Short Duration Pulse Shock Initiation Characteristics of Ultrafine LLM-105

2016-05-08FUQiuboLIMinGUOFeiWANGMengWANGYao

FU Qiu-bo, LI Min, GUO Fei, WANG Meng, WANG Yao

(Institute of Chemical Materials, China Academy of Engineering Physics, Mianyang 621999, China)

1 Introduction

To meet the high energy and insentive reqirement of advanced weapon, safety and reliability of explosive were made more stringent requirements or even contradictory[1]. This problem gave rise to researchers′attention around the world. 2,6-Diamino-3,5-dintropyrazine-1-oxide (LLM-105) is a new compound, which synthesized by LLNL at 1993[2]. Its performance and insensitivity is between those of HMX and TATB. Its calculated energy content is about 85% that of HMX and 15% higher than that of TATB[3-7]. It is thermally stable, insensitive to shock, spark, and friction and has impact insensitivity approaching that of TATB in comparision to traditional explosive[5]. These properites make it very interesting for several applications such as insensitive boosters, detonators, and possibly main charges in specialty munitions. But it has few reports about slapper detonator application based on LLM-105.

Slapper detonator usually is applied to in-line fuse, which is important component of advanced weapon. Although the safety performance of TATB explosive can satisfy insensitive ammunition criterion, it has high input energy which is not agree with the miniaturization development of weapon. So, it is potential to apply for LLM-105 in the slapper detonator. In this paper, study on short duration pulse shock initiation characteristics of ultrafine LLM-105 has been conducted, which is useful for slapper detonator development.

2 Experimental

2.1 Materials

The ultrafine LLM-105(100-600 nm) was synthesized by institute of chemical materials (ICM). The purity of ultrafine LLM-105 is higher than 98.7%. The specific surface area of ultrafine LLM-105 is higher than 7.7 m2·g-1. The dimensions of charge used isΦ5 mm×4 mm for shock test, whose density is 1.63 g·cm-3.

2.2 FlyerImpacting Initiator

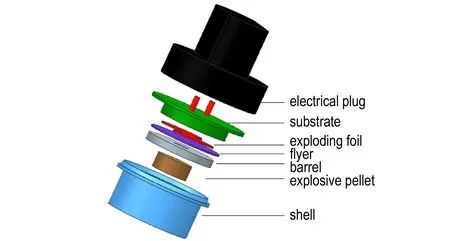

The flyer impacting initiating device is composed of five parts, namely exploding foil, flyer, barrel, explosive charge, and seal apparatus, which is shown on Fig.1. The material is copper, steel andkapton of exploding foil, barrel and flyer, respectively.

2.3 Equipment

The velocity of flyer is measured byphotonic dopplar velocity (PDV) which is made by Nanjing university of science and technology. The principle diagram of PDV system has shown on Fig.2. The movement velocity of sample is based on difference frequency between basic light and reflection light. The basic light is the reflection of probe by the 2-port optical circulator laser. The reflection light is the reflection of movement sample. The light probe detector collects the two different lights from the 3-port circulator[8].

The high voltage discharge circuit is fabricated by ICM. The capacitor is 0.22 μF. The duration of discharge circuit is 1.10 μs.

Fig.1 Schematic image of flyer impactingintiator

Fig.2 Principle diagram of PDV system

2.4 Experimental

The initiation threshold testing is implemented of ultrafine LLM-105 under two type flyers. The curve of flyer velocity is collected by PDV system, which is shown on Fig.3. The short duration pulse shock initiation sensitivity is achieved by calculation. The total amount of sample is twelve. The D-optimal method is applied for testing pulse initiation threshold.

Fig.3 Curve of flyer velocity by PDV

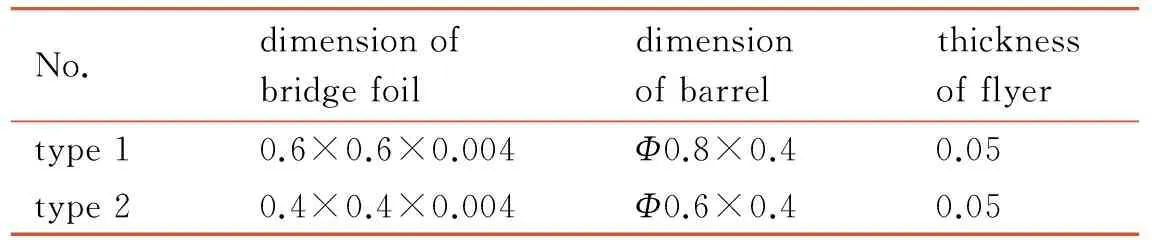

The contrasting test has been conducted of two different flyer parameters. The material of flyer iskapton. The parameter of two type flyer is shown on Table 1. The type 1 is corresponding to large dimension flyer. The type 2 is corresponding to small dimension flyer.

Table 1 Parameter of two type flyer mm

3 Results and Discussions

3.1 Results of Flyer Velocity

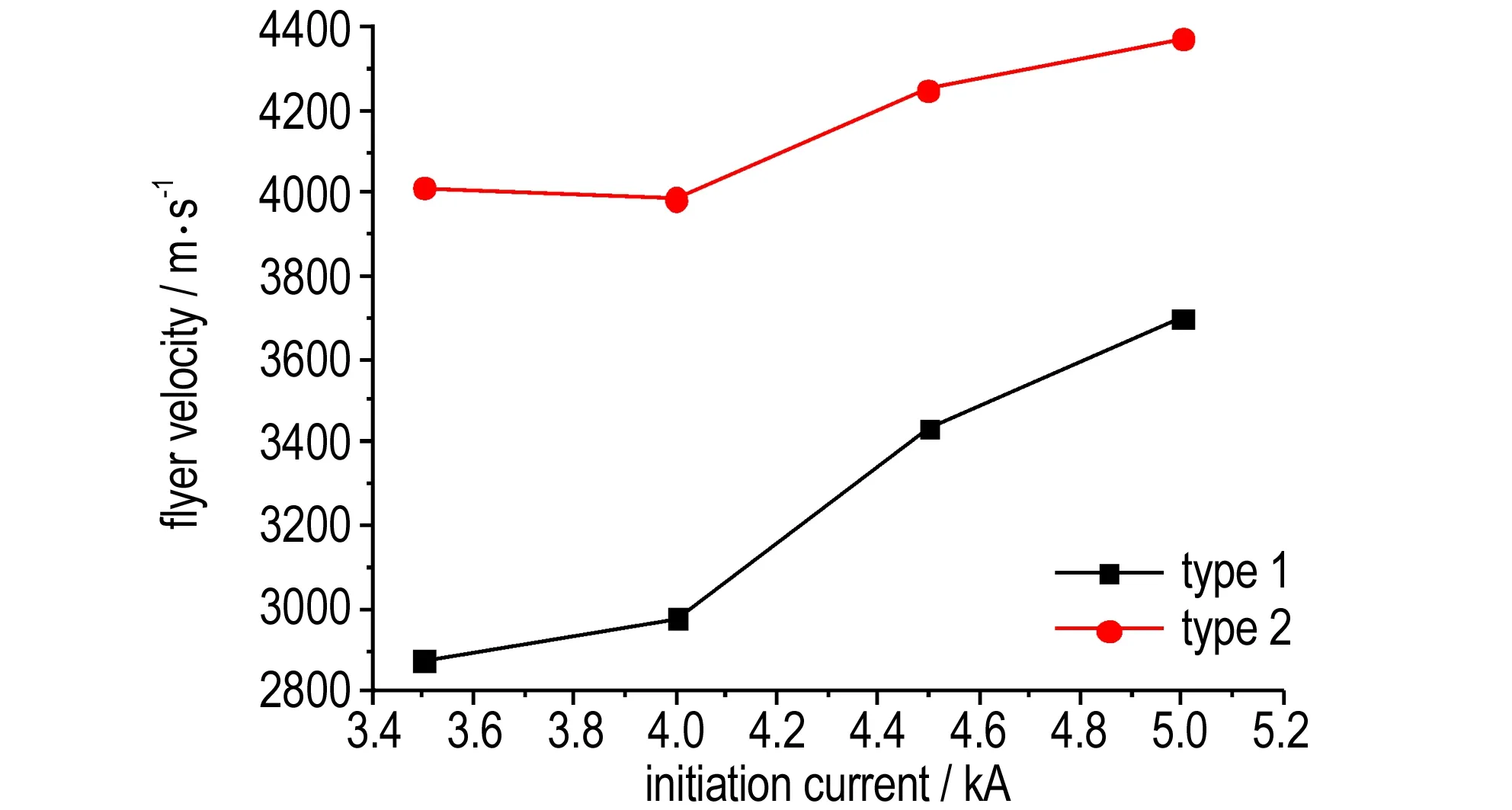

The velocity of two type flyer has shown on Table 2. It is indicated that the flyer velocity is increasing as increasing pulse current. But the increase amplitude of flyer velocity is high based on type 1(Fig.4) by contrasting with type 2. It is indicated that the large dimension flyer is sensitive to input electrical energy in comparision with small dimension flyer. But the velocity of flyer is higer with type 2 than type 1 under the same inputting pulse current. It can be explained by Gurney equation (1)[9].

(1)

Wherekandnare the constants of experiment determined, respectively,k=2.36×10-6,n=0.85[9]for the Cu foil,mfandmeare the flyer and exploding foil masses per unit area, respectively,Jbis the density of exploding current A/cm-2.

Jbis calculated by equation (2):

(2)

WhereIis the initiation current,A;Sis the cross-section area of exploding foil,cm-2.

The velocity of flyer is increasing as increasing pulse current according to equation (1) and (2) under the same dimension of exploding foil. The type 2 with small dimension flyer has high velocity because of high current density, resulting high energy per area under the same input pulse current.

The velocity consistency is not good of type 1 with large dimension flyer under the same pulse current. It may be resulted by error during testing process. But the phenomenon is only existing big flyer, so it is not true. The air resistance may be the main reason caused the bad consistency of flyer velocity based on large dimension flyer. According to aerodynamics, the distance can not keep constant between the centers of air resistance and mass during the flying process based on large dimension flyer. The departure of center has caused the existence of turning torque, resulting competition of distortion and anti-distortion. So, the flyer can not keep the plane integrity, which will exacerbate centroid departure, resulting velocity dispersity of type 1.

Table 2 Results of flyer velocity

No.type1initiationcurrent/kAvelocityofflyer/m·s-1averageