自蔓延燃烧合成法制备分层及梯度结构的Ni-Al/金刚石复合材料研究

2017-09-19卢家锋张凤林杨志峰周玉梅

卢家锋,张凤林,杨志峰,周玉梅

自蔓延燃烧合成法制备分层及梯度结构的Ni-Al/金刚石复合材料研究

卢家锋,张凤林,杨志峰,周玉梅

(广东工业大学机电工程学院,广州 510006)

采用自蔓延燃烧合成法制备了分层及梯度结构的Ni-Al/金刚石复合材料。研究了多层及金刚石粒度梯度结构对Ni-Al/金刚石复合材料其自蔓延反应过程及微观相貌的影响。结果表明:随着分层数的增加,自蔓延反应的燃烧波速度下降;自蔓延反应在金刚石粒度梯度结构的燃烧波速率比其在金刚石分层结构的速率快。微观形貌分析表明,自蔓延反应使得钎料合金Ni-Cr与金刚石生成了强碳化合物Cr3C2和Cr7C3,增强了金刚石和合金粉末基体的结合力。

自蔓延燃烧合成;分层SHS结构;梯度SHS结构;Ni-Al金属间化合物;金刚石

金刚石具有硬度高,热导率高,耐腐蚀性能良好等优点,使得其被广泛地应用于各种超硬材料工具制备中[11]。金刚石工具常用的制造方法有:真空热压烧结法,电镀法以及高温钎焊法等。[7,16,17]其中高温钎焊法能使金刚石与Ni-Cr或者Cu-Sn-Ti钎料合金产生高强度的化学结合[4,5],所制备的金刚石工具有较高的出刃高度,大大提高了金刚石工具的工作效率[8]。

自蔓延高温合成法(SHS)可以在短时间内对材料进行快速致密化。此外,自蔓延高温合成法适合于制备具有多层结构的材料。如以TiC或MoC为粘结剂制备的梯度金刚石复合材料[1,9],以Ti-B和金刚石制备的具有多层功能梯度结构的材料(FGM)[12-14]。在我们之前的研究中,基于Ni-Al金属间化合物体系,用自蔓延的方法制备了一个金刚石磨具,但是通过磨削实验发现,自蔓延反应后金刚石磨粒的抗压强度下降了约20%[24]。此外,我们还发现在Ni-Al金属间化合物体系中加入Ni-Cr-P, Cu合金粉末和B元素能降低自蔓延反应中燃烧波的速率,使得反应更稳定,并且能改善反应产物的微观结构形貌[10,15,23]。

在本试验中用自蔓延方法制备了分层和梯度结构的Ni-Al/金刚石复合材料,并且研究了分层数量和梯度结构对自蔓延反应过程和复合材料微观形貌的影响,为优化金刚石工具的结构和材料设计提供了依据。

1 实验方法

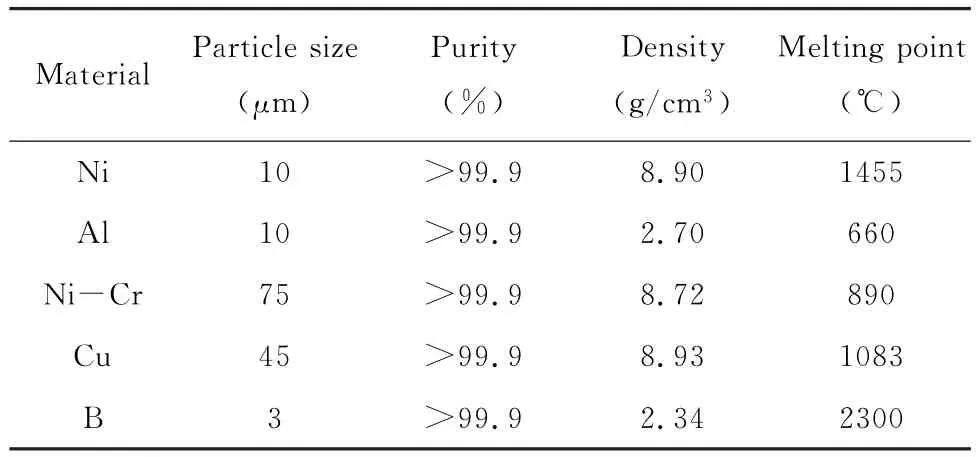

本文所用的原料如表1所示,其中Ni、Al、B粉末采购于北京中金研新材料有限公司。金刚石采购于ElementSix公司,粒径为60/70目、120/140目、325/400目。

表1 试验原料的特性Table 1 Characteristics of the raw materials

多层结构分为Ni-Al层和金刚石层。其中Ni-Al层的成分包括Ni粉、Al粉(化学计量比为Ni∶Al =1∶1),以及60 wt.%的稀释剂,稀释剂的成分为60 wt.%Ni-Cr,35wt.%Cu和5wt.%B。金刚石层的成分:目数为325/400的金刚石,60 wt.%的稀释剂。将Ni-Al层和金刚石层材料分别用行星式球磨机进行球磨混合,其中球磨机的转速为150 r/min,时间为6 h,球料比为5∶1。Ni-Al/金刚石复合材料多层结构如图1所示,具体分层参数如表2所示。

图1 自蔓延反应多层结构示意图Fig.1 Schematic diagram of multilayer design of self-propagating reaction

表2 分层结构具体参数Table 2 The specific parameters of layered structure

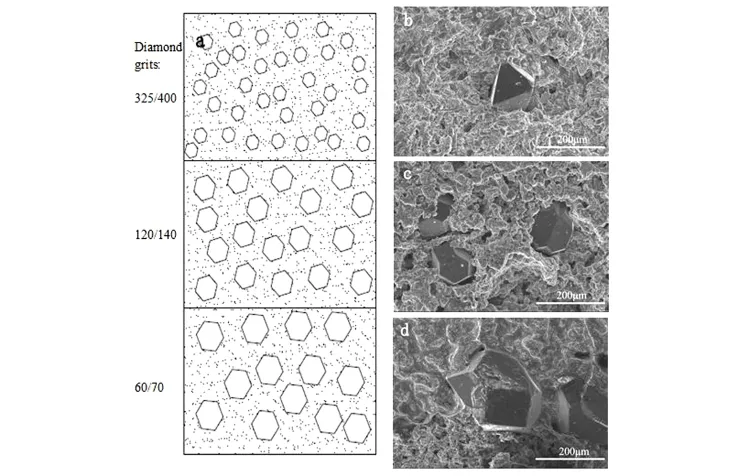

如图2所示,金刚石粒度梯度结构分为四个,每个梯度高度为5 mm,最上面为Ni-Al层;其余的为金刚石层,金刚石层金刚石的浓度为5wt.%。将多层结构和梯度结构的Ni-Al/金刚石混合料放到Φ8 ×15mm的圆柱形磨具中冷压成型,压强为60 MPa。最后,自蔓延反应,反应通过一根直径为0.28 mm的钨丝引燃,并在一个真空度为0.1 Pa的炉内进行,反应如图3所示。

图2 自蔓延反应粒度梯度结构示意图Fig.2 Schematic diagram of particle gradient structure of self-propagating reaction

图3 自蔓延反应合成和冷压模具示意图Fig.3 The schematic diagram of SHS and the cold pressing mold

SHS反应速率通过彩色摄像机以25 frames/s拍摄并计算。将反应后的样品表面及纵切面用金刚石砂纸和研磨膏进行抛光,然后用体积分数为1∶1∶1的硝酸,盐酸,酒精腐蚀液进行腐蚀。采用型号为HITACH S3400的电子扫面显微镜分析样品的断口形貌,并利用X射线能谱仪对SHS基体、金刚石与SHS基体界面等做元素的线分布分析。

