R1234ze(E)在水平圆管内流动沸腾换热过程中摩擦压降特性实验研究

2016-09-06邱金友余晓明祁影霞刘占杰

邱金友 张 华 余晓明 祁影霞 王 袭 刘占杰

(1 上海理工大学制冷与低温工程研究所 上海 200093;2 海尔集团技术研发中心 青岛 266103)

R1234ze(E)在水平圆管内流动沸腾换热过程中摩擦压降特性实验研究

邱金友1张 华1余晓明1祁影霞1王 袭2刘占杰2

(1 上海理工大学制冷与低温工程研究所上海200093;2 海尔集团技术研发中心青岛266103)

新型制冷剂R1234ze(E)(trans-1, 3, 3, 3-tetrafluoropropene)因较低的GWP而被广泛关注,有望在热泵中作为R134a的替代品。本文对R1234ze(E)在内径为8 mm水平管内流动沸腾过程中摩擦压降特性进行实验研究,并在相同实验工况下与R134a进行对比。实验研究的流动沸腾换热的饱和温度为10 ℃,热流密度为5.0 kW/m2和10.0 kW/m2,质流密度范围为300~500 kg/(m2·s),并分析质流密度、热流密度对R1234ze(E)和R134a饱和流动沸腾过程中摩擦压降的影响。结果表明,在相同工况下R1234ze(E)的流动沸腾过程的摩擦压降略大于R134a,如质流密度为500 kg/(m2·s)时,R1234ze(E)的平均摩擦压降值比R134a大8.4%左右。最后,将实验结果同四种摩擦压降经验关联式进行比较分析。

R1234ze(E);R134a;水平圆管;流动沸腾;摩擦压降

目前正在大量使用的氢氟烃类制冷剂(Hydrofluorocarbons,缩写HFCs)由于其温室效应潜值(global warming potential,GWP)较高,大量使用会引起全球气候变暖[1-2]。全球变暖日益加剧,国际上已经开始对此类物质加以管控。2014年欧盟对F-Gas法规进行修订[3],对HFCs的使用给出了消减的时间节点,从2015年1月1日起,禁止包含HFCs且GWP大于150的家用冰箱和冷冻机进入市场;从2022年1月1日起,禁止包含HFCs且GWP大于150工质在商用冷藏箱和冷冻箱中使用。这必然带动制冷工质从高GWP向低GWP过渡。

近年来,HFOs(Hydro-Fluoro-Olefins)类物质因其优越的环境友好性备受关注,其中R1234ze(E)可作为家用空调、热泵的替代工质已初步得到认可[4-7]。最新的研究报告[8]表明R1234ze(E)的GWP小于1。表1列举R1234ze(E)与R134a的基本热物性。

已有文献对R1234ze(E)的研究主要集中在热物性[9-10]和直接替代实验研究[11-13],管内流动沸腾换热过程中摩擦压降的数据相对较为缺乏。Grauso S等[14]在水平光管中对R1234ze(E)的流动换热与压降特性进行了初步探索。Hossain M A等[15]在水平管中对R1234ze(E)、R32、R410A及R1234ze(E)和R32混合物的流动沸腾传热与压降特性进行了实验研究和比较。本文在内径为8 mm的水平紫铜管内研究R1234ze(E)和R134a饱和流动沸腾换热过程中摩擦压降特性,分析质流密度、热流密度和干度对摩擦压降的影响,并将实验数据同四种常见的摩擦压降预估关联式进行比较,找出预测效果良好的关联式。

表1R1234ze(E)与R134a的基本物性[16]

Tab.1Physical properties of R1234ze(E) and R134a

制冷剂沸点/K摩尔质量/(kg/kmol)临界温度/K临界压力/MPaODPGWPR-134a247.1102.03374.214.059301430R-1234ze(E)254.2114.04382.523.63630<1

1 实验系统

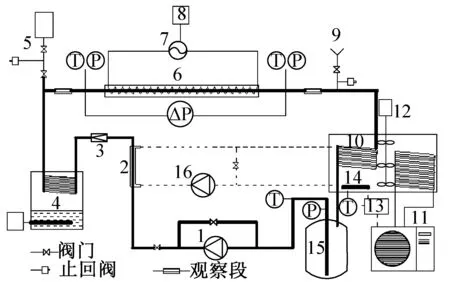

1叶片泵2过冷段3质量流量计4预热段5取样装置6实验段7稳压直流电8电量检测仪9油充灌口10冷凝器11制冷机组12搅拌器13控制器14加热器 15储液罐16过冷循环泵图1 实验装置系统图Fig.1 Schematic diagram of the experimental system

