AP1000机组小破口失水事故模拟分析

2016-05-09陈杰周涛刘亮李宇

陈杰,周涛,刘亮,李宇

(华北电力大学a.核热工安全与标准化研究所; b.非能动核能安全技术北京市重点实验室,北京 102206)

AP1000机组小破口失水事故模拟分析

陈杰a,b,周涛a,b,刘亮a,b,李宇a,b

(华北电力大学a.核热工安全与标准化研究所; b.非能动核能安全技术北京市重点实验室,北京102206)

摘要:采用美国MST公司核事故仿真软件PCTRAN,对AP1000小破口失水事故进行瞬态曲线分析,仿真结果表明:当发生400 cm2小破口失水事故后,AP1000机组堆芯补水箱和堆芯安注箱水位随反应堆系统压力下降而下降,反应堆系统压力降到13.09 MPa时,触发AP1000机组非能动余热排出系统热交换器导出堆芯余热;当反应堆系统的压力降到1.52 MPa时,堆芯水位开始上升;到反应堆系统压力达到0.29 MPa后,压力开始趋于稳定。计算后的反应堆系统压力在数值上与西屋公司用NOTRUMP软件分析的结果大致一样。

关键词:AP1000机组;小破口失水事故; PCTRAN软件;瞬态曲线;模拟分析

0 引言

核电机组安全问题不仅会影响其自身的发展,而且会波及周围的环境,更为严重的是会引起人们的恐慌,因此,确保安全非常重要。由于机组小破口失水事故(SBLOCA)在冷却剂丧失事故(LOCA)中发生频率很高,而且SBLOCA会使反应堆冷却剂系统(RCS)降压速率减慢,甚至会让堆芯裸露,导致燃料元件温度过高,进一步引起反应堆发生一系列问题,如RCS丧失后压力降低、冷却能力降弱、放射性冷却剂释放等。目前,我国山东海阳核电站、浙江三门核电站正在建造AP1000机组[1],因此,研究其SBLOCA对AP1000机组运行的影响具有现实意义。

1 研究的几何模型

AP1000核电机组是第3代压水堆[2],其非能动RCS让反应堆保护系统的安全性能得到提高。AP1000有效地利用重力、自然循环和空气压缩膨胀等驱动原理[3],减少人为控制安全系统的次数,提高核电站运行的安全性。AP1000 RCS是由2条并联环路组成的反应堆闭式循环回路[4](如图1所示),其中RCS设计采用“4进2出”布置的冷却剂管道,即2条环路有4根冷管段和2根热管段。

