不同边膜铲起膜性能分析及其起膜率对比试验

2017-03-27张佳喜刘旋峰蒋永新王吉奎

张佳喜,张 丽,刘旋峰,蒋永新,王吉奎

不同边膜铲起膜性能分析及其起膜率对比试验

张佳喜1,张 丽2,刘旋峰2,蒋永新2,王吉奎3※

(1. 新疆农业大学机械交通学院,乌鲁木齐 830052;2. 新疆农业科学院农业机械化研究所,乌鲁木齐 830091; 3. 石河子大学机械电气工程学院,石河子 832003)

农田地膜污染治理中,由于秋后残膜回收中缺乏较为理想的机构起翻边膜,致使边膜埋于地表不易被回收部件进行回收,对土壤及环境造成一定的污染。为解决这一问题,选取目前较为普遍使用的2种边膜起膜机构开沟器和双翼铲,新设计一种单翼铲,对其进行力学分析,对比3种不同结构的边膜铲受力情况,并且在新疆库尔勒尉犁县开展田间对比试验,对比不同结构的边膜铲在田间的工作性能,考核起出残膜完整率、起膜率及有无壅土现象发生这3个关键因素。结果表明:边膜铲的受力大小与边膜铲入土角度和铲刃的长度有关,对3种边摸铲理论分析得出单翼铲的受力最大,开沟器受力最小,双翼铲受力较为合理,而在田间性能试验中虽然单翼铲受力最大但其作业效果最佳,起出边膜的完整率达100%、起膜率在95.4%、并且在作业中没有壅土现象发生,考虑到作业效果的突出,推荐单翼铲作为秋后残膜回收机的边膜起膜机构。研究结果可为秋后残膜回收机的边膜起膜机构的设计选择提供参考。

农业;力学分析;地膜;残膜;边膜铲

0 引 言

自70年代以来地膜种植技术在中国的快速推广,地膜造成的白色污染日趋严重,人们对地膜回收也越来越重视[1-2]。目前市场上残膜回收机的种类很多,主要分为苗期残膜回收和秋后残膜回收2种,2种机型对存留在地表地膜回收相对容易,基本上能回收到95%以上,针对边膜回收区别较大,苗期残膜回收边膜效果较好,原因是苗期残膜受到的日晒等因素的影响时间较短,所以其残膜的强度较高,几乎不用什么辅助机构便可以将边膜从土中带出,残膜回收率可达95%以上[3-7];秋后残膜回收针对边膜回收较困难,造成残膜回收率在80%左右[8-9],究其原因,以覆盖膜宽为1.25 m地膜为例,边膜单边覆土宽度为0.07 m,深度为0.08 m,则边膜占所铺膜的比例达到16%[10],而边膜埋于地表以下,由于秋后残膜受到的侵蚀时间较长,与泥土粘连严重,残膜强度受到很大的影响,依靠地表残膜的拉扯连带回收边膜,几乎不可能了,大多秋后地膜回收机没有将这部分残膜回收起来,因此残膜回收率较低[11-12]。为了降低残膜造成的污染,促进新农村的建设,提高残膜回收率,开发设计新型边膜铲,在理论分析的基础上,进行田间对比试验寻求最佳的边膜起膜机构,从根本解决边膜回收难的问题。

1 边膜铲工作原理

如图1所示,地膜覆盖种植中通常单侧边膜被掩埋于地表下7~8 cm左右,掩埋的地膜长度为10cm左右,边膜铲工作时入土深度需大于10 cm,将掩埋的边膜平翻于地表,最大限度地保证边膜的完整性,不要撕裂边膜的情况下,同时保护好地表非边膜区域的地膜,不要对其移动或者损害,以利于后续拾膜部件将其回收。

2 边膜铲的种类

目前市场上使用的边膜铲种类较多,较为普遍的是开沟器、双翼铲及单翼铲[13-16],为此选定以上3种边膜铲进行研究分析,如图2所示,3种边膜铲分别为:图2a为开沟器(常用),图2b为双翼铲(常用),图2c为单翼铲(改进设计:在铲柄的一侧安装有铲托,铲刀平放与铲托之上,铲刀长度为30 mm),3种边膜铲的高度均为500 mm,根据不同边膜铲的结构分别进行力学分析。

3 不同边膜起膜部件的力学分析

边膜铲工作时匀速前行,假设边膜铲入土角为1,受力如图3所示,其水平方向平衡方程为[17]

式中为土壤与边膜铲间的摩擦力(=),N;为楔面上受到土壤的法向载荷,N;为牵引力,N;为楔面切土阻力(=),N;1为楔面与地面夹角,(°)。

注:为土壤与边膜铲间的摩擦力(=),N;为楔面上受到土壤的法向载荷,N;为牵引力,N;为楔面切土阻力(=),N;1为楔面与地面夹角,(°);为边膜铲刃宽,m;为单位刃宽上的刃切阻力,N。

Note:is the friction between soil and side film shovel (=N), N;is the normal load of soil in wedge face, N;is the tractive force,N;is the drag force of cutting soil in wedge face (=), N;1is the angle between the wedge face and the ground, (°);is the blade width of side film shovel, m;is the cutting resistance on the blade unit, N.

图3 边膜铲入土受力分析

Fig.3 Workforce analysis of side film shovel

边膜铲工作根据翻垡原理[18],边膜铲入土1角愈大,边膜铲对它前面的土壤压缩和破碎愈大,边膜铲的工作阻力也愈大[19],一般情况1应小于38°[20],但由于被铲起土垡前端有土壤支承,故可以适当超过38°。根据机具的结构1可取15°~40°之间,1值小于25°时,边膜铲应当为上磨刃[15]。结合式(1)深入分析可知,减小刃宽,增加侧刃更利于破土。结构如图3所示。减小了直刀刃的宽度,增加了侧刃长度,侧刃具有滑切的作用,滑切较正切省力。

下面分别对几种边膜铲进行力学分析。

3.1 开沟器力学分析

开沟器是农业机械中较为常用的土壤工作部件,主要用于播种、施肥及除草使用,结构是一根扁铁,具有一定的厚度,材料大多为铸钢,结构较为简单,成本低。

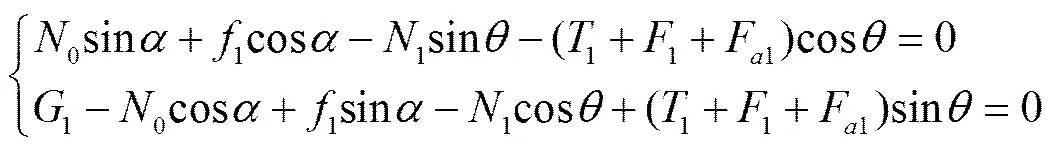

入土深度10 cm,开沟器入土作业时,开沟器受力如图4a所示,各力在水平方向上(前进方向)有如下关系

开沟器入土作业时,被松土壤所受力如图4b所示,图中的力系平衡方程式为

式中为土壤容重;1为开沟器宽度,m;为土壤内聚力,N/m2;为松土深度,m;为作业速度,m/s;1为土垡剪切面面积,m2;′为土壤内摩擦系数;为土壤与开沟器表面的摩擦系数。

由式(2)、(3)和(4)可得牵引力为

3.2 双翼铲力学分析

双翼铲入土部分在立柱左右方向对称布置有一定弧度的圆弧面板,面板材料多为65 Mn,工作时比较容易入土,在双翼铲面板的正前方堆积土壤,随着机具的前进,压力逐渐增大,堆积土壤沿着圆弧面向两侧分流,落回所开的沟内,在湿度较高的土壤中容易壅土。

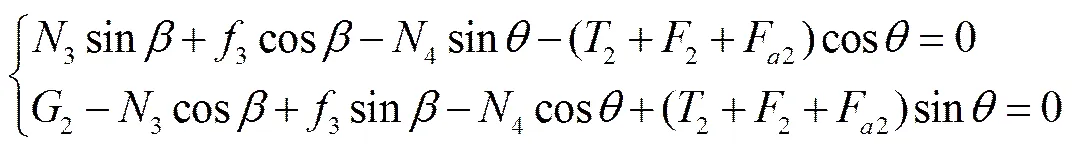

双翼铲入土作业时,受力如图5所示,双翼铲翼张角的大小直接关系到能否采用滑切的方式切断杂草,如果不能切断杂草就会被草缠住并使双翼铲出土,一般近似为45°。各力在双翼铲水平方向上(前进方向)有如下关系

注:2为双翼铲斜面受土壤摩擦力(2=2)(双翼铲两侧受力相似),N;3为双翼铲斜面受土壤摩擦力(3=3),N;2为双翼铲前端切土阻力(2=KB),N;2为牵引力,N;2为双翼铲铲刃受到的土壤压力(双翼铲两侧受力相似),N;3为双翼铲表面法向载荷,N;为双翼铲翼张角,(°);为双翼铲斜面与地面夹角,(°)。

Note:2is the friction of double wing shovels along the slant (22)(the force on both sides of double wing shovels is almost similar), N;3is the friction of double wing shovels face along the slant (f=μN3), N;2is the friction drag force at the front of double wing shovels cutting soil (2);2is the tractive force, N;2is the pressure force of double wing shovels blade(the force on both sides of double wing shovels is almost similar), N;3is the surface normal load of double wing shovels, N;is the opening angle of double wing shovels, (°);is the angle of double wing shovels between the wedge face and the ground, (°).

图5 双翼铲受力分析

Fig.5 Force analysis of double wing shovels

同理,双翼铲入土作业时,土壤所受力与双翼铲入土作业时土壤所受力相同(图5b),由于双翼铲前端宽度较小,切土阻力可忽略不计,用相似的方法,可以得到如下关系

式中2为土垡剪切面面积,m2;2为双翼铲宽度,m;2为土块重力,2为土壤内部剪切失效时的剪切力,N;N;a2为使土壤运动的加速力,N;2为土壤内部摩擦力,N;4为双翼铲表面土壤受地表土壤的挤压力,N。

由式(6)和(7)可得牵引力2为

3.3 单翼铲力学分析

单翼铲是由立柱一侧固定一铲托,在铲托上固定边铲,需要边铲材料具有较高耐磨性,一般为65 Mn材料,工作时,边铲以一定角度入土,将土壤沿着边铲平面向后推移,顺滑地落入边铲后方。

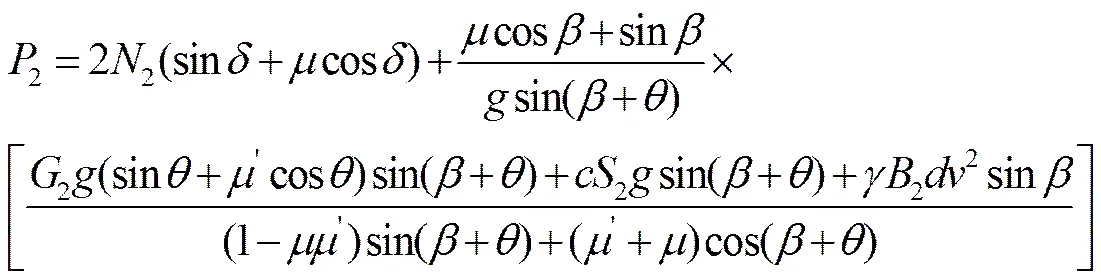

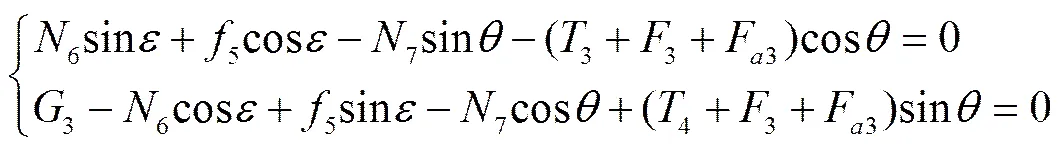

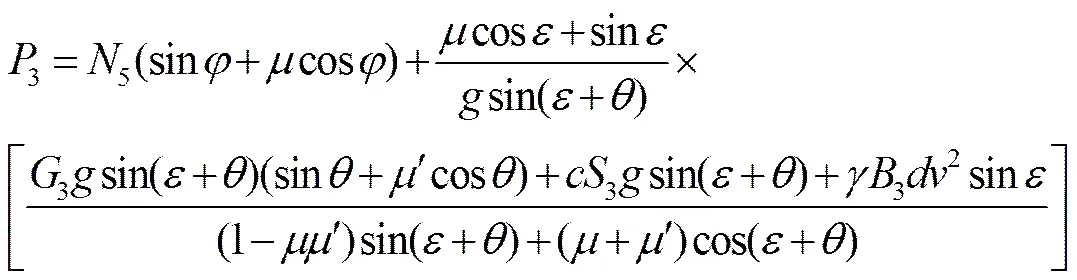

单翼铲入土作业时,受力如图6所示,由于单翼铲前端宽度较小,切土阻力可忽略不计,各力在单翼铲水平方向上(前进方向)[20-24],有如下关系

注:4为单翼铲斜面受土壤摩擦力(4=5),N;5为单翼铲斜面受土壤摩擦力(5=6),N;3为牵引力,N;3为单翼铲前端切土阻力(3=),N;5为单翼铲铲刃受到的土壤压力,N;6为单翼铲表面法向载荷,N;为单翼铲斜面与地面夹角,(°);为单翼铲铲刃与前进方向夹角,(°)。

Note:4is the friction of one wing shovel along the slant (45), N;fis the friction of one wing shovel face along the slant (56), N;3is the tractive force, N;3is the friction drag force at the front of one wing shovel cutting soil (3), N;5is the pressure force of one wing shovel blade, N;6is the surface normal load of one wing shovel, N;is the angle of one wing shovel between the wedge face and the ground, (°);is the opening angle of one wing shovel, (°).

图6 单翼铲入土受力分析

Fig.6 Force analysis of one wing shovel

单翼铲入土作业时,土壤所受力参照图6b,同理可以得到如下关系

式中3为土垡剪切面面积,m2;3为单翼铲宽度,m;3为土壤内部摩擦力,N。3为土壤内部剪切失效时的剪切力,N;3为土块重力,N;a3为使土壤运动的加速力,N;7为单翼铲表面土壤受地表土壤的挤压力,N。

由式(9)和(10)可得牵引力3为

通过以上计算分析,可以看出在单翼铲由于具有较长的刃宽,所以在土壤中起翻的边膜宽度最大,而且向一侧翻土,这样就有利于将边膜翻出,但是在土壤中受到较大的阻力;开沟器则几乎没有刃宽,则开沟器受力也最小[25-27],但是在土壤中起翻的边膜压土很小,因此起翻的边膜面积也越小,同时有可能撕裂边膜;双翼铲受力比单翼铲较小,并且双翼铲的结构设计较为合理,立柱的左右侧向力可以互相抵消,并且铲面受到土壤的阻力也较小,但双翼铲工作位置如在边膜中间则容易撕裂边膜,增加回收难度,如在一侧受到起翻宽度的影响,不能完全起翻边膜,另外一侧同样入土,没有起到任何作用。

4 边膜起膜部件对比试验

4.1 试验条件

以上对3种不同结构的边膜铲受力情况进行了理论分析,为了分析边膜铲的受力情况与作业效果的关系,即作业效果是否与受力大小成正比,在新疆库尔勒尉犁县棉田针对3种结构边膜铲进行了田间对比试验。棉田采用宽窄行种植模式(740 mm+40 mm),地面平整,土壤含水率为11%,棉花已收获,且棉秆已切碎清理,棉秆留茬高度为50~75 mm,地膜厚度为0.008 mm,膜边覆土宽度为110~120 mm,厚度为40~50 mm。机具作业速度均为3 km/h,配套动力由福田雷沃M800-D拖拉机提供,试验平台采用新疆农业科学院农业机械化研究所生产的4JSM-1800型棉秸秆还田及残膜回收联合作业机[28-29],该机在试验中只作为一个固定平台,无需挂接传递动力,在机架的横梁处,设计通用固定座,可以方便更换边膜铲,机构上设有开销孔和固定锁紧装置,用以保证边膜铲具有相同的入土深度,入土深度均为70 cm。图7为3种边膜铲起膜试验效果图。

a. 开沟器起膜试验

a. Side films dug by furrow opener

b. 双翼铲起膜试验

b. Side films dug by double wing shovel

4.2 试验指标与方法

为对比3种边膜铲的起膜效果,选取起膜率和边膜破损程度为试验指标。测试地块长度为100 m,随机选出9个试验区为试验对象,对3种边膜铲各进行3次重复试验,每个试验区随机选取5个点作为检测点,每个检测点长度为10 m,边膜宽度0.12 m[30],每次试验结束后,将各检测点翻起的残膜洗净晒干后,采用盛博SB-A1003电子精密天平秤(100 g/0.001g)称其质量,分别计算3种类型边膜铲所有检测点平均值2作为该类型边膜铲的试验结果,各检测点当年所铺边膜质量1=9.41 g。

