畜禽养殖恶臭物质组成与测定及评估方法研究进展

2017-10-24王文林杨婉静曾杰亮李文静

刘 波, 王文林, 刘 筱, 范 婤, 杨婉静, 徐 乔, 关 雷, 曾杰亮, 李文静, 何 斐①

(1.南通大学地理科学学院, 江苏 南通 226007; 2.环境保护部南京环境科学研究所, 江苏 南京 210042)

畜禽养殖恶臭物质组成与测定及评估方法研究进展

刘 波1, 王文林2, 刘 筱1, 范 婤2, 杨婉静1, 徐 乔1, 关 雷1, 曾杰亮1, 李文静2, 何 斐2①

(1.南通大学地理科学学院, 江苏 南通 226007; 2.环境保护部南京环境科学研究所, 江苏 南京 210042)

随着我国畜禽养殖业的迅速发展,恶臭已成为引发周边居民投诉和纠纷的主要环境问题,严重制约了畜禽养殖业的可持续发展。因此,识别畜禽养殖恶臭来源及物质组成、总结恶臭测定技术和了解恶臭表征与评估方法,对于科学评估恶臭危害进而针对性地提出控制措施具有重要意义。系统梳理了畜禽恶臭物质的主要组成与特征,对比分析了畜禽恶臭主要测定技术的优缺点,讨论了主要的恶臭表征评估方法。畜禽恶臭中起关键作用的物质主要是挥发性脂肪酸类、含硫化合物、芳香族化合物(主要是酚类和吲哚)以及氨和挥发性胺类4类物质。畜禽恶臭的测定方法大致分为仪器分析法和嗅觉法2类,2类方法各有优劣。在分析现有恶臭成分的基础上,判别畜禽恶臭的关键物质,实现畜禽恶臭的现场连续监测是今后研究的热点。针对恶臭成分的复杂性,构建恶臭物质浓度与恶臭强度间的合理转化关系是进行恶臭评估的一种可行方法。

畜禽养殖; 恶臭物质; 测定方法; 评估方法

随着经济发展和人民生活水平的不断提高,畜产品的需求量逐渐增大,专业化、规模化的畜禽养殖业得到迅速发展。但是,在畜禽养殖业迅速发展的同时,其带来的环境问题也日益凸显[1]。大量的畜禽废弃物对水体、土壤、大气等产生了严重污染[2-3],其中,畜禽养殖造成的恶臭问题越来越引起关注。畜禽养殖产生的恶臭不但气味令人厌恶,而且伴随着病原微生物、悬浮颗粒、寄生虫卵、氨气、硫化氢等有毒有害成分,造成严重的空气污染,威胁人畜的身心健康[4]。养殖场散发的恶臭已成为引发周边居民投诉和纠纷的主要环境问题,被称为“畜产公害”,严重制约了畜禽养殖业的可持续发展[5-6]。20世纪60年代以来,欧美国家在对恶臭成分开展鉴定分析和科学评估的基础上,出台了一系列恶臭监测与管理标准和法规[7]。畜禽恶臭释放源多样,物质组成复杂,且随着恶臭物质分析测试技术的发展,新恶臭成分不断被发现。由此,识别畜禽养殖恶臭来源及物质组成、总结恶臭测定技术和了解恶臭表征与评估方法,对于判别畜禽恶臭关键物质、科学评估恶臭危害,进而针对性地提出控制措施具有重要意义。基于此,笔者就畜禽养殖恶臭来源与组成、测定技术及表征评估方法的国内外研究现状进行归纳总结,并对今后的研究方向进行简要展望。

1 来源与种类组成

1.1 来源与形成

畜禽养殖场恶臭排放源主要有畜禽舍、粪污贮存装置与处理场所(堆肥车间、污水池等)、饲料间和粪污施用区域等[8]。有调查显示,关于恶臭的投诉大约50%涉及施粪过程,20%涉及粪污贮藏场所,30%涉及畜禽舍[9-10]。随着注入式施肥技术的应用,欧洲国家的恶臭投诉更多涉及粪污处理设施和畜禽舍[11]。但是,目前尚无关于各排放源对畜禽恶臭贡献率的系统研究[12]。

从恶臭形成过程来看,恶臭物质主要是畜禽废弃物,包括粪尿,溢洒饲料及废水,垫料,废水等在厌氧条件下发酵产生的挥发性化合物和气体,其中,绝大部分为挥发性有机物(volatile organic compounds, VOCs)[13-14]。而在好氧条件下,畜禽废弃物一般不会产生恶臭物质[15]。畜禽粪尿被认为是恶臭物质最主要的来源[16]。育成猪消化道内容物中检测到吲哚、粪臭素,表明粪便在结肠和直肠中已开始腐败,故新鲜粪便也具有一定的臭味[17]。而排出后的粪便在土著微生物、外源微生物等腐败性微生物作用下继续厌氧分解,导致恶臭强度迅速升高;同时鲜尿中的尿素和酚类聚合体,会因粪便的混入而急剧分解,挥发出氨(NH3)和酚类物质,导致恶臭加剧[18]。研究已发现形成恶臭的基质主要是随粪尿一起排出的未降解蛋白质和易发酵碳水化合物[19-20]。蛋白质在腐败性微生物作用下分解产生各种氨基酸后通过氨基酸脱羧和脱氨作用形成恶臭物质散发到环境中[21]。例如,氨基酸在高pH值条件下可产生NH3和挥发性脂肪酸(volatile fat acids, VFAs)[22];色氨酸和酪氨酸分解产生酚类和吲哚类物质[23];胱氨酸生成了硫化氢;蛋氨酸生成了甲硫醇、二甲硫、乙硫醇等含硫化合物类恶臭物质[24]。畜禽排泄物中的碳水化合物在厌氧发酵过程中可以形成乙酸、丙酸和丁酸[25]。

1.2 组成与特性

自1963年在猪粪中鉴定出硬脂酸(stearic acid)以来,人们对于畜禽养殖恶臭物质的鉴定已有50多年的历史[26]。随着分析测试技术的发展,被鉴定出的恶臭物质种类不断增多,一次性鉴定出的恶臭物质种类从20多到400多种不等,去除相同的种类至今共发现510余种不同的恶臭物质[21,27-31]。不同畜禽类型的恶臭物质种类也有所差异,牛场中恶臭物质种类有70多种[27],鸡场中有150 余种[32],猪场中高达500多种[28,31,33]。养殖场不同设施的恶臭物质种类有所不同,畜禽粪便的堆积和处理设施中恶臭物质种类最多,研究发现猪场粪便储存设施的上部空气中鉴定出295种恶臭物质[28,34],粪便氧化塘污水中含有167种不同的恶臭物质[31],禽舍内部大约有100~150种恶臭物质[29]。