实验系统如图1所示。储液罐液态制冷剂经溶液泵加压分流,一部分通过实验循环回路,另一部分经旁通管回到溶液泵,主回路上经泵加压后液态制冷剂经过冷段以抵消经过溶液泵后焓值的增加,确保进入流量计的是纯液态制冷剂,主回路上制冷剂流量采用科氏力质量流量计测量。实验段前设有预热段,控制预热段的加热量并可以控制实验段入口的干度。经实验段后的制冷剂进入恒温槽中的冷凝盘管进行冷凝,最后回储液罐完成循环。实验段进出口分别设有石英玻璃管,可观察测试管段流型。实验段采用管内径为8 mm,外径为9.52 mm的铜管。实验段的进出口各安装一个绝对压力变送器,用于测量进出口压力。实验段铜管外缠有电加热带,为实验段提供所需热量,电加热带外依次缠有玻璃纤维布、硅酸铝保温棉和隔气带,确保与环境的隔热效果良好。

2 实验研究

2.1 数据处理

实验段流动沸腾换热的总压降由三部分组成:加速压降Δpmom、重力压降Δpstatic和摩擦压降Δpfrict。本实验是在水平圆管内进行,可以忽略重力压降,Δpstatic=0。

Δptotal=Δpstatic+Δpmom+Δpfrict

(1)

实验过程中,工质的加速压降Δpmom一般小于总压降的5%,可由式(2)确定。

(2)

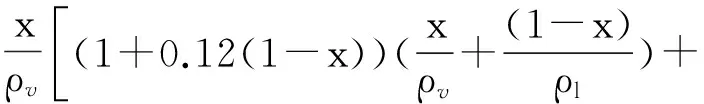

式中:G为实验段制冷剂质流密度,kg/(m2·s);x为实验段平均制冷剂干度;ρl和ρv分别是实验段制冷剂液相和气相密度,kg/m3;ε为空泡系数,采用Rouhani and Axelsson的空泡系数计算方法[16],如式(3)所示。

(3)

式中:g为重力加速度,9.81 m/s2;σ为制冷剂表面张力,N/m。实验段平均干度的计算可通过预热器热平衡计算得到:

htest,in=xinhtest,v,in+(1-xin)htest,l,in

(4)

htest,out=xouthtest,v,out+(1-xout)htest,l,out

(5)

(6)

(7)

(8)

式中:m为质量流量,kg/s;Qpreh为预热段加热量,kW;htest,in和htest,out分别为实验段进出口焓值,kJ/kg;htest,v,in和htest,l,in分别为实验段进口气相和液相制冷剂焓值,kJ/kg;htest,v,out和htest,l,out分别为实验段出口气相和液相制冷剂焓值,kJ/kg。以上数据计算中用到的流体热物性通过NIST Refprop V9.0[17]查得。

2.2 测试工况与测试仪表

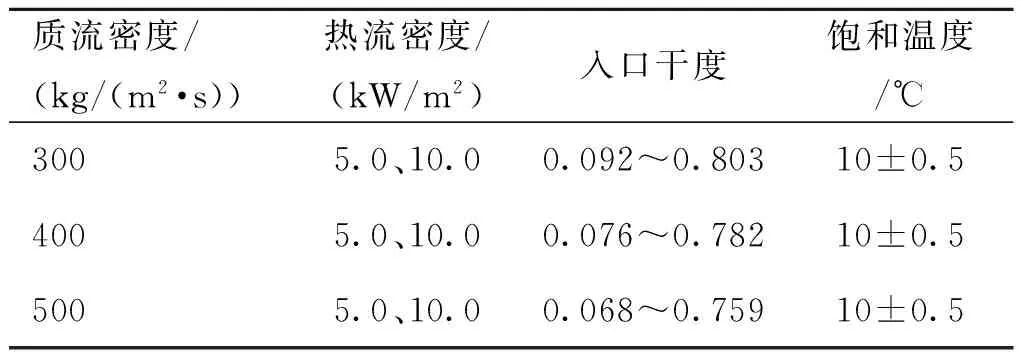

本次实验的测试工况如表1所示,质流密度范围为300~500 kg/(m2·s);热流密度为5.0 kW/m2和10.0 kW/m2;沸腾换热的饱和温度为10±0.5 ℃;测试的制冷剂干度范围为0.068~0.803。

