Quasi-static tensile behavior of large-diameter thin-walled Ti–6Al–4V tubes at elevated temperature

2016-11-23TaoZhijunYangHeLiHengFanXiaoguang

Tao Zhijun,Yang He,Li Heng,Fan Xiaoguang

State Key Laboratory of Solidification Processing,School of Materials Science and Engineering,Northwestern Polytechnical University,Xi’an 710072,China

Quasi-static tensile behavior of large-diameter thin-walled Ti–6Al–4V tubes at elevated temperature

Tao Zhijun,Yang He*,Li Heng,Fan Xiaoguang

State Key Laboratory of Solidification Processing,School of Materials Science and Engineering,Northwestern Polytechnical University,Xi’an 710072,China

Fractography;LDTW TC4 tube;Strain rate;Tensile behavior;Warm bending

As promising light-weight and high-performance structure components,large-diameter thin-walled(LDTW)Ti–6Al–4V titanium alloy(TC4)bent tubes are needed most urgently in many industries such as aviation and aerospace.Warm bending may be a feasible way for manufacturing these components.Understanding their temperature and strain rate dependent tensile behavior is the foundation for formability improvement and warm bending design.In this paper,uniaxial tensile tests were conducted at elevated temperatures ranging from 298 K to 873 K at tensile velocities of 2,10,15 mm/min.The main results show that the tensile behavior of LDTW TC4 tubes is different from that of TC4 sheets.The typical elongation of TC4 tubes at room temperature is 10%lower than that of TC4 sheets.The flow stress of TC4 tubes decreases greatly by about 50%with the temperature rising to 873 K.At temperatures of 573–673 K,the hardening exponent is at its highest value,which means the deformation mechanism changes from twining to more dislocation movement by slipping.The fracture elongation of TC4 tubes fluctuates with increasing temperature,which is associated with changes in the deformation mechanism and with the blue brittleness.The fractography of TC4 tubes at various temperatures,especially at 673 K,shows that second phases and impurities significantly influence fracture elongation.By considering the characteristics of the tensile behavior and by properly choosing the die material,the warm bending for TC4 tubes can be achieved at temperatures of 723–823 K.

1.Introduction

Large-diameter thin-walled(LDTW)titanium alloy tubes are urgent needs as typical structure components in many industries such as aviation and aerospace,automotive,energy delivery,etc.,due to their unique advantages of light weight,low density,high strength,toughness,corrosion resistance,andproperties at low to median temperatures.1–3Ti–6Al–4V(TC4),the most widely applied commercial titanium alloy,is widely used to manufacture thin-walled bent tube components.4,5The tube bending technology is a solid foundation for the application of TC4 tube systems.It involves many methods containing rolling-bending,push-bending,and buckling-bending.Among various bending processes,the numerical control(NC)rotary-drawing bending is the most widely used method,exhibiting a unique combination of high efficiency,energy saving,stable quality and mass production.However,the process is a tri-nonlinear physical process with large rotation/deformation and coupling effects governed by multiple factors.The stress–strain state is complex and the deformation is severe.At the same time,the large size factor(D/t>20,Dis outer diameter andtwall thickness)could cause many defects such as instable wrinkling,undue reduction,tension fracture,cross section distortion,etc.6–9On the other hand,TC4 has a high deformation resistance(σs> 800-MPa)and a low elongation(δ < 10%)at room temperature,which means it is difficult to bend.5The maximum elongation needed in the tube bending process should reach 20%.Also,a high σsmeans a high ability to resist deformation.Thus,bending an LDTW TC4 tube at room temperature cannot be realized.

As is well-known,increasing the working temperature is an effective method to improve the plastic deformability of metals.To date,warm bending(at a working temperature below the recrystallization temperature)has been applied to tubes made from materials difficult to deform.Wu et al.10,11found that heating could improve the bending ability of wrought magnesium alloy AM30 tubes using a rotary draw bender while the temperature was 473 K and the strain rate was 8 mm/s.Luo et al.12,13also proved that it was feasible to bend magnesium alloy AZ31 tubesatelevated temperature(423–473 K).Zhang et al.14studied the quasi-static tensile behavior of LDTW CP-Ti tubes at various temperatures in the 298–873 K range and at different strain rates in the 0.001–0.1 s-1range and achieved tube warm bending at 573 K.From the above,warm bending can be used to form LDTW TC4 bent tubes.It is also of significant importance to obtain feasible process parameters for the warm bending of TC4 tubes.However,different materials and specifications of tubes will result in different deformation properties,which need distinguishing process parameters.The elongation of AM30 could be 25%,nevertheless,that of TC4 could be only about 8%at 423 K,while the maximum plastic strain along the axial direction would exceed 25%.Then,theD/tratio(D=42 mm,t=4 mm)of an AM30 tube is much smaller than that of a TC4 tube,which would result in less deformation defects.Otherwise,the yield strength of a TC4 tube is 4 times more than that of an AM30 tube at room temperature.Besides,CP-Ti is a α titanium alloy and TC4 is a α + β titanium alloy.The two-phase structure has more complex microstructure development mechanism and flow stress behavior.Therefore,it is important to investigate the warm bending of TC4 tubes so as to determine the proper process parameters.