畜禽恶臭成分复杂,主要包括挥发性脂肪酸(VFAs)、酚类(phenols)、醇类(alcohols)、醛类(aldehydes)、酮类(ketones)、酯类(esters)、醚类(ethers)、胺类(amines)、烃类(hydrocarbons)、卤代烃类(halogenated hydrocarbons)、硫化物(sulphides)、含氮杂环化合物(nitrogen heterocycles)及芳香族化合物(aromatics)等有机成分[28,31,35-37]。各类VOCs包含具体不同的物质,可以进一步分为次一级的亚类。除了有机成分外,恶臭物质还包括氨气、硫化氢等无机成分[38]。由于不同条件下形成的畜禽恶臭物质复杂多样,且在大气中极易迁移转化[39],因而目前关于各类恶臭物质对畜禽恶臭的贡献尚不完全清楚[40]。从已有研究来看,一般认为畜禽恶臭中起关键作用的物质主要是挥发性脂肪酸类,含硫化合物,芳香族化合物(主要是酚类和吲哚),以及氨和挥发性胺类4类[9,41-42]。

VFAs被认为是畜禽恶臭物质中最主要的组成[13,43]。大约60%的VFAs是乙酸[44],其次主要有丙酸、正丁酸、异丁酸、异戊酸、正癸酸、戊酸[45]。具有长碳链结构的VFAs(C4~C9,如丁酸、戊酸、辛酸等)恶臭程度显著高于短碳链结构的VFAs(如乙酸和丙酸),其嗅阈值也较低[44]。由于在畜禽养殖中排放的VFAs大多是短碳链结构,故虽然检测到的VFAs浓度很高,但一般也不会产生刺激性恶臭[42]。

含硫化合物一般具有强烈的刺激性恶臭气味,是畜禽恶臭物质的一个重要组成[38,46]。已经鉴定出的最低嗅阈值的物质中,有6种为含硫化合物[47]。含硫化合物主要有硫化氢、甲硫醇、丙硫醇、二甲基硫醚、二甲基二硫醚[31]。畜禽粪便中的硫大多以硫化氢和甲硫醇形式散发到空气中[48],2种物质占畜禽挥发性含硫恶臭物质的70%~97%[49]。猪粪便挥发出的硫化氢质量浓度达到90 μg·m-3[43],而猪舍空气中甲硫醇质量浓度达到3.6×104μg·m-3,是自身嗅阈值的947~120×106倍[50],因而甲硫醇被认为是对畜禽恶臭贡献最大的含硫化合物。通常情况下,含硫化合物浓度明显高于VFAs,且含硫化合物嗅阈值低于VFAs,故一般认为含硫化合物在恶臭中的作用要强于VFAs[21]。

畜禽恶臭物质中的芳香族化合物主要是酚类和吲哚,具体包括苯酚、对甲酚、间甲酚、乙基苯酚、吲哚和甲基吲哚等[13]。空气中酚类浓度较高[31],研究发现猪舍空气中对甲酚和苯酚分别占芳香族化合物的64%和26%,而吲哚和甲基吲哚浓度较低[13]。对甲酚不但其浓度要高于其他芳香族化合物,而且在芳香族化合物中其嗅阈值是最低的,因而相比于吲哚和苯酚,对甲酚是重要的恶臭物质[51]。虽然畜禽恶臭物质中苯酚浓度高于吲哚和甲基吲哚,但是其嗅阈值也高,同时苯酚具有芳香气味,因而在该类物质中,苯酚对恶臭贡献度并不高[52]。

氨具有强烈的刺激性气味,同时相比于其他恶臭成分,氨有相对较高的嗅阈值(0.3×10-6~53×10-6)[53],所以在早期研究中氨一度被认为是表征畜禽恶臭的唯一指标[40,54],至今许多国家还将氨作为恶臭评价的主要指标[55]。但是,也有研究发现氨与恶臭之间并无显著正相关关系[56-57]。畜禽养殖过程中散发的挥发性胺主要有甲胺、乙胺、三甲胺、尸胺和腐胺[58]。挥发性胺占挥发性氮化合物的比例很小,目前关于挥发性胺排放浓度测定研究还很少[21]。

从已鉴定出的恶臭物质组成来看,恶臭物质具有不同的相对分子质量和分子结构,其沸点、蒸汽压、水溶性和嗅阈值等理化性质也不尽相同[59],因此各物质在大气中的反应特性与环境行为也不同,在恶臭中的贡献作用也存在差异。有研究[28]发现,猪粪便排放的含有OH自由基的恶臭物质中,68%在大气中的存在时间短于24 h。CAI等[59]从环境毒性角度,将畜禽排放的50种VOCs分为9类,其中有5类为危险大气污染物。此外,不同畜禽类型产生恶臭成分不同,猪粪排放的臭气物质以挥发性低级脂肪酸类为主[14],鸡粪的臭味成分以NH3、二甲基二硫和硫化氢为主[13,48],牛粪恶臭以低级脂肪酸为主[29]。

2 测定方法

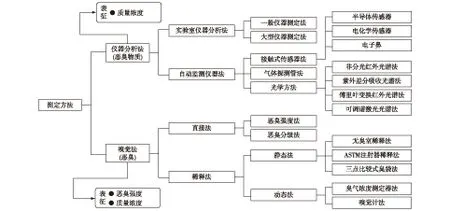

目前畜禽恶臭的测定方法大致分为2类[60]:一是定量测定恶臭物质组成的质量浓度,即仪器分析法;二是通过嗅觉感受表征待测场所的恶臭程度,即嗅觉法。畜禽恶臭测定方法见图1。

图1 畜禽恶臭主要测定方法Fig.1 Main methods for measurement of odor in animal production

2.1 仪器分析法

仪器分析法主要用于测定单一的恶臭物质,包括实验室仪器分析法和自动监测仪器法2类。实验室仪器分析法主要有气相色谱(GC)法、气相色谱质谱联用(GC-MS)法、高效液相色谱(HPLC)法、质子传递反应质谱仪(PTR-MS)[61]、分光光度法(紫外-可见分光光度法)等。实验室仪器分析法在测定恶臭物质种类和浓度方面发挥重要作用,针对恶臭物质的样品前处理和主要分析方法已有较为全面的综述[62],在此不再赘述。随着监测技术的发展,由于自动监测仪器法可以连续和自动监测畜禽恶臭物质的排放情况,在恶臭物质排放机理研究和恶臭管理方面发挥的作用越来越突出。自动监测仪器法主要包括气体探测管、接触式传感器法和光学方法[63]。表1列出了常用畜禽恶臭自动监测方法[64-89]。