2 实验结果与讨论

2.1 多层结构对SHS过程的影响

如图4所示,随着Ni-Al/金刚石层数的增加, SHS过程的燃烧波速率下降。这是因为层数越多,稀释剂的含量就越多,稀释剂中Ni-Cr合金融化时吸收了大部分Ni-Al自蔓延反应的热量,使得燃烧波速率下降,反应变得更慢。B、TiC和VN也能在自蔓延反应中产生相似的效果[20-22]。

图4 层数对燃烧波速率的影响Fig.4 Inflence of the number of layer on combustion velocity

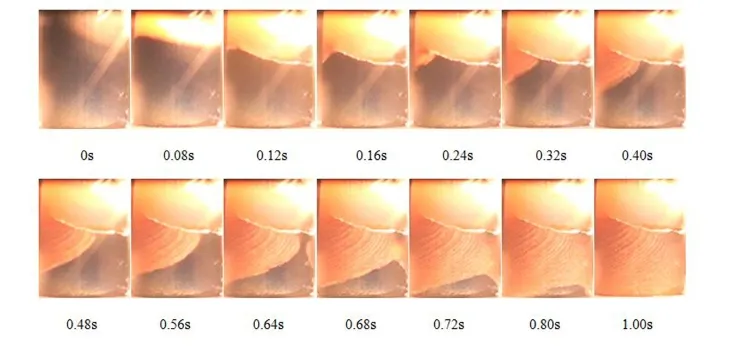

3、4、6和10层结构的SHS过程如图5、6、7、8所示。可以发现,对于3层结构的SHS过程其平均燃烧波速率为15 mm/s。在0.48 s到0.88 s之间的速率是不均匀的,越往后面其速率越快,这可能是因为随着反应的进行,底部的物料得到了一定的预加热作用。

图5 3层结构样品的SHS过程Fig.5 Images of SHS process of three-layer structure sample

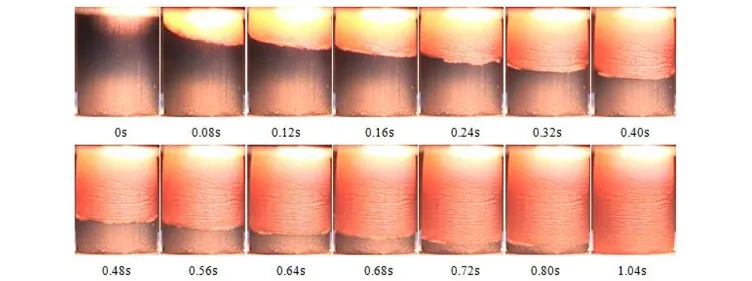

从图6可以看出,4层结构样品的SHS过程稳定,燃烧波的速率为14.42 mm/s,反应后样品的形状保持良好。如图7所示,6层结构样品的燃烧波速率为13.89 mm/s,此外可以明显地看出燃烧波在金刚石层的速率要比在Ni-Al层的速率小。图8是10层结构样品的SHS过程,其反应时间为1.52 s,燃烧波的速率为9.87mm/s,反应火焰呈淡黄色。

2.2 多层结构Ni-Al/金刚石微观结构

多层结构Ni-Al/金刚石微观相貌如图9(b)所示。在Ni-Al层可以看到自蔓延高温合成反应常见的微孔结构;而在金刚石层,可以看到Ni-Cr钎料合金和Ni-Al紧紧的包覆着金刚石,为金刚石提供了较大的把持力。

图6 4层结构样品的SHS过程Fig.6 Images of SHS process of four-layer structure sample

图7 6层结构样品的SHS过程Fig.7 Images of SHS process of six-layer structure sample

图8 10层结构样品的SHS过程Fig.8 Images of SHS process of ten-layer structure sample

图9 4层结构示意图及微观形貌(a),Ni-Al层微观相貌,(b)金刚石层微观形貌(c)Fig.9 The schematic diagram of four-layer structure and microscopic appearance(a),SEM images of Ni-Al layer, (b)microscopic appearance of diamond layer(c)

