热解油水相酸洗-烘焙二级预处理改善玉米秸秆热解特性

2017-07-18胡志超梅艳阳王贤华杨海平邵敬爱陈汉平

胡志超,梅艳阳,杨 晴,王贤华,杨海平,邵敬爱,陈汉平

热解油水相酸洗-烘焙二级预处理改善玉米秸秆热解特性

胡志超,梅艳阳,杨 晴※,王贤华,杨海平,邵敬爱,陈汉平

(华中科技大学煤燃烧国家重点实验室,武汉 430074)

烘焙和酸洗都是可提升生物质品质的预处理方法。烘焙可以脱除生物质中的氧,酸洗则可有效脱除碱金属及碱土金属,而氧和AAEMs对热解油的品质和产率均具有影响。该文研究了酸洗-烘焙两级耦合预处理对玉米秸秆热解特性的影响。试验用酸液取自热解联产联供示范项目热解油的水相部分,烘焙温度选取230、260、290 ℃。研究发现,酸洗预处理能够有效脱除AAEMs,对K、Na、Mg脱除率分别达到97.53%、81.38%、84.86%。两级预处理能明显降低O/C;酸洗-290 ℃烘焙半焦相比玉米秸秆原样,O/C降低了25.32%。两级预处理能明显削弱烘焙对热解油产率的不利影响,酸洗-290 ℃烘焙半焦相比290 ℃烘焙半焦,其热解油产率提高127.66%;两级预处理显著提高了热解油中糖类的含量,同时降低了酚类和酸类的含量;对酸洗-290 ℃烘焙半焦,其热解油中糖类含量高达45.89%,酚类和酸类则低至9.76%和6.31%。其他化学组成如酮类和呋喃类的含量存在一定程度的下降,醛类含量则有小幅度的提升。该文提出的利用热解联产联供示范项目热解油的水相部分对秸秆进行酸洗,并结合烘焙的两级预处理方法可为对生物质热解提供参考。

烘焙;秸秆;热解;酸洗;碱金属及碱土金属

0 引 言

生物质热解是一种重要的生物质热转化技术,可以把低品位生物质转化为品质相对较高的热解油、气体、焦炭等产品。但是,生物质的高含氧量会导致热解油水分含量大、氧含量高、酸性强、黏度大、稳定性差等问题[1]。因此,采取适当的预处理方法降低生物质的氧含量十分有必要。烘焙预处理是一种在惰性氛围下,温度介于200~300 ℃的热化学转化过程[2],是一种能够降低生物质氧含量、增强疏水性和易磨性的预处理方法[3-5]。同时,烘焙可以降低生物油的水含量和酸含量[6]。

但烘焙预处理之后,生物质中仍残留有不少的AAEMs(alkali and alkaline earth metals,AAEMs)。AAEMs会催化热解挥发分中的大分子发生重聚反应,致使热解油产率降低而产生更多的气体和焦炭[7]。同时,热解油中的AAEMs会导致后续提质过程的催化剂中毒[8-9]。所以,有必要采取适当的预处理方法脱除AAEMs。酸洗预处理则能有效脱除AAEMs,理论上能够增加热解油产率,降低气体和焦炭产率[10]。此外,酸洗还有利于提升糖类产量,同时降低生物油中羧酸,酮类及酚类含量[11]。且酸洗后热解油中无机矿物质元素含量很低,理论上后续利用过程中催化剂中毒或者灰沉积影响将被减弱。因此,采取有效的预处理手段提升热解油的品质十分必要。

目前,关于烘焙预处理及酸洗预处理的研究已有很多,但是将二者结合起来研究对热解特性的影响还少有报道。在现有的报道中,Wigley等在烘焙预处理之前,分别利用烘焙液体产物和热解油的轻质油部分进行酸洗,认为2种预处理的结合可以有效脱除AAEMs、乙酰基及水分,并可显著提升热解油中糖类的含量[12-13]。张理等分别利用水和水溶相生物油对生物质洗样,并联合烘焙预处理,发现热解油中糖类含量有所增加[14-15]。热解联产联供示范项目热解油的水相部分富集了热解过程产生的酸性物质,如果能将这部分酸类利用起来进行酸洗,对增加系统的经济性和实现产业物质内部循环均有益处。因此,本文提出一种利用热解联产联供示范项目热解油的水相部分对玉米秸秆进行酸洗,并结合烘焙的两级预处理方法,同时研究二者耦合对生物质热解特性的影响。

1 试验样品及方法

1.1 原料选取与制备

试验用玉米秸秆收集自河南洛阳,经粉碎和筛分之后选取60~120目的粉末颗粒备用,记作CS。试验之前在105 ℃的烘箱中烘48 h至恒质量。

试验用酸液取自鄂州万吨级生物质热解联产联供示范项目的热解油中的水相部分(含水率91%左右),有机成分为酸类69%(乙酸67.88%、丙酸1.12%)、酚类12.9%、酮类2.56%、酯类1.77%等。鄂州万吨级生物质热解联产联供示范项目由华中科技大学煤燃烧国家重点实验室与湖北蓝焰生态能源有限公司合作建设,以秸秆为原料,通过热解技术,连续生产生物燃气、生物炭和生物油,实现供气、供电、供热,为新农村集中居住区提供高品位清洁能源。

酸洗过程为称取30 g玉米秸秆粉末与600 mL酸液(pH值3.4)混合均匀,在30 ℃下,连续搅拌4 h[10];然后水洗过滤,直至冲洗后的去离子水接近中性,水洗后的玉米秸秆粉末放置于105 ℃的烘箱中烘至恒质量。酸洗后的玉米秸秆粉末记作WCS。

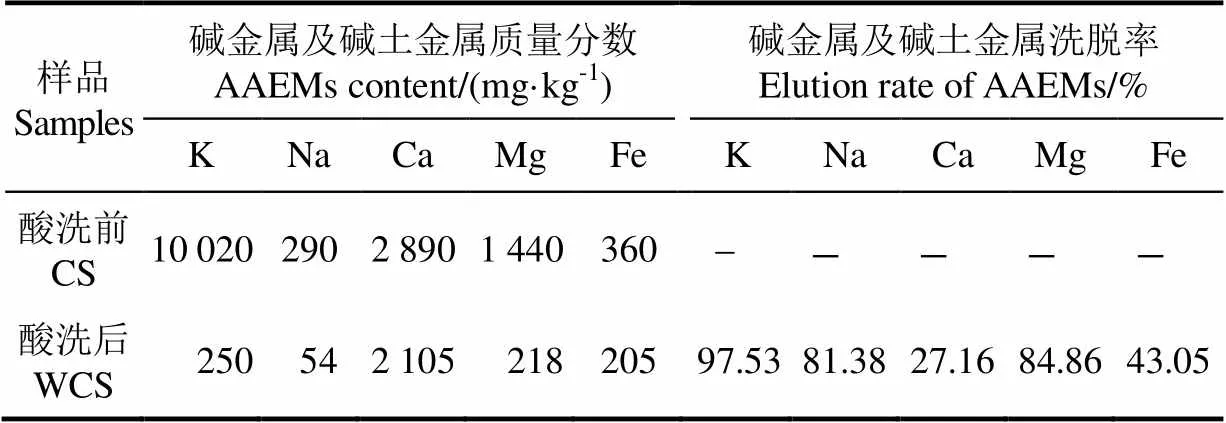

表1是玉米秸秆酸洗前后主要的AAEMs的电感耦合等离子体质谱仪(ICP-MS)分析。可以看出WSC相比SC,酸洗对K、Na、Ca、Mg、Fe脱除率分别达到97.53%、81.38%、27.16%、84.86%、43.05%,这表明酸洗对AAEMs有很好的脱除效果[16]。同时,在酸洗过程中酸液中的其他有机成分也可能起到了一定的作用,Karnowo等认为酚类会弥漫到有机质中和大分子形成H键,形成疏水作用使得乙酸和水更容易通过有机质,进而提高对附着在有机质上的AAEMs的脱除效率[17]。如表2所示,酸洗对灰分的脱除也十分明显,WCS相比CS,灰分含量降低65.89%,这是由于酸洗脱除了玉米秸秆原样中的部分AAEMs及可溶性杂质。

表1 酸洗前后玉米秸秆碱金属及碱土金属结果分析

1.2 烘焙及热解试验

烘焙试验在卧式炉上进行,采用高纯N2为载气,N2流量300 mL/min;选取的烘焙温度分别为:230、260、290 ℃[18];卧式炉达到目标温度后,迅速将3 g的玉米秸秆粉末推至反应器中央恒温段,在此温度下恒温30 min。CS和WCS在230、260、290 ℃烘焙温度下得到的半焦分别记作CS230、CS260、CS290、WCS230、WCS260、WCS290。

热解试验系统为固定床热解系统。热解试验中,采用高纯N2为载气,N2流量设定为400 mL/min。玉米秸秆粉末质量为3 g,待反应器温度升高到550 ℃时,快速推至反应器中央恒温段,恒温时间为30 min[19];热解挥发分经冰水混合冷凝后,不凝性气体采用气袋收集。分别对试验前后样品瓷舟和冷凝瓶进行称量,确定固体产率和液体产率,气体产率通过差减法得到。烘焙及热解的每组试验重复3次,重复性良好,标准偏差在5%以内,最终结果取3次结果平均值。

1.3 热解产物特性分析方法

元素分析采用的是美国珀金埃尔默公司生产的2400系列II型CHNS/O元素分析仪,测定过程利用纯氧燃烧的方法。工业分析使用的是SDTGA5000a型工业分析仪,其测试的依据是利用样品的热失重原理。

AAEMs的测定采用美国珀金埃尔默公司生产的ELAN DRC-e型电感耦合等离子体质谱仪(ICP-MS)进行测定。检测之前,需要将固体样品消解成液态,采用HG08Z-8/10/12/16型高通量智能微波消解仪对样品进行消解。

热解气体的测定使用安捷伦公司的7890B气相色谱仪,利用Agilent OpenLAB CDS软件进行运行。利用气相色谱仪可以测定气体中的CO2、H2、CH4和CO的相对体积含量。

热解油组分的测定选用安捷伦公司的1909IS- 433UI型气相色谱质谱联用仪。每次进样1L,流量设定为1mL/min,运行45 min。MS的试验参数为:加热器的试验温度300 ℃,进样模式为分流的方式,分流比例10:1,即分流流量10 mL/min。

