of vacuum microwave processing of potato snacks.Food and Fermentation Industry, 29(8): 40-43.

Liu C H, Huo J W, Zheng X Z,et al.2009.Study on extrusion of blue indigo fragment by microwave vacuum method.Journal of Agricultural University, 40(11): 116-120.

Liu C H, Zheng X Z, Shi J,et al.2010.Optimizing microwave vacuum puffing for blue honeysuck pale snack.International Journal of Food Science and Technology, 45(3): 506-511.

Liu D Y.2013.The experimental study of microwave vacuum puffing raspberry snacks on sensory quality.Northeast Agricultural University, Harbin.

Mu Y Q.2011.Study on microwave vacuum extrusion technology and mathematical simulation of raspberry crisp.Northeast Agricultural University, Harbin.

Mu Y Q, Liu C H, Zheng X Z,et al.2010.Effects of microwave vacuum puffing conditions on the texture characteristics and sensory properties of black pacurrant (Ribes nigrum.L) snackPa.International Agricultural Engineering Journal, 19(3): 45-52.

Ran X, Lv L T, Liu X W,et al.2004.Thermal heat transfer model and drying characteristics of flake food microwave drying.Chinese Journal of Agricultural Engineering, 20(3): 145-148.

Ressing H, Ressing M, Durance T.2007.Modeling the mechanisms of dough puffing during vacuum microwave drying using the finite element method.Journal of Food Engineering, 82(4): 498-508.

Sun L N.1996.Development of microwave puffed potato snacks.Food Science, (6): 71-72.

Yang W, Ou Y C, Zhang F J,et al.2008.Comparative test of hot air,microwave convection and microwave vacuum drying mushroom.Journal of Agricultural Mechanization, 39(6): 102-140, 112.

Zheng X Z, Liu C H, Mu Y Q,et al.2012.Analysis of puffing characteristics using a sigmodal function for the berry fruit snack subjected to microwave vacuum conditions.Drying Technology, 30(5): 494-504.

Zheng X Z, Liu C H, Shi J,et al.2013.Analysis of volume expansion and dehydration rate of berry slab under microwave-vacuum puffing conditions.LWT-Food Science and Technology, 52(1): 39-48.

Zheng X Z, Liu D Y, Song X Y,et al.2013.Optimization of raspberry formula on microwave vacuum puffing and effect of microwave intensity.Journal of Northeast Agricultural University, 44(8): 1-5.

杂志排行

Journal of Northeast Agricultural University(English Edition)的其它文章

- Operational Performance Evaluation of Corn Processing Industry Technological Innovation Alliance Based on Survey Data in Heilongjiang Province

- Spatial and Temporal Variation in Water Productivity and Grain Water Utilization Assessment of Heilongjiang Province, Northeast China

- Stability Analysis of a Lignocellulose Degrading Microbial Consortium

- Pharmacokinetics of Milbemycin Oxime in Dogs Following Its Intravenous and Oral Administration

- Comparative Research on Facultative Anaerobic Cellulose Decomposing Bacteria Screened from Soil and Rumen Content and Diet of Dairy Cow

- Effect of Mineral and Vitamin Supplementation on Performance and Haemotological Values in Broilers