AP1000机组SBLOCA分为4个阶段[5]:喷放阶段、自然循环阶段、自动降压系统阶段和长期冷却循环阶段,4个阶段AP1000设备工作状态见表1。

图1 RCS组成

表1 AP1000 SBLOCA的发展阶段

2 PCTRAN/AP1000 仿真分析

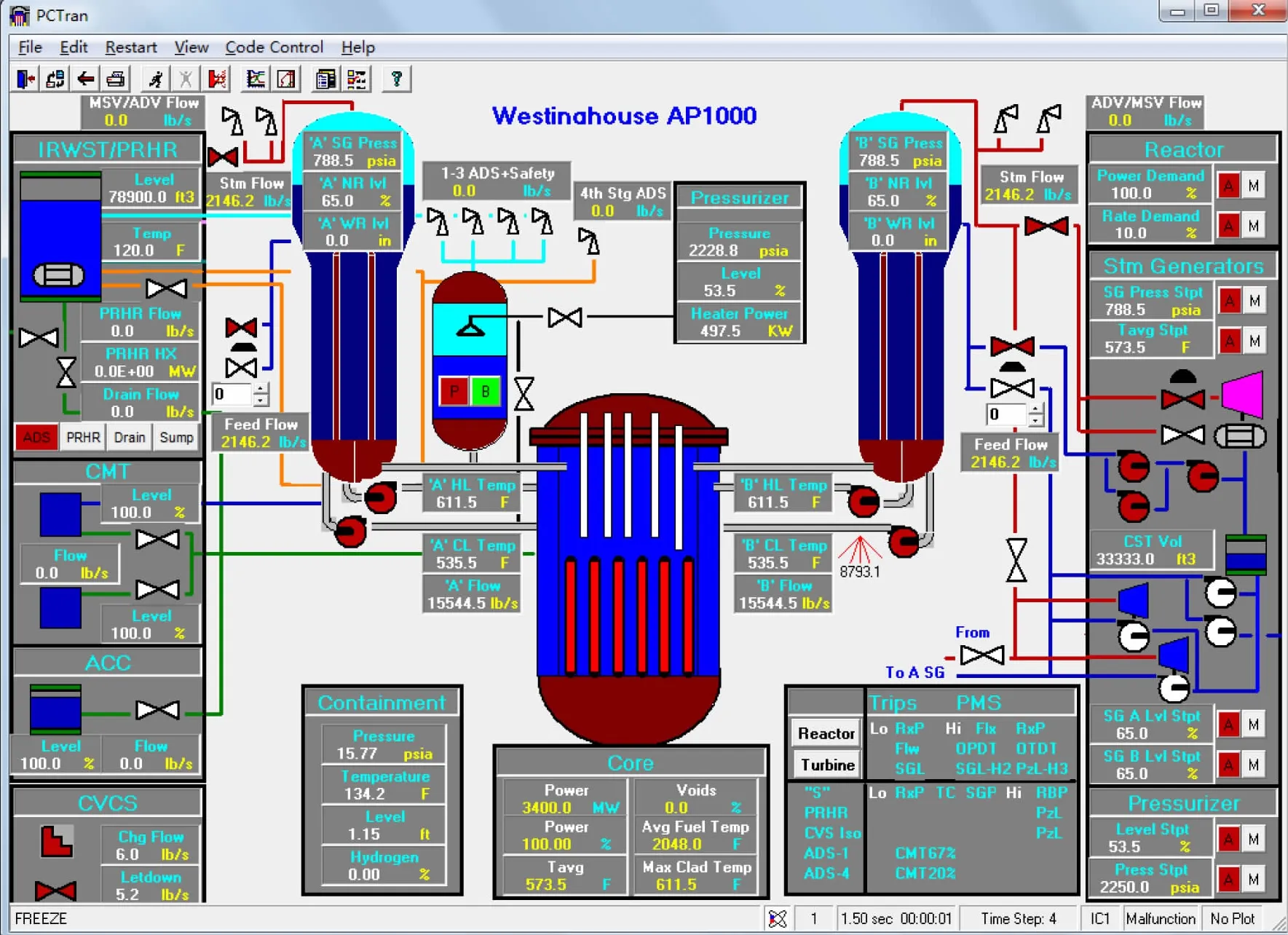

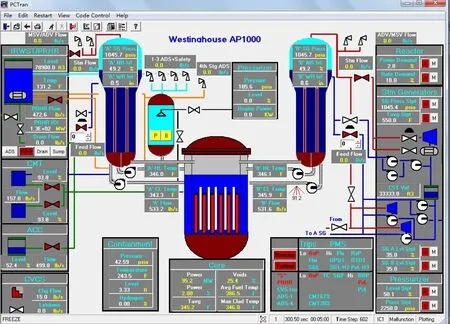

采用美国MST公司PCTRAN[6]软件对AP1000 SBLOCA进行模拟分析,采用定性对比和定量分析相结合的方法,分事故发生时AP1000机组工作状态和未发生事故时AP1000机组工作状态来研究AP1000机组工作性能变化,然后通过PCTRAN导出事故发生后的瞬态曲线图(如图2~7所示),当冷管段发生400cm2的SBLOCA时,可通过PCTRAN主控页面初步观察失水事故发生后AP1000机组设备及系统之间的工作状态变化(如图8、图9所示)。

图2 A蒸汽发生器蒸汽和堆芯补水箱流量瞬态曲线

图3 堆芯水位瞬态曲线

图4 稳压器水位瞬态曲线

图5 反应堆RCS压力的瞬态曲线

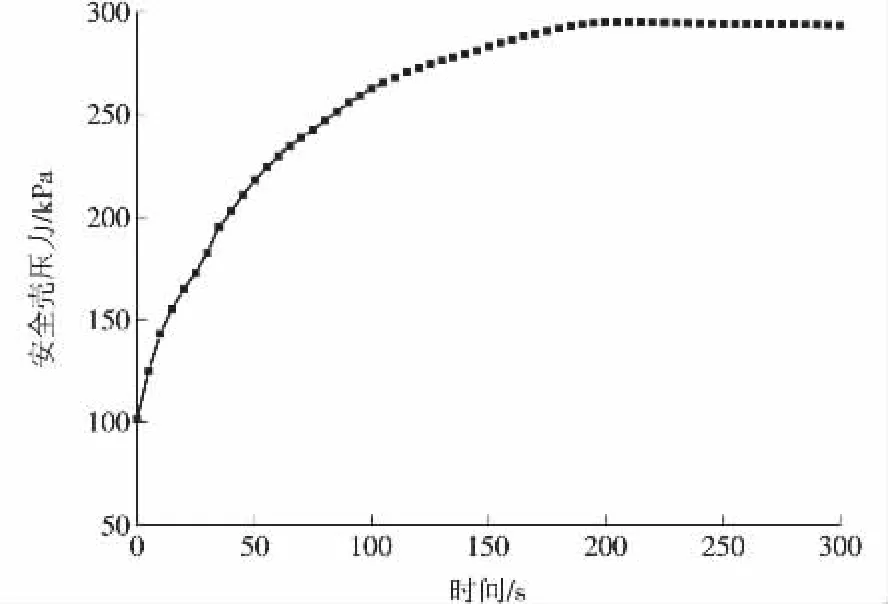

图6 安全壳压力的瞬态曲线

图7 包壳峰值温度、燃料峰值温度和RCS平均温度瞬态曲线

3 管段SBLOCA仿真过程分析

3.1设备水位及流量参数变化

通过图8和图9可知:在AP1000机组冷管段发生SBLOCA 1.5 s时,非能动余热排出流量并未开启流动;当事故发生300 s时,AP1000机组非能动余热排出系统启动,带出堆芯和RCS的热量以降低堆芯温度,冷却一回路系统;当事故发生1.5s时,堆芯补水箱水位和安注箱水位为100%,当事故发生300 s时,堆芯补水箱水位降为93.80%、安注箱水位降为52.40%,说明事故发生一段时间后,堆芯补水箱和安注箱启动,为反应堆冷却系统注入低温含硼水冷却堆芯;化学容积系统在事故发生前段时间其流量为27.69 kg/s,并未发生改变,说明仍正常工作,但当失水事故发生到300 s时,化学容积系统排出流量升高为68.55 kg/s,说明AP1000机组反应堆中辅助系统开始启动,并对堆芯进行反应性控制,通过堆芯补水箱上的连接管调节硼的浓度来进行补水,从而控制一路系统的堆芯装水量,并向反应堆冷却剂泵提供含硼水。通过对图3和图4对比也可看出,在失水事故发生时,反应堆控制棒插入堆芯使得反应堆紧急停堆,非能动冷却系统提供的硼水为反应堆提供额外的负反应性,从而保证反应堆在温度较低时有充足停堆裕量。

图8 事故刚发生1.5 s后AP1000机组的状态

图9 事故发生后300 s AP1000机组的状态

3.2部分系统参数的变化

通过分析瞬态曲线图各因素变化及瞬态曲线数据异常情况并仿真分析得到:当发生400 cm2小破口时,RCS压力快速下降,当其压力下降到13.09 MPa时,触发AP1000机组非能动余热排出系统热交换器导出堆芯余热。安全壳压力随着RCS压力下降而增加,在RCS压力降到大约1.81 MPa后其压力趋于稳定(约0.29 MPa)。随着温度和稳压器水位的下降,堆芯补水箱(CMT)相关系统启动,堆芯补水箱以水循环模型进行:冷管段的热水开始进入堆芯补水箱,将部分冷的含硼水排出,补水箱的冷水则注入RCS。由于安全壳压力升高而触发非能动安全壳冷却剂系统(PCS)信号,当RCS压力降至比安全壳压力略高时,安全壳内置换料水箱(IRWST)开始向堆芯提供冷却水,导出安全壳热量,降低安全壳压力和温度,使堆芯保持在冷却状态。通过图7可以看出:包壳峰值温度、燃料峰值温度在15s之前迅速下降,之后下降趋势变缓,但随着堆芯再次被淹没,燃料峰值温度再一次降低。堆芯的水位因为SBLOCA而逐渐下降,直到反应堆系统的压力降到1.51 MPa时,堆芯水位开始上升(如图3所示)。

3.3冷管段小破口失水事故参数变化

根据图5 RCS压力趋势变化,可得到冷管段SBLOCA前2个阶段RCS压力瞬态曲线。

3.3.1喷放阶段

当稳压器压力高于10.65 MPa(事故发生后10 s左右)时,该阶段反应堆冷却剂压力迅速下降,当RCS压力降到9.62 MPa(约事故发生15s)时触发反应堆紧急停堆。同时,堆芯补水箱开始向堆芯注水,非能动余热排出系统热交换器带走堆芯余热。稳压器水位开始由原来的100%降为0(如图4所示),堆芯补水箱通过直接管线开始向堆芯注入含硼水。非能动系统通过自然循环将RCS冷却,并通过再循环流流向堆芯补水箱。

3.3.2自然循环阶段

当稳压器压力从10.65 MPa开始下降到1.98 MPa(大约事故发生165 s)时,冷却剂系统向外排水,流出的冷却剂流体带走一部分衰变热,使堆芯冷管段和热管段温度下降,同时堆芯补水箱和非能动余热排出系统热交换器也通过再循环进一步导出堆芯热量,让稳压器压力进一步下降。当RCS压力下降到1.65 MPa,堆芯水位下降到最低(约为44.99%)时,堆芯补水箱和安注箱继续向堆芯注水导致堆芯水位开始上升(如图2和图3所示)。

4 冷管段SBLOCA仿真结论

(1)用PCTRAN模拟后误差分析。对于AP1000机组所属的工况III(稀有事故)标准:受损的燃料元件不应超过规定值,保持正常堆芯冷却功能;燃料元件要能保持在正常温度值,其中燃料包壳温度值低于1204℃;一回路压力边界值低于120%设计值。

(2)在冷管段小破口事故发生300 s后,燃料包壳峰值温度728.15℃低于AP1000机组规定值;其中一回路压力在300 s后降至0.73 MPa,远远低于120%设计值,大致符合AP1000机组设定值。通过对比分析,本文计算的结果在时间和数值上与西屋公司用NOTRUMP分析的结果[5]大致一样(如图10所示)。

图10 PCTRAN与NOTRUMP分析AP1000机组小破口对比分析(前300 s分析)

(3)当发生SBLOCA时,AP1000机组的非能动余热排出系统启动,导出堆芯和RCS产生的热量,降低反应堆系统压力,冷却堆芯。当反应堆系统压力下降到一定值时,堆芯补水箱启动,为反应堆冷却系统注入低温含硼水。随着反应堆压力进一步降低,AP1000机组非能动安注箱开始向堆芯注入含硼水进一步冷却堆芯。当堆芯水位降到一定程度时,AP1000机组辅助系统(化学容积系统)开始控制反应堆反应性,辅助系统通过堆芯补水箱上的连接管调节硼的浓度来进行补水,控制一路系统的水装量,并向反应堆冷却剂泵提供轴封水。为了避免反应堆受损,AP1000机组的控制棒会插入堆芯使反应堆紧急停堆,非能动冷却系统提供的硼水为反应堆提供额外的负反应性,从而保证反应堆在温度较低时有足够停堆裕量。

参考文献:

[1]林诚格,郁祖盛,欧阳予.非能动安全先进核电厂AP1000 [M].北京:原子能出版社,2008.

[2]吴萍,杨艳晨,陈昊,等.第三代核电堆型AP1000运行特点及堆芯仿真研究[J].电网技术,2014,38(5) : 1196-1202.

[3]于平安,朱瑞安,喻真烷.核反应堆热工分析[M].上海:上海交通大学出版社,2002.

[4]向延,孙都成.AP1000 ASD-4空气-水夹带实验研究[J].原子能科学技术,2015(49) : 5-10.

[5]林支康.AP1000核电厂小破口失水事故RELAP5分析模式建立与应用[D].上海:上海交通大学,2012.

[6]王祺琦,武祥.基于PCTRAN的AP10000核电厂卡轴事故的模拟与分析[J].价值工程,2014(29) : 44-46.

(本文责编:白银雷)

陈杰(1991—),男,湖南衡阳人,在读硕士研究生,从事核热工水力与安全方面的研究(E-mail: 805072298 @ qq.com)。

周涛(1965—),男,陕西西安人,教授,博士生导师,从事反应堆热工水力与安全方面的研究工作(E-mail: zhoutao @ ncepuedu.cn)。

2016-01-05Realization of telecontrol channel for power plant rapid regulating system and its application in scale small hydropower stations group

XU Yutao1,WU Jinhui2,LIN Chenghui1,JIAO Shaohua2,GU Wei1,ZHAO Jiwei3,LONG QiuFeng1(1.Electric Power Research Institute of Guizhou Power Grid Company Limited,Guiyang 550002,China; 2.Beijing Sifang Automation Company Limited,Beijing 100084,China; 3.Liupanshui Power Supply Bureau,Guizhou Power Grid Company Limited,Liupanshui 553001,China)

2016-01-09Application of automatic generation control in gas and steam combined cycle power plant

XU Zhenhua(China Huadian Engineering Company Limited,Beijing 100160,China)

2016-01-13The heat transfer and flow resistance characteristics of snake-like finned tubes of air-cooling unit at low wind speed in winter

ZOU Qingjiang1,LI Peng1,GUO Minchen2,LI Ansheng2(1.Shenhua Guoneng Mengdong Energy Corporation Limited,Hulunbeir 021000,China; 2.School of Energy,Power and Mechanical Engineering,North China Electric Power University,Beijing 102206,China)

2016-01-18A logic optimization for power control of control system of M701D gas turbine

ZHAO Junhua(Jiangsu Huadian Qishuyan Power Generation Company Limited,Changzhou 213011,China)

2016-01-22Controlsystem design analysis of coal-fired power plant in heating transformation of condensing power unit

LIU Bing1,GAI Dongfei2(1.Huadian Zhangqiu Power Generation Company Limited,Ji’nan 250216,China; 2.Shandong E-lectric Power Engineering Consulting Institute Corporation Limited,Ji’nan 250013,China)

2016-01-25The design of the electric synchronous system of 2×1000 kN trolley type hoist

XIE Haijian1,WANG Jidong2,GAO Jinming1(1.Huadian Zhengzhou Mechanical Design Institute Company Limited,Zhengzhou 450015,China; 2.Mechanic Electronic Automobile Egineering College of Zhongzhou University,Zhengzhou 450044,China)

2016-01-28 600 MW boiler air pre-heater online water wash

WANG Weinian (Huayang Power Company Limited Houshi Power Plant,Zhangzhou 363105,China)

2016-01-32Analysis and treatment for seal cast back problem of ball valve

WU Jinrong,WANG Jun(Mindong Hydropower Development Company Limited,Ningde 352100,China)

2016-01-36 Failure cause and treatment of 600 MW unit steam pump booster pump

MU Xiaojing(Huaneng Tongchuan Zhaojin Power Plant,Tongchuan 727100,China)

2016-01-39 Estimate of 600 MW generator rotor turn-to-turn short circuit

YANG Qunfa,WANG Dongya,SHEN Wenhua(Guangdong Zhuhai Jinwan Power Plant Company Limited,Zhuhai 519050,China)

2016-01-42Analysis of generator outage caused by HV plant transformer LV side non-segregated busbar failure

QIN Zhuoxin (Shanxi Zhangshan Power Company Limited,Changzhi 046021,China)

2016-01-45 2×150 MW generator ends winding loose and corona treatment

HUANG Yijin(Huadian Sichuan Power Generation Company Limited Panzhihua Branch,Panzhihua 617065,China)

2016-01-47Reason analysis and preventive measures of tripping caused by 600 MW steam turbine fuel injection test

ZHANG Xuehai (Huaneng Tongchuan Zhaojin Power Plant,Tongchuan 727100,China)

2016-01-49The reasonable application of frequency converter in coal-fired power plant

CHEN Lixin,SUN Jianbang,CHEN Rui(Harbin Thermal Power Company Limited,Harbin 150046,China)

2016-01-51Economy improvement analysis during hot start of 6FA gas turbine combined cycle unit

TANG Mingfeng,WU Minjie (Hangzhou Huadian Xiasha Thermal Power Company Limited,Hangzhou 310018,China)

2016-01-54Domestic 600 MW supercritical coal-fired unit“near zero emission”reconstruction

YIN Pengfei(Guangdong Zhuhai Jinwan Power Plant Company Limited,Zhuhai 519050,China)

2016-01-59Low NOxcombustion retrofit of boilerand its effect analysis for 330 MW power unit

FAN Aibing (Jiangsu Huadian Yangzhou Power Generation Company Limited,Yangzhou 225007,China)

2016-01-62The application of selective noncatalytic reduction denitration technology in garbage incineration power plant

ZHANG Hui(Shenzhen Energy Environmental Protection Company Limited,Shenzhen 518052,China)

2016-01-64 Failure analysis and design optimization of non-metallic expansion joint at inlet duct of denitrification device

WANG Sen1,AN Hong2,ZHU Bin2,WANG Shushan2(1.Shenghua Guohua(Beijing) Electric Power Research Institute Company Limited,Beijing 100025,China; 2.Shenhua Guangdong GuohuaYuedian Taishan Power Generation Company Limited,Taishan 529228,China)

Abstract: Some faults are existed in the non-metallic expansion joint at inlet duct of denitrification device for a certain 1000 MW power unit,such as the lower skin cracking and serious deformation of flange etc.Through the analysis,the failure reason is considered as the unreasonable structure design of double-wave type middle flange hinge of expansion joint.In this paper,the original expansion joint was replaced by single-wave structural non-metallic expansion joint,and some structural optimizations of expansion joint frame,thermal-protective coating and skin were also conducted.More than two years of operation shows that the expansion joint works well and the surface temperature is less than 50℃under full load condition.

2016-01-68Simulation analysis of small break loss of coolant accident of AP1000 power unit

CHEN Jiea,b,ZHOU Taoa,b,LIU Lianga,b,LI Yua,b(North China Electric Power University,a.Institute of Nuclear Thermalhydraulic Safety and Standardization; b.Beijing Key Laboratory for Passive Safety Technology of Nuclear Energy,Beijing 102206,China)

2016-01-72Anemometer monitoring method based on adjacent wind turbines correlation model

WU Lizeng(China Huadian Corporation,Beijing 100031,China)

2016-01-01 Research of one-dimensional shielding calculationusing finite element method

ZHAO Jingchang,ZHANG Bin,CHEN Yixue(School of Nuclear Science and Engineering,North China Electric Power University,Beijing 102206,China)

Abstract:In this paper,the shielding calculations of one-dimensional plate and one-dimensional sphericity using deterministic method were studied and a one-dimensional steady-state neutron transport calculation program DONTRAN1D using discrete SNfinite element method (FEM) was developed.In the calculations,a virtual point setting method was proposed when processing the model boundary conditions.In addition,a zeroing modification and a neutron balance calculation using transporte quation were adopted for negative flux.At last,a comparative analysis was conducted between DONTRAN1D and other mature program in the world using calculation examples.The results show that the solving accuracy of DONTRAN1D could be guaranteed well.Besides that,a mount of functional module interfaces were reserved for future development in DONTRAN1D program. In order to stabilize the power grid fluctuation due to the grid-connection of wind and photovoltaicenergies and realize the combined operation of scale small hydropower stations group witha variety ofnew energies,this paper aimed at the characteristics of stability,adjustability and rapid regulation of scale small hydropower stations group,developed an embedded controller integrating the rapid regulating functions of active power and reactive power for hydropower station,which could make small hydropower stations have the ability of power rapid regulation.In addition,in order to realize the closed-loop control of scale small hydropower stations group according to the remote control strategies,a closed-loop control telecontrol channelamong remote hoststation and hydropower stations must be built.Therefore,this paper proposed two solutions that based on the dispatching data network and wireless communication that taking the practical features of small hydropower station into consideration.The demonstration plants shows that the power rapid regulating system and the closed-loop control of scale small hydropower stations group was realized successfully. Automatic generation control(AGC) has become increasingly important with the development of power industry.Based on a gas and steam combined cycle power plant in Malaysia,an AGC system had been designed.This paper introduces the control pattern of AGC system,load limit,load rate of change and design content of operation procedure of AGC.The practical application indicates that the application effect of AGC system turns out good and meet the technical requirements of electric power control center. In winter,the ambient temperature is relatively low and the fan below the direct air-cooling condenser is forced to run at low flow rate or shutdown in order to prevent the finned tube bundlesfrozen under low heat load conditions.Therefore,it is necessary to study the heat transfer and flow resistance characteristics of finned tubesat low wind speed,as well as the air cooling system status under natural ventilation condition.This paper simulated the influence rules of ambient temperature,wall temperature of finned tubes and inlet velocity of air to the velocity and temperature fields of finned tubes using Fluent,and built a driving force generation model of airflow for direct air-cooling condenser under natural ventilation condition.On the basis of numerical simulation,this paper analyzed the heat transfer and flow resistance characteristics of single row snake-likefinned tubes,obtained the natural ventilation air flow rate under certain condition through the balance of the lift and drag,and calculated the corresponding heat transfer coefficient.It provided a reference for the optimization design of direct air-cooling condenserthat operating at low wind speed. Based on the fact that a trip failure occurred to a M701D gas turbine,this paper concludes that the cause of this failure is because the potential transformer is inconsistent with original design on the actual wiring and the logic of power control of turbine control system (TCS) is unreasonable.To overcome this problem,this paper suggests to take action by reconnecting,adding power controller and optimizing logic of TCS.After these modification,under the circumstances that each power transmitter and TCS are consistent on channel and adopted value,and one or three phase of fuse of power transmitter is fusing,the result showed that the logic of TCS is calculated correctly,which effectively improved circuit fault of control system. In coal-fired power plants,the economic benefits of medium and small sized condensing power units are not as ideal as expected due to existing problems,such as low efficiency,high coal consumption and large-scale pollution etc.In addition to the shutdown of medium and small sized cogeneration units,the formed heating gap is in urgent needsto be filled.Therefore,a large number of condensing power units has been transformed to extraction condensing cogeneration units gradually in recent years in order to meet the changing situation.Taking the 2×225 MW +2×300 MW units of a certain power plant as an example and aiming at the problems that exist in the heating transformation of subcritical condensing power units,this paper analyzed the design of control system and control logic and provided corresponding recommendations. Taking 2×1 000 kN platform hoist at Xijiang Changzhou hub ship lock project for example,the method how to use absolute value encoder,Siemens S120 inverter and Siemens S7-300 PLC to realize electrical synchronization with double lifting point of platform hoist was introduced in this paper.The synchronous system save the project cost,make the manual more flexible,simple and reliable. This paper analyzed the necessity of water wash to boiler air pre-heater and feasibility of on-line water wash,indicated two methods to water wash air pre-heater,and descried the process of air pre-heater on-line water wash.The operation parameter and waste water parameter indicated that water wash is effective and secured the safety and stability of unit operation. Two ball valves with diameter1 720 mm were installed in Fujian Muyangxi Zhouning Hydropower Station.The overall operation of No.2 ball valve run well when it was first put into use,while seal cast back problem which affected automatic boot occurred at later stage.After analysis,the main reasons were seal damage and congenital design deficiency.The problems were solved by modifying the open process of No.2 ball valve,replacing the three D type seal and redesigning the package D type sealing packing. After years of operation,many defects appeared on the booster pump of Huaneng Tongchuan Zhaojin Power Plant,such as abrasion of pump cover interface,serious axial movement while low load,damage of bearings,leakage of mechanical sealed cooling jacket and etc.After analyzation,solutions and suggestions to those defects was indicated,which are effective to improve the unit operation. While Guangdong Zhuhai Jinwan Power Plant Company Limited No.3 unit overhauling,site test found there is trace of turn-to-turn short circuit at rotor winding.Turn-to-turn short circuit was determined by two-pole voltage balance test.Winding alternating voltage distribution test determined the coil with failure.After the rotor was sent back to factory to repair,failure was analyzed and repaired.The overhaul duration was secured. The author studied on a generator outage,which caused by plant transformer LV side non-segregated enclosed busbar failure.Based on the treatment of this accident and record analysis,the author indicated that the direct reason of this accident is the enclosure of LV side non-segregated busbar was not well-sealed,and insulator was damped.This paper also included the preventive measurement based on aspects of operation and equipment maintenance. Panzhihua Power Plant 2×150 MW generator stator winding end part bearing fixing structure,lashing rope and a su-book=78,ebook=82pport ring and supporting plate loosening effect,stator winding surface potential distribution is not uniform,in the high voltage,resulting in the big local potential gradient winding end part fixed and banding of tip and burr discharge phenomenon.In order to improve the life safety operation of generator,generator stator end winding were processed,and used the Harbin motor factory research obtains the reliable anti corona technology and anti corona treatment experience of winding of corona treatment,to take measures and through long-term monitoring on line partial discharge monitoring of generator stator winding insulation,can timely evaluation the state of generator stator winding fault,found early signs of early,to avoid the occurrence of accidents.After four years of operation,has achieved remarkable results. The process and principles of the injection test of a 600 MW steam turbine were introduced in this paper.Taking the tripping accident of turbine caused by the injection test for example,the causes were confirmed,the jam of the electromagnetic valve and the logic blocking of the DEH tripping were main reasons for the accident.Through the analysis above,preventive measures were put forward,which provided a good guidance to prevent the failure of units akin to the above. In order to achieve the goal of saving energy and reducing consumption of 300 MW coal-fired unit,additional frequency converter was installed on auxiliary electric motor in a certain power plant.After the installation,a tracking analysis of equipment running status was conducted and the corresponding treatment methods of problems occurred were given in this paper,which provided a reference for the energy saving and consumption reducing work of similar units. To reduce the gas consumption of natural gas during the host start of combined cycle unit and improve the economy of plant operation,several measures such as appropriate impulse starting parameter and reference datum selection,as well as the cylinder temperature reduction are performed to achieve lower plant operation costs.After optimization,the gas consumption during hot start has a significant descent and the plant operation has obvious economic benefits. To realize“near zero emission”,Guangdong Zhuhai Jinwan Power Plant Company Limited’s No.3 and No.4 unit took reconstruction.This paper introduced the reconstruction of desulfurization system,adding wet ESP(electrical precipitator),classification of economizer,denitration system adding catalyst,combination of duct fan and booster fan.After reconstruction,the emission concentration of dust,SO2and NOxis lower than gas turbine unit,“near zero”emission was realized. The NOxemission concentration of an air preheater is up to 655.7mg/m3for the No.6 unit of a certain power plant.In order to meet the emission requirement of new standard,a low NOxcombustion retrofit of boiler burners conducted using a multi air stereo-staged and horizontal bias coal combustion technology,which carries out a multi air stereo-staged combustion along the vertical direction and horizontal direction in the chamber of a stove.The performance test of the retrofitted boiler shows that the retrofit effect is significant with the NOxemission concentration of an air preheater could be kept below 300mg/m3for a long time,and the boiler efficiency and combustible matter content in flue dust are also meeting the requirements. SNCR is characteristic of a short-term construction,minor investment and medium efficiency for denitration,which is fit for the medium scale or small-scale power plant,especially the waste incineration plant.Combined with the examples,the theory for the SCNR was introduced.The cases that should be paid more attention to are put forward.The conclusion are draw that SNCR technology,together with other denitration technologies can drop the NOxemissions at the low investment. Using the nuclear accident simulation software PCTRAN of MST Company,this paper carried out a transient curve analysis of small break loss of coolant accident (SBLOCA) of AP1000 power unit.The simulation results are as follows: After the occurrence of 400 cm2SBLOCA of AP1000 power unit,the water levels of makeup tank and safety injection tank of reactor core fall with the pressure decrease of reactor system.When the pressure drops to 13.09 MPa,the heat exchanger of passive residual heat removal system is triggered to remove the residual heat of reactor core.When the pressure continues to drop to 1.52 MPa,the water level of reactor core begins to rise.After the pressure reaches to 0.29 MPa,it begins to be stabilizing.The calculated system pressure is in concordance with the results that obtained using the software NOTRUMP by Westinghouse Corporation in time and number. It has important significance for real-time monitoring of wind turbine anemometer due to its high failure probability.This paper proposed an anemometer monitoring method based on adjacent wind turbines correlation model for the high correlation of operation conditions and measured values of anemometers among adjacent wind turbines.This paper processed the normal measured data of anemometers of adjacent wind turbines using particle swarm optimization (PSO) algorithm and built a correlation model.In this model,the real-time measured wind velocities of anemometers are considered as the inputs.When a certain wind turbine anemometer is abnormal,the correlation among adjacent wind turbines is destroyed and the predicted residual of the certain wind turbine anemometer will increase significantly,which indicates that anemometer may have a fault.Hence this method could realize the real-time monitoring of anemometer.The practical operation data of a certain wind farm verified the effectiveness of this method.