1.4 试验数据处理方法

对于工业分析和元素分析数据,采用专业统计分析软件SPSS(Statistical Product and Service Solutions),版本为22.0,对数据之间的显著性差异进行了分析。检验方法选择检验中的配对样本检验法,置信区间百分比设为95%。

2 结果与讨论

2.1 酸洗对玉米秸秆烘焙三态产率的影响

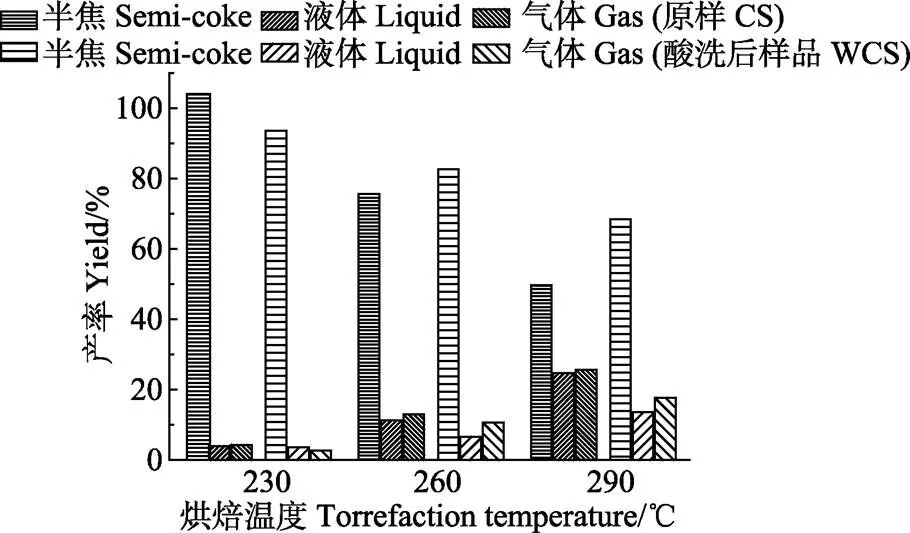

酸洗对玉米秸秆烘焙三态产率的影响如图1所示。从图1中可以看出,酸洗前后,烘焙三态产率的变化趋势基本一致:随烘焙温度提高,半焦产率不断下降,液体和气体产率逐渐增加;但是,相比酸洗前,酸洗后烘焙半焦产率的下降更加缓慢;290 ℃烘焙半焦产率降至49.67%,而酸洗-290 ℃烘焙半焦产率仍可达68.50%,差异显著(<0.05)。这可归因于具有降低热解温度和促进挥发分析出的作用AAEMs的脱除[20]。酸洗后,随烘焙温度提高,烘焙气体产物和液体产物的产率依然呈上升趋势,在酸洗-290 ℃烘焙条件下,气体产物和液体产物产率分别为17.67%和13.59%。但是,酸洗后的烘焙气体产物和液体产物产率的上升速率相比酸洗前二者的上升速率更为缓慢。

2.2 两级预处理对玉米秸秆特性的影响

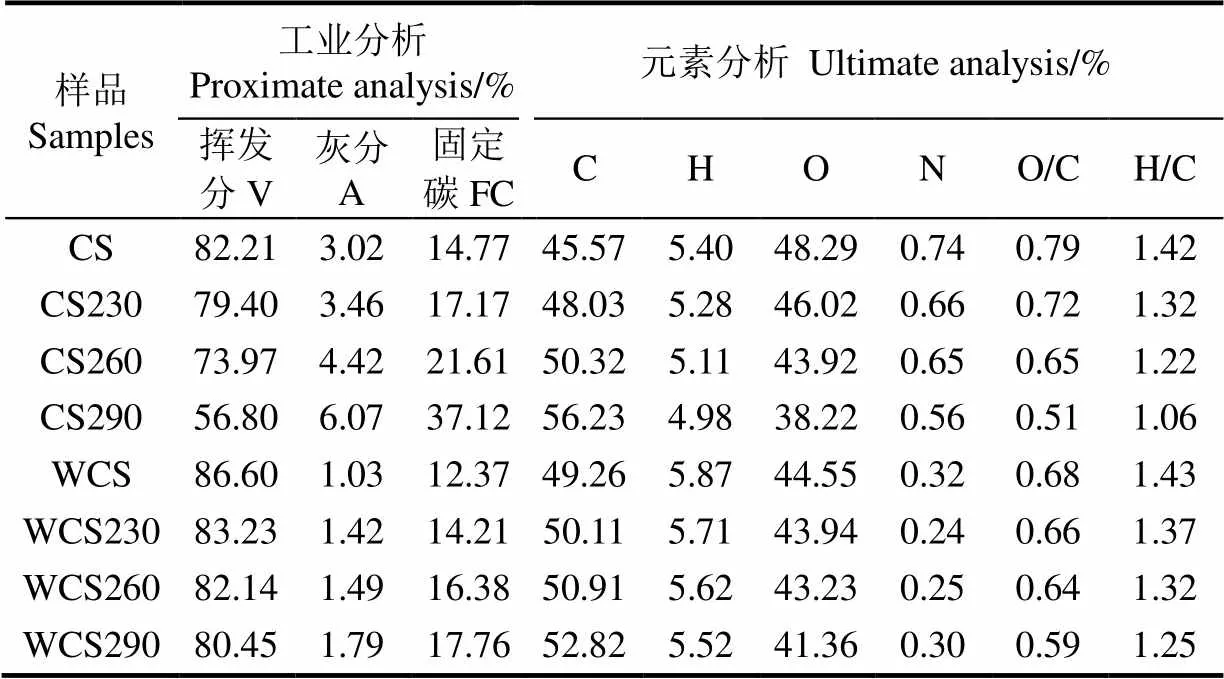

两级预处理前后玉米秸秆的工业分析和元素分析结果如表2所示。从表2中可以看出,对于烘焙预处理,随着烘焙温度的提高,挥发分含量明显减少,固定碳含量和灰分含量不断增加;290 ℃烘焙半焦相比CS,挥发分质量分数降低30.91%,固定碳含量和灰分含量分别增加151.32%和50.25%,差异性不显著(>0.05)。这可归因于烘焙过程中挥发分的析出、碳化作用的不断增强及灰分的残留。对于两级预处理,随着烘焙温度的提高,挥发分含量整体上呈降低趋势,WCS290相比CS降低2.14%;固定碳含量整体上呈增加趋势,WCS290相比CS增加20.24%(<0.05);灰分含量整体上有所增加,WCS290相比WCS,差异不显著(>0.05)。

图1 酸洗对玉米秸秆烘焙三态产率的影响

表2 两级预处理前后玉米秸秆工业分析、元素分析结果

注:氧含量由差减法计算得出;表中数据均以干基计。

Note: The oxygen content was determined by difference; Value in table were calculated based on dry basis.

预处理后,玉米秸秆主要元素有不同程度的变化,其中C元素和O元素变化最为明显。从表2中可以看出,对于烘焙预处理,随着烘焙温度的提高,C元素含量逐渐升高,O元素含量和O/C分子摩尔比逐渐降低,这表明烘焙预处理具有很好的脱氧效果[21];CS290相比CS,C元素含量增加23.39%,O元素含量和O/C分子摩尔比分别降低20.85%和25.35%,差异性显著(<0.05)。这可归因于烘焙过程中发生了脱水反应、脱羧基、羰基化反应,生成了大量的H2O、CO2、CO和较多的含氧化合物[12-13, 22]。对于两级预处理,随着烘焙温度的提高,C元素含量整体上呈升高趋势,WCS290相比CS增加15.91%,差异性显著(<0.05);O元素含量和O/C分子摩尔比整体上呈降低趋势,WCS290相比CS,O元素含量和O/C分子摩尔比分别下降14.35%和25.32%,差异性显著(<0.05)。H元素整体上有所降低,这是因为部分H元素以H2O、CH4、C2H6等形式释放出去。

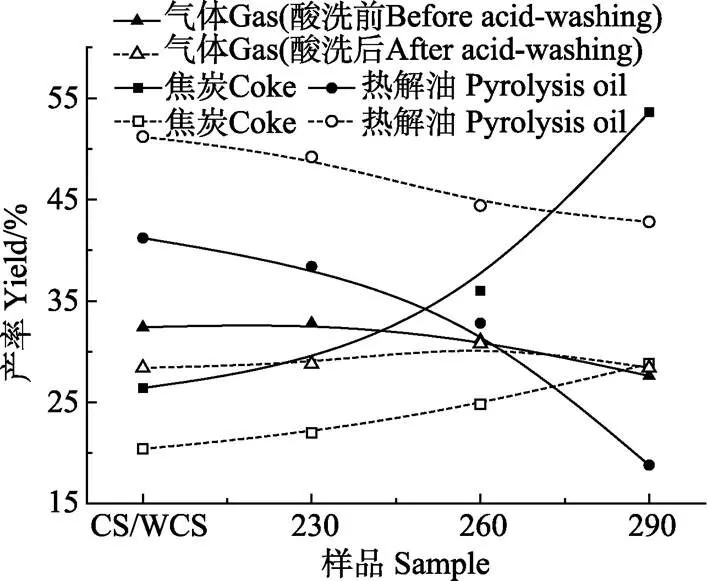

2.3 两级预处理对热解三态产率的影响

两级预处理对玉米秸秆热解三态产率的影响如图2所示。酸洗预处理之后,WCS热解三态产率相比CS热解三态产率,热解油产率提升了10%。这可能是因为酸处理使部分C-O断裂,半纤维素、纤维素及木质素的链单元变得更短,因此更容易转化为热解油[23]。而气体产率降低了4%,可能是因为脱除了促进挥发分发生二次裂解反应的AAEMs[24]。

图2 两级预处理对玉米秸秆热解三态产物产率的影响

从图2中可以看出,随着烘焙温度升高,酸洗-烘焙半焦热解过程中热解油产率不断降低,焦炭产率逐渐增加。这可以归因于烘焙过程中挥发分的析出、交联反应及碳化反应随烘焙温度升高而不断增强[25-27]。但是,相比烘焙半焦,酸洗-烘焙半焦的热解油产率降低和焦炭产率增加的趋势都变得更加缓慢;WCS290相比CS290,其热解油产率增加了127.66%,而焦炭产率下降了46.27%。这可以解释为酸洗脱除了AAEMs,抑制了热解过程中纤维素-木质素及纤维素-碱金属之间的反应,改变了热解路径,促进了热解油的生成和抑制了焦炭的形成[28]。