图10为多层结构Ni-Al/金刚石复合材料的X射线衍射图,图中主峰为NiAl、Ni-Cr、Cr3C2和Cr7C3。因为Ni-Al自蔓延高温合成反应在温度达到750℃时,铝已经融化而镍还没有,反应属于过铝的状态,首先生成NiAl3,随着反应的进行,温度不断升高,然后出现Ni2Al3,最后才生成NiAl,这表明反应已完全进行[2]。

2.3 金刚石粒度梯度结构对SHS过程的影响

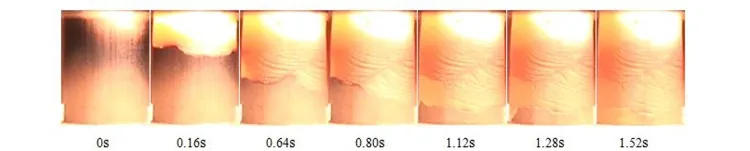

金刚石粒度梯度结构SHS过程如图11所示。可以看到自蔓延反应为稳态燃烧模式,燃烧波的速率为55.56 mm/s。燃烧波在梯度结构反应中速度比在多层结构中传播的速度要快。这是因为金刚石粒度梯度结构中稀释剂相对于多层结构少,故燃烧波的传播受到的影响较小。

2.4 金刚石粒度梯度结构Ni-Al/金刚石微观结构

每个梯度的微观形貌如图12所示。可以看到金刚石嵌入到Ni-Al基体中,被Ni-Al紧紧地包覆着,表明金刚石与Ni-Al结合强度较好。从图13的线扫描可以看到Cr元素富集在金刚石的表面,这和其他钎焊金刚石工具的研究发现一致[3,6,19]。这是因为在高温条件下金刚石易与Cr元素形成强碳化合物如Cr3C2和Cr7C3[18]。同时也解释了图10出现Cr3C2和Cr7C3物相的原因。

图10 3层结构样品的X射线衍射图Fig.10 X-ray diffraction patterns of three-layer structure sample

图11 金刚石粒度梯度结构SHS过程Fig.11 Images of SHS process of diamond particle gradient structure

图12 金刚石粒度梯度结构示意图及微观形貌(a),金刚石和合金基体SEM,325/400目、(b)120/140目(c)、60/70目(c)Fig.12 The schematic diagram of diamond particle gradient structure and microscopic appearance(a),SEM images of the diamond and alloy matrix,325/400 meshs(b),120/140 meshs(c),60/70 meshs(d)

图13 金刚石粒度梯度(325/400)EDX线扫描区域SEM(a),EDX线扫描区域BSEM(b), EDX碳的线扫描结果(c)、铬(d)、镍(e)、铝(f)Fig.13 SEM of EDX line scanning area of diamond particle gradient(325/400)(a),BSEM images of EDX line scanning area(b),line scanning result of EDX of C(c),Cr(d),Ni(e),Al(f)

3 结 论

多层结构及金刚石粒度梯度结构的Ni-Al/金刚石自蔓延反应是稳态燃烧的过程。在多层结构中,随着层数的增加,燃烧波的速率降低,烧波在Ni-Al层中的传播速度比在金刚石层中快;金刚石与Ni-Al的结合良好,自蔓延反应使得钎料合金Ni-Cr与金刚石生成了强碳化合物Cr3C2和Cr7C3。

[1] Biswas A.and S.K.Roy,Comparison between the microstructural evolutions of two modes of SHS of NiAl:key to a common reaction mechanism[J].Acta Materialia,2004.52(2):257-270.

