克劳斯·费舍尔访谈

2016-10-19路培LUPei

路培/LU Pei

黄华青 译/Translated by HUANG Huaqing

克劳斯·费舍尔访谈

Interview with Klaus Fischer

路培/LU Pei

黄华青 译/Translated by HUANG Huaqing

成立于1948年的德国慧鱼集团,因其建筑锚固系统而闻名于世。1997年慧鱼在中国成立分公司,并在江苏太仓建厂。慧鱼在中国近20年的发展历程中,凭借着杰出而全面的锚固系统解决方案,在中国市场取得了不俗的业绩;慧鱼中国公司亦成为慧鱼集团锚固系统业务领域在全球范围内的第4大子公司。近年来,慧鱼锚固产品除应用在包括国家体育场(“鸟巢”)、上海金茂君悦大酒店、上海世博轴、上海一级方程式赛道、上海迪斯尼乐园和诺华研发中心等众多知名的建筑工程中以外,慧鱼中国还积极投身于中国的基础设施和工业设施领域,如三峡水电站、津京城际高铁、上海地铁4号线、贵广高铁隧道等案例。

克劳斯·费舍尔先生,作为慧鱼集团的总裁、首席执行官,日前接受了本刊记者的书面采访。

1 慧鱼集团总裁克劳斯·费舍尔/Klaus Fischer, the president of fischer

2 慧鱼总部,位于德国黑森林地区的图木岭/fischer Headquarters in Tumlingen, Germany

WA: 从1958年慧鱼发明的第一枚尼龙锚栓开始,到2015年最新推出的DUOPOWER(塑料制双组件锚栓),慧鱼建筑锚固系统至今经历了将近60年的发展,共研发出14000多款产品。您作为慧鱼集团的第二代领导人和公司不断发展壮大的见证者,在您看来,慧鱼之所以取得今天的成就,其背后的原因有哪些?

费舍尔:我们公司能够成功,最可贵的资本和最重要的因素就是我们的员工——而非工厂或建筑。我们这些训练有素、积极进取的员工有着很强的主人翁精神,正是依靠他们的努力,我们才能在各个领域开发出创新性的产品。早在1980年代,我们就确立了公司的使命,并通过员工与管理层之间的协同共进而逐步践行。它也呼应了我们公司哲学的三个核心价值:创新、责任和高尚。

公司的目标很明确:盈利。我们的可持续性发展建立在三大支柱上:经济、生态和社会责任。慧鱼的流程系统引入包括“持续进步”“避免浪费”“终身学习”以及若干健康倡议在内的理念,这都是我们公司成功的重要因素。

我们持续的国际化拓展,尤其是在亚洲市场的成功,提升了公司的附加价值。就此,我们将在2016年年底在菲律宾开设一家新的分公司,之后还会有更多。在中国,我们现在拥有328名员工,分布在3座生产基地、一个供货部门以及16家销售办公室。为了确保这些分公司的持续竞争力,我们考虑了当地特殊条件,从而开发出适应特定市场的系列产品。这也促成了我们与亚洲最大的家具生产商的成功合作,例如广州的欧派家居集团。此外,我们的锚固系统已被用于多项重要的中国建筑工程中,例如武汉万达广场和南京新城科技园。

WA: 由德国提出的“工业4.0”战略,已在全球范围内引发了新一轮的工业转型竞赛。自动化向来是德国制造业的强项,德国在信息技术方面也有着不俗的实力。慧鱼一直以来注重产品的多样化,并可以为客户提供个性化的产品解决方案,这在一定程度上符合工业4.0的标准。作为一名富有远见的企业家,为更好地迎接甚至引领工业4.0时代,您认为慧鱼应该做好哪些准备?

费舍尔:“工业4.0”对我们也是个非常重要的话题。在“工业4.0”框架内,随着虚拟世界和现实世界的逐步统一,我们将会自信地参与其中。实际上,我们公司已经有所行动。我们的慧鱼流程系统在其中也发挥了很大作用,它在“工业4.0”框架内奠定了我们所有生产活动的基础。我们的跨部门项目团队已经启动了具体的试验计划,从而逐步推进它在公司内部的有效应用。

WA: 众所周知,建筑行业是个发展相对滞后的行业,若干年来,人们对建筑的要求长久以来无非局限在“坚固、适用、美观”这三点上。随着全球气候变暖,人们对建筑行业节能减排的呼声愈发强烈。建筑,作为人类生产生活的基本物质载体和最大的终端能耗部门,如何在建材生产这一初始环节尽可能减少能源消耗,对整个地球的生态环境和人类社会有着非常重要的意义。作为建材行业的领军者,可否请您谈谈您对环保事业的看法,以及慧鱼是如何在日复一日的生产中履行“节能减排”的目标的?

费舍尔:自从2000年以来,我们的慧鱼流程系统就在可持续性的企业管理中发挥了关键作用。其中,避免浪费扮演着尤为重要的角色。为了实现这一目标,我们并不是简单地将自己框束在个体化的节能措施中,例如合成材料的注射成型过程。我们同样采取面向未来的策略。例如,位于法兰克福的德国未来研究院就提出了若干个未来发展的主流趋势。从中,我们选择了4项趋势作为本公司发展策略的核心,包括全球化、机动性、新生态和银色社会。新生态的趋势也与慧鱼的可持续性管理体系有关。我们已实施的可持续性项目都有明确详细的记录。

这也促成了“蓝路工作站”的建设及持续扩张。它展示了成功的商业解决方案,能够在各个领域促进可持续性节能。例如,我们通过对金属制造过程的简化和改良,大大减少了燃油的消耗。“蓝路工作站”的设计就是为了建立并持续提升员工的可持续性意识。

此外,我们所有部门都设置了定期的可持续性训练课程。

我们必须在生活的方方面面避免浪费。未来的建造行为,将会建立在减少使用资源及化石燃料、回收和减排之上。就此,我们即将重新定义未来的生活方式。“主动性住宅”就是我们正在开发的项目,与建筑师团队及建筑工程师维纳·索贝克教授合作。这种住宅完全使用可回收材料,并采用简单的装配方式而没有任何粘结剂。因此,它们能在任何时候拆卸,而不留下任何残余。我们要为模数化建造和可持续性树立新的标准。我们的“绿色产品线”系列产品也为可持续性做出贡献。这是世界上第一条基本由植物原料制作的锚固产品的产品线。

WA: 有赖于优秀的产品和可靠的质量,慧鱼建筑锚固系统在中国建筑市场享有较高的知名度和良好的口碑。本刊记者也是通过这次到访慧鱼集团总部,才有机会亲身体会到慧鱼的企业文化,并对慧鱼旗下的其他业务有了更多了解和直观印象。请问,您是否打算在中国市场扩大除建筑锚固系统以外的其他三大业务(汽车储物系统、创意组合模型和以流程体系专业知识为基础的咨询顾问服务)?

费舍尔:慧鱼汽车储物系统这些年来一直有在中国的分工厂生产。鉴于分工厂的技术实力,这一系统应该会在中国市场有很好的发展机会。我们希望在2020年将在中国的收益扩大一倍。慧鱼不仅为在中国的德国和美国汽车生产商提供零部件,也与腾势电动汽车的生产商有着成功的合作。我们目前正在江苏太仓工厂建造一座新的生产车间。

慧鱼的创意组合模型自从1998年以来就在太仓生产。我们的主要定位是作为高等教育部门的教学辅助材料,其中我们的建造组合模型能够作为教授自然科学原理的创造性方法。

慧鱼的咨询顾问服务已经在德国奠定了良好的声誉,并不断拓展其国际化程度。2016年,慧鱼咨询部门的第一家海外分公司落户意大利。中国对于采用慧鱼流程系统来优化制造过程的业务,也会是一个很吸引人的市场。我们已经与中国的合作方在机械工程领域完成了多个项目。

WA: “创新”是慧鱼的三大核心价值之一,创新意味着开拓、从无到有;“流程管理”对慧鱼的重要性同样不言而喻,是公司得以持续改善的保障,流程管理的内涵包括规范化、系统化。请问您如何理解这二者之间的关系?

4 应用慧鱼产品的北京南站项目/Beijing South Railway Station

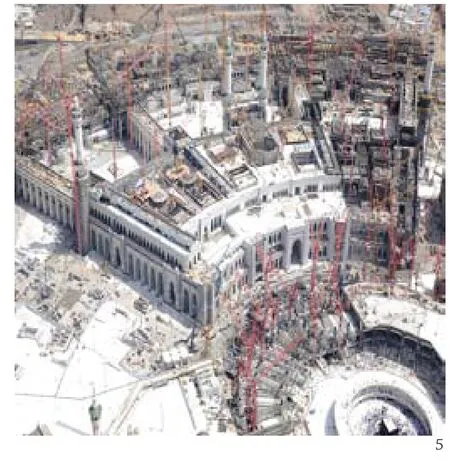

5 应用慧鱼产品的沙特阿拉伯圣地清真寺项目/Haram Mosque in Saudi-Arabia

6 慧鱼锚固系统产品/fischer fixing systems portfolio

7 慧鱼MEP系统解决方案(机械、电子和管道安装系统)/ fischer SaMontec installation systems

费舍尔:没有规范就没有进步,否则就不会有比较的基准。即便我们可以不参照规范来做出改变,也无从知晓是否取得了进步。我们需要以规范为基础,进而整体优化组织结构,并确保整个流程的弹性和灵敏性。慧鱼并未教条地将它的工具用于其他系统,但它将整个系统看作由应用于每道流程的8个基本原则组成:透明性、增加价值、流动、同步、流程导向、消除错误、灵活性和持续进步。著名的精益工具就是应用这些原则的结果。

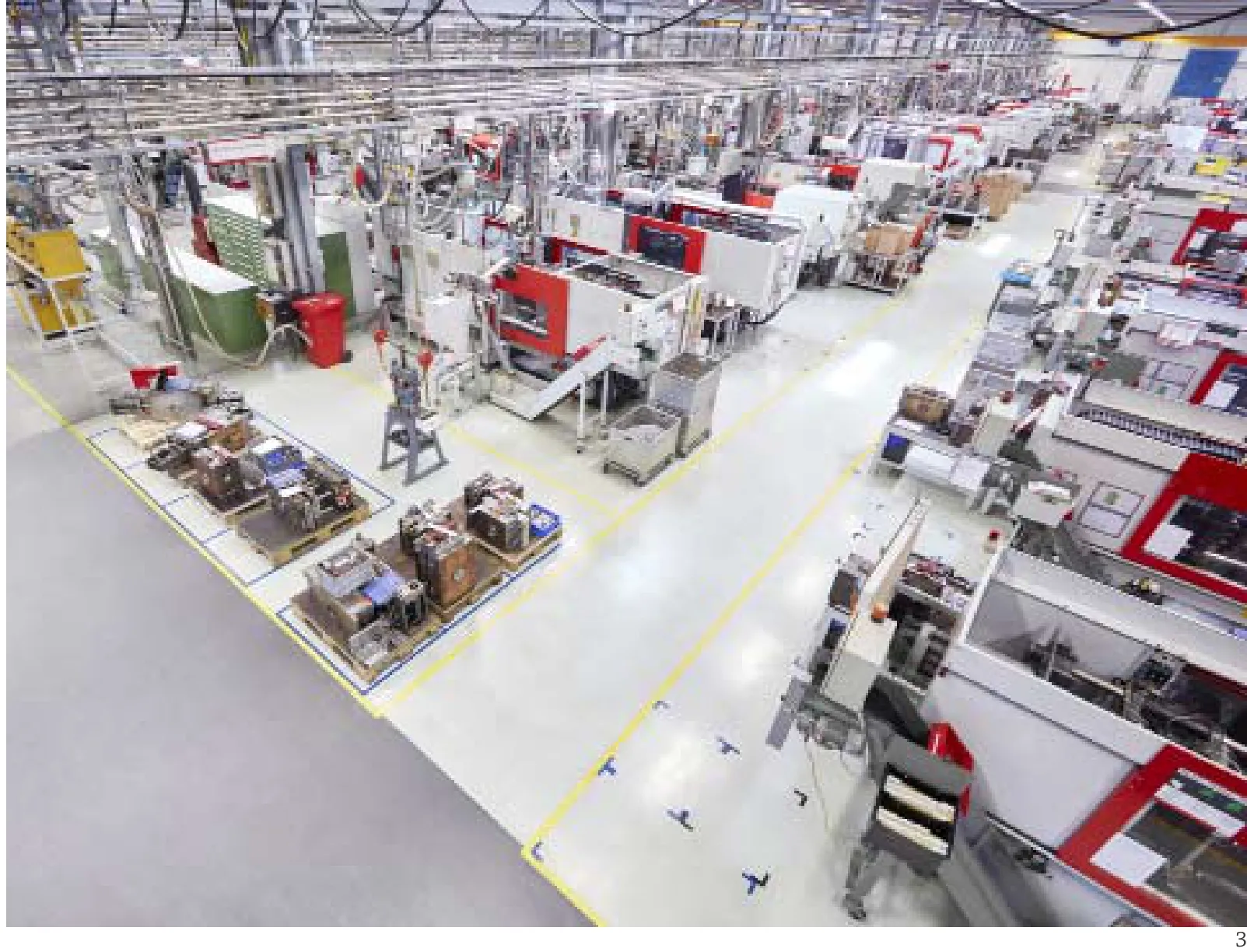

3 慧鱼总部锚固系统工厂/fischer production site in Tumlingen,Germany

Founded in 1948, the German company fischer is world famous for its fixing systems in the construction industry. In 1997, fischer established a branch in China with the opening of the production site in Taicang, Jiangsu province. fischer has obtained so far great achievement in Chinese market with its comprehensive and outstanding fixing systems solution during its development of nearly 20 years in China; meanwhile, fischer China has grown into the fischer's fourth-largest branch in the business area of fixing systems. In recent years, the fixing products of fischer were not only applied in the world-known building projects such as National Stadium "Bird's Nest", Shanghai World Expo Axis, Shanghai Formula One Race Track, Shanghai Disneyland and Novartis R & D Center, but also in Chinese infrastructure as well as industrial facilities, for example, Three Gorges Hydropower Station Tianjin-Beijing High Speed Rail,Shanghai Subway No.4 Line, Guiyang-Guangzhou High Speed Rail tunnels and etc.

Lately, we were honoured to have the opportunity of doing a written interview with Mr. Klaus Fischer, the president and CEO of fischer.

WA: From the first invention of the nylon plug in 1958 to the current DUOPOWER in 2015, fischer has almost 60 years of experience in the fixing industry with over 14,000 fixing products. You are the head of corporation in the second generation and you have witnessed the rapid growth of the company, in your opinion, how was fischer able to reach these proud achievements? What are the reasons for your success?

Klaus Fischer (KF): The biggest capital and the most important factor for success in our company are the employees – not the plants and buildings. Thanks to our well-trained and highly motivated people, who practically work as entrepreneurs in our enterprise, we develop innovative products in all divisions. We developed a company mission statement as early as the 1980s, which was procured through an intense process between the employees together with senior staff and which corresponds to our philosophy with three central values: innovative,responsible, respectable.

The aim is clear: to generate profit. Economy,ecology and social responsibility are the three pillars on which the sustainable development of our company is founded. The fischer ProcessSystem concerns topics such as "continuous improvement", "avoiding waste" and "lifelong learning" as well as numerous health initiatives that are important components that contribute to our company's success.

Our continuous internationalisation in the Asian market in particular increases our added value. In this sense we will be opening a new subsidiary in the Philippines at the end of the year,with more to follow. In China we are represented by 328 employees across three production sites,a purchasing organisation and 16 sales offices. In order to ensure the sustainable success of our sites we consider local conditions and develop a range of products that is adapted to the respective market.This has resulted in our successful partnership with Asia's largest furniture manufacturer for example,the OPPEIN Group in Guangzhou. In addition,our fixing systems have been used in important construction projects in China such as Wuhan Wanda Plaza and the Nanjing New Town Science & Technology Park.

WA: The Industry 4.0 strategy is a German development which runs in a new phase of industrial transformation in the global market. In Germany, automation has always been a force of the manufacturing industry, while German information technology is also in good shape. fischer focuses on the diversification of products and is able to offer its customers custom product solutions, already corresponding in part to the standards of Industry 4.0. As a visionary entrepreneur, which preparations do you think fischer should make in order to be prepared and even a leading force in the Industry 4.0 era?

KF: Industry 4.0 is a very important topic for us,too. When it comes to the consolidation between the virtual world and the real world within Industry 4.0 we are able to perform confidently. We can already show a thing or two in our company. Our fischer ProcessSystem has provided great support here too, forming a basis for all our activities with Industry 4.0. Our sector-wide project team has already launched concrete pilot projects in order to advance its useful application within our company.

WA: As is universally known, the building industry is behind in comparison with the development of other industries. For years, the requirements set for building are reduced to "firmness", "utility" and "beauty". In light of global warming, people are placing more and more value on saving energy and reducing CO2emissions in this industry. Because buildings are feedstock fuels and the most energy-intensive sector of the people, it is important to reduce energy use during production of building materials as much as possible for the good of human society and for earth's ecological environment. Could you please share your views on the protection of the environment as the market leader in the building material industry? And how does fischer achieve the goal of saving energy and reducing emissions on a daily basis?

KF: Our fischer ProcessSystem has been a significant part of sustainable corporate management since 2000. Avoiding waste plays a particularly important role in this context. In doing so we do not simply restrict ourselves to individual measures such as saving energy during the injection moulding of our synthetic materials. Here, we also take a futureorientated approach. The German Zukunftsinstitut("Institute for the Future") in Frankfurt am Main has defined various megatrends of the future, for example. From this we have deducted the four megatrends to urbanisation, mobility, neo-ecology and Silver Society as focal points for our company's strategy. The neo-ecology megatrend forms a link to fischer's sustainability management. Sustainability projects which have already been implemented are explicitly accounted and documented.

This has resulted in the stations of the socalled "blue path" which is continuously being expanded. It shows successful business solutions that have contributed to sustainable savings across various levels. For example, we have been able to significantly reduce the use of oil by cleansing it, simultaneously improving the processes in metalwork. The stations of the "blue path" are intended to promote and continuously develop sustainability in our employee's consciousness.

In addition, there will be regular training sessions on sustainability in all divisions.

We must avoid waste in all aspects of our lives. The construction of the future is based on using as few resources and fossil fuels as possible and on recyclability and avoiding emissions. Which is why we are about to redefine the future of living. The aktivhäuser ("active houses") which we are developing along with a team of architects and the building engineer Prof. Werner Sobek are made completely from recyclable materials that are simply assembled without being glued. Therefore, they can be disassembled at any time without residue. We are thereby setting new standards for modular construction and for sustainability. We are also contributing to the topic of sustainability with our greenline range. It is the first line of products in the world that features fixing products made of mostly vegetable raw materials.

WA: fischer fixing systems are well-known in the Chinese market, with a good reputation thanks to the excellent products and reliable quality. As journalists we were able to personally experience fischer's company culture. In addition, we were able to develop a better understanding and an intuitive impression of the various divisions during our visit. Aside from fixing systems, do you have any intentions of expanding into the Chinese market with the other three divisions (automotive systems,fischertechnik and fischer Consulting)?

KF: fischer automotive systems has been represented by its own Chinese production subsidiary for many years, and thanks to its technical knowhow it faces good opportunities for growth in the Chinese market. We will double the revenue in the Middle Kingdom by 2020. fischer not only produces for German and American car manufacturers in China, but also successfully supplies the manufacturer of the Denza electric car. We are currently expanding our Taicang site with the construction of a further production hall.

fischertechnik has also been represented in Taicang since 1998. Our main target group is the teaching material and high school sector, which utilise our construction kits as a creative method for teaching the foundations of science-orientated principals.

fischer Consulting has established itself as a reputable business consultancy in Germany and continues its internationalisation. This year,fischer Consulting's first overseas subsidiary was founded in Italy. China is also proving to be an attractive market for process optimisations with our fischer ProcessSystem, as we have already realised several projects with our Chinese colleagues in the mechanical engineering sector.

WA: Innovation is one of fischer's three core values. Innovation signifies a new beginning. Process management is just as important for fischer, as it enables the company to continuously improve. The connotations of process management include standardisation and systematisation. How do you interpret the relationship between the two?

KF: There is no improvement without standards,otherwise there wouldn't be a benchmark for comparison. While we would be able to carry out changes without these standards, we wouldn't be able to know whether they are improving. We need standards as a basis in order to optimise the organisation as a whole and in order to guarantee the resilience and agility of the processes. fischer isn't dogmatic in the transfer of its tools onto other systems, but it sees the entire systems as a composition of eight principles which apply to every process: transparency, added value, flow,synchronisation, process orientation, elimination of errors, flexibility and continuous improvement. The well-known Lean Tools are a result of these principles.

8 位于德国内卡河霍尔普的慧鱼汽车储物系统工厂/fischerautomotive systems production site in Horb am Neckar, Germany

9 慧鱼创意组合模型/fische fischer)