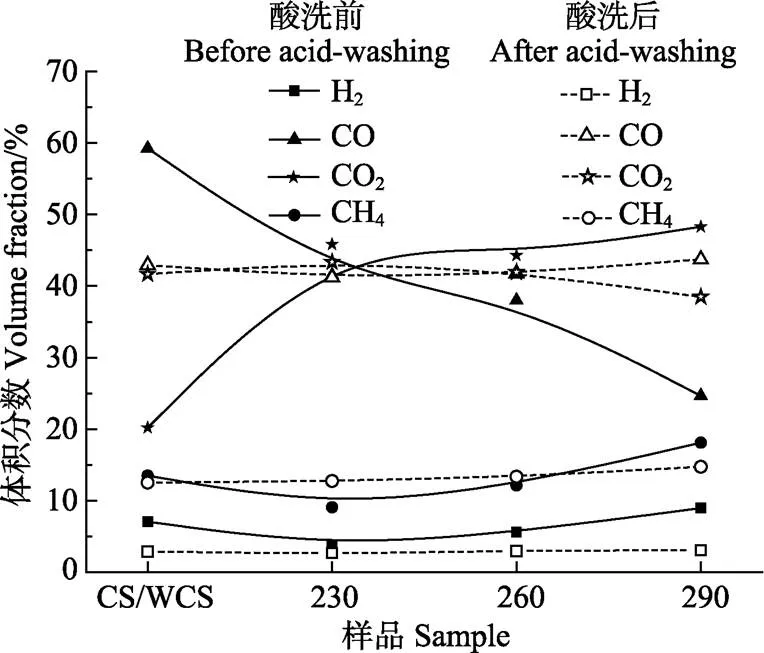

2.4 两级预处理对热解气体产物特性的影响

两级预处理对玉米秸秆热解气体产物组分的影响如图3所示。从图3中可以看出,对于烘焙预处理,随着烘焙温度的提高,CO含量呈明显下降趋势,CS290相比CS下降了37.77%。这可归因于CO主要来自半纤维素中羰基的脱除以及含氧分子的裂解,半纤维素相对含量随烘焙温度提高逐渐降低[29]。随烘焙温度的提高,热解气体中CO2含量逐渐增加,CS290相比CS增加了40.01%。这是因为对于500℃以上的热解过程,CO2的生成主要与木质素有关,烘焙过程中半纤维素与纤维素的部分分解造成了木质素的富集,因此CO2含量呈升高趋势。CH4与H2的含量较低,整体上呈现轻微的增长趋势。

对于酸洗-烘焙预处理,随着烘焙温度的提高,CO、CO2、CH4与H2含量均没有明显的变化趋势。这可能是因为在酸洗过程中脱除了玉米秸秆中的部分的碱金属及碱土金属,而碱金属及碱土金属具有促进挥发分发生二次裂解反应的催化作用,碱金属及碱土金属的脱除使得这种催化作用被弱化,进而抑制了挥发分中小分子物质的生成[24]。

图3 两级预处理对玉米秸秆热解气体组分的影响

2.5 两级预处理对热解液体产物特性的影响

预处理对玉米秸秆热解液体产物组分的影响如图4所示。从图4中可以看到,两级预处理明显的改变了热解液体产物的化学组成,主要是促进了糖类含量的提升,同时降低了酚类、酸类、呋喃类、酮类的含量。

CS及烘焙半焦的热解油中都没有检测到糖类的含量。这可能是因为AAEMs对脱水反应、碳架裂解反应及葡萄糖单元的分解具有促进作用,使得一些中间体如糖类被立即分解或发生了二次反应[30-32]。酸洗预处理之后,热解油中糖类相对含量达到20.80%;且随烘焙温度升高,糖类含量不断提升,WCS290达到45.89%。这可能是因为AAEMs以羧酸盐或以交联点的形式存在于木质素、纤维素及半纤维素之间,酸洗过程中AAEMs被H+替代,导致了相关交联点的分解,形成了一种松散的结构,这些结构变化会提升对糖类选择性[33-35]。此外,半纤维素和纤维素的交互作用会抑制糖类的生成,烘焙则会减弱这种交互作用,因此能够强化热解油中糖类的生成[36-37]。

CS热解的液体产物中,酚类相对含量最高,为25.92%。对烘焙半焦,随着烘焙温度提高,其热解油中酚类含量不断增加,CS290达到47.32%。这可归因于酚类主要来源于木质素的分解,而木质素相对含量随烘焙温度升高不断增加[22]。对酸洗-烘焙半焦,随烘焙温度提高,其热解油中酚类含量逐渐降低,由WCS的18.42%降低至WCS290的9.76%。Mourant等认为AAEMs以弱键形式存在于木质素三维结构、木质素-纤维素及木质素-半纤维素之间,热分解时这些键会断裂生成小分子量一元酚。而AAEMs的脱除,使得这些弱键密度降低,抑制了木质素的解聚,增强了木质素的碳化程度,导致酚类含量的降低[20, 38-39]。

CS热解的液体产物中,酸类相对含量达到20.79%。对烘焙半焦和酸洗-烘焙半焦,其热解油中酸类含量都随烘焙温度提高而不断降低,CS290和WCS290分别降至16.81%和6.31%。这是因为酸类主要来源于半纤维素和纤维素的热解,而在烘焙过程中半纤维素和纤维素逐渐减少和不断碳化。其他化学组成如酮类和呋喃类的含量存在一定程度上的下降,而醛类含量则有小幅度的提升。