[2] Biswas A.,S.K.Roy,K.R.Gurumurthy,N.Prabhu,and S.Banerjee.A study of self-propagating high-temperature synthesis of NiAl in thermal explosion mode[J].Acta Materialia, 2002.50(4):757-773.

[3] Chattopadhyay A.K.,L.Chollet,and H.E.Hintermann. Containing papers presented at the European Materials Research Society 1990 Spring Meeting on Metallurgical Coatings and Materials Surface ModificationsInduction brazing of diamond with Ni-Cr hardfacing alloy under argon atmosphere[J].Surface and Coatings Technology,1991.45(1):293-298.

[4] Duan Duan-Zhi,Bing Xiao,Bo Wang,Peng Han,Wen-Jie Li, and Si-Wei Xia.Microstructure and mechanical properties of pre-brazed diamond abrasive grains using Cu-Sn-Ti alloy [J].International Journal of Refractory Metals and Hard Materials,2015.48:427-432.

[5] Duan Duan-Zhi,Bing Xiao,Wei Wang,Zi-Yu Zhang,Bo Wang,Peng Han,and Xiao-Yang Ding.Interface characteristics and performance of pre-brazed diamond grains with Ni-Cr composite alloy[J].Journal of Alloys and Compounds, 2015.644:626-631.

[6] Feng Jicai,Xiangyu Dai,Dong Wang,Rui Li,and Jian Cao. Microstructure evolution and mechanical properties of Zr O2/ TiAl joints vacuum brazed by Ag-Cu filler metal[J].Materials Science and Engineering:A,2015.639:739-746.

[7] Islak S.and H.Celik.Effect of Sintering Temperature and Boron Carbide Content on the Wear Behavior of Hot Pressed Diamond Cutting Segments[J].Science Of Sintering,2015.47 (2):131-143.

[8] Kir Durmus,Serkan Islak,Halis Celik,and Ertugrul Celik. Effect of the cBN Content and Sintering Temperature on the Transverse Rupture Strength and Hardness of cBN/Diamond Cutting Tools[J].Science Of Sintering,2012.44(2):235-243.

[9] Levashov E.A.,I.P.Borovinskaya,A.V.Yatsenko,M. Ohyanagi,S.Hosomi,and M.Koizumi.SHS-A New Technological Approach for Creation of Novel Multilayered Diamond-Containing Materials With Graded Structure,in Functionally Graded Materials 1996[M],I.S.Miyamoto,Editor.1997, Elsevier Science B.V.:Amsterdam.283-288.

[10] Li Y.X.,J.D.Hu,Y.H.Liu,and Z.X.Guo.Effect of Cu addition and heat treatment self-propagating high temperature synthesis reaction in Al-Ti-C system[J].Science Of Sintering,2008.40(2):207-214.

[11] Loginov Pavel,Leon Mishnaevsky Jr,Evgeny Levashov,and

Mikhail Petrzhik.Diamond and cBN hybrid and nanomodified cutting tools with enhanced performance:Development,testing and modelling[J].Materials&Design,2015.88:310-319.

[12] Michalski Andrzej and Konrad Cymerman.Ni3Al/diamond composites produced by pulse plasma sintering(PPS)with the participation of the SHS reaction[J].Journal of Alloys and Compounds,2015.636:196-201.

[13] Ohyanagi M Yoshikava T,Koizumi M,Hosomi S,Levashov Ea,Borovinskaya Ip.Fabrication of diamond dispersed cermets by SHS,in Dynamic Pseudo IsostaticCompaction (DPIC).Int J SHS.2015.387-394.

[14] Padyukov Konstantin L.and Evgeny A.Levashov,Self-propagating high-temperature synthesis:a new method for the production of diamond-containing materials[J].Diamond and Related Materials,1993.2(2-4):207-210.

[15] Qin L.,J.Hu,C.Cui,H.Wang,and Z.Guo.Effect of Al Content on Reaction Laser Sintering of Ni-Al Powder[J].Science Of Sintering,2008.40(3):295-301.

[16] Sung C.M.Brazed diamond grid:a revolutionary design for diamond saws[J].Diamond and Related Materials,1999.8(8 -9):1540-1543.

[17] Sung James C.and Michael Sung.The brazing of diamond[J]. International Journal of Refractory Metals and Hard Materials, 2009.27(2):382-393.

[18] Wang C.Y.,Y.M.Zhou,F.L.Zhang,and Z.C.Xu.Interfacial microstructure and performance of brazed diamond grits with Ni-Cr-P alloy[J].Journal of Alloys and Compounds,2009.476(1-2):884-888.

[19] Wang Tianpeng,Toni Ivas,Christian Leinenbach,and Jie Zhang.Microstructural characterization of Si3N4/42Cr Mo joint brazed with Ag-Cu-Ti+TiNp composite filler[J]. Journal of Alloys and Compounds,2015.651:623-630.

[20] Yeh C.L.,H.C.Chuang,E.W.Liu,and Y.C.Chang. Effects of dilution and preheating on SHS of vanadium nitride [J].Ceramics International,2005.31(1):95-104.

[21] Yeh C.L.,S.H.Su,and H.Y.Chang.Effects of TiCaddition on combustion synthesis of NiAl in SHS mode[J].Journal of Alloys and Compounds,2005.398(1-2):85-93.

[22] Yeh C.L.and W.Y.Sung.Combustion synthesis of Ni3Al by SHS with boron additions[J].Journal of Alloys and Compounds,2005.390(1-2):74-81.

[23] Zhang F.L.,Z.F.Yang,Y.M.Zhou,C.Y.Wang,and H.P.Huang.Fabrication of grinding tool material by the SHS of Ni-Al/diamond/dilute[J].International Journal of Refractory Metals and Hard Materials,2011.29(3):344-350.

[24] Zhou Y.M.,F.L.Zhang,and C.Y.Wang.Effect of Ni-Al SHS reaction on diamond grit for fabrication of diamond tool material[J].International Journal of Refractory Metals and Hard Materials,2010.28(3):416-423.

Study of Layered and Gradient Structural Ni-Al/Diamond Composite Prepared by SHS Method

LU Jia-feng,ZHANG Feng-lin,YANG Zhi-feng,ZHOU Yu-mei

(School of Mechanical and Electronic Engineering,Guangdong University of Technology,Guangzhou,China 510006)

The layered and gradient structural Ni-Al/diamond composite has been prepared by SHS method.The influence of the multilayer nature and the diamond particle size gradient structure on the self-propagating reaction process and microscopic appearance of Ni-Al/diamond composite has been studied.Result shows that as the number of layers increases,the combustion wave velocity of the self-propagating reaction decreases;the combustion wave velocity of the self-propagating reaction in the diamond particle gradient structure is higher than that in the diamond layered structure.The microscopic appearance analysis result shows that strong carbon compounds,Cr3C2and Cr7C3,were created by solder alloy Ni-Cr and diamond through self-propagating reaction,which strenghens the adhesion of diamond and the alloy powder matrix.

SHS;Layered SHS structure;gradient SHS structure;Ni-Al intermetallics; diamond

TQ164

A

1673-1433(2017)04-0019-08

2016-11-15

项目获得国家自然科学基金(51275096)、广东省自然科学基金(2015A030313491)和广东省科技计划(2013B010204025)资助

卢家锋(1988-),男,在读研究生,从事超硬材料及磨料磨具研究。

张凤林(1972-),男,博士,教授,主要研究方向为超硬材料工具制造硬脆材料加工及仿真。E-mail:zhangfl@gdut.edu

卢家锋,张凤林,杨志峰,等.自蔓延燃烧合成法制备分层及梯度结构的Ni-Al/金刚石复合材料研究[J].超硬材料工程,2017,29(4):19-26.