CFRP筋拉伸强度预测模型评价及应用

2017-10-17杨勇新岳清瑞

王 彬,杨勇新,岳清瑞,曾 滨

(中冶建筑研究总院有限公司,北京 100088)

CFRP筋拉伸强度预测模型评价及应用

王 彬,杨勇新,岳清瑞,曾 滨

(中冶建筑研究总院有限公司,北京 100088)

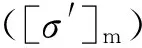

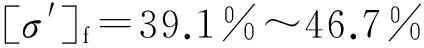

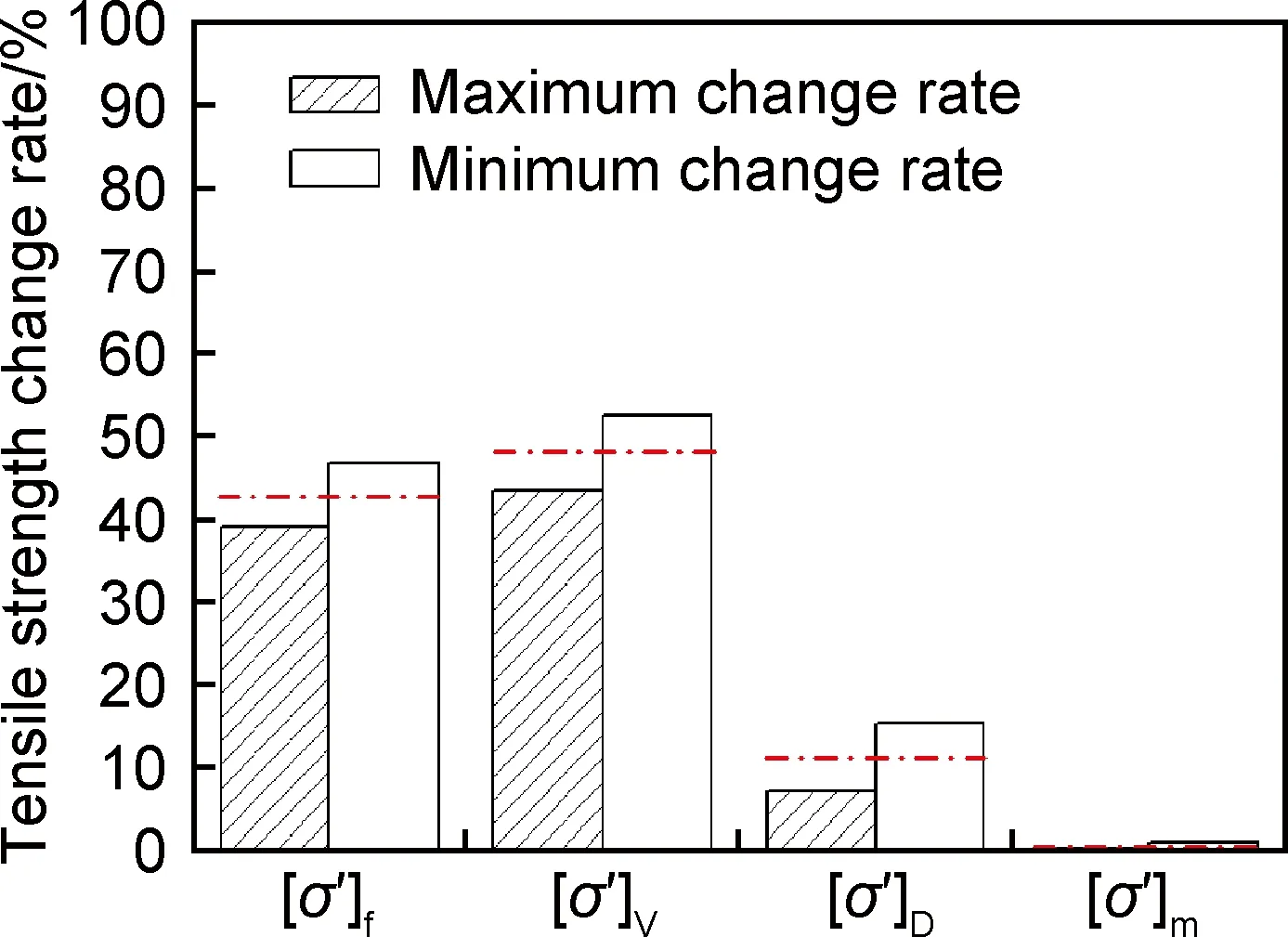

在初步建立CFRP筋拉伸强度预测模型基础上,对该模型典型因子影响材料强度权重进行研究评价,根据结果提出CFRP筋制备过程中强度补偿机制。结果表明:典型因子碳纤维拉伸强度(σf)和体积分数(Vf)对CFRP筋拉伸强度影响最为显著(影响率为39.1%~46.7%和43.5%~52.6%),是决定CFRP筋拉伸性能的最重要因素。公称直径(D)对CFRP筋拉伸强度存在一定程度影响(影响率7.1%~15.4%)。基体树脂强度(σm)对CFRP筋拉伸强度影响不明显(影响率0.3%~1.0%),相比其他三种因素,可近似忽略。依据预测模型典型因子强度补偿规律,可较方便推测CFRP筋组分碳纤维强度及体积分数参数。

CFRP筋;拉伸强度;预测;评价

Abstract: Based on the prediction formula of tensile strength for CFRP bars, weight of influence of the typical factors on material strength was evaluated, and the mechanism of intensity compensation in the process of preparing CFRP bar was proposed. The results show that the effect of typical factors of carbon fiber tensile strength and volume fraction effect on the tensile strength of CFRP bars is most significant (influence rate:39.1%-46.7% and 43.5-52.6%). They are the most important factors that determine the tensile properties of CFRP bars. Nominal diameter has a certain effect on the tensile strength of CFRP bars (influence rate: 7.1%-15.4%). Influence of resin matrix strength on the tensile strength of the CFRP bar is not obvious (influence rate: 0.3%-1.0%). Compared to the other three factors, the influence of the tensile strength of resin can be nearly neglected. According to the intensity compensation rule of the typical factors, the strength and volume fraction of carbon fiber in CFRP bars can be easily inferred.

Keywords:CFRP bars;tensile strength;prediction;evaluation

碳纤维增强复合材料筋(CFRP筋)具有优异的力学性能和耐腐蚀特性,在桥梁、岩土、隧道、岛礁等工程建设领域,作为新型结构材料,可部分代替钢筋,应用前景良好,受到国内外专家学者的普遍关注[1-3]。

目前我国CFRP筋产品规格型号繁多,质量悬殊较大,深入推进其在工程建设领域的规范、安全应用具有诸多困难[4-5]。

基于经典复合材料混合理论,结合实验研究提出的CFRP筋拉伸强度预测模型σ=0.95×[σfVf+σm(1-Vf)]-B×D[6],为工程设计应用提供了材料制备的有效指导。在此基础上,本工作借助大数据分析手段,结合归一化处理方法,对该模型的典型因子影响权重进行研究评价,提出典型因子影响的CFRP筋强度补偿机制及产品组分参数预测评估方法建议,以期为调控低成本高强度质量稳定的CFRP筋制备生产以及工程应用的高效检测评估提供理论基础。

1 典型因子对CFRP筋拉伸强度的影响权重研究

CFRP筋拉伸强度预测模型:σ=0.95×[σfVf+σm(1-Vf)]-B×D,其中σf,Vf分别表示碳纤维拉伸强度和体积分数;σm为基体树脂拉伸强度;D为CFRP筋公称直径;B为由直径D带来的强度折损系数(B一般在34~40MPa/mm)[6]。

以CFRP筋拉伸强度预测模型为基础,深入研究典型因子对CFRP筋拉伸强度的影响权重。这里,对典型因子影响的CFRP筋拉伸强度变化进行归一化处理,以建立不同量纲典型因子影响材料强度权重的可比关系。

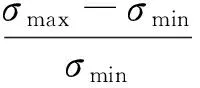

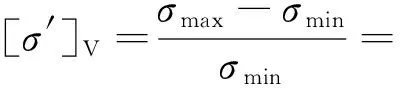

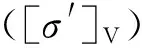

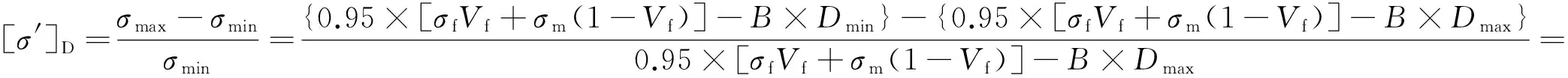

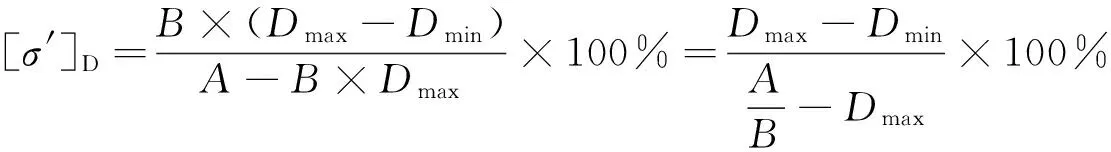

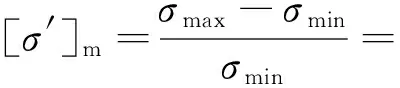

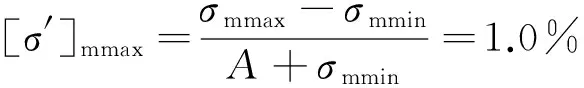

定义σ′为归一化处理后CFRP筋拉伸强度变化率,即:

(1)

式中:σmax和σmin分别表示改变一种典型因素的指标参数,对应CFRP筋拉伸强度预测最大值和最小值。则该模型中典型因子对CFRP筋拉伸强度的影响权重,可借助σ′进行比较。

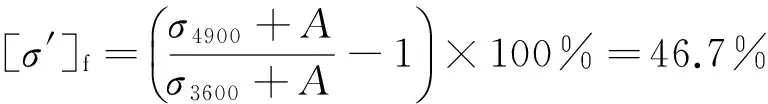

1.1碳纤维拉伸强度σf

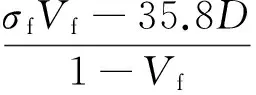

依据式(1),改变碳纤维拉伸强度σf,对应CFRP筋拉伸强度变化率:

(2)

式中:A是σm,Vf,D三种因素的共同函数,影响碳纤

依据目前市场常规CFRP筋组分参数指标值范围,其中:碳纤维拉伸强度σf为3600~4900MPa,碳纤维体积分数Vf为50%~70%,基体环氧树脂拉伸强度σm为42~70MPa,CFRP筋公称直径D为6~12mm,直径折损系数B取34MPa/mm,则:

(1)当基体树脂拉伸强度σm=70MPa,碳纤维体积分数Vf=70%,CFRP筋公称直径D=6mm时,A取最大值:

取碳纤维拉伸强度σfmax=4900MPa,σfmin=3600MPa,则:

(2)当基体树脂拉伸强度σm=42MPa,碳纤维体积分数Vf=50%,CFRP筋公称直径D=12mm时,A取最小值:

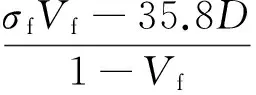

1.2碳纤维体积分数Vf

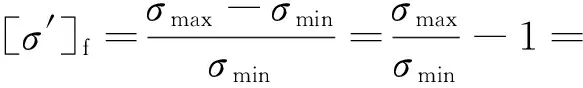

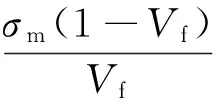

依据式(1),改变碳纤维体积分数Vf,对应CFRP筋拉伸强度变化率:

(3)

(4)

(1)当基体树脂拉伸强度σm=70MPa,碳纤维拉伸强度σf=3600MPa时,A取最大值:

(2)当基体树脂拉伸强度σm=42MPa,碳纤维拉伸强度σf=4900MPa时,A取最小值:

(5)

取碳纤维体积分数Vfmax=70%,Vfmin=50%

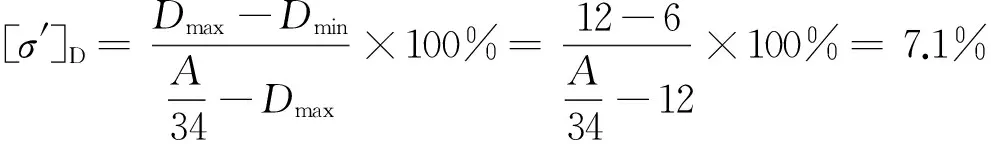

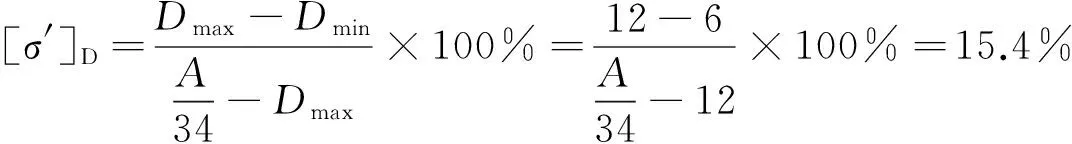

1.3 CFRP筋公称直径D

依据式(1),改变公称直径D,对应CFRP筋拉伸强度变化率:

(6)

(1)当碳纤维拉伸强度σf=4900MPa,碳纤维体积分数Vf=70%,基体树脂拉伸强度σm=70MPa时,A取最大值:

Amax=0.95×[σfVf+σm(1-Vf)]= 0.95×[4900×70%+70×(1-70%)]=3278

(2)当碳纤维拉伸强度σf=3600MPa,碳纤维体积分数Vf=50%,基体树脂拉伸强度σm=42MPa时,A取最小值:

Amin=0.95×[σfVf+σm(1-Vf)]= 0.95×[3600×50%+42×(1-50%)]=1730

1.4基体树脂拉伸强度σm

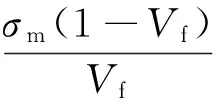

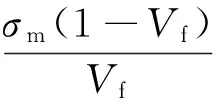

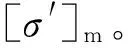

依据式(1),改变基体树脂σm,对应CFRP筋拉伸强度变化率:

(7)