3 结 论

本文主要研究了热解油水相洗-烘焙两级预处理对玉米秸秆热解产物的影响,结论如下:

1)酸洗预处理能够有效脱除碱土及碱土金属,对K、Na、Mg脱除率分别达到97.53%、81.38%、84.86%;同时,灰分含量降低65.89%。

2)两级预处理能够明显降低O/C,且O/C随烘焙温度提高而不断低;酸洗-290 ℃烘焙半焦相比玉米秸秆原样,O/C降低了25.32%。

3)酸洗-烘焙半焦相比烘焙半焦,热解油产率降低和焦炭产率增加的趋势更加缓慢。酸洗-290 ℃烘焙半焦相比290 ℃烘焙半焦,热解油产率增加了127.66%,而焦炭产率下降了46.27%。这表明两级预处理相比烘焙预处理,既达到了脱氧的效果,又提高了热解油的产率。

4)两级预处理显著提升了热解液体产物中糖类的含量,降低了酚类和酸类的含量。酸洗-290 ℃烘焙半焦热解油中糖类相对含量高达45.89%,而酚类和酸类则分别降至9.76%和6.31%。

[1] Wang S, Wang K, Liu Q, et al. Comparison of the pyrolysis behavior of lignins from different tree species[J]. Biotechnol Adv, 2009, 27(5): 562-567.

[2] Prins M J, Ptasinski K J, Janssen F J J G. Torrefaction of wood Part 1: Weight loss kinetics[J]. Journal of Analytical and Applied Pyrolysis, 2006, 77(1): 28-34.

[3] Mei Y, Liu R, Yang Q, et al. Torrefaction of cedarwood in a pilot scale rotary kiln and the influence of industrial flue gas[J]. Bioresour Technol, 2015, 177: 355-360.

[4] Chen Y, Liu B, Yang H, et al. Evolution of functional groups and pore structure during cotton and corn stalks torrefaction and its correlation with hydrophobicity[J]. Fuel, 2014, 137: 41-49.

[5] Chen Y, Yang H, Yang Q, et al. Torrefaction of agriculture straws and its application on biomass pyrolysis poly- generation[J]. Bioresour Technol, 2014, 156: 70-77.

[6] Chen W H, Liu S H, Juang T T, et al. Characterization of solid and liquid products from bamboo torrefaction[J].Applied Energy, 2015, 160: 829-835.

[7] Hu S, Jiang L, Wang Y, et al. Effects of inherent alkali and alkaline earth metallic species on biomass pyrolysis at different temperatures[J]. Bioresour Technol, 2015, 192: 23-30.

[8] Leijenhorst E J, Wolters W, van De Beld L, et al. Inorganic element transfer from biomass to fast pyrolysis oil: Review and experiments[J]. Fuel Processing Technology, 2016, 149: 96-111.

[9] 姬登祥,黄承洁,于平,等. 原料预处理对生物质热裂解动力学特性的影响[J]. 农业工程学报,2011,27(13):112-117.Ji Dengxiang, Huang Chengjie, Yu Ping, et al. Influence of feedstock pretreatment on biomass pyrolysis kinetics[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(13): 112-117. (in Chinese with English abstract)

[10] Dong Q, Zhang S, Zhang L, et al. Effects of four types of dilute acid washing on moso bamboo pyrolysis using Py–GC/MS[J]. Bioresource Technology, 2015, 185: 62-69.

[11] Stefanidis S D, Heracleous E, Patiaka D T, et al. Optimization of bio-oil yields by demineralization of low quality biomass[J]. Biomass and Bioenergy, 2015, 83: 105-115.

[12] Wigley T, Yip A C K, Pang S. The use of demineralisation and torrefaction to improve the properties of biomass intended as a feedstock for fast pyrolysis[J]. Journal of Analytical and Applied Pyrolysis, 2015, 113: 296-306.

[13] Zhang S, Dong Q, Chen T, et al. Combination of light bio-oil washing and torrefaction pretreatment of rice husk: Its effects on physicochemical characteristics and fast pyrolysis behavior[J]. Energy & Fuels, 2016, 30(4): 3030-3037.

[14] 张理,张书平,董庆,等. 水洗-烘焙联合预处理对稻壳微波热解产品特性的影响[J]. 化工进展,2015,34(9): 3286-3290. Zhang Li, Zhang Shuping, Dong Qing, et al. Effect of combined washing and torrefaction pretreatment on properties of product from microwave-induced pyrosis of rice husk[J]. Chemical Industry and Engineering Progress, 2015, 34(9): 3286-3290.(in Chinese with English abstract)

[15] 陈涛,张书平,李弯,等. 酸洗-烘焙预处理对生物质热解产物的影响[J]. 化工进展,2017,36(2):506-512. Chen Tao, Zhang Shuping, Li Wan, et al. Effect of acid washing and torrefaction on pyrossis products of biomass[J]. 2017, 36(2):506-512. (in Chinese with English abstract)

[16] Scott D S, Paterson L, Piskorz J, et al. Pretreatment of poplar wood for fast pyrolysis rate of cation removal[J]. Journal of Analytical and Applied Pyrolysis, 2000, 57: 169-176.

[17] Karnowo, Zahara Z F, Kudo S, et al. Leaching of Alkali and Alkaline Earth Metallic Species from Rice Husk with Bio-oil from Its Pyrolysis[J]. Energy & Fuels, 2014, 28(10): 6459-6466.

[18] 张杨,梅艳阳,杨晴,等. 烘焙与HZSM-5催化剂联用改善柏木热解产物品质[J]. 农业工程学报,2015,31(23):208-213.Zhang Yang, Mei Yanyang, Yang Qing, et al. Torrefaction and HZSM-5 catalyst combination improving pyrolytic products of cedarwood[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(23): 208-213. (in Chinese with English abstract)

[19] 杨晴,梅艳阳,郝宏蒙,等. 烘焙对生物质热解产物特性的影响[J]. 农业工程学报,2013,29(20):214-219.Yang Qing, Mei Yanyang, Hao Hongmeng, et al. Effect of torrefaction on characteristics of pyrolytic products of biomass[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(20): 214-219. (in Chinese with English abstract)

[20] Mourant D, Wang Z, He M, et al. Mallee wood fast pyrolysis: Effects of alkali and alkaline earth metallic species on the yield and composition of bio-oil[J]. Fuel, 2011, 90(9): 2915-2922.

[21] Mei Y, Che Q, Yang Q, et al. Torrefaction of different parts from a corn stalk and its effect on the characterization of products[J]. Industrial Crops and Products, 2016, 92: 26-33.

[22] Zheng A, Zhao Z, Chang S, et al. Effect of torrefaction on structure and fast pyrolysis behavior of corncobs[J]. Bioresour Technol, 2013, 128: 370-377.

[23] Kumagai S, Matsuno R, Grause G, et al. Enhancement of bio-oil production via pyrolysis of wood biomass by pretreatment with H2SO4[J]. Bioresour Technol, 2015, 178: 76-82.

[24] Saddawi A, Jones J M, Williams A, et al. Commodity Fuels from Biomass through Pretreatment and Torrefaction: Effects of Mineral Content on Torrefied Fuel Characteristics and Quality[J]. Energy & Fuels, 2012, 26: 6466-6474.

[25] Boateng A A, Mullen C A. Fast pyrolysis of biomass thermally pretreated by torrefaction[J]. Journal of Analytical and Applied Pyrolysis, 2013, 100: 95-102.

[26] Zheng A, Zhao Z, Chang S, et al. Effect of Torrefaction Temperature on Product Distribution from Two-Staged Pyrolysis of Biomass[J]. Energy & Fuels, 2012, 26(5): 2968-2974.

[27] Meng J, Park J, Tilotta D, et al. The effect of torrefaction on the chemistry of fast-pyrolysis bio-oil[J]. Bioresour Technol, 2012, 111: 439-446.

[28] Dobele G, Dizhbite T, Rossinskaja G, et al. Pre-treatment of biomass with phosphoric acid prior to fast pyrolysis[J]. Journal of Analytical and Applied Pyrolysis, 2003, 68-69: 197-211.

[29] Yang H, Yan R, Chen H, et al. Characteristics of hemicellulose, cellulose and lignin pyrolysis[J]. Fuel, 2007, 86(12/13): 1781-1788.

[30] Oudenhoven S R G, Westerhof R J M, Aldenkamp N, et al. Demineralization of wood using wood-derived acid: Towards a selective pyrolysis process for fuel and chemicals production[J]. Journal of Analytical and Applied Pyrolysis, 2013, 103: 112-118.

[31] Oudenhoven S R G, Westerhof R J M, Kersten S R A. Fast pyrolysis of organic acid leached wood, straw, hay and bagasse: Improved oil and sugar yields[J]. Journal of Analytical and Applied Pyrolysis, 2015, 116: 253-262.

[32] Westerhof R J M, Brilman D W F, Garcia-Perez M, et al. Stepwise Fast Pyrolysis of Pine Wood[J]. Energy & Fuels, 2012, 26(12): 7263-7273.

[33] Zhou S, Osman N B, Li H, et al. Effect of sulfuric acid addition on the yield and composition of lignin derived oligomers obtained by the auger and fast pyrolysis of Douglas-fir wood[J]. Fuel, 2013, 103: 512-523.

[34] Yang H, Yan R, Chen H, et al. Influence of mineral matter on pyrolysis of palm oil wastes[J]. Combustion and Flame, 2006, 146(4): 605-611.

[35] Jiang L, Hu S, Sun L S, et al. Influence of different demineralization treatments on physicochemical structure and thermal degradation of biomass[J]. Bioresour Technol, 2013, 146: 254-260.

[36] Das O, Sarmah A K. Value added liquid products from waste biomass pyrolysis using pretreatments[J]. Sci Total Environ, 2015, 538: 145-151.

[37] Zhang S, Dong Q, Zhang L, et al. Effects of water washing and torrefaction on the pyrolysis behavior and kinetics of rice husk through TGA and Py-GC/MS[J]. Bioresour Technol, 2016, 199: 352-361.

[38] Wang S, Guo X, Wang K, et al. Influence of the interaction of components on the pyrolysis behavior of biomass[J]. Journal of Analytical and Applied Pyrolysis, 2011, 91(1): 183-189.

[39] 刘慧慧,邹俊,邓勇,等. 改性生物质炭对棉秆热解挥发分析出特性的影响[J]. 农业工程学报,2016,32(22): 239-243.Liu Huihui, Zou Jun, Deng Yong, et al. Influence of modified biomass char on releases characteristics of volatiles during pyrolysis of cotton stalk[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(22): 239-243. (in Chinese with English abstract)

Effect of two-stage pretreatment combined acid-washing with aqueous portion of pyrolysis oil and torrefaction on pyrolysis characteristics of corn stalk

Hu Zhichao, Mei Yanyang, Yang Qing※, Wang Xianhua, Yang Haiping, Shao Jingai, Chen Hanping

(430074,)

Torrefaction and acid-washing are both the pretreatment methods to improve the quality of biomass. Torrefaction can remove oxygen in the biomass, and acid-washing can effectively remove alkali metals and alkaline earth metals (AAEMs). Both oxygen and alkali metals and alkaline earth metals have effect on the quality and yield of pyrolysis oil. However, after torrefaction, there are still a lot of alkali metals and alkaline earth metals remaining in the biomass. Therefore, it is necessary to take appropriate pretreatment methods to remove alkali metals and alkaline earth metals. But acid-washing can not remove oxygen from the biomass. Therefore, for improving the quality of biomass, torrefaction and acid-washing have some limitations. At present, there are many researches on torrefaction and acid-washing, but the the coupling effect of the torrefaction and acid-washing on pyrolysis characteristics is rarely reported. In this paper, a method of two-stage pretreatment by acid-washing and torrefaction was proposed and the coupling effect of the torrefaction and acid-washing on pyrolysis characteristics of corn stalk was studied. The acid liquor was taken from the aqueous portion of the pyrolysis oil from a demonstration project. If the aqueous portion can be used for washing biomass, it is beneficial to increase the benefit of the system and realize the internal circulation of industrial materials. The torrefaction temperature is 230, 260 and 290 ℃. It is found that the AAEMs can be effectively removed by acid-washing, and the removal rates of K, Na, and Mg are 97.53%, 81.38% and 84.86%, respectively. Two-stage pretreatment can significantly reduce O/C ratio; compared to the original corn stalk, the O/C of semi-coke with washing-torrefaction under 290 ℃ reduces by 25.32%. Two-stage pretreatment can obviously reduce the unfavorable effects of torrefaction on oil yield; compared to 290 ℃ torrefaction semi-coke, the oil yield of semi-coke with washing −290 ℃ torrefaction increases by 127.66%. Compared to original corn stalk, there is still a 3.88% increase in the oil yield. Two-stage pretreatment can significantly enhance the carbohydrate content in pyrolysis oil, while reducing the content of phenols and acids. There is no carbohydrate in the pyrolysis oil of corn stalks and torrefaction semi-coke. With the increasing of torrefaction temperature, the relative content of carbohydrate in the pyrolysis oil of washing-torrefaction semi-coke gradually increases. For semi-coke with washing −290 ℃ torrefaction, the content of the carbohydrate in the pyrolysis oil is 45.89%. The relative content of phenols in the pyrolysis oil of corn stalks is the highest, reaching 25.92%. With the increasing of torrefaction temperature, the content of phenols in the pyrolysis oil decreases gradually from 18.42% of sampling with acid-washing to 9.76% of sampling with acid-washing and 290℃ torrefaction. For straw without pretreament, the relative content of the acids in the pyrolysis oil is 20.79%. With the increasing of torrefaction temperature, the relative content of acids in the pyrolysis oil of the torrefaction semi-coke and the washing-torrefaction semi-coke decreases. For 290 ℃torrefaction semi-coke and the washing and 290℃torrefaction semi-coke, the content falls to 16.81% and 6.31%, respectively. Contents of other chemical components such as ketones and furans reduce to a certain extent, but there is a small increase in aldehydes content. On the whole, the two-stage pretreatment not only improves the yield and quality of the pyrolysis oil, but also finds a good way for the use of the aqueous portion.

torrefaction; straw; pyrolysis; acid-washing; alkali metals and alkaline earth metals

10.11975/j.issn.1002-6819.2017.12.029

TK6

A

1002-6819(2017)-12-0224-06

2016-12-15

2017-05-15

国家自然科学基金:生物质低温脱氧及其与热解过程的关联耦合机制研究(51306067);生物质低温强化脱氧与催化热解共耦合制备单环芳烃的机理研究(51576087);基于组分的生物质分级液化机理及产物分离方法研究(51676075)

胡志超,男,河南许昌人,主要从事生物质热化学转化技术研究。武汉 华中科技大学煤燃烧国家重点实验室,430074。 Email:zc.hu@outlook.com

杨 晴,女,湖北京山人,副教授,博士生导师,主要从事生物质热转化理论及技术研究。武汉 华中科技大学煤燃烧国家重点实验室,430074。Email:qingyang@g.harvard.edu

胡志超,梅艳阳,杨 晴,王贤华,杨海平,邵敬爱,陈汉平. 热解油水相酸洗-烘焙二级预处理改善玉米秸秆热解特性[J]. 农业工程学报,2017,33(12):224-229. doi:10.11975/j.issn.1002-6819.2017.12.029 http://www.tcsae.org

Hu Zhichao, Mei Yanyang, Yang Qing, Wang Xianhua, Yang Haiping, Shao Jingai, Chen Hanping. Effect of two-stage pretreatment combined acid-washing with aqueous portion of pyrolysis oil and torrefaction on pyrolysis characteristics of corn stalk[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(12): 224-229. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.12.029 http://www.tcsae.org