Keywords:one-dimension; shielding calculation; finite element method; neutron transport calculation scale small hydropower stations group; dispatching data network; wireless communication; telecontrol channel gas and steam combined cycle power plant; AGC; load air-cooling unit; numerical simulation; snake-like finned tubes; heat transfercharacteristic; flow resistance characteristic TCS; trip failure; PT; power transmitter; wiring; power control logic; optimization coal-fired power plant; condensing power units; heating transformation; cogeneration; control system absolute value encoder; inverter; programmable logic controller; electrical synchronization; hydraulic grab beam 600 MW unit; air pre-heater; on-line water wash; waste water ball valve; seal; cast back problem; gland packing booster pump; bearing; axial movement; mechanical sealed cooling jacket generator; rotor; turn-to-turn short circuit; coil non-segregated enclosed busbar; single-phase ground failure; damp; room temperature vulcanized silicone rubber; busbar heat tracing generator; winding; corona; online inspection injection test; DEH; tripping; jam; logic blocking; preventive measures coal-fired power plant; electric motor; frequency converter; energy saving and consumption reducing 6FA gas turbine; combined cycle; hot start; economy near zero emission; gas dust; SO2; NOx; wet electric precipitator; desulfurization; denitration; economizer classification burner; low NOxcombustion; NOx; air stereo-staged combustion; horizontal bias MSW incineration; flue gas denitrification; selective non-catalytic reduction technology; ammonia injection denitrification device; inlet duct; non-metallic expansion joint; skin; flange; thermal-protective coating AP1000 power unit; small break loss of coolant accident; PCTRAN; transient curve; simulation analysis wind turbine; anemometer; correlation model; condition monitoring; particle swarm optimization algorithm; back propagation neural network; residual

作者简介:

基金项目:中央高校基本科研业务专项资金项目(2014BJ0086) ;国家重点实验室开发课题(2014BJ0041)

收稿日期:2015-09-28;修回日期:2015-12-20

中图分类号:TL 33

文献标志码:B

文章编号:1674-1951(2016)01-0068-04