边膜起膜率可由式(12)得出

式中为边膜起膜率,%;1为各检测点当年所铺边膜质量,g;2为作业后翻起的边膜平均质量,g。

4.3 试验结果与分析

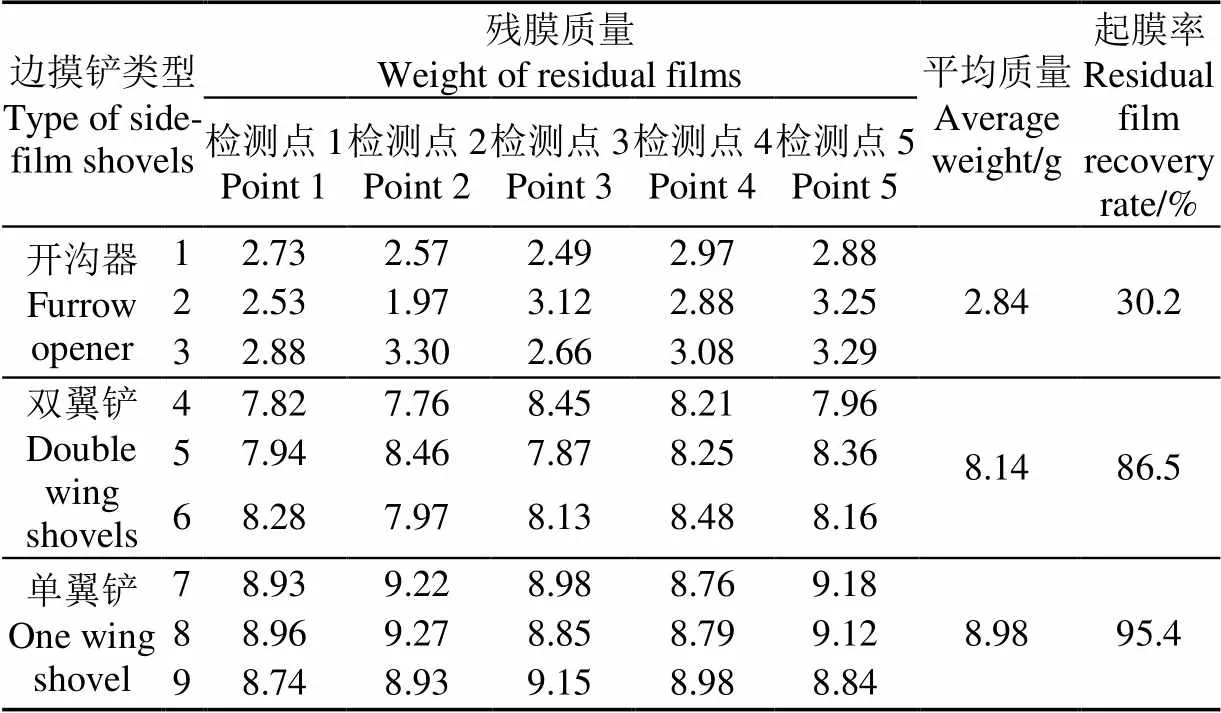

经过田间对比试验,3种边膜铲起膜性能指标如表1所示。由于边膜破损程度不易从数据直接判断,因此未给出边膜破损统计的数据,这里只给出边膜起膜率的统计数据。

表1 性能指标测试结果

如图7a所示,开沟器作业过程中,开沟器基本上在地表上划了一道较深的划痕,只是将边膜划开,并没有将埋在地下的边膜起翻出来,从表1可以得知,边膜起膜率能达到30%左右,虽然通过前面理论计算受力最小,但是效果较差。

如图7b所示,双翼铲田间试验效果较开沟器有较大的提高,对边膜的起翻有较好的效果,边膜大部分都可以翻起,从表1可以得知,边膜起膜率可以达到86.5%,虽然受力较为合理,但由于另一侧翼也将入土起膜,会将边膜与地表整片地膜撕裂,边膜破损程度较大,并伴有壅土现象,且立柱易变形需要加固或者调整结构。

针对双翼铲易将边膜中间撕开或将边膜与整片膜分开的问题,设计了一侧带翼铲的边膜铲,作业效果如图7c所示。单翼铲可以将边膜翻起,同时翻起的边膜较为完整浮于地表,起出边膜的完整率达100%,且没有发生壅土现象,便于地膜回收,从表1可知,边膜起膜率能达到95.4%,虽然单翼铲理论分析受力最大,但是与开沟器和双翼铲相比,作业起边膜效果最好,起膜效果这一点完全可以将受力最大的缺点忽略,单翼铲能有效解决边膜回收难的问题,因此可在实际生产中采用。

5 结 论

1)边膜铲的受力大小与边膜铲前进方向上的垂直长度的刃口成正比,刃口越长则边膜铲受力越大,与边膜铲入土角成正相关,边膜铲入土角越大则受力越大。对比3种结构边膜铲,计算结果单翼铲受力较大,对铲立柱有较高要求,双翼铲的受力较为合理,其中单翼铲的工作宽度最大。

2)开沟器、双翼铲及单翼铲3种不同的边膜铲安装在试验装置上进行起边膜试验,试验效果最佳的是单翼铲,虽然单翼铲的受力最大,但是单翼铲边膜完整率较好,起膜率达95.4%,而且不壅土。衡量残膜回收机的作业质量的关键一点就是边膜是否回收,原因是边膜占整张膜的16%左右,是否回收边膜直接影响到了地膜回收率,因此为了追求残膜机的作业质量,提高地膜回收率,秋后地膜回收装置的边膜铲的结构建议使用单翼铲,并希望在实际生产中得到快速推广使用。