表1常用畜禽恶臭自动监测方法

Table1Summaryofautomaticmonitoringandanalysismethodsforodorinanimalproduction

方法原理常测畜禽恶臭物质优点缺点参考文献气体探测管法利用被测气体成分附着在固体指示剂表面的显色反应来测定气体浓度NH3、H2S、CO2、二甲基硫醚使用方便检测精度较低[64-67]接触式传感器法 半导体传感器以半导体材料与气体接触后所产生的性质变化表征待测气体浓度与成分NH3、H2S操作简单,对气体具有一定的选择性,成本较低稳定性较差,受环境影响较大[68] 电化学传感器利用物质的氧化还原特性,通过测量待测物质与电极的电化学反应所释放的电流大小来测量气体浓度NH3、H2S具有良好的气体选择性,检测精度高不宜长时间使用,需要定期进行校准,且使用寿命短[69-72] 电子鼻主要由传感器阵列和智能算法组成,通过模式识别模拟人的嗅觉NH3、H2S、二甲基硫醚与人工嗅觉法相比,电子鼻更加稳定所用的传感器阵列数目多且复杂,成本昂贵[73-76]光学方法 非分光红外光谱利用化合物分子对红外光具有吸收作用、通过在红外光谱上形成吸收谱线来鉴别气体浓度NH3、H2S、CO、N2O、CH4方法成熟,检测精度较高信噪比较低,无法进行开放光程测定[77-79] 紫外差分吸收光谱利用空气中分子的紫外可见谱区的窄带特性来鉴别气体成分,并根据吸收强度反演气体浓度NH3、氮氧化物、碳氧化物开放光程测定,检测精度高,可以达到10-9数量级气体选择性不高[80-82] 傅里叶变换红外光谱利用干涉仪对光源发出的光进行调制,对接受到的干涉图样进行傅里叶变换,得到被待测气体吸收后的光谱图,经光谱图分析后得到待测气体浓度NH3、N2O、CO、CH4能够实现对畜禽生产场所区域气体分布的监测价格昂贵且体积巨大[83-86] 可调谐激光光谱激光器发出的经调制的单色光通过待测气体后由探测器接收,并提取其中的谐波信号,利用谐波信号的强度反演待测气体浓度NH3、N2O、CH4可获取气体空间分布情况,小型化,操作更简单,成本低每次只能进行1种气体成分的检测[87-89]

综合现有恶臭测定方法,目前还无理想的畜禽恶臭测定方法。仪器分析法在恶臭物质鉴定与某些关键恶臭物质的监测方面有一定优势。从环境管理角度来看,自动监测技术具有非常好的应用前景。近年来,电子鼻技术在不断的发展,随着系统简化和成本降低,会逐渐成为接触式传感器技术的一个主要发展方向。光学方法由于其成本较高,操作复杂,故很难推广。但是,开放光程技术在养殖场尺度上针对某些恶臭物质的高分辨时空测定还是有很好的应用前景。

2.2 嗅觉法

嗅觉法是利用人类的鼻子作为传感器,对具有气味的气体成分和浓度进行测量的方法,实质上是对待测场所恶臭的一个综合判断[7]。嗅觉法分为直接法和稀释法2种。

2.2.1直接法

直接法是一种定性方法,直接通过嗅觉感知的恶臭感觉对照恶臭强度分级判定恶臭程度,即用数字等级或语言描述表示臭气强弱。目前,国内外恶臭等级的分级方法很多,大致有3种分级方法:语言描述分级法、数值估量法、参考恶臭等级分级法[90]。其中,语言描述分级法较为常用,我国目前推荐的恶臭等级即为语言描述分级法,采用的是6级分类。数值估量法因误差较大而很少使用。参考恶臭等级分级法根据实际情况选择合适的恶臭等级参考范围。欧洲采用不同浓度的正丁醇水溶液或稀释气体恶臭程度表征恶臭等级,通过对样品进行嗅辨判定,得出相应的恶臭等级[91]。由于在高恶臭强度时很难区分其等级,如果要将此分级方法运用于畜禽养殖场这种特殊环境,还需要对其分级描述进行改善[92]。

2.2.2稀释法

稀释法是一种相对定量方法,是指用无臭空气对某一恶臭样品进行连续稀释,直至达到无臭状态。根据稀释方法分为静态稀释法和动态稀释法。静态稀释法主要包括无臭室法、注射器法和三点比较式臭袋法。无臭室法测试精度高,但设备造价很高且不便于现场测定。注射器法操作简便,但精度不高,且注射器体积有限,难以配制出高稀释倍数的试样。三点比较式臭袋法是目前最为常用的分析方法。这种方法的测量精度相对较高,测量的重复性和再现性好,嗅辨员个体之间的误差小。我国的GB/T 14675—93《空气质量 恶臭的测定 三点比较式臭袋法》就是基于三点比较式臭袋法制定的。汪开英等[93]运用静态稀释法研究了不同类型地面结构的育肥猪舍恶臭浓度与恶臭排放系数。

动态稀释法是使用仪器设备对臭气样品进行连续稀释后供人嗅辨的方法。动态嗅觉仪使用微电脑控制自动完成样品定比稀释,提高了稀释效率,同时提高了稀释精度和重复精度[94]。欧洲标准CSN EN 13725对于动态嗅觉仪的使用进行了详细规定,澳大利亚、新西兰和美国都依据此标准形成本国的标准[7,90]。国外关于畜禽养殖恶臭的研究多基于动态嗅觉计技术开展[32, 95-96]。

但是,嗅觉法同样存在很多不足。嗅觉法极易受到嗅辨员自身因素的影响,测量结果的精度较低[61]。该方法需要采样并与嗅觉专家小组配合,导致测定成本较高[97]。嗅觉法只能进行间断测定,且通常在实验室内完成,测量并不具备实时性,无法实现对畜禽恶臭的实时监测[98]。此外,该方法在采样、保存样品以及稀释过程中会出现恶臭物质损耗的现象[99-101],导致测定精度降低。而许多情况下,畜禽养殖环境中恶臭物质浓度很低,因而限制了该方法的运用。

3 畜禽恶臭表征与评估

3.1 恶臭表征

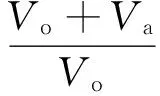

所谓恶臭浓度(odor concentration,OC,Co)是刚刚稀释到无臭时所需的稀释倍数,并非恶臭的物质浓度[7]。Co无量纲,通常也写作恶臭单位(odor unit,OU)。欧洲标准中采用每立方米空气中恶臭的单位数(OU·m-3)表示Co。实质上,Co是样品稀释到阈值浓度的稀释倍数,故可以根据某一具体恶臭物质的实测浓度与阈值浓度的比值计算Co值。Co计算公式为

(1)

(2)

式(1)~(2)中,Co为恶臭浓度,OU·m-3;Vo为恶臭样品体积,L;Va为无臭空气体积,L;ρo为某恶臭物质实测浓度,μg·m-3;ρd为某恶臭物质阈值浓度,μg·m-3。为了便于比较,在欧洲标准CSN EN 13725中,规定1 OU·m-3相当于123 μg正丁醇在1 m3无味气体中产生的气味浓度,即相当于0.040 μL·L-1正丁醇的嗅阈值浓度[7]。

在测量畜禽恶臭排放时,通常将Co与通风速率(Q,m3·s-1)相乘得到排放系数(E,OU·s-1)[102]。

由于恶臭浓度数值有时很大,不易与恶臭给人的感觉联系起来,目前也常用恶臭强度(odor intensity,OI,Io)表示恶臭污染的程度。Io可用韦伯-费希纳公式(Weber-Fechner公式)来表示:

Io=10lgCo。

(3)

但用式(3)计算常出现较大误差,如Co=1时,Io=0,显然与事实不符。因此,式(3)应修正为

Io=10algCo+b。

(4)

式(4)中,a、b为常数。

3.2 恶臭评估

恶臭是通过嗅觉产生的一种心理感受,由于畜禽恶臭物质成分复杂,且各种气体散发出的臭味相互干扰而并非简单叠加,这给恶臭的评估带来了难度。因此,到目前为止,尚没有一种十分理想的恶臭评估方法[98]。有学者通过仪器测定某种(如硫化氢[41])或某一类恶臭物质(如VAFs[44])的释放速率和环境中的浓度,以此来进行恶臭评估。因为恶臭通常都是由多种恶臭物质混合形成的,仅仅依靠对其中几种恶臭物质的测定无法衡量其整体上给人带来厌恶感的程度[55]。嗅觉法可以直接表征对恶臭的心理感受程度,亦可以通过恶臭浓度和恶臭指数半定量地表征畜禽恶臭。与许多国家一样,我国也采用嗅觉测定法来判别恶臭的综合污染程度[55,93]。可见,嗅觉法是目前主流的恶臭评估方法。

但是,如2.2节所述该方法也存在不可控制的测定误差。可见,目前畜禽恶臭的评估面临2个方面的挑战:一方面,全部测定恶臭物质存在技术和成本的制约,另一方面,主观表征存在不可避免的误差。面对畜禽恶臭评估存在的挑战,现在有学者在致力于构建恶臭具体成分物质的质量浓度与OC或OI之间的定量关系,即将测定畜禽恶臭物质浓度转变为测定恶臭浓度或恶臭强度[98]。

在相关研究中,借鉴食品学中关于恶臭活性值(odor activity value,OAV,VOA)的方法对畜禽恶臭进行评估成为一个研究热点[103]。所谓的OAV即某种物质实测浓度与嗅阈值的比值,可以采用式(1)~(2)进行计算;若是多种恶臭物质,则将各测定物质的OAV累加得到恶臭活性值之和(sum of the odor activity value,SOAV)[104]。从概念上来理解,OAV值越大的物质对恶臭的贡献就越大,通过比较各物质的OAV值,可以判别畜禽恶臭的主要贡献物质[105]。BLAZY等[106]通过测定生猪屠宰场猪粪中的66种恶臭物质浓度来计算各恶臭物质的OAV,发现三甲胺、硫化氢和甲硫醇是产生恶臭的主要物质。PARKER等[107]通过计算猪场和牛场20种恶臭物质的OAV,发现硫化氢、对甲酚、异戊酸、氨气和二乙基二硫醚为猪场恶臭的主要贡献物,而硫化氢、对甲酚、丁酸和异戊酸为牛场恶臭的主要贡献物。通过拟合OAV和OC的关系,发现运用SOAV拟合的结果会低估恶臭浓度2~3倍[107],而VOA,max可以更好地确定化学组成与OC的关系[106]。但是,OAV法还是需要通过嗅觉法来测定OC值,而无法避免人为主观因素的影响。WU等[108]对该方法做了改进,无需通过嗅觉法来同步测定OC值,客观地实现恶臭物质浓度向OC或OI的转变,取得了很好的拟合效果。

4 总结与展望

自20世纪60年代以来,关于畜禽养殖中恶臭物质的鉴定已经取得了长足进步。欧美已经有了大量关于畜禽恶臭的研究报道,亚洲的日本和韩国的相关研究也陆续开展。我国开展畜禽恶臭方面的研究起步较晚,多见于20世纪90年代。

随着测试技术的发展,对畜禽恶臭物质成分的鉴定已经有了相当的积累,为进一步进行恶臭评估、恶臭管控提供了一定理论支撑。总的来看,学者对恶臭物质的鉴定投入了很大精力,发现了越来越多的畜禽恶臭物质组成成分,发现的恶臭物质种类逐渐增加。研究更多关注于测定各恶臭源释放出的恶臭物质成分和种类,对于各恶臭物质在畜禽环境中的相互作用过程、各物质在恶臭中的贡献作用及关键恶臭物质的识别还显得不足。同时,对于关键恶臭物质的环境行为与影响机制研究,多是基于温室气体的研究需要开展的。从畜禽类型来看,对猪场恶臭的研究明显多于牛场和鸡场等其他养殖类型。从恶臭来源来看,多数研究集中于畜禽场所的环境空气,对于粪便储存、处理设施上方空气及空气中的悬浮颗粒物研究还相对较少。此外,目前多单独研究禽舍、粪便处理设施或还田过程,缺少针对整个养殖场各恶臭排污节点的整体研究,也无基于养殖场尺度的恶臭物质组成特征的系统研究。

实现连续、高精度恶臭监测是目前恶臭测定技术发展的主要方向。从环境管理角度来看,嗅觉法在综合评判恶臭污染程度方面具有一定优势。嗅觉仪与分析仪器结合使用是嗅觉法发展的一个主要趋势。在测定恶臭物质的基础上,对恶臭进行科学评估是进行畜禽恶臭控制与管理的基础。但是,目前畜禽恶臭的评估方法多源于食品学恶臭的相关评估技术方法。为了统一畜禽恶臭管理标准,同时能在实际中尽量减少恶臭评估工作量,在目前的技术条件下,将测定畜禽恶臭物质浓度客观地转变为测定恶臭强度是畜禽恶臭评估中亟待解决的关键问题。

[1] HOODA P S,EDWARDS A C,ANDERSON H A,etal.A Review of Water Quality Concerns in Livestock Farming Areas[J].Science of the Total Environment,2000,250(1/2/3):143-167.

[3] KAY D,ANTHONY S,CROWTHER J,etal.Microbial Water Pollution:A Screening Tool for Initial Catchment-Scale Assessment and Source Apportionment[J].Science of the Total Environment,2010,408(23):5649-5656.

[4] SCHIFFMAN S S,WILLIAMS C M.Science of Odor as a Potential Health Issue[J].Journal of Environmental Quality,2005,34(1):129-138.

[5] NICELL J A.Assessment and Regulation of Odour Impacts[J].Atmospheric Environment,2009,43(1):196-206.

[6] SUN C,WU H J.Assessment of Pollution From Livestock and Poultry Breeding in China[J].International Journal of Environmental Studies,2013,70(2):232-240.

[7] VAN HARREVELD A P,HEERES P,HARSSEMA H.A Review of 20 Years of Standardization of Odor Concentration Measurement by Dynamic Olfactometry in Europe[J].Journal of the Air and Waste Management Association,1999,49(6):705-715.

[8] BITTMAN S,MASSÉ D I,PATTEY E,etal.Effects of Agriculture on Air Quality in Canada[M]∥TAYLOR E,MCMILLAN A.Air Quality Management:Canadian Perspectives on a Global Issue.Dordrecht,the Netherlands:Springer,2014:237-259.

[9] RAPPERT S,MÜLLER R.Odor Compounds in Waste Gas Emissions From Agricultural Operations and Food Industries[J].Waste Management,2005,25(9):887-907.

[10] SHUSTERMAN D.Critical Review:The Health Significance of Environmental Odor Pollution[J].Archives of Environmental Health:An International Journal,1992,47(1):76-87.

[11] 魏波.集约化猪场的恶臭排放与扩散研究[D].杭州:浙江大学,2011.[WEI Bo.Study on Odor Emission and Dispersion Form Concentrated Pig Farm[D].Hangzhou:Zhejiang University,2011.]

[13] O′NEILL D H,PHILLIPS V R.A Review of the Control of Odour Nuisance From Livestock Buildings,Part 3:Properties of the Odorous Substances Which Have Been Identified in Livestock Wastes or in the Air Around Them[J].Journal of Agricultural Engineering Research,1992,53:23-50.

[14] PARKER D B,GILLEY J,WOODBURY B,etal.Odorous VOC Emission Following Land Application of Swine Manure Slurry[J].Atmospheric Environment,2013,66:91-100.

[15] WESTERMAN P W,ZHANG R H.Aeration of Livestock Manure Slurry and Lagoon Liquid for Odor Control:A Review[J].Applied Engineering in Agriculture,1997,13(2):245-249.

[16] MACKIE R I,STROOT P G,VAREL V H.Biochemical Identification and Biological Origin of Key Odor Components in Livestock Waste[J].Journal of Animal Science,1998,76(5):1331-1342.

[17] NAHM K H.Efficient Feed Nutrient Utilization to Reduce Pollutants in Poultry and Swine Manure[J].Critical Reviews in Environmental Science and Technology,2002,32(1):1-16.

[18] 闫志英,许力山,李志东,等.畜禽粪便恶臭控制研究及应用进展[J].应用与环境生物学报,2014,20(2):322-327.[YAN Zhi-ying,XU Li-shan,LI Zhi-dong,etal.Progress in Research and Application of Controlling Odor From Livestock Manure[J].Chinese Journal of Applied and Environmental Biology,2014,20(2):322-327.]

[19] MACKIE R I,STROOT P G,VAREL V H.Biochemical Identification and Biological Origin of Key Odor Components in Livestock Waste[J].Journal of Animal Science,1998,76(5):1331-1342.

[20] SUTTON A L,KEPHART K B,VERSTEGEN M W,etal.Potential for Reduction of Odorous Compounds in Swine Manure Through Diet Modification[J].Journal of Animal Science,1999,77(2):430-439.

[21] LE P D,AARNINK A J,OGINK N W,etal.Odour From Animal Production Facilities:Its Relationship to Diet[J].Nutrition Research Reviews,2005,18(1):3-30.

[22] MROZ Z,MOESER A J,VREMAN K,etal.Effects of Dietary Carbohydrates and Buffering Capacity on Nutrient Digestibility and Manure Characteristics in Finishing Pigs[J].Journal of Animal Science,2000,78(12):3096-3106.

[23] SPOELSTRA S F.Simple Phenols and Indoles in Anaerobically Stored Piggery Wastes[J].Journal of the Science of Food and Agriculture,1977,28(5):415-423.

[24] KIM K Y,KO H J,KIM H T,etal.Sulfuric Odorous Compounds Emitted From Pig-Feeding Operations[J].Atmospheric Environment,2007,41(23):4811-4818.

[25] RASMUSSEN H S,HOLTUG K,MORTENSEN P B.Degradation of Amino Acids to Short-Chain Fatty Acids in Humans:AninVitroStudy[J].Scandinavian Journal of Gastroenterology,1988,23(2):178-182.

[26] DAY D L,HANSEN E L,ANDERSON S.Gases and Odors in Confinement Swine Buildings[J].Transactions of the ASAE,1965,8(1):118-121.

[27] FILIPY J,RUMBURG B,MOUNT G,etal.Identification and Quantification of Volatile Organic Compounds From a Dairy[J].Atmospheric Environment,2006,40(8):1480-1494.

[28] LO Y C M,KOZIEL J A,CAI L S,etal.Simultaneous Chemical and Sensory Characterization of Volatile Organic Compounds and Semi-Volatile Organic Compounds Emitted From Swine Manure Using Solid Phase Microextraction and Multidimensional Gas Chromatography-Mass Spectrometry-Olfactometry[J].Journal of Environmental Quality,2008,37(2):521-534.

[29] MÅRTENSSON L,MAGNUSSON M,SHEN Y,etal.Air Concentrations of Volatile Organic Acids in Confined Animal Buildings-Determination With Ion Chromatography[J].Agriculture,Ecosystems & Environment,1999,75(1/2):101-108.

[30] RITTER W F.Odour Control of Livestock Wastes:State-of-the-Art in North America[J].Journal of Agricultural Engineering Research,1989,42(1):51-62.

[31] SCHIFFMAN S S,BENNETT J L,RAYMER J H.Quantification of Odors and Odorants From Swine Operations in North Carolina[J].Agricultural and Forest Meteorology,2001,108(3):213-240.

[32] DUNLOP M W,BLACKALL P J,STUETZ R M.Odour Emissions From Poultry Litter:A Review Litter Properties,Odour Formation and Odorant Emissions From Porous Materials[J].Journal of Environmental Management,2016,177:306-319.

[33] THU K M.Public Health Concerns for Neighbors of Large-Scale Swine Production Operations[J].Journal of Agricultural Safety and Health,2002,8(2):175-184.

[34] NI J Q,ROBARGE W P,XIAO C H,etal.Volatile Organic Compounds at Swine Facilities:A Critical Review[J].Chemosphere,2012,89(7):769-788.

[35] BLUNDEN J,ANEJA V P,LONNEMAN W A.Characterization of Non-Methane Volatile Organic Compounds at Swine Facilities in Eastern North Carolina[J].Atmospheric Environment,2005,39(36):6707-6718.

[36] CIGANEK M,NECA J.Chemical Characterization of Volatile Organic Compounds on Animal Farms[J].Veterinarni Medicina,2008,53(12):641-651.

[37] SCHAEFFER J.Sampling,Characterisation and Analysis of Malodours[J].Agriculture and Environment,1977,3(2/3):121-127.

[38] KIM K Y,JONG KO H,TAE KIM H,etal.Quantification of Ammonia and Hydrogen Sulfide Emitted From Pig Buildings in Korea[J].Journal of Environmental Management,2008,88(2):195-202.

[39] SUN G,GUO H Q,PETERSON J,etal.Diurnal Odor,Ammonia,Hydrogen Sulfide,and Carbon Dioxide Emission Profiles of Confined Swine Grower/Finisher Rooms[J].Journal of the Air & Waste Management Association,2008,58(11):1434-1448.

[40] YAO H Q,CHOI H L,ZHU K,etal.Key Volatile Organic Compounds Emitted From Swine Nursery House[J].Atmospheric Environment,2011,45(15):2577-2584.

[41] FEILBERG A,LIU D Z,ADAMSEN A P S,etal.Odorant Emissions From Intensive Pig Production Measured by Online Proton-Transfer-Reaction Mass Spectrometry[J].Environmental Science & Technology,2010,44(15):5894-5900.

[42] ZHU J.A Review of Microbiology in Swine Manure Odor Control[J].Agriculture,Ecosystems & Environment,2000,78(2):93-106.

[43] ZAHN J A,HATFIELD J L,DO Y S,etal.Characterization of Volatile Organic Emissions and Wastes From a Swine Production Facility[J].Journal of Environmental Quality,1997,26(6):1687-1696.

[44] ZHU J,RISKOWSKI G L,TORREMORELL M.Volatile Fatty Acids as Odor Indicators in Swine Manure:A Critical Review[J].Transactions of the American Society of Agricultural Engineers,1999,42(1):175-182.

[45] SPOELSTRA S F.Origin of Objectionable Odorous Components in Piggery Wastes and the Possibility of Applying Indicator Components for Studying Odour Development[J].Agriculture and Environment,1980,5(3):241-260.

[46] GAY S W,SCHMIDT D R,CLANTON C J,etal.Odor,Total Reduced Sulfur,and Ammonia Emissions From Animal Housing Facilities and Manure Storage Units in Minnesota[J].Applied Engineering in Agriculture,2003,19(3):347-360.

[47] O′NEILL D H,STEWART I W,PHILLIPS V R.A Review of the Control of Odour Nuisance From Livestock Buildings,Part 2:The Costs of Odour Abatement Systems as Predicted From Ventilation Requirements[J].Journal of Agricultural Engineering Research,1992,51:157-165.

[48] LIU Z F,POWERS W,MUKHTAR S.A Review of Practices and Technologies for Odor Control in Swine Production Facilities[J].Applied Engineering in Agriculture,2014,30(3):477-492.

[49] BANWART W L,BREMNER J M.Identification of Sulfur Gases Evolved From Animal Manures[J].Journal of Environmental Quality,1975,4(3):363-366.

[50] HOBBS P J,MISSELBROOK T H,PAIN B F.Characterisation of Odorous Compounds and Emissions From Slurries Produced From Weaner Pigs Fed Dry Feed and Liquid Diets[J].Journal of the Science of Food and Agriculture,1997,73(4):437-445.

[51] CHEN A,LIAO P H,LO K V.Headspace Analysis of Malodorous Compounds From Swine Wastewater Under Aerobic Treatment[J].Bioresource Technology,1994,49(1):83-87.

[52] SPIEHS M J,VAREL V H.Nutrient Excretion and Odorant Production in Manure From Cattle Fed Corn Wet Distillers Grains With Solubles[J].Journal of Animal Science,2009,87(9):2977-2984.

[53] LACEY R E,MUKHTAR S,CAREY J B,etal.A Review of Literature Concerning Odors,Ammonia,and Dust From Broiler Production Facilities,1:Odor Concentrations and Emissions[J].The Journal of Applied Poultry Research,2004,13(3):500-508.

[54] ZHANG R,YAMAMOTO T,BUNDY D S.Control of Ammonia and Odors in Animal Houses by a Ferroelectric Plasma Reactor[J].IEEE Transactions on Industry Applications,1996,32(1):113-117.

[55] 郑芳.规模化畜禽养殖场恶臭污染物扩散规律及其防护距离研究[D].北京:中国农业科学院,2010.[ZHENG Fang.Downwind Diffusion Laws and Separation Distance of Odorous Pollutants From Large-Scale Livestock and Poultry Farms[J].Beijing:Chinese Academy of Agricultural Sciences,2010.]

[56] HAYES E T,CURRAN T P,DODD V A.Odour and Ammonia Emissions From Intensive Poultry Units in Ireland[J].Bioresource Technology,2006,97(7):933-939.

[57] VERDOES N,OGINK N W M.Odour Emissions From Pig Houses With Low Ammonia Emission[C]∥Proceedings of the International Symposium on Ammonia and Odour Emissions From Animal Production Facilities,October 6-10,1997,Vinkeloord.Rosmalen,the Netherlands:[s. n.],1997:317-325.

[58] CHEN L,HOFF S J.Mitigating Odors From Agricultural Facilities:A Review of Literature Concerning Biofilters[J].Applied Engineering in Agriculture,2009,25(5):751-766.

[59] CAI L S,KOZIEL J A,LO Y C,etal.Characterization of Volatile Organic Compounds and Odorants Associated With Swine Barn Particulate Matter Using Solid-Phase Microextraction and Gas Chromatography-Mass Spectrometry-Olfactometry[J].Journal of Chromatography A,2006,1102(1/2):60-72.

[60] SCHLEGELMILCH M,STREESE J,STEGMANN R.Odour Management and Treatment Technologies:An Overview[J].Waste Management,2005,25(9):928-939.

[61] HANSEN M J,JONASSEN K E N,LØKKE M M,etal.Multivariate Prediction of Odor From Pig Production Based onIn-SituMeasurement of Odorants[J].Atmospheric Environment,2016,135:50-58.

[62] 李利荣,王艳丽,崔连喜,等.恶臭成分的仪器分析方法研究进展[J].分析测试学报,2015,34(6):724-733.[LI Li-rong,WANG Yan-li,CUI Lian-xi,etal.Progess on Instrumental Analysis Methods for Malodorous Substances[J].Journal of Instrumental Analysis,2015,34(6):724-733.]

[63] 张石锐.畜禽生产环境中主要有害气体监测方法研究[D].上海:上海交通大学,2014.[ZHANG Shi-rui.Monitoring Methods Research for Harmful Gases in Livestock Production Environment[D].Shanghai:Shanghai Jiao Tong University,2014.]

[64] JACOBSON L D,JANNI K A,ARELLANO P E,etal.Winter Swine Ventilation Evaluation Using Air Quality Criteria[J].Paper-American Society of Agricultural Engineers (USA),1992,56(1):103-119.

[65] MELSE R W,WERF A W V D.Biofiltration for Mitigation of Methane Emission From Animal Husbandry[J].Environmental Science & Technology,2005,39(14):5460-5468.

[66] STOWELL R R,KEENER H,ELWELL D,etal.High-RiseTMHog Facility[C]∥American Society of Agricultural Engineers Swine Housing.Proceedings of the First International Conference,October 9-11,2000,Des Moines,Iowa.St.Joseph,USA:ASAE,2000:273-282.

[67] WORLEY J W,DAS K C.Swine Manure Solids Separation and Composting Using Alum[J].Applied Engineering in Agriculture,2000,16(5):555-561.

[68] KAWASHIMA S,YONEMURA S.Measuring Ammonia Concentration Over a Grassland Near Livestock Facilities Using a Semiconductor Ammonia Sensor[J].Atmospheric Environment,2001,35(22):3831-3839.

[69] PREDICALA B Z,CORTUS E L,FENGLER R,etal.Assessing the Performance of Hydrogen Sulfide Monitoring Devices and a Water Spray Method to Reduce Worker Exposure in Swine Buildings[C].ASAE Annual Meeting,Portland.[s. l.]:[s. n.],2006.

[70] SAHA C K,ZHANG G Q,KAI P,etal.Effects of a Partial Pit Ventilation System on Indoor Air Quality and Ammonia Emission From a Fattening Pig Room[J].Biosystems Engineering,2010,105(3):279-287.

[71] ZHANG G,STRØM J S,LI B,etal.Emission of Ammonia and Other Contaminant Gases From Naturally Ventilated Dairy Cattle Buildings[J].Biosystems Engineering,2005,92(3):355-364.

[72] 陈长伦,何建波,刘伟,等.电化学式气体传感器的研究进展[J].传感器世界,2004,10(4):11-15.[CHEN Chang-lun,HE Jian-bo,LIU Wei,etal.The Research Advance of Electrochemical Gas Sensors[J].Sensor World,2004,10(4):11-15.]

[73] 高大启,杨根兴.电子鼻技术新进展及其应用前景[J].传感器与微系统,2001,20(9):1-5.[GAO Da-qi,YANG Gen-xing.Recent Developments and Application Prospects of Electronic Noses[J].Journal of Transducer and Microsystem Technologies,2001,20(9):1-5.]

[74] GUTIERREZ-OSUNA R,SCHIFFMAN S S,NAGLE H T.Correlaiton of Sensory Analysis With Electronic Nose Data for Swine Odor Remediation Assesment[C]∥Proceedings of the 3rd European Congress on Odours,Metrology and Electronic Noses,June 19-21,2001,Paris,France.[s. l.]:[s. n.],2001.

[75] PAN L L,YANG S X.A New Intelligent Electronic Nose System for Measuring and Analysing Livestock and Poultry Farm Odours[J].Environmental Monitoring and Assessment,2007,135(1):399-408.

[76] PAN L L,YANG S X.A New Electronic Nose for Downwind Livestock Farm Odour Measurement[C]∥Proceedings of the 2006 IEEE International Conference on Networking,Sensing and Control,April 23-25,2006,Ft.Laudeidale,Florida.New York:IEEE,2006:410-415.

[77] PHILLIPS V R,LEE D S,SCHOLTENS R,etal.SE:Structures and Environment:A Review of Methods for Measuring Emission Rates of Ammonia From Livestock Buildings and Slurry or Manure Stores,Part 2:Monitoring Flux Rates,Concentrations and Airflow Rates[J].Journal of Agricultural Engineering Research,2001,78(1):1-14.

[78] BAJWA S G,GADIRAJU H.Laboratory Evaluation of Clinoptilolite for Ammonia Emission Mitigation From Broiler Litter[C]∥Proceedings of the International Symposium on Air Quality and Waste Management for Agriculture,September 16-19,2007,Broomfield,Colorado.St. Joseph:ASABE,2007.

[79] MARTINEZ J,GUIZIOU F,PEU P,etal.Influence of Treatment Techniques for Pig Slurry on Methane Emissions During Subsequent Storage[J].Biosystems Engineering,2003,85(3):347-354.

[80] 刘文清,崔志成,董凤忠.环境污染监测的光学和光谱学技术[J].大气与环境光学学报,2002,15(5):1-12.[LIU Wen-qing,CUI Zhi-cheng,DONG Feng-zhong.Optical and Spectroscopic Techniques for Environmental Pollution[J].Optoelectronic Technology & Information,2002,15(5):1-12.]

[81] RUMBURG B,MOUNT G H,YONGE D,etal.Measurements and Modeling of Atmospheric Flux of Ammonia From an Anaerobic Dairy Waste Lagoon[J].Atmospheric Environment,2008,42(14):3380-3393.

[82] SECREST C D.Field Measurement of Air Pollutants Near Swine Confined-Animal Feeding Operations Using UV DOAS and FTIR[C]∥The International Society for Optical Engineering.Water,Ground,and Air Pollution Monitoring and Remediation,November 5,2000,Boston,Massachusetts.Bellingham,USA:SPIE,2001:98-104.

[83] CHILDERS J W,THOMPSON J E L,HARRIS D B,etal.Multi-Pollutant Concentration Measurements Around a Concentrated Swine Production Facility Using Open-Path FTIR Spectrometry[J].Atmospheric Environment,2001,35(11):1923-1936.

[84] SUN J L,BAI M,SHEN J L,etal.Effects of Lignite Application on Ammonia and Nitrous Oxide Emissions From Cattle Pens[J].Science of the Total Environment,2016,565:148-154.

[85] TODD L A,RAMANATHAN M,MOTTUS K,etal.Measuring Chemical Emissions Using Open-Path Fourier Transform Infrared (OP-FTIR) Spectroscopy and Computer-Assisted Tomography[J].Atmospheric Environment,2001,35(11):1937-1947.

[86] ZHANG S R,DONG D M,ZHENG W G,etal.Optical Methods for Monitoring Harmful Gas in Animal Facilities[J].Optical Engineering,2013,53(6):061602.

[87] HENSEN A,GROOT T T,WCM VAN DEN B,etal.Dairy Farm CH4and N2O Emissions,From One Square Metre to the Full Farm Scale[J].Agriculture Ecosystems & Environment,2006,112(2/3):146-152.

[88] VANOTTI M B,SZÖGI A A.Enhanced Animal Productivity and Health With Improved Manure Management in 2nd Generation Environmentally Superior Technology in North Carolina,I:Water Quality[C]∥American Society of Agricultural and Biological Engineers.Livestock Environment Ⅷ,August 31-September 4,2008,Iguassu Falls,Brazil.St. Joseph,USA:ASABE,2008.

[89] 郑龙江,李鹏,秦瑞峰,等.气体浓度检测光学技术的研究现状和发展趋势[J].激光与光电子学进展,2008,45(8):24-32.[ZHENG Long-jiang,LI Peng,QIN Rui-feng,etal.Research Situation and Developing Tendengcy for Optical Measurement Technology of Gas Density[J].Laser & Optoelectronics Progress,2008,45(8):24-32.]

[90] JIANG J,COFFEY P,TOOHEY B.Improvement of Odor Intensity Measurement Using Dynamic Olfactometry[J].Journal of the Air & Waste Management Association,2006,56(5):675-683.