(1)当碳纤维拉伸强度σf=4900MPa,碳纤维体积分数Vf=70%,CFRP筋公称直径D=6mm时,A取最大值:

取基体树脂σmmax=70MPa,σmmin=42MPa,则

(2)当碳纤维拉伸强度σf=3600MPa,碳纤维体积

分数Vf=50%,CFRP筋公称直径D=12mm时,A取最小值:

2 典型因子对CFRP筋拉伸强度的影响权重评价

依据典型因子对CFRP筋拉伸强度的影响权重研究,对各因子影响权重指标进行综合评价。

图1 CFRP筋拉伸强度预测模型几种典型因子影响权重Fig.1 Weight of influence for some typical factors in the tensile strength prediction model of CFRP bars

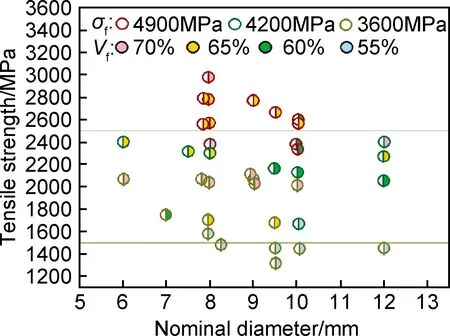

图2收集了国内外文献报道中涉及实验室制备研究及工程化规模生产的大量CFRP筋实测性能参数[7-40],对预测模型中典型因子影响材料强度权重进行大数据分析评价。

图2 文献报道CFRP筋性能指标[7-40]Fig.2 Properties of CFRP bars in the literatures[7-40]

定义ψ为CFRP筋拉伸强度分布率,即在一定拉伸强度范围内出现样本数占总样本数的概率,则

(8)

其中N为总样本数,n为在确定范围内出现样本数。

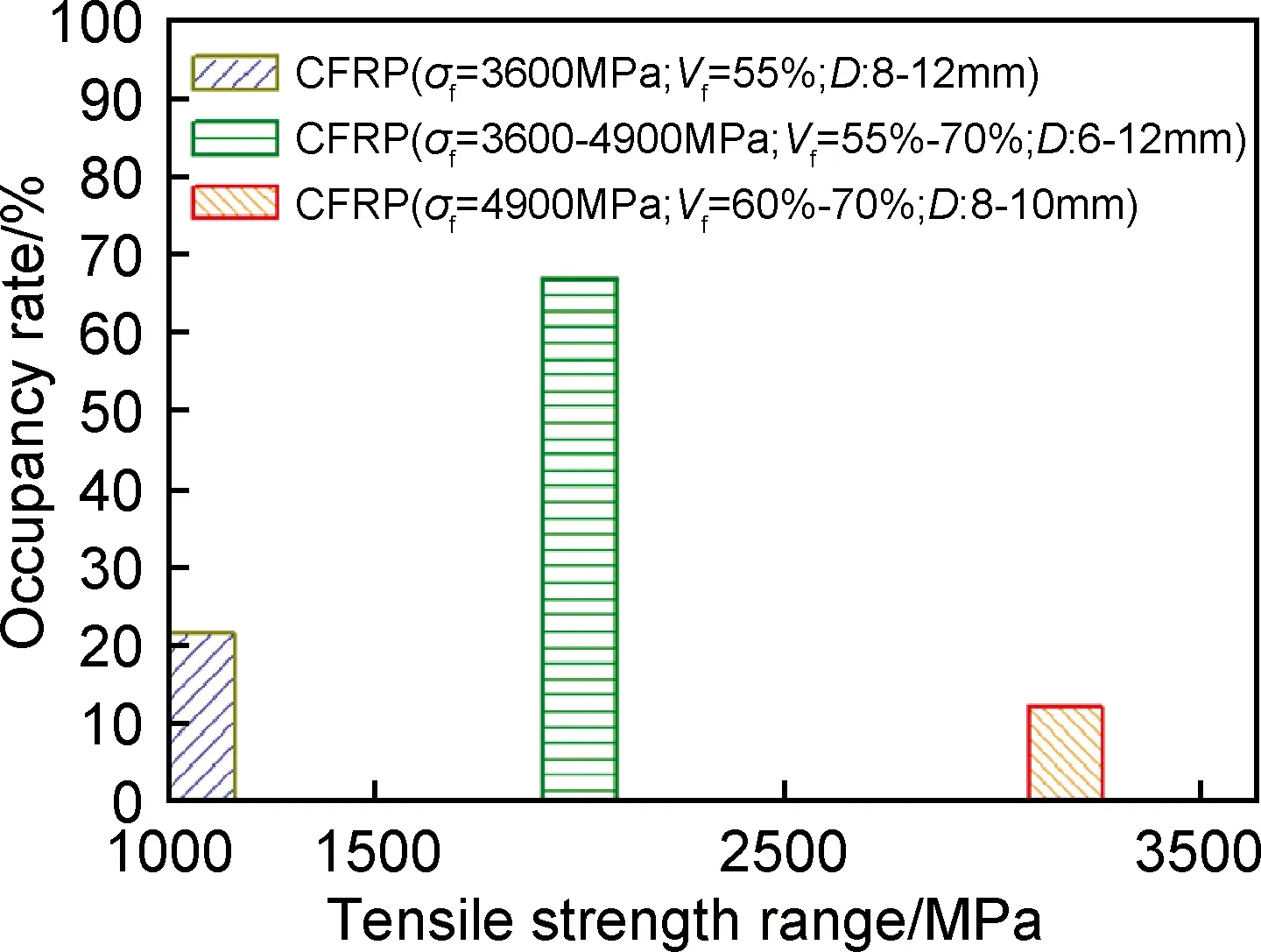

以CFRP筋拉伸强度σ≤1500MPa定义为Ⅰ级范围;1500MPa<σ≤2500MPa为Ⅱ级;σ>2500MPa为Ⅲ级,围绕图2数据,分别计算不同范围CFRP筋拉伸强度分布率,主要规律如图3所示。

图3 CFRP筋拉伸强度分布规律Fig.3 Distribution of the tensile strength for CFRP bars

图3结果较清晰地显示,碳纤维拉伸强度σf及体积分数Vf指标对CFRP筋拉伸强度影响最为显著,基本决定了CFRP筋的拉伸强度范围。其中,Ⅰ级(σ≤1500MPa)强度范围的CFRP筋,分布律相对较低,主要为碳纤维拉伸强度3600MPa,纤维体积分数55%的CFRP筋;Ⅲ级(σ>2500MPa)强度范围的CFRP筋,分布律最低,主要为碳纤维拉伸强度4900MPa,体积分数60%~70%,公称直径10mm以下的CFRP筋;Ⅱ级(1500MPa<σ≤2500MPa)强度范围的CFRP筋,其碳纤维强度、体积分数及公称直径指标一定范围内有较大可选性,影响Ⅱ级CFRP筋强度分布率显著高于其他两级。

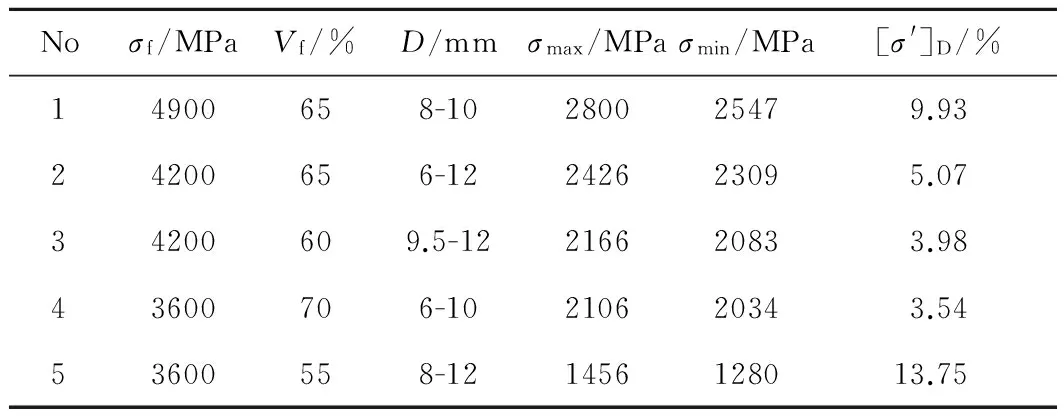

表1 不同公称直径CFRP筋拉伸强度的差异Table 1 Difference of tensile strength of CFRP bars with different nominal diameters

3 CFRP筋拉伸强度补偿机制及产品组分参数预测评估

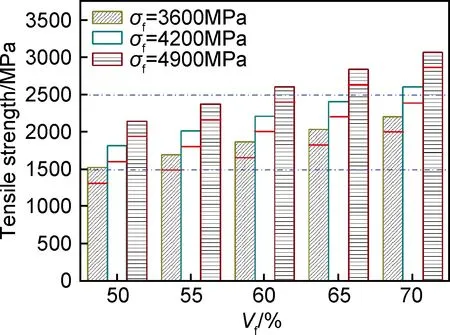

综合CFRP筋拉伸强度预测模型,以及典型因子对CFRP筋拉伸强度影响权重规律研究,可以较清晰地形成一套CFRP筋制备过程强度补偿机制,如图4所示。

图4 不同CFRP筋拉伸强度典型因子强度补偿关系Fig.4 Intensity compensation relationship with some typical factors for the tensile strength of CFRP bars

图4分类整理了碳纤维强度、体积分数、CFRP筋公称直径(这里忽略树脂拉伸强度)等典型参数设计匹配与CFRP筋宏观拉伸强度的关联关系(其中公称直径对CFRP筋拉伸强度的折损影响限值由红色线条进行标注)。不同级别的CFRP筋强度补偿机制存在一定差别。

处于Ⅰ级强度范围(σ≤1500MPa)的CFRP筋,使用碳纤维拉伸强度为3600MPa,纤维体积分数55%以下。改变公称直径,CFRP筋拉伸强度一般不超过2500MPa,补偿效果不明显。

处于Ⅱ级强度范围(1500MPa<σ≤2500MPa)的CFRP筋,碳纤维强度、体积分数及公称直径参数存在一定范围的补偿关系:(1)拉伸强度一定的碳纤维,体积分数每增加5%,对应CFRP筋拉伸强度增长率约10%以上;(2)碳纤维体积分数一定时,可选用三类不同强度碳纤维对材料的性能进行补偿,纤维强度每提升一级,对应CFRP筋拉伸强度增长率约18%以上;(3)增大公称直径,CFRP筋拉伸强度会有一定损失,影响程度由直径折损系数B决定。受CFRP生产技术等条件影响,B值存在一定波动。依据目前统计结果,公称直径对CFRP筋拉伸强度的折损率约为10%左右。因此可以选用强度低、体积分数大或强度高、体积分数小的碳纤维原料对CFRP筋拉伸强度目标值进行设计匹配;在较大直径CFRP筋拉伸强度设计中,须考虑大直径对CFRP筋拉伸强度折损的影响,选择碳纤维强度、体积分数匹配目标值应高于设计值10%以上,从而综合达到满足性能要求且降低生产成本的效果。

处于Ⅲ级强度范围(σ>2500MPa)的CFRP筋,使用碳纤维拉伸强度为4900MPa,体积分数60%以上。根据补偿机制,当碳纤维拉伸强度为4200MPa时,增加纤维体积含量达70%、公称直径≤8mm时,其拉伸强度也能达到2500MPa以上。

CFRP筋产品的组分参数预测,基于碳纤维强度及体积分数对CFRP筋拉伸强度的影响远大于其他因素的研究规律,已知CFRP筋拉伸强度、公称直径及体密度,对照图4典型因子强度补偿规律,可较方便地推测其组分碳纤维强度及体积分数参数。

4 结论

(1)CFRP筋拉伸强度预测模型σ=0.95×[σfVf+σm(1-Vf)]-B×D综合揭示了碳纤维及基体树脂拉伸强度(σf,σm)、碳纤维体积分数(Vf),以及CFRP筋公称直径(D)等四种典型因素对材料宏观拉伸强度的影响关系,对实际工程应用具有较优的适用性。

(2)CFRP筋拉伸强度预测模型中典型因子碳纤维拉伸强度(σf)和体积分数(Vf)变化对材料宏观拉伸强度影响最为重要(影响率为39.1%~46.7%和43.5%~52.6%),是决定CFRP筋拉伸强度的最重要因素。随着公称直径(D)增大,CFRP筋拉伸强度会有一定损失,影响率由直径折损系数B决定,一般为7.1%~15.4%)。基体树脂强度(σm)对CFRP筋的拉伸强度影响不明显(影响率为0.3%~1.0%),相比其他三种影响因素,树脂拉伸强度的影响可近似忽略。

(3)已知CFRP筋拉伸强度、公称直径及体密度,对照预测模型典型因子强度补偿规律,可较方便地推测其组分碳纤维强度及体积分数参数。

[1] SMITH S J, BANK L C, GENTRY T R, et al. Analysis and testing of a prototype pultruded composite causeway structure[J]. Composite Structures, 2000, 49(2): 141-150.

[2] BANK L C, GENTRY T R, NUSS K H, et al. Construction of a pultruded composite structure: case study[J]. Journal of Composites for Construction, 2000, 4(3): 112-119.

[3] HARPER L T, TURNER T A, WARRIOR N A, et al. Characterisation of random carbon fiber composites from a directed fiber preforming process:the effect of tow filamentisation[J]. Composites:Part A, 2007, 38: 755-770.

[4] LI B, YANG Y X, YUE Q R, et al. Experimental study on mechanical properties of CFRP tendon[J]. Applied Mechanics and Materials, 2013, 357/360: 1097-1101.

[5] 黎伟捷, 李彪, 杨勇新, 等. 我国FRP筋产品标准及指标的探讨[J].玻璃钢/复合材料, 2014(8): 101-104.

LI W J, LI B, YANG Y X, et al. Discussion on the Chinese standard and specifications of FRP bar products[J]. Fiber Reinforced Plastics/Composites,2014(8):101-104.

[6] 王彬, 杨勇新, 岳清瑞, 等. 复合理论预测国产碳纤维复合材料筋拉伸强度的离散性研究[J]. 玻璃钢/复合材料, 2014(12): 63-67.

WANG B, YANG Y X, YUE Q R, et al. The discrete research on the values predicted by composite theories and measured for carbon fiber reinforced composite rods[J]. Fiber Reinforced Plastics/Composites, 2014(12): 63-67.

[7] 程东辉, 郑文忠. 无粘结部分预应力纤维聚合物筋混凝土梁试验[J]. 沈阳建筑大学学报 (自然科学版), 2008, 24(4): 537-542.

CHENG D H, ZHENG W Z. Behavioral research concrete beam prestressed with unbonded[J].Journal of Shenyang Jianzhu University(Natural Science), 2008, 24(4): 537-542.

[8] 郁步军, 蔡文华, 张继文, 等. 碳纤维增强复合材料筋黏结型群锚静载试验研究[J]. 工业建筑, 2013, 43(4): 118-121.

YU B J, CAI W H, ZHANG J W, et al. Study on static load tests of bond type anchors for CFRP tendons[J]. Industrial Construction, 2013, 43(4): 118-121.

[9] 孟履祥, 关建光, 徐福泉. 碳纤维筋 (CFRP筋) 锚具研制及力学性能试验研究[J]. 施工技术, 2005, 34(7): 42-45.

MENG L X, GUAN J G, XU F Q. The anchorage development and experiment study on the mechanical properties for CFRP tendons[J]. Construction Technology, 2005, 34(7): 42-45.

[10] 詹界东, 杜修力, 王作虎. 预应力 CFRP 筋夹片-粘结型锚具的试验[J]. 沈阳建筑大学学报(自然科学版), 2010, 26(1): 31-36.

ZHAN J D, DU X L, WANG Z H. Experimental study on the wedge-bond anchorage of CFRP tendons[J]. Journal of Shenyang Jianzhu University(Natural Science), 2010, 26(1): 31-36.

[11] 方志, 梁栋, 蒋田勇. 不同粘结介质中 CFRP 筋锚固性能的试验研究[J]. 土木工程学报, 2006, 39(6): 47-51.

FANG Z, LIANG D, JIANG T Y. Experimental investigation on the anchorage performance of CFRP tendon in different bond mediums[J]. China Civil Engineering Journal, 2006, 39(6): 47-51.

[12] 方志, 蒋田勇, 梁栋. CFRP 筋在活性粉末混凝土中的锚固性能[J]. 湖南大学学报(自然科学版), 2007, 34(7): 1-5.

FANG Z, JIANG T Y, LIANG D. The anchorage behavior of CFRP tendons in RPC[J]. Journal of Hunan University(Natural Sciences), 2007, 34(7): 1-5.

[13] 李俊波. 配置体外CFRP预应力筋混凝土梁抗弯性能的试验研究[D]. 长沙:湖南大学, 2005.

LI J B. Experimental study on flexural behavior of concrete beam prestressed with external CFRP tendons[D]. Changsha:Hunan University, 2005.

[14] 张继文, 龚永智. CFRP 筋增强混凝土柱受力性能的研究[C]∥第五届全国 FRP 学术交流会论文集.北京:土木工程学报,2007:495-504.

ZHANG J W, GONG Y Z. Study on the behavior of concrete columns reinforced with CFRP tendons[C]∥Proceedings of the 5th National FRP Symposium Conference. Beijing:China Civil Engineering Journal, 2007:495-504.

[15] 徐平, 丁亚红, 曾宪桃, 等. 预应力CFRP筋粘结夹片式球面锚具的研制与试验[J]. 玻璃钢/复合材料, 2011(2): 3-7.

XU P, DING Y H, ZENG X T, et al. Experimental study and development on the CFRP tendons bonding spherical jaw vice anchorage[J]. Fiber Reinforced Plastics/Composites, 2011(2): 3-7.

[16] CHOI H T, WEST J S, SOUDKI K A. Effect of partial unbonding on prestressed near-surface-mounted CFRP-strengthened concrete T-beams[J]. Journal of Composites for Construction, 2010, 15(1): 93-102.

[17] CHOI H T, WEST J S, SOUDKI K A. Partially bonded near-surface-mounted CFRP bars for strengthened concrete T-beams[J]. Construction and Building Materials, 2011, 25(5): 2441-2449.

[18] GRANCE N, ENOMOTO T, BAAH P, et al. Flexural behavior of CFRP precast prestressed decked bulb T-beams[J]. Journal of Composites for Construction, 2011, 16(3): 225-234.

[19] RAFI M M, NADJAI A, ALI F, et al. Aspects of behaviour of CFRP reinforced concrete beams in bending[J]. Construction and Building Materials, 2008, 22(3): 277-285.

[20] DAVALOS J F, CHEN Y, RAY I. Effect of FRP bar degradation on interface bond with high strength concrete[J]. Cement and Concrete Composites, 2008, 30(8): 722-730.

[21] VOGEL H, SVECOVA D. Thermal compatibility and bond strength of FRP reinforcement in prestressed concrete applications[J]. Journal of Composites for Construction, 2007, 11(5): 459-468.

[22] DAVOUDI S, VOGEL H, SVECOVA D, et al. CFRP prestressed high-strength concrete prisms subjected to direct tension[J]. Journal of Composites for Construction, 2008, 12(6): 588-595.

[23] AHMAD F S, FORET G, Le ROY R. Bond between carbon fibre-reinforced polymer (CFRP) bars and ultra high performance fibre reinforced concrete (UHPFRC): experimental study[J]. Construction and Building Materials, 2011, 25(2): 479-485.

[24] MOON D Y, SIM J, OH H. Detailing considerations on RC beams strengthened with CFRP bars embedded in mortar overlay[J]. Construction and Building Materials, 2007, 21(8): 1636-1646.

[25] HA G J, KIM Y Y, CHO C G. Groove and embedding techniques using CFRP trapezoidal bars for strengthening of concrete structures[J]. Engineering Structures, 2008,30(4): 1067-1078.

[26] LORENZIS L D, SCIALPI V, TEGOLA A L. Analytical and experimental study on bonded-in CFRP bars in glulam timber[J]. Composites Part B: Engineering, 2005, 36(4): 279-289.

[27] HA G J, CHO C G, KANG H W, et al. Seismic improvement of RC beam-column joints using hexagonal CFRP bars combined with CFRP sheets[J]. Composite Structures, 2013, 95: 464-470.

[28] WAHAB N, SOUDKI K A, TOPPER T. Mechanism of bond behavior of concrete beams strengthened with near-surface-mounted CFRP rods[J]. Journal of Composites for Construction, 2010, 15(1): 85-92.

[29] ELREFAI A, WEST J, SOUDKI K. Fatigue of reinforced concrete beams strengthened with externally post-tensioned CFRP tendons[J]. Construction and Building Materials, 2012, 29: 246-256.

[30] TANARSLAN H M. The effects of NSM CFRP reinforcements for improving the shear capacity of RC beams[J]. Construction and Building Materials, 2011, 25(5): 2663-2673.

[31] NOVIDIS D G, PANTAZOPOULOU S J. Bond tests of short NSM-FRP and steel bar anchorages[J]. Journal of Composites for Construction, 2008, 12(3): 323-333.

[32] ANWARUL ISLAM A K M. Effective methods of using CFRP bars in shear strengthening of concrete girders[J]. Engineering Structures, 2009, 31(3): 709-714.

[33] WON J P, PARK C G, KIM H H, et al. Effect of fibers on the bonds between FRP reinforcing bars and high-strength concrete[J]. Composites Part B: Engineering, 2008, 39(5): 747-755.

[34] SASMAL S, KHATRI C P, RAMANJANEYULU K, et al. Numerical evaluation of bond-slip relations for near-surface mounted carbon fiber bars embedded in concrete[J]. Construction and Building Materials, 2013, 40: 1097-1109.

[35] ELBADRY M, ELZAROUG O. Control of cracking due to temperature in structural concrete reinforced with CFRP bars[J]. Composite structures, 2004, 64(1): 37-45.

[36] MALVAR L J, COX J V, COCHRAN K B. Bond between carbon fiber reinforced polymer bars and concrete. I: experimental study[J]. Journal of composites for construction, 2003, 7(2): 154-163.

[37] FLAGA K. Advances in materials applied in civil engineering[J]. Journal of Materials Processing Technology, 2000, 106(1): 173-183.

[38] SHARBATDAR M K, SAATCIOGLU M, BENMOKRANE B. Seismic flexural behavior of concrete connections reinforced with CFRP bars and grids[J]. Composite Structures, 2011, 93(10): 2439-2449.

[39] BOUGUERRA K, AHMED E A, EL GAMAL S, et al. Testing of full-scale concrete bridge deck slabs reinforced with fiber-reinforced polymer (FRP) bars[J]. Construction and Building Materials, 2011, 25(10): 3956-3965.

[40] WANG Y C, KODUR V. Variation of strength and stiffness of fibre reinforced polymer reinforcing bars with temperature[J]. Cement and Concrete Composites, 2005, 27(9): 864-874.

(本文责编:解 宏)

Evaluation and Application of Tensile Strength Prediction for CFRP Bars

WANG Bin,YANG Yong-xin,YUE Qing-rui,ZENG Bin

(Central Research Institute of Building and Construction Co.,Ltd.,Beijing 100088,China)

10.11868/j.issn.1001-4381.2015.001435

TQ327.3

A

1001-4381(2017)10-0117-07

国家高技术研究发展计划项目(2012AA03A204)

2015-11-24;

2016-04-07

王彬(1984-),女,工程师,博士,主要从事高性能纤维增强复合材料方向研究,联系地址:北京市海淀区西土城路33号中冶建筑研究总院有限公司2#504检测中心研发部(100088),E-mail:mccwangbin@126.com