表1实验工况

Tab.1Experimental operation conditions

质流密度/(kg/(m2·s))热流密度/(kW/m2)入口干度饱和温度/℃3005.0、10.00.092~0.80310±0.54005.0、10.00.076~0.78210±0.55005.0、10.00.068~0.75910±0.5

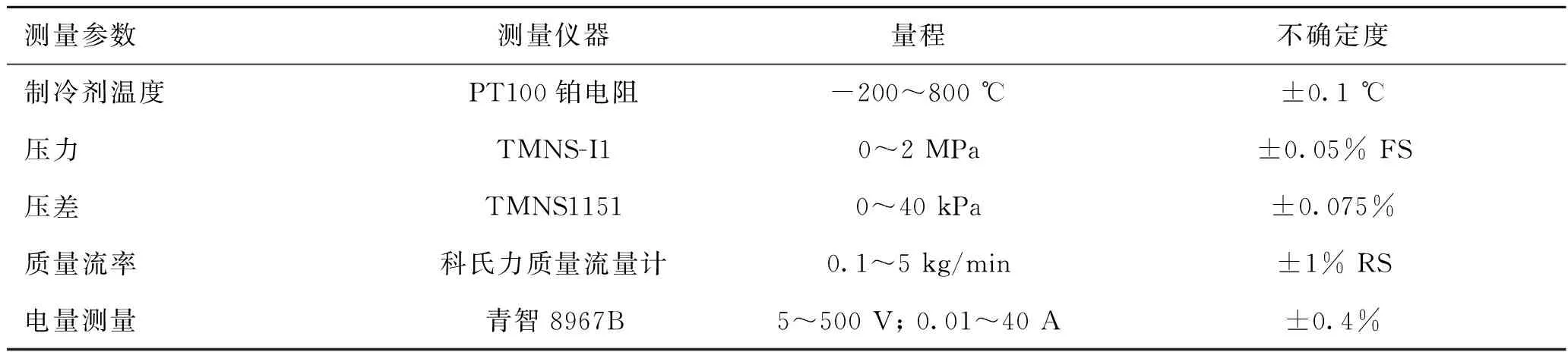

测试仪表及不确定度如表2所示,温度采用PT100铂电阻测量;实验段进出口压力采用TMNS-I1压力传感器测量;压差采用TMNS1151压差传感器测量;质量流量采用科氏力质量流量计测量;功率测量采用青智8967B综合电量测量。

表2测量系统仪表及其不确定值

Tab.2Measurement instruments and their uncertainties

测量参数测量仪器量程不确定度制冷剂温度PT100铂电阻-200~800℃±0.1℃压力TMNS-I10~2MPa±0.05%FS压差TMNS11510~40kPa±0.075%质量流率科氏力质量流量计0.1~5kg/min±1%RS电量测量青智8967B5~500V;0.01~40A±0.4%

3 实验分析及关联式比较

3.1 实验结果

图2 不同质流密度R1234ze(E)摩擦压降随干度变化Fig.2 Frictional pressure dorps as a function of vapor quality with different flow fluxes for R1234ze(E)

图3 不同质流密度R134a摩擦压降随干度变化Fig.3 Frictional pressure dorps as a function of vapor quality with different flow fluxes for R134a

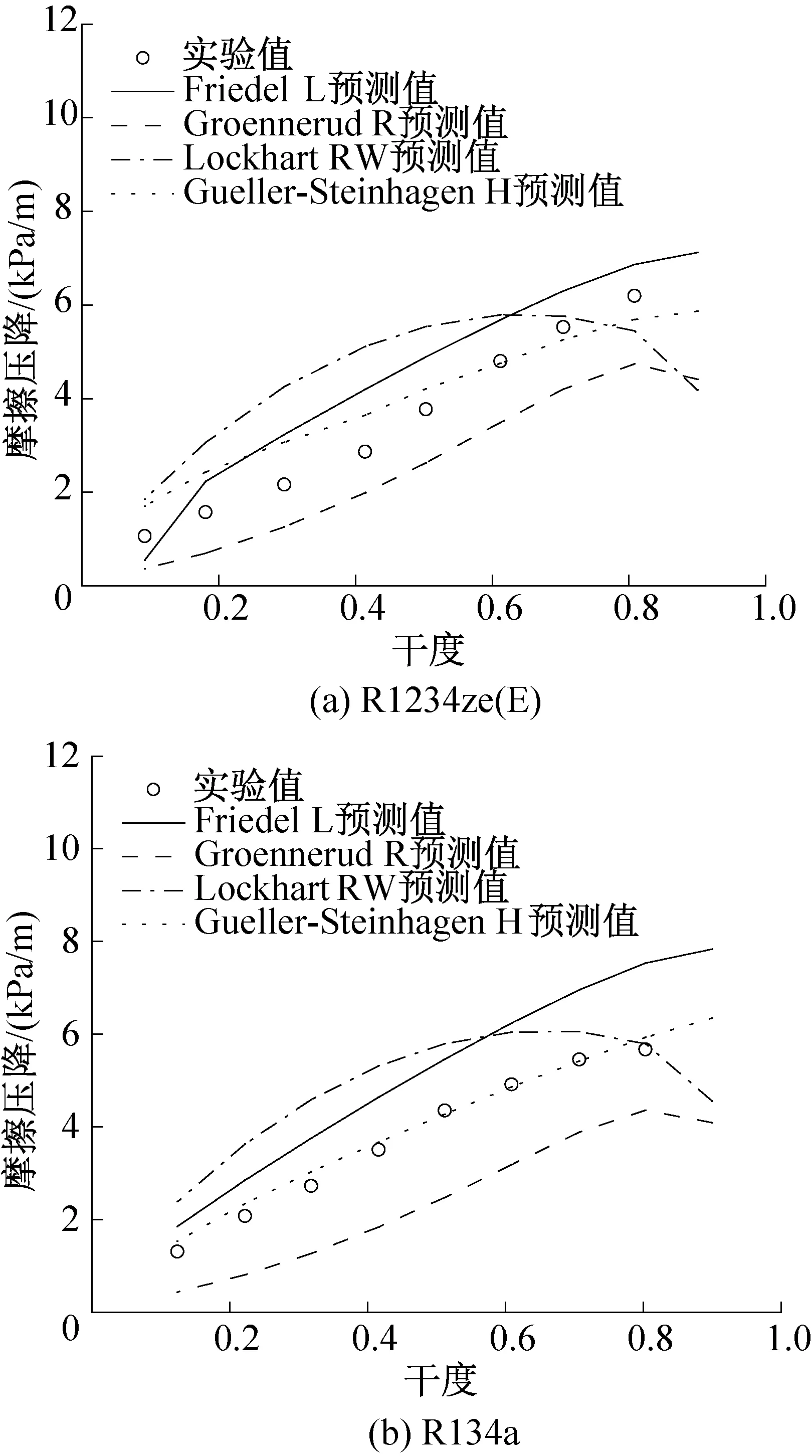

图4 质流密度G=300 kg/(m2·s)工况下,摩擦压降实验数据与4种关联式的比较Fig.4 Experimental frictional pressure drop data compared to prediction methods with mass flux of 300 kg/(m2·s)

图2表示在热流密度为5 kW/m2和10 kW/m2,质流密度分别为300 kg/(m2·s)、400 kg/(m2·s)和500 kg/(m2·s)工况下,R1234ze(E)在水平光管内流动沸腾换热过程中摩擦压降随干度的变化趋势。由图可知,随干度和质流密度的增加,R1234ze(E)的摩擦压降逐渐增大。这是由于,在相同的质流密度下,随着干度的增大制冷剂在圆管内的流型由单相流逐渐向泡状流、块状流和环状流转变,气相含量逐渐增加,流速增大,因此摩擦压降不断增大。当质流密度增大时,制冷剂在管内的流速增大,摩擦阻力显然也增大。当热流密度增大时,其对R1234ze(E)在管内流动沸腾换热过程中的摩擦压降的变化趋势几乎没有明显的影响,因为热流密度变化时,其对制冷剂的物性以及管内的流速均没有影响,因此对摩擦压降的影响可以忽略。图3表示在与R1234ze(E)相同的运行工况下,R134a在水平光管内流动沸腾换热过程中摩擦压降随干度的变化趋势。由图可知,R134a在流动沸腾换热过程中摩擦压降与R1234ze(E)具有相似的变化规律,随干度和质流密度的增加,摩擦压降逐渐增大。由图3和图4比较可知,质量流量对R1234ze(E)的影响要大于R134a,如在质流密度为500 kg/(m2·s)的工况下,R1234ze(E)的平均摩擦压降值比R134a大8.4%左右,这是由于在此压力下R1234ze(E)的气液密度比(ρv/ρl=0.0114)小于R134a(ρv/ρl=0.0160),导致在相同质流密度下,干度增大时,R1234ze(E)的流速的增大值大于R134a,因此在相同质流密度工况下,R1234ze(E)的摩擦压降略大于R134a。

3.2 预估关联式比较

在已有的文献中,对流动沸腾换热过程中的摩擦压降的研究,已提出大量理论预估经验关联式,本文选取4种经典的关联式进行实验数据对比,分别是Friedel L[18]关联式、Groennerud R[19]关联式、Lockhart R W 等[20]关联式和Mueller-Steinhagen H 等[21]关联式。图4表示在质流密度为300 kg/(m2·s)工况下,R1234ze(E)和R134a的实验摩擦压降数据与4种预估关联式的比较。由图4(a)可知,在低质流密度300 kg/(m2·s)工况下,Mueller-Steinhagen H等关联式和Friedel L关联式可以较好的预测R1234ze(E)摩擦压降值,平均偏差分别为26.3%和32.4%。由图4(b)可知,在低质流密度300 kg/(m2·s)工况下,Mueller-Steinhagen H关联式可以很好的预测R134a摩擦压降值,平均偏差为6.8%。其它两种关联式在低质流密度300 kg/(m2·s)工况下对R1234ze(E)和R134a摩擦压降的预估值与实验值偏差较大。

图5 质流密度G=400 kg/(m2·s)工况下,摩擦压降实验数据与4种关联式的比较Fig.5 Experimental frictional pressure drop data compared to prediction methods with mass flux of 400 kg/(m2·s)

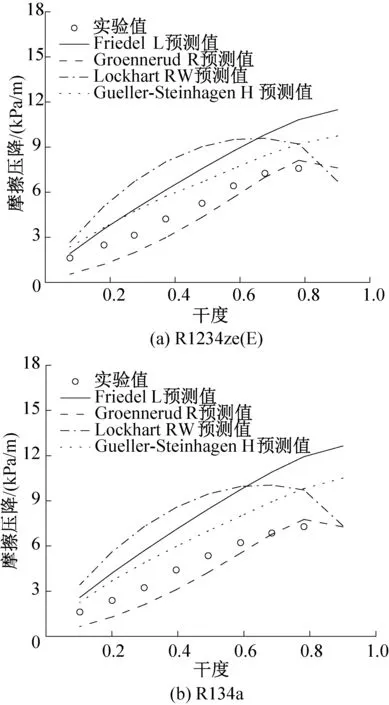

图5表示在质流密度为400 kg/(m2·s)工况下,R1234ze(E)和R134a的实验摩擦压降数据与4种预估关联式的比较。由图可知,当质流密度为400 kg/(m2·s)工况时,Groennerud R关联式和Mueller-Steinhagen H关联式能够较准确预测R1234ze(E)和R134a摩擦压降值。对于R1234ze(E),其预估值与实验值的平均偏差分别为28.2%和32.8%;对于R134a,其预估值与实验值的平均偏差分别为26.1%和38.5%。

图6表示在质流密度为500 kg/(m2·s)工况下, R1234ze(E)和R134a的实验摩擦压降数据与4种预估关联式的比较。由图可知,当质流密度为500 kg/(m2·s) 工况时,Groennerud R关联式能够较准确预测R1234ze(E)和R134a摩擦压降值。对R1234ze(E)和R134a的预测值与实验值的平均偏差分别为22.0%和25.5%。

图6 质流密度G=500 kg/(m2·s)工况下,摩擦压降实验数据与4种关联式的比较Fig.6 Experimental frictional pressure drop data compared to prediction methods with mass flux of 500 kg/(m2·s)

综上所述,在低质流密度工况下,Mueller-Steinhagen H 等关联式的预估值与实验值的总体吻合度较好。在中高质流密度工况下,Greoennerud R关联式的预估值与实验值的总体吻合度较好。其中,Greoennerud R关联式可以较准确预测出摩擦压降随干度变化的最大值,此时干度值为0.8左右,其流型逐渐从环状流过渡到部分干涸流。

4 结论

本文实验研究了新型制冷剂R1234ze(E)和R134a在内径为8 mm水平圆管内饱和流动沸腾换热过程中摩擦压降特性,并将实验数据同四种经典摩擦压降关联式预估值进行比较分析,得出以下结论:

1)质流密度和热流密度对R1234ze(E)和R134a流动沸腾换热过程中摩擦压降的影响,表明随着质流密度的增加摩擦压降明显增强;热流密度的增强对摩擦压降几乎没有影响;对比R1234ze(E)和R134a的摩擦压降值,表明相同质流密度下,R1234ze(E)的摩擦压降略大于R134a,且随干度的增大,R1234ze(E)的摩擦压降增加值也略大于R134a,由于R1234ze(E)的气液密度比略小于R134a,在干度增大时,相应R1234ze(E)的流速增加值大于R134a。

2)摩擦压降实验值同预估关联式比较,结果表明,在低质流密度300 kg/(m2·s)工况下,Mueller-Steinhagen H 等关联式的预估效果与实验值的总体吻合度较好。在中高质流密度400 kg/(m2·s)和500 kg/(m2·s)工况下,Greoennerud R关联式的预估效果与实验值的总体吻合度较好,且Greoennerud R关联式可以较为准确地预测出摩擦压降随干度变化的最大值。

本文受上海市研究生创新基金(JWCXSL1401)项目资助。(The project was supported by the Innovation Fund Project for Graduate Student of Shanghai (No. JWCXSL1401).)

[1]李连生.制冷剂替代技术研究进展及发展趋势[J].制冷学报,2011,32(6):54-57.(LI Liansheng. Research progress on alternative refrigerants and their development trend[J]. Journal of Refrigeration,2011,32(6):54-57.)

[2]马一太,王伟.制冷剂的替代与延续技术[J].制冷学报,2010,31(5):12-17.(MA Yitai, WANG Wei. Substitution and postponable technology of refrigerants[J]. Journal of Refrigeration,2010,31(5):12-17.)

[3]Regulation(EU) No.517/2014 of the European Parliament and of the Council of 16 April 2014 on fluorinated greenhouse gases and repealing Regulation(EC) No 842/2006[EB/OL]. Official J. Eur. Union, http://eurlex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2014.150.01.0195.01.ENG.

[4]Calm J M. The next generation of refrigerants historical review consideration and outlook [J]. International Journal of Refrigeration,2008,31(2):1123-1133.

[5]邱金友,张华,祁影霞,等.新型制冷剂R1234ze(E)及其混合工质研究进展[J].制冷学报,2015,36(3):9-16.(QIU Jinyou, ZHANG Hua, QI Yingxia, et al. A study on new refrigerant R1234ze(E) and its mixtures[J]. Journal of Refrigeration, 2015, 36(3):9-16.)

[6]杨昭,吴曦,尹海蛟,等.低温室效应HCFCs替代物性能分析[J].制冷学报,2011,32(1):1-6.(YANG Zhao,WU Xi,YIN Haijiao,et al.Analysis on alternatives for HCFCs with low greenhouse effect[J]. Journal of Refrigeration,2011,32(1):1-6.)

[7]McLinden M O, Kazakov A F, Brown J S,et al. A thermodynamic analysis of refrigerants:Possibilities and tradeoffs for Low-GWP refrigerants[J]. International Journal of Refrigeration,2014,38(1):80-92.

[8]Wallington T J, Sulbaek Andersen M P ,Nielsen O J. Atmospheric chemistry of short-chain haloolefins: photochemical ozone creation potentials (POCPs), global warming potentials (GWPs), and ozone depletion potentials (ODPs) main[J]. Chemosphere, 2014,129: 135-141.

[9]Akasaka R. Thermodynamic property models for the difluoromethane (R-32) + trans-1,3,3,3-tetra-fluoropropene (R-1234ze(E)) and difluoromethane +2,3,3,3-tetrafluoropropene (R-1234yf) mixtures[J]. Fluid Phase Equilibria,2013,35(8):98-104.

[10] Brown J S, Zilio C, Cavallini A. Thermodynamic properties of eight fluorinated olefins[J]. International Journal of Refrigeration,2010,33(2):235-241.

[11] Adrian M B,Joaquin N E,Angel B,et al. Theoretical comparison of low GWP alternatives for different refrigeration configurations taking R404A as baseline[J].International Journal of Refrigeration ,2014; 44(1): 81-90.

[12] Adrian M B, Joaquin N E, Angel B, et al. Drop-in energy performance evaluation of R1234yf and R1234ze(E) in a vapor compression system as R134a replacements[J]. Applied Thermal Engineering, 2014,71(1): 259-265.