[91] A Review of the Science and Technology of Odor Measurement[R].Lake Elmo:St. Croix Sensory,Inc.,2005.

[92] 汪开英,魏波,罗皓杰.畜禽规模养殖场的恶臭检测与评估方法[J].中国畜牧杂志,2009,45(24):24-27.[WANG Kai-ying,WEI Bo,LUO Hao-jie.Odor Detection and Evaluation Methods for Livestock Farms[J].Chinese Journal of Animal Science,2009,45(24):24-27.]

[93] 汪开英,魏波,应洪仓,等.不同地面结构育肥猪舍的恶臭排放影响因素分析[J].农业机械学报,2011,42(9):186-190,161.[WANG Kai-ying,WEI Bo,YING Hong-cang.Odor Emissions and Impact Factors of Fattening Pig Rooms With Different Floor Systems[J].Transactions of the Chinese Society of Agricultural Machinery,2011,42(9):186-190,161.]

[94] CAPELLI L,SIRONI S,DEL ROSSO R.Odor Sampling:Techniques and Strategies for the Estimation of Odor Emission Rates From Different Source Types[J].Sensors,2013,13(1):938-955.

[95] AKDENIZ N,JACOBSON L D,HETCHLER B P,etal.Odor and Odorous Chemical Emissions From Animal Buildings,Part 2:Odor Emissions[J].Transactions of the American Society of Agricultural and Biological Engineers,2012,55(6):2357-2368.

[96] CHEN Y,BUNDY D S,HOFF S J.Using Olfactometry to Measure Intensity and Threshold Dilution Ratio for Evaluating Swine Odor[J].Journal of the Air & Waste Management Association,1999,49(7):847-853.

[97] HUDSON N,AYOKO G A.Odour Sampling 1:Physical Chemistry Considerations[J].Bioresource Technology,2008,99(10):3982-3992.

[98] LAOR Y,PARKER D B,PAGÉ T.Measurement,Prediction,and Monitoring of Odors in the Environment:A Critical Review[J].Reviews in Chemical Engineering,2014,30(2):139-166.

[99] HANSEN M J,ADAMSEN A P S,FEILBERG A.Recovery of Odorants From an Olfactometer Measured by Proton-Transfer-Reaction Mass Spectrometry[J].Sensors,2013,13(6):7860-7871.

[100]KOZIEL J A,SPINHIRNE J P,LLOYD J D,etal.Evaluation of Sample Recovery of Malodorous Livestock Gases From Air Sampling Bags,Solid-Phase Microextraction Fibers,Tenax TA Sorbent Tubes,and Sampling Canisters[J].Journal of the Air & Waste Management Association,2005,55(8):1147-1157.

[101]PARKER D B,PERSCHBACHER-BUSER Z L,COLE N A,etal.Recovery of Agricultural Odors and Odorous Compounds From Polyvinyl Fluoride Film Bags[J].Sensors,2010,10(9):8536-8552.

[102]LIM T T,HEBER A,NI J Q,etal.Effects of Manure Removal Strategies on Odor and Gas Emissions From Swine Finishing[J].Transactions of the ASAE,2002,47(6):2041-2050.

[103]ACREE T E,BARNARD J,CUNNINGHAM D G.A Procedure for the Sensory Analysis of Gas Chromatographic Effluents[J].Food Chemistry,1984,14(4):273-286.

[104]TRABUE S L,ANHALT J C,ZAHN J A.Bias of Tedlar Bags in the Measurement of Agricultural Odorants[J].Journal of Environmental Quality,2006,35(5):1668-1677.

[105]TRABUE S,KERR B,BEARSON B,etal.Swine Odor Analyzed by Odor Panels and Chemical Techniques[J].Journal of Environmental Quality,2011,40(5):1510-1520.

[106]BLAZY V,DE GUARDIA A,BENOIST J C,etal.Correlation of Chemical Composition and Odor Concentration for Emissions From Pig Slaughterhouse Sludge Composting and Storage[J].Chemical Engineering Journal,2015,276:398-409.

[107]PARKER D B,KOZIEL J A,CAI L,etal.Odor and Odorous Chemical Emissions From Animal Buildings,Part 6:Odor Activity Value[J].Transactions of the American Society of Agricultural and Biological Engineers,2012,55(6):2357-2368.

[108]WU C D,LIU J M,ZHAO P,etal.Conversion of the Chemical Concentration of Odorous Mixtures Into Odour Concentration and Odour Intensity:A Comparison of Methods[J].Atmospheric Environment,2016,127:283-292.

AReviewofResearchesonComposition,MeasurementandAssessmentofOdorantsinLivestockandPoultryBreeding.

LIU Bo1, WANG Wen-lin2, LIU Xiao1, FAN Zhou2, YANG Wan-jing1, XU Qiao1, GUAN Lei1, ZENG Jie-liang1, LI Wen-jing2, HE Fei2

(1.School of Geography Science, Nantong University, Nantong 226007, China; 2.Nanjing Institute of Environmental Sciences, Ministry of Environmental Protection, Nanjing 210042, China)

With rapid development of the livestock and poultry breeding industry in China, odor from the industry has become a main environment issue that not only arouses complaints from nearby residents and disputes between the residents and the industry, but also seriously restrains sustainable development of the industry. It is, therefore, essential to determine sources and composition of the odor and sum up techniques or methods to determine, characterize and evaluate the odor, which is of great significance to scientific assessment of hazard of the odor and designing of control measures. In this review, compositions and characteristics of the odorants from the industry were collated, main techniques to measure odor compared for advantage and disadvantage, and chief methods to characterize and assess odor discussed. Volatile fatty acids (VFAs), sulfocompound, aromatics (phenols and benzpyrole) as well as ammonia and volatile amine are the key substances in odor from the industry. Methods to determine the odor can be roughly sorted into two types, instrumental and olfactory, of which each has its own advantages and disadvantages. Based on analysis of compositions of the odorants available, key components of the odor from the industry are identified, and continuous in-situ monitoring of odor will be the focus for researches in future. Moreover, as the composition of odor is very complicated, establishment of a reasonable relationship model for mutual conversion between odor concentration and odor intensity may be a workable approach to quantitative evaluation of odor.

livestock and poultry breeding; odorant; measurement technique; assessment method

2017-02-04

环保公益性行业科研专项(201509038); 环境保护部部门预算项目(2110107); 江苏省自然科学基金(BK20131201); 江苏省大学生创新训练计划(201610304038Z,2016114); 中央级公益性科研院所基本科研业务专项

① 通信作者E-mail: 175729057@qq.com

X512

A

1673-4831(2017)10-0872-10

10.11934/j.issn.1673-4831.2017.10.002

刘波(1976—),男,江苏连云港人,副教授,博士,从事环境面源污染过程与防治研究。E-mail: lb@ntu.edu.cn

责任编辑: 李祥敏)