Up to now,few research efforts have been made on the rotary-drawing-bending process for TC4 tubes at elevated temperature.Most of the TC4 studies have focused on constitutive modeling and microstructure evolution on the hot compression forming at temperatures above 1073 K(above recrystallization temperature).15–22Lee and Lin23investigated the plastic deformation behavior and the compressive characteristics of the TC4 alloy by means of compression tests at constant strain rates of 0.02,0.1,1.0 s-1and at temperatures ranging from 298 K to 773 K.They related microstructure development to temperature dependence.Nevertheless,the compressive specimens were of square-cylindrical geometry and cut from a TC4 bar of 12.7 mm diameter,differing from the tube specimens in the deformation process and in the initial microstructure.The major deformation during tube bending is tensile,the stress–strain state of which differs from the one for compressive deformation,which is in effect for square cylinders.What is more,elongation,the most important performance index,cannot be reflected in the compression.Kotkunde et al.24,25conducted a set of isothermal uniaxial tensile tests at elevated temperatures(323–673 K)and constant strain rates(10-5,10-4,10-3,10-2s-1)to study the formability during the warm deep drawing of TC4 alloy sheets.The author analyzed the microstructure development and the fractography.Then,four constitutive models were applied to predict the constitutive behavior.As a result,this research confirmed that warm tube bending at elevated temperature could achieve a better formability of TC4 tubes.However,the temperature range for warm deep drawing utilized in literature24,25brought about failure in the deep drawing process.We concluded that there should definitely be some focus on higher temperatures for the TC4 deformation.At the same time,the forming method for TC4 sheets differs from the one for TC4 tubes,which leads to considerable difference in mechanical properties.In consequence,the proper temperature range for the TC4 tube warm tensile deformation should be confirmed further.

In this paper,first a set of uniaxial tensile tests are conducted in the temperature range of 298–873 K and at strain rates from 2 mm/min to 15 mm/min,taking∅60 mm×1 mm TC4 tubes as the object.Second,the tensile behavior is analyzed in terms of flow stress behavior,fracture elongation,strain hardening behavior,and strain rate sensitivity,considering an increasing temperature and microstructure development.Ultimately,fracturefractographyisemployed to explain the overall plastic response of LDTW TC4 tubes,so that the major fracture mode occurring during warm deformation could be determined.Combining the macroscopic analysis of mechanical properties and the microscopic fractography,the proposed method is able to discover the deformation mechanism occurring during the warm forming of TC4 tubes,as well as to determine a proper bending temperature for TC4 tubes.

2.Material and experimental procedure

2.1.Starting material

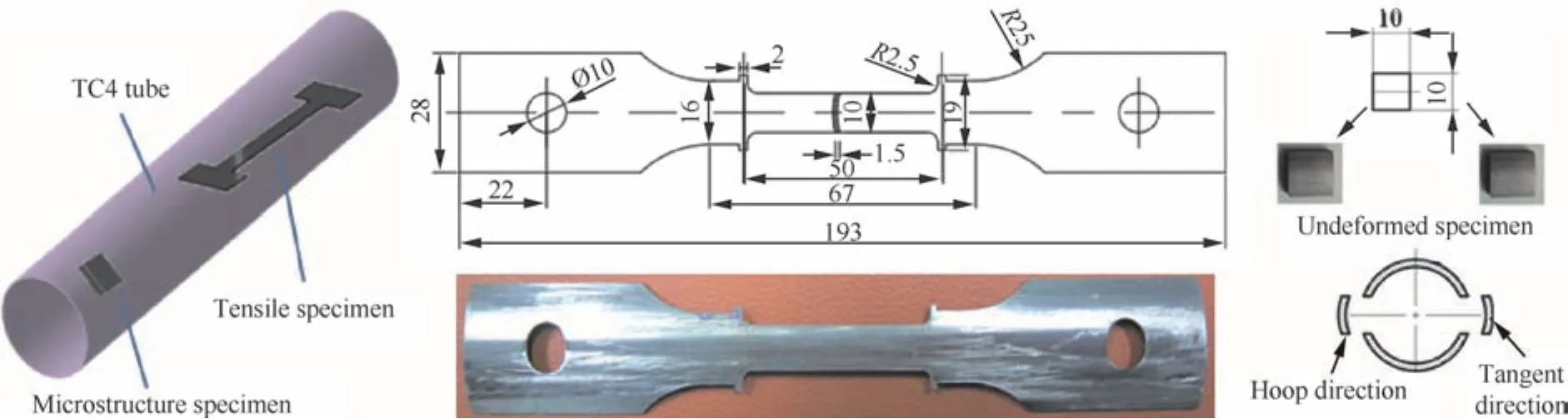

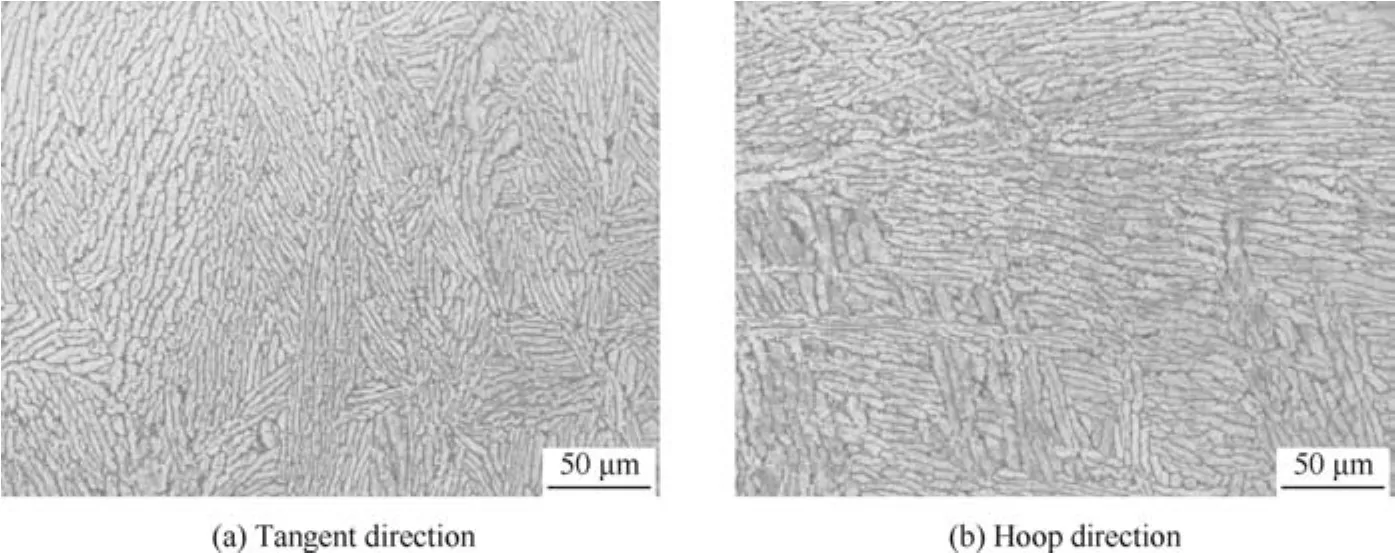

The material used in this study consists of TC4 tubes with a nominal outer diameter(OD)of 60 mm and a nominal thickness of 1 mm(∅60 mm×1 mm).The final tubes were hot extruded to be∅65 mm×10 mm thick-walled tubes from homogenized ingots,and then manufactured on a high-speed lathe to achieve the required size(see Fig.1).The chemical composition of the received tubes in weight percentage is 6.05wt%Al,4.12wt%V,0.20wt%Fe,0.093wt%C,0.05wt%N,0.012wt%H,0.20wt%O and balanced Ti.The designed tensile specimens were directly cut from the tube along the longitudinal direction shown in Fig.2,which were specially designed to avoid stress concentration.The microstructure at room temperature(see Fig.3)is mainly a Widmansta¨tten structurecomposedoflamellateαandstructureofβ transformation.

Fig.1 Manufacturing process of LDTW TC4 tubes.

2.2.Experimental procedure

A set of uniaxial warm tensile tests were carried out on the CMT5205 electronic universal testing machine.Three tensile velocities of 2,10,15 mm/min were applied at the temperature of 298–873 K.In order to guarantee the accuracy of experimental results,the tensile tests were repeated at least twice under the same condition.Three thermocouples were fixed on the surface of specimens to control temperature variation throughout the warm tensile test.A longitudinal extensometer was also applied during the tensile test to obtain accurate force–displacement data.The specimens were held for 5 min after reaching the target temperature and then tensed to failure.The morphology of fracture was obtained using SUPRA55 FSEM.

3.Results

3.1.Tensile behavior of TC4 tubes

While bending,an LDTW TC4 tube can easily fracture on the outside because of its low fracture elongation,which makes it impossible to realize TC4 tube bending at room temperature.Increasing the working temperature can increase the fracture elongation and decrease the deformation resistance.Thus,it is necessary to analyze the changes appearing with increased temperature in terms of yield strength,ultimate strength,fracture elongation,hardening exponent,and strain rate sensitivity.

3.1.1.Flow stress behavior

Fig.4 shows the true stress–strain curves for TC4 tubes from the tensile tests performed at elevated temperatures ranging from 298 to 873 K,when the deformation rates ranged from 2 to 15 mm/min.For example,the top curve in Fig.4(a)shows that true stress changes with temperature arising whenT=298 K andv=2 mm/min,vis strain rate.Fig.5 shows the effects of temperature and strain rate on yield strength and ultimate strength.A kind of unstable deformation is associated with the diffusion necking formed in the tensile specimen,which leads to flow localization followed by ultimate ductile fracture.By organizing the data of tensile tests and comparing these curves,the most obvious difference is declared to be an influence of the test temperature.

In the tests at a train rate of 2 mm/min and at different temperatures(see Fig.4(a)),the material shows an obvious drop of about 50%of flow stress while the temperature is increasing to 873 K,which is consistent with the results obtained for CP3 tubes and TC4 bars.As before,the flow stress obtained at 298 K is greater than those obtained for the other nine higher temperatures.At room temperature,the material with high stress enters the stage of plastic deformation at a true strain of about 0.01 and exhibits a slight upslope indicating working hardening when the true strain is raised from 0.01 to 0.08.The unstable fracture occurs quickly after necking at a true strain of 0.08.When the temperature increases from 298 K to 673 K,the flow stress at different temperatures,and for a true strain between 0.02 and 0.08,has a significant reduction.Hardening is more obvious at higher temperature in the same strain range.The working hardening rate is an indicator for the material’s hardening degree,whose change rules are studied later with regard to the hardening exponent.When the temperature continues to rise above 673 K,the flow stress curves tend to be horizontal.The phenomenon that can be observed is a combined production of working hardening and of dynamic recovery softening.Especially when the temperature exceeds 823 K,the flow stress shows a long platform before fracture,a platform which is dominated by dynamic recovery.Also,the necking at 873 K appears at a true strain of 0.26.Obviously,a higher temperature is beneficial for achieving a good ductility in order to satisfy the needs of TC4 tube bending.At 673 K,the ductility obviously decreases because of the blue brittleness caused by Nitride and Oxide.Thus,the tube bending process should avoid that temperature range below 673 K.

The influence of strain rate on flow stress is presented in Fig.4(b).At room temperature,the strain rate of 15 mm/min results in a rapid fracture at a strain of about 0.04,bringing the sample much earlier to fracture than other two conditions.The rate of 10 mm/min results in a better plasticity than 2 mm/min at higher temperatures;the differences caused by strain rate are much less obvious.This phenomenon shows that the train rate has both advantage and disadvantage on plastic deformation.First,plastic deformation cannot be fully performed when the strain rate is much higher and,at the same time,the elastic deformation is performed quickly.In the case of fracture the resistance changes slightly,the stress reaches the ultimate strength earlier and fracture occurs.This will give rise to a decrease in plasticity.Second,a higher strain rate makes the temperature effect more obvious,as a result of the fact that the temperature of the specimen has been increased.Then,a better plasticity is obtained.At room temperature,when the strain rate increases from 2 mm/min to 10 mm/min,the advantage is predominant while at 15 mm/min the disadvantage is predominant.When the temperature is increased,the strain rate has less impact,because the lower deformation resistance results in less thermal transformation and the temperature effect of strain rate increase is less.

3.1.2.Fracture elongation

Fig.6 shows the effects of temperature and strain rate on fracture elongation.It is obvious that the fracture elongation of TC4 tubes has an increasing–decreasing–increasing tendency with the temperature increasing.However,in the 298–723 K range,the temperature and the deformation rate have little effect on fracture elongation,which shows a gentle increasing–decreasing change.The elongation is under 10%.When temperature increases over 723 K,fracture elongation increases to an obvious degree.The fracture elongation is enough for the tube bending to be achieved at the temperature of 773 K.This phenomenon can be interpreted as happening under the combined influence of many factors.Above all,the increased temperature can make more slip systems take part in the plastic deformation.This will cause both the yield strength(σs)and the ultimate strength(σb)to decrease with the temperature increasing,as shown in Fig.5,which has a significant effect on fracture elongation.Let us analyze carefully.First,decreasing σs/σbmakes the elongation always increase in parallel with elevating the temperature.Second,the working hardening is a significant factor with regard to σb.A larger hardening exponent will result in a lower elongation.At last,other particles oppose the motion of dislocation such as Nitride and Oxide,which is called blue brittle.Therefore,a study on the hardening exponent and the fractography may help explain the phenomena appearing in this work.

Fig.2 Specimens for tensile test and microstructure observation.

Fig.3 Microstructure of as-received∅60 mm×1 mm TC4 tube.

Fig.4 True stress–strain curves of LDTW TC4 tube at various temperatures and strain rates.

3.1.3.Strain hardening behavior

The working hardening has a very important influence on the ductility of TC4 tubes.With regard to hardening,the hardening exponent can be used to characterize the strain hardening.And the larger hardening exponent,the better necking resistance the sample will have. σt=k(εt+ ε0)ncan be used to get the hardening exponent at different temperatures and strain rates by fitting the uniform plastic forming stage of true stress–strain curves to swift strain hardening function.In this equation,σtis the true stress,εtthe true strain,kthe strengthen coefficient,ε0the pre-strain andnthe hardening exponent.

Fig.7 shows the hardening exponent under different conditions.For all the strain rates and temperatures in this study,the hardening exponent increases considerably as the temperature increases from 298 K to 573 K.At temperature in the 573–673 K range,the hardening exponent is the highest.Subsequently,its values obviously decrease when the temperature increases.At lower temperatures,the deformation of hexagonal α phase makes the main contribution to the tensile tests.The twinning deformation modes are the dominating deformation mechanism.With increasing temperature,the twinning density increases along with the strain augmentation.The increasing dislocation density and the interaction effects may have the major roles in the increase of the hardening exponent.Meanwhile,the dynamic strain aging also plays an important role in increasing the hardening exponent.The larger hardening exponent could reduce the tube wrinkling possibility,a reduction that would be helpful for the tube bending process.With the temperature continuing to increase,more slip systems are activated and material softening appears.The dynamic recovery is playing a dominant role during the deformation.It leads to the decrease of hardening exponent.Thus,larger hardening exponent means more slip systems and lattice tweaks which will cause higher residual stress opposing plastic deformation.With temperature increasing,an increasing hardening exponent indicates an increasing resistance to plastic deformation,which results in lower elongation.As a result,higher temperature makes slip systems more and more active in going ahead of opponents.The hardening exponent drops down and obviously the fracture elongation increases.

Fig.6 Effect of temperature and strain rate on fracture elongation of LDTW TC4 tube.

Fig.7 Effects of temperature and strain rate on work hardening exponent of LDTW TC4 tube.

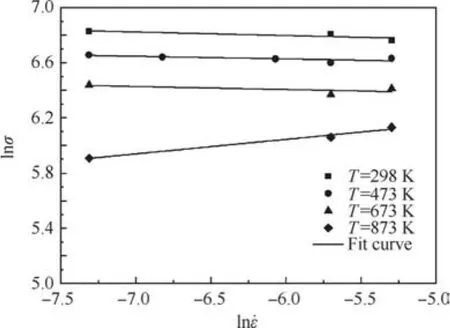

3.1.4.Strain rate sensitivity exponent

The strain rate sensitivity of the TC4 tube under different conditions is described asm=∂lnσ/∂ln˙ε.In this equation,mis strain rate sensitivity exponent,σ the true stress and˙ε the true strain rate.Fig.8 shows the values of strain rate sensitivity exponent(m)under different conditions.The strain rate sensitivity makes a big difference to the resistance to necking22and a largermwill lead to large fracture elongation,which means better plastic deformability.When the specimen appears to be necking,it results in the increase of strain.The strain rate hardening causes to slow down the rate of deformation,thereby resisting strain localization.The resistance of materials to necking results in an enhanced fracture elongation and a more gradual rate of loss for the load-carrying ability.This phenomenon can be observed by comparing the fracture elongation in Fig.6 and the magnitude of strain rate sensitivity(m)calculated from Fig.8.In this work,the train rate sensitivity changes slightly in the strainrate ranges used.When the temperature changes from 298 K to 673 K,the strain rate sensitivity is very little and almost 0.At 873 K andmis almost 0.02,which means a better deformation ability.

3.2.Morphology of fracture

In the tube bending process,fracture is the main weakness that needs to be prevented.Thus it is important to observe and study fractures seriously.By analyzing the morphology of the fracture,the issues that can be studied include fracture cause,fracture properties,fracture method,fracture mechanism,fracture toughness andstress offracture process,etc.Fracture analysis has become an effective and important means for the failure analysis of metal components.Macroscopic and microscopic fractography of fracture is in fact the experimental foundation of fracture analysis.SUPRA55 FSEM was used to observe the microscopic morphology of fracture.

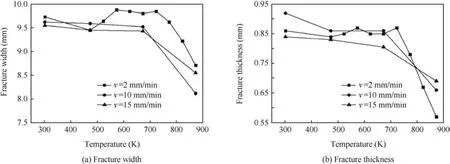

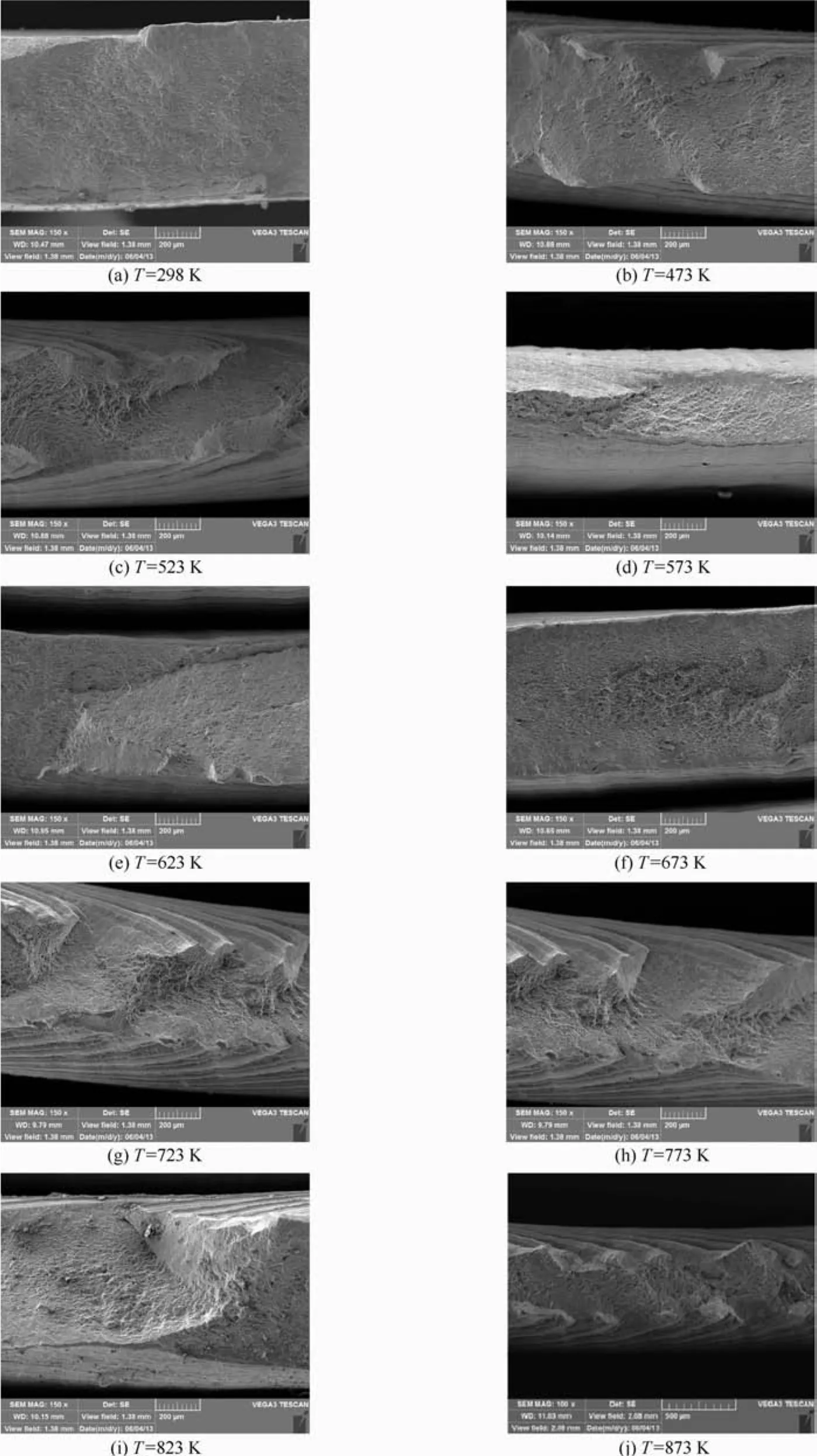

3.2.1.Macroscopic fractography

The specimens for fracture analysis were arc cut from deformed tensile specimens,as shown in Fig.9.In parallel with the temperature increasing,the necking phenomenon became clear.Fig.10 shows the fracture width and thickness under different conditions,after measuring the fracture analysis specimens.The fracture width and thickness tend to decrease with the temperature increasing.When temperature ranges from 523 K to 673 K,both of them have an increasing–decreas ing–increasing tendency.Fig.11 presents the macroscopic structure evolution of the TC4 tube fractures from 298 K to 873 K.This evolution is consistent with the change of fracture elongation.The better ductility results in larger fracture elongation,which means that fracture width and thickness decreases more.This behavior proves that at higher temperatures,the ductility and the mechanical properties of TC4 have been improved significantly,which is good for the NC tube bending process.

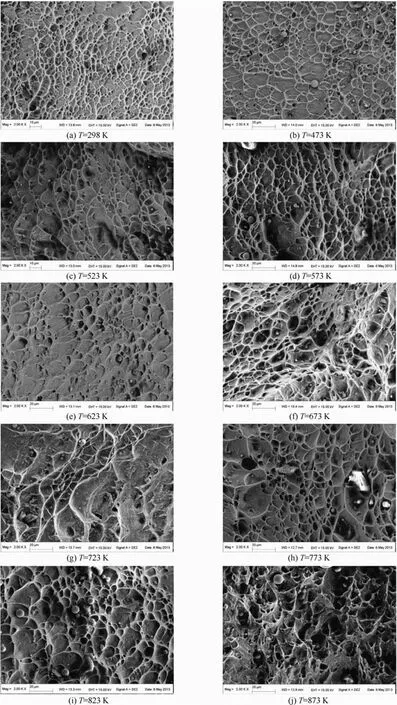

3.2.2.Microscopic fractography

Fig.12 shows the microscopic structure evolution of the TC4 tube fracture following the temperature rising.All of the fracture is ductile fracture and the morphology has a significant relationship with temperature being elevated.In this figure,the change of dimples can be observed at different temperatures.At the temperature of 298 K,the density of dimples is large and the dimples are equiaxial and shallow.With the increase of temperature,a number of dimples decrease and they change to flat and deep.Besides the effect of temperature,the structure,the impurities,and the second phase all have important effects on the ductile fracture.The existence of large second phases and impurities is found to be relative to the size of dimples.The overall evolution tendency is that dimples are becoming larger and deeper when temperature is increased.However,at the interval of 623–723 K,the dimples are much different in terms of evolution trend.As is well-known,the morphology and the size of dimples are affected by the material structure and plasticity.Thus,the microscopic fractography ofTC4 tubeisdecided by hardening exponent,plasticity,stress–strain,second phase and temperature.Large impurities and second phases will result in large dimples.A material with a larger hardening exponent is difficult to neck and will cause more microscopic holes or shear fracture;also,the dimples will be smaller and brighter.By affecting the plasticity and the hardening exponent,the temperature and the stress also significantly affect the size of dimples.Especially at 673 K,blue brittleness is present,as shown in Fig.13,which explains quite well why the elongation is the lowest at 673 K.

Fig.8 Variation of strain rate sensitivity exponent at different temperatures.

Fig.9 Fractured specimens of LDTW TC4 tube at various temperatures and strain.

Fig.10 Effects of temperature and strain rate on fracture width and thickness.

Fig.11 Macroscopic fractography at different temperatures of LDTW TC4 tube.

Fig.12 Microscopic fractography at different temperatures of LDTW TC4 tube.

Fig.13 Difference of microscopic fractography at 673 K.

4.Discussion

4.1.Comparison of mechanical behavior

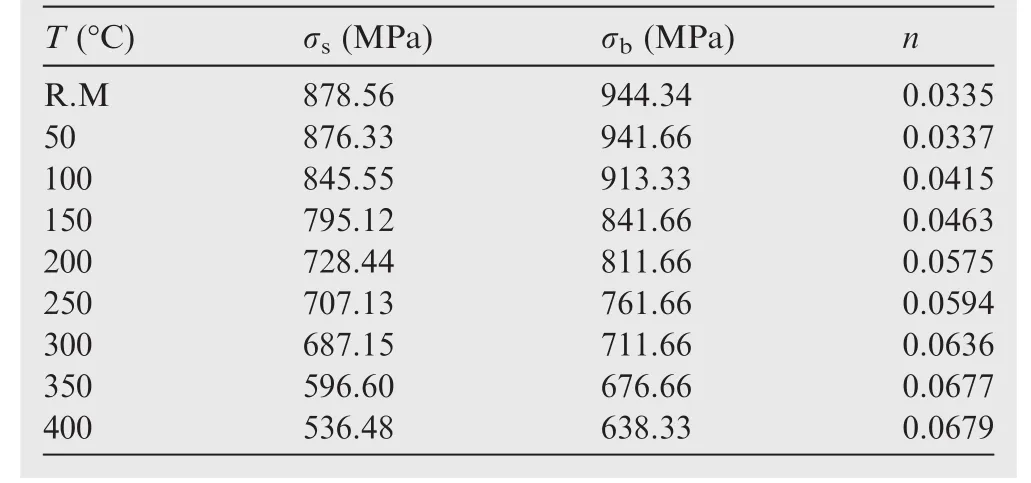

The results of tensile tests on LDTW TC4 tubes are shown in the above,which can be compared with the experimental results for∅76.2 mm×1.07 mm CP-Ti tubes(Table 1 and Fig.14).14CP-Ti is commercial titanium with only α phase,while TC4 is α + β titanium alloy.The change tendency for the yield strength σs,the ultimate strength σband the hardening exponentnis almost similar,while the change tendency for the fracture elongation is different.σsand σbdrop quickly with the temperature rising.The σbof the CP-Ti tube drops by almost 80%from about 500 MPa at room temperature to about 100 MPa at 873 K,while σbof the TC4 tube drops only 50%from about 900 MPa at room temperature to about 450 MPa at 873 K.Thus,the flow stress of the CP-Ti tube is more sensitive to temperature than that of the TC4 tube.Also,the yield ratio(σs/σb)of CP-Ti is much lower than that of TC4,and the lower yield ratio means better plasticity.Both of the hardening exponents firstly increase obviously with the temperature increasing,and then drop down from a specific temperature point,which is about 0.17 for CP-Ti at about 600 K and 0.13 for TC4 at about 630 K.A highernwill result in lower strain crest and a more uniform strain distribution in the material deformation.Therefore,the hardening exponent of CP-Ti is higher than that of TC4 and it is clear that TC4 has worse tensile properties.The fracture elongation of CPTi shows an increasing–decreasing–increasing tendency with the temperature increasing,while the relative higher elongation of 40%can be obtained at 573 K.Also,the maximum elongation,of over 70%,occurs at 873 K.However,the elongation of TC4 shows a flat-decreasing–increasing tendency and theminimum elongation of 8%occurs at 673 K.The elongation is improved by 150%when temperature is elevated to 873 K.In consequence,the elongation is not only related to temperature,hardening and yield ratio,but also to other factors.Subsequently,it is necessary to study the fractography of the TC4 tube at different temperatures.

Table 1 True stress–strain data of LDTW CP-Ti tube at various temperatures(˙ε=10-3s-1).14

Fig.14 True stress–strain curves of LDTW CP-Ti tube at various temperatures and strain rates.14

Table 2 Mechanical properties data of TC4 sheet.15

At the same time,the comparison between TC4 sheets(Tables 2 and 3)and TC4 tubes must be studied.15In Tables 2 and 3,Eis modulus of elasticity.Fig.15 shows the comparison of TC4 sheets and TC4 tubes.The manufacturing process used for the TC4 sheets is rolling and for the TC4 tubes is hot extrusion,resulting in different microscopic structures.The data and the change tendency for σsand σbare much similar.The elongation of sheets is 18%at room temperature but the elongation of tubes is about 8%.The minimum elongation of sheets is 15%at 673 K and the maximum is 46%at 873 K.However,the elongation of tubes is much lower than that of sheets although the change tendency is similar.The elongation determines the possibility of achieving a good bendability.The temperature achieving proper elongation might be the proper temperature for warm bending.Therefore,it is important to study the mechanical behavior of TC4 tubes to determine the warm bending temperature range.

Table 3 Mechanical properties data of TC4 alloy.25

4.2.Bendability of TC4 tube

Fig.15 Comparison of mechanical properties between TC4 sheet and TC4 tube at different temperatures.

Fig.16 Selection of proper temperature of TC4 tube warm bending process.

The bendability of the TC4 tube can be defined by several factors such as stress,fracture elongation and hardening index.In order to reduce the forming load,the stress must be low enough.The fracture elongation should be large enough to prevent fracture from occurring on the outside of the tube.To prevent wrinkling on the inside of the tube,the hardening exponentshouldbelarger.Basedontheaboveconclusions,whenthe temperature is in the 573–673 K range,the hardening exponent of TC4 is larger than 0.12.When in the 723–823 K range,the elongation can approach 18%,while the stress decreases by 45%(see Fig.16).All of these can improve the resistance to instability,making it easy to achieve die manufacturing and heating.Also,the bending radius can approach 3 times the diameter.When temperature reaches 873 K,the bending radius can be smaller,but choosing the die material and the heating method will be difficult.What is more,softening will cause heavily wrinkling during the bending process.A heating temperature of 723–823 K is the best choice for TC4 tube bending.

5.Conclusions

In this work,the tensile behavior of LDTW TC4 tubes at various temperatures and strain rates has been studied and the morphology of fracture has been obtained.It has been found that:

(1)The tensile behavior of LDTW TC4 tubes is different from that for CP-Ti tubes and from that for TC4 sheets.Both the CP-Ti tubes and the TC4 sheets have a better plastic deformability.The elongation of the TC4 sheets is 18%at room temperature,but the elongation of tubes is about 8%,although the change tendency is similar.The study of the mechanical behavior of LDTW TC4 tubes at various temperatures is necessary for choosing a proper heating temperature range during warm tube bending.

(2)The flow stress has an obvious drop of about 50%while temperature increases to 873 K.At the temperatures of 573–673 K the hardening exponent is up to its highest value,which means the dominating deformation mechanism has changed,with temperature increasing,from twinning to dislocation slipping.

(3)The fracture elongation of the TC4 tube has an increas ing–decreasing–increasing tendency,and that is related to the increase in temperature,the working hardening,and the blue brittleness.The fractography of TC4 tubes at various temperatures,especially at 673 K,shows second phases and impurities those are of significant influence on flow stress and fracture elongation.

(4)By considering the characteristics of the tensile behavior and of the tube bending process,and by a proper choice for the die material,temperatures in the range of 723–823 K can realize the warm tube bending process.

The tensile behavior obtained in the present study is helpful for understanding the deformation mechanism of TC4 tubes at elevated temperature.Meanwhile,the results can improve the deformation potential and develop forming limits for the TC4 tubes.

Acknowledgments

Theauthorswouldliketogratefullyacknowledgethesupportof the National Natural Science Foundation of China(No.51275415 and No.50905144),the program for New Century Excellent Talents in University,the Natural Science Basic ResearchPlanin ShaanxiProvince(No.2011JQ6004)ofChina,the fund of the State Key Laboratory of Solidification Processing in NWPU of China and the 111 Project(No.B08040)of China.

1.Yang H,Li H,Zhang ZY,Zhan M,Liu J,Li GJ.Advances and trends on tube bending forming technologies.Chin J Aeronaut2012;25(1):1–12.

2.Hashmi MSJ.Aspects of tube and pipe manufacturing processes:meter to nanometer diameter.Mater Proc Technol2006;179(1–3):5–10.

3.Adib AML,Baptista CARP,Barboza MJR,Haga C,Marques CCF.Aircraft engine bleed system tubes:material and failure mode analysis.Eng Fail Anal2007;14(8):1605–17.

4.Schweibold DJ.Titanium tube bending for aerospace.Aircraft Eng Aerospace Technol1989;61:8–11.

5.Yapici GG,Karaman I,Lu ZP.Mechanical twinning and texture evolution in severely deformed Ti–6Al–4V at high temperatures.Acta Metall2006;54(14):3755–71.

6.Li H,Yang H,Wang D.FE-based analysis of heat bending of thin-walled Ti-alloy tube with large diameter and small bending radius.Adv Mater Res2013;622–623:25–9.

7.Yang H,Li H,Zhang ZY.Bendability of large diameter thinwalled CP-Ti tube under rotary-draw-bending with small bending radius.In:Proc 10th Int Conf Technol Plast;2011.p.293–8.

8.Li H,Yang H,Yan J,Zhan M.Numerical study on deformation behaviors of thin-walled tube NC bending with large diameter and small bending radius.Comput Mater Sci2009;45(4):921–34.

9.Yang H,Lin Y.Wrinkling analysis for forming limit of tube bending processes.J Mater Proc Technol2004;152(3):363–9.

10.Wu WY,Zhang P,Zeng XQ,Jin L,Yao SS,Luo AA.Bendability of the wrought magnesium alloy AM30 tubes using a rotrary draw bender.Mater Sci Eng A2008;486(1–2):596–601.

11.Wu WY,Jin L,Dong J.Bending mechanisms in AM30 alloy tube using a rotary draw bender.Mater Manuf Proc2010;25:1359–64.

12.Luo AA,Sachdev AK.Development of a moderate temperature bending process for magnesium alloy extrusions.Mater Sci Forum2003;488–489:57–9.

13.Luo AA,Sachdev AK,Mishra RK.Bendability and microstructure of magnesium alloy tubes at room and elevated temperatures.Magnesium Technol2005;145–8.

14.Zhang ZY,Yang H,Li H,Ren N,Wang D.Quasi-static tensile behavior and constitutive modeling of large diameter thin-walled commercial pure titanium tube.Mater Sci Eng A2013;569:96–105.

15.Xiong ZQ.The hot forming performance of TC4 sheet on calender and flanging experiment[dissertation].Nanjing:Nanjing University of Aeronautics and Astronautics;1984[Chinese].

16.Yu WX,Li MQ,Luo J,Su SB,Li CQ.Prediction of the mechanical properties of the post-forged Ti–6Al–4V alloy using fuzzy neural network.Mater Des2010;31(7):3282–8.

17.Zherebtsov S,Murzinova M,Salishchev G.Spheroidization of the lamellar microstructure in Ti–6Al–4V alloy during warm deformation and annealing.Acta Metall2011;59(10):4138–50.

18.Seshacharyulu T,Medeiros SC,Frazier WG,Prasad YVRK.Hot workingofcommercialTi–6Al–4V with an equiaxed α–β microstructure:materials modeling considerations.Mater Sci Eng A2000;284(1–2):184–94.

19.Yapici GG,Karaman I,Luo ZP.Mechanical twinning and texture evolution in severely deformed Ti–6Al–4V at high temperatures.Acta Metall2006;54(14):3755–71.

20.Ding R,Guo ZX,Wilson A.Microstructural evolution of a Ti–6Al–4V alloy during thermomechanical processing.Mater Sci Eng A2002;327(2):233–40.

21.Majorell A,Srivatsa S,Picu RC.Mechanical behavior of Ti–6Al–4V at high and moderate temperatures—part I:experimental results.Mater Sci Eng A2002;326(2):297–305.

22.Picu RC,Majorell A.Mechanical behavior of Ti–6Al–4V at high and moderate temperatures—part II:constitutive modeling.Mater Sci Eng A2002;306(2):306–16.

23.Lee WS,Lin CF.Plastic deformation and fracture behaviour of Ti–6Al–4V alloy loaded with high strain rate under various temperatures.Mater Sci Eng A1998;241(1–2):48–59.

24.Kotkunde N,Aditya DD,Gupta AK,Swadesh KS.Experimental and numerical investigation of anisotropic yield criteria for warm deep drawing of Ti–6Al–4V alloy.Mater Des2014;63:336–44.

25.Kotkunde N,Aditya DD,Gupta AK,Swadesh KS,Aditya B.Failure and formability studies in warm deep drawing of Ti–6Al–4V alloy.Mater Des2014;60:540–7.

8 April 2015;revised 2 June 2015;accepted 17 June 2015

Available online 28 August 2015

ⓒ2016 Production and hosting by Elsevier Ltd.on behalf of CSAA&BUAA.This is an open access

article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

*Corresponding author.Tel.:+86 29 88495632.

E-mail addresses:15929550612@163.com(Z.Tao),yanghe@nwpu.edu.cn(H.Yang),liheng@nwpu.edu.cn(H.Li),fxg3200@126.com(X.Fan).

Peer review under responsibility of Editorial Committee of CJA.

Tao Zhijunis a Ph.D.student at School of Materials Science and Engineering,Northwestern Polytechnical University.She received her B.S.degree from Northwestern Polytechnical University in 2010.Her area of research includes experiment and FE simulation of warm tube bending and database development of tube bending knowledge.

Yang Hereceived the B.S.and M.S.degrees in Aeronautical and Manufacturing Engineering from Nanjing University of Aeronautics and Astronautics in 1983 and 1986 respectively,and then received Ph.D.degree in Metal Plastic Forming from Harbin Institute of Technology in 1990.He became a teacher in Northwestern Polytechnical University in 1992.His main research interests are metal precision plastic forming and manufacturing engineering of aerospace.

Li Hengis a professor at College of Materials Science and Engineering,Northwestern Polytechnical University.

Fan Xiaoguangis an associate professor of Materials Science and Engineering,Northwestern Polytechnical University.

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- Hypersonic starting flow at high angle of attack

- Advances and trends in plastic forming technologies for welded tubes

- Instability and sensitivity analysis of flows using OpenFOAM®

- Numerical simulations of high enthalpy flows around entry bodies

- Modeling and simulation of a time-varying inertia aircraft in aerial refueling

- Experimental investigations for parametric effects of dual synthetic jets on delaying stall of a thick airfoil