[13] Francisco M,Joaquin N E,Bernardo P,et al. Theoretical energy performance evaluation of different single stage vapor compression refrigeration configurations using R1234yf and R1234ze(E) as working fluids[J].International Journal of Refrigeration, 2014,44(1): 141-150.

[14] Grauso S,Mastrullo R,Mauro A W,et al. Flow pattern map,heat transfer and pressure drops during evaporation of R-1234ze(E) and R134a in a horizontal,circular smooth tube:experiments and assessment of predictive methods[J]. International Journal of Refrigeration,2013,36(2):478-491.

[15] Hossain M A,Onaka Y, Afron H M M,et al. Heat transfer during evaporateon of R1234ze(E),R32,R410A and a mixture of R1234ze(E) and R32 inside a horizontal smooth tube[J]. International Journal of Refrigeration,2013,36(2):465-477.

[16] Rouhani S Z, Axelsson E. Calculation of void volume fraction in the subcooled and quality boiling regions [J].International Journal of Heat & Mass Transfer,1970; 13(2): 383-393.

[17] Lemmon E W,Huber M L,McLinden M O. NIST Reference fluids thermodynamic and transport properties-REFPROP 9,standard reference database 23 [DB].National Institute of Standard and Technology,Gaithersburg,MD,USA,2009.

[18] Friedel L. Pressure drop during gas/vapor liquid flow in pipes[J]. International Chemical Engineering, 1980, 20: 352-367.

[19] Groennerud R. Investigation of liquid hold-up, flow resistance and heat transfer in circulation type evaporators, Part IV: two-phase flow resistance in boiling refrigerants[R]. Annexe 1972-1, Bulletin of Institute International du Froid, 1979.

[20] Lockhart R W, Martinelli R C. Proposed correlation of data for isothermal two-phase, two component flow in pipes[J]. Chemical Engineering & Processing, 1949, 45: 39-48.

[21] Mueller-Steinhagen H, Heck K S. A simple friction pressure drop correlation for two-phase flow in pipes[J]. Chemical Engineering & Processing, 1980, 20(6): 297-308.

About the corresponding author

Qiu Jinyou, male, Ph.D. candidate, Institute of Refrigeration and Cryogenics, University of Shanghai for Science and Technology, +86 21-55275542, E-mail: junior51020@163.com. Research fields: environmental friendly refrigerants, flow boiling heat transfer.

Investigation of Frictional Pressure Drop During Flow Boiling of R1234ze(E) in Horizontal Tube

Qiu Jinyou1Zhang Hua1Yu Xiaoming1Qi Yingxia1Wang Xi2Liu Zhanjie2

(1.Institute of Refrigeration and Cryogenic Engineering, University of Shanghai for Science and Technology, Shanghai, 200093, China; 2.Haier Group Technology Research Center, Qingdao, 266103, China)

Recently, more attention have been paid to the new refrigerant R1234ze(E), which is supposed to be the most promising alternative of R134a in heat pump system. In this paper, the saturated flow boiling frictional pressure drops characteristics of R1234ze(E) and R134a inside an 8 mm ID horizontal tube were investigated. The experiment were carried out at the saturation temperature of 10 ℃ with heat flux ranging from 5.0 kW/m2to 10.0 kW/m2and mass flux ranging from 300 kg/(m2·s) to 500 kg/(m2·s). The influence of mass flux and heat flux on the frictional pressure drops were examined and discussed. The results show that, the frictional pressure drops of R1234ze(E) are slightly greater than those of R134a. Meanwhile, the experimental data of the frictional pressure drops are compared with four well-known empirical correlations.

R1234ze(E); R134a; horizontal tube; flow boiling; frictional pressure drops

0253-4339(2016) 01-0032-06

10.3969/j.issn.0253-4339.2016.01.032

国家自然科学基金(51176124)、国际科技合作项目(2012DFR70430)资助项目。(The project was supported by the National Natural Science Foundation of China (No.5117612)&International Science and Technology Cooperation Projects(No.2012DFR70430).)

2015年7月3日

TB61+2;TK124

A

简介

邱金友,男,博士研究生,上海理工大学能源与动力工程学院制冷与低温工程研究所,(021)55275542,E-mail: junior51020@163.com。研究方向:环保制冷剂、制冷剂管内流动沸腾换热。