[1] 严昌荣,梅旭荣,何文清,等. 农用地膜残留污染的现状与防治[J]. 农业工程学报,2006,22(11):269-272. Yan Changrong, Mei Xurong, He Wenqing, et al. Present situation of residue pollution of mulching plastic film and controlling measures[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006, 22(11): 269-272. (in Chinese with English abstract)

[2] 盛言忠. 揭膜拔秆技术试验分析[J]. 农业开发与装备,2010(7):29-30. Sheng Yanzhong. Experiment and analysis on techniques of removing coating and rocker[J]. Agricultural Development & Equipments, 2010(7): 29-30. (in Chinese with English abstract)

[3] 那明君,董欣,侯书林,等. 残膜回收机主要工作部件的研究[J]. 农业工程学报,1999,15(2):112-115.

Na Mingjun, Dong Xin, Hou Shulin, et al. Research on main components of the machine for retrieving the used plastic film after harvesting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1999, 15(2): 112-115. (in Chinese with English abstract)

[4] 张东兴. 残膜回收机的设计[J]. 中国农业大学学报,1999(6):41-43.

Zhang Dongxing. Research and design on collector of used plastic film on farm field[J]. Journal of China Agricultural University, 1999(6): 41-43. (in Chinese with English abstract)

[5] 侯书林,胡三媛,孔建铭,等. 国内残膜回收机研究的现状[J]. 农业工程学报,2002,18(3):186-190.

Hou Shulin, Hu Sanyuan, Kong Jianming, et al. Present situation of research on plastic film residue collector in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2002, 18(3): 186-190. (in Chinese with English abstract)

[6] 卢博友,杨青,薛少平,等. 圆弧形弹齿滚筒式残膜捡拾机构设计及捡膜性能分析[J]. 农业工程学报,2000,16(6):68-71. Lu Boyou, Yang Qing, Xue Shaoping, et al. Design of arcspring-tooth type collector for collecting plastic filming plastic film the collecting property analysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2000, 16(6): 68-71. (in Chinese with English abstract)

[7] 张佳喜,谢建华,薛党勤,等. 国内外地膜应用及回收装备的发展现状[J]. 农机化研究,2013(12):237-240. Zhang Jiaxi, Xie Jianhua, Xue Dangqin, et al. Development status of applying plastic film and the residue plastic filming film collecting machine at domestic and overseas[J]. Journal of Agricultural Mechanization Research, 2013(12): 237-240. (in Chinese with English abstract)

[8] 谢建华,侯书林,刘英超,等. 残膜清理回收机具的研究现状及存在的问题[J]. 中国农机化,2012(5):41-44. Xie Jianhua, Hou Shulin, Liu Yingchao. Research on status and trends of plastic film residue collectors[J]. Chinese Agricultural Mechanization, 2012(5): 41-44. (in Chinese with English abstract)

[9] 王吉奎,付威,王卫兵,等. SMS-1500 型秸秆粉碎与残膜回收机的设计[J]. 农业工程学报,2011,7(7):168-172. Wang Jikui, Fu Wei, Wang Weibing, et al. Design ofSMS-1500 type straw chopping and plastic film residue collecting machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 7(7): 168-172. (in Chinese with English abstract)

[10] 马少辉,张学军. 边膜残膜回收机的设计与试验[J]. 农业工程,2012,28(1):73-75. Ma Shaohu, Zhang Xuejun. Design and experiment of side of used plastic film collector machine[J]. Agricultural Engineering, 2012, 28(1): 73-75. (in Chinese with English abstract)

[11] 孙兴冻,陈玉龙,罗昕,等. 针对秋后立秆模式的残膜回收机的设计[J]. 农机化研究,2015(9):73-76. Sun Xingdong, Chen Yulong, Luo Xin, et al. Design and research of plastic film residue collector used on vertical stem after autumn[J]. Journal of Agricultural Mechanization Research, 2015(9): 73-76. (in Chinese with English abstract)

[12] 张佳喜,王学农,张丽,等. 农田地膜拉伸性能变化对缠绕式回收的影响[J]. 农业工程学报,2015,31(20):41-47. Zhang Jiaxi, Wang Xuenong, Zhang Li, et al. Degree that the mechanical tensile properties of the plastic film on crops influences on plastic recycling machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(20): 41-47. (in Chinese with English abstract)

[13] 姚宗路,高焕文,李洪文,等. 不同结构免耕开沟器对土壤阻力的影响[J]. 农机化研究,2009,31(7):30-34. Yao Zonglu, Gao Huanwen, Li Hongwen, et al. Effect of different structural no-till openers on soil resistant force[J]. Journal of Agricultural Mechanization Research, 2009, 31(7) : 30-34. (in Chinese with English abstract)

[14] 李艳龙,刘宝,崔涛,等. 1SZ-460 型杠杆式深松机设计与试验[J]. 农业机械学报,2009,40(增刊):37-40.

Li Yanlong, Liu Bao, Cui Tao, et al. Design and field experiment on 1SZ-460 lever-type subsoiler[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(Supp.): 37-40. (in Chinese with English abstract)

[15] 杨有刚,张宏,冯涛,等. 土壤浅深松联合松耕机设计和浅松土试验[J]. 机械工程学报,2012,48(19):163-168.

Yang Yougang, Zhang Hong, Feng Tao, et al. Topsoil and subsoil combined cultivator and top-soiling experiment[J]. Journal of Mechanical Engineering, 2012, 48(19): 163-168. (in Chinese with English abstract)

[16] 赵金辉,杨学军,周军平,等. 播种机开沟器及其性能测试装置的现状分析[J]. 农机化研究,2014,36(1):238-241. Zhao Jinhui, Yang Xuejun, Zhou Junping, et al. Analysis the current situation about furrow opener and its performance test device[J]. Journal of Agricultural Mechanization Research, 2014, 36(1): 238-241. (in Chinese with English abstract)

[17] 西涅阿科夫,潘诺夫. 土壤耕作机械的理论和计算[M]. 北京:中国农业出版社,1981.

[18] 吉尔W R,范德伯奇G E. 耕作和牵引土壤动力学[M]. 耕作和牵引土壤动力学翻译组,译. 北京:中国农业机械出版社,1983.

[19] 曾德超. 机械土壤动力学[M]. 北京:北京科学技术出版社,1995:414-433.

[20] 农业机械设计手册[M]. 北京:中国农业科学技术出版社,2007:1104-1105 .

[21] 赵伟,张文春,周志立,等. 深松旋耕组合作业机的研制与试验研究[J]. 农业工程学报,2007,23(1):125-128.

Zhao Wei, Zhang Wenchun, Zhou Zhili, et al. Development and experimental research of combined subsoiling and rotary tilling set[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(1): 125-128. (in Chinese with English abstract)

[22] 薛惠岚,杨林青,廉登极,等. 双翼深松铲设计参数的试验研究[J]. 西北农业大学学报,1987,15(1):24-29.

Xue Huilan, Yang Linqing, Lian Dengji, et al. Tests of designing parameters of double-wing subsiler[J]. Journal of Northwest A&F University, 1987, 15(1): 24-29. (in Chinese with English abstract)

[23] 朴顺男,张青松,刘宏博,等. 基于EDEM的双翼式深松铲设计与仿真试验[J]. 广东农业科学,2014,41(16):182-186. Sun Nam Pak, Zhang Qingsong, Liu Hongbo, et al. Design and simulation experiment on double-wings deep-shovel based on EDEM[J]. Shandong Agricultural Sciences, 2014, 41(16) :182-186. (in Chinese with English abstract)

[24] 甄文斌,杨丹彤,黄世醒,等. 带翼深松铲的试验研究[J]. 农机化研究,2011,33(8):119-122. Zhen Wenbin, Yang Dantong, Huang Shixing, et al. Experimental study on a type of subsoiling shovel with flank[J]. Journal of Agricultural Mechanization Research, 2011, 33(8): 119-122. (in Chinese with English abstract)

[25] 娄秀华,张东兴,耿端阳,等. 残膜回收机起膜器的设计与试验研究[J] . 农业工程学报,2002,18(6):88-90. Lou Xiuhua, Zhang Dongxing, Gen Duanyang, et al. Research and design on loosening shovel of polythene film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2002, 18(6): 88-90. (in Chinese with English abstract)

[26] 张昭,朱瑞祥. 双翼深松铲结构的有限元分析与改进设计[J].甘肃农业大学学报,2012,47(1):140-144. Zhang Zhao, Zhu Ruixiang. Finite element analysis and improving design of double-wing deep loosening shovel[J]. Journal of Gansu Agricultural University, 2012, 47(1): 140-144. (in Chinese with English abstract)

[27] 邱立春,李宝筏. 自激振动深松机减阻试验研究[J]. 农业工程学报,2000,16(6):72-76.

Qiu Lichun, Li Baofa. Experimental study on the self-excited vibration subsoiler for reducing draft force[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2000, 16(6): 72-76. (in Chinese with English abstract)

[28] 王学农,冯斌,陈发,等. 4JSM-1800棉秸秆还田及残膜回收联合作业机研制[J]. 新疆农机化,2003(4):53-54.

[29] 刘旋峰,张丽,郭兆峰,等. 1SM-1.8(2.0)型牵引式棉田残膜回收机的研制[J]. 新疆农机化,2015(3):13-14.

[30] 茆诗松. 试验设计[M]. 北京:中国统计出版社,2004:120-124.

Mechanical analysis and contrast experiment on collecting residual plastic film with different side-film shovels

Zhang Jiaxi1, Zhang Li2, Liu Xuanfeng2, Jiang Yongxin2, Wang Jikui3※

(1.,830052;2,830091; 3.,832003)

In the pollution controlling of the residual plastic films in the farmland, due to the lack of preferable side-film shovel mechanics in autumn plastic film recycling, the side-film can’t be recycled by the side-film shovel but be buried under the ground surface. A large amount of residual plastic film into soil due to long-term using film on the crops has caused great serious influence on the high quality of farmland planting, crop growth, the rural ecological environment. The side-film accounted for 16% of the whole plastic film, which would result in the lower recovery rate for plastic film recycling and the recovery rate was generally maintained at about 80%, nearly 20% of the plastic film still remained in the soil, which caused definite pollution to the soil and the environment. Current research on the recovery mechanism is limited to the equipment of plastic film enwinding recycling itself. In order to solve these problems, the more widespread used mechanics for collecting the side-film was chosen such as furrow opener and double wing shovel. Then the mechanical analysis of one wing shovel newly designed was carried out with opener and double wings shovel. The forces of collecting the side-film were compared among three different structural shovels and the field contrast tests were carried out in Yuli county, Korla city in Xinjiang. The working performances of different side-film collecting shovels were compared in the field test. The three key factors were assessed about the integrity rate, film recovery rate and no heap soil phenomenon of residual plastic film. Results showed that the force of the side-film shovel taken was related with the angle into soil and blade length of the side-film shovel during the shovels picking the side-film. According to analyze the force of three types of shovels, we gained the balance equation, the equation involved some kinds of forces, such as the friction along the slant, the normal load along the slant, the shear force of soil internal shear failure, the friction force between the internal soil and the accelerating force of soil movement. Theoretical analysis of three side-film shovels showed that the force of one wing shovel was maximum while the stress of furrow opener device was minimum, the stress of double wing shovel was relatively reasonable. However, the performance effect of the one wing shovel was the best in the field testing although the force of one wing shovel was maximum. The integrity rate of the side-film was reached at 100%, the film recovery rate was at 95.4%, and without obstructing the soil in working performance. Taking the prominent operational effectiveness into account, the one wing shovel was highly recommended as autumn residual side-film recovery machine of the plastic film collecting structure. The research results can be provided a reference for the design of the side-film collecting mechanism section during the whole residual film recovery machine and also provide theory basis for the development of the plastic film recycling machine.

agriculture; mechanical analysis; films; residual plastic films; side-film shovels

10.11975/j.issn.1002-6819.2017.04.002

S223.5

A

1002-6819(2017)-04-0010-06

2016-05-23

2016-12 -22

国家自然科学基金资助项目(51565060,51465050);新疆维吾尔自治区高技术研究发展项目(201511104);新疆维吾尔自治区自然科学基金(2014211B029)和自治区创新人才项目(2014721030)联合资助。

张佳喜,男(汉族),陕西佳县人,博士,研究员,主要从事循环农业研究。乌鲁木齐 新疆农业大学机械交通学院,830052。Email:563810112@qq.com

王吉奎,男(汉族),新疆玛纳斯人,博士,教授,主要从事农业机械设计。石河子 石河子大学机械电气工程学院,832003。Email:shzwjk@126.com

张佳喜,张 丽,刘旋峰,蒋永新,王吉奎. 不同边膜铲起膜性能分析及其起膜率对比试验[J]. 农业工程学报,2017,33(4):10-15. doi:10.11975/j.issn.1002-6819.2017.04.002 http://www.tcsae.org

Zhang Jiaxi, Zhang Li, Liu Xuanfeng, Jiang Yongxin, Wang Jikui. Mechanical analysis and contrast experiment on collecting residual plastic film with different side-film shovels[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(4): 10-15. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.04.002 http://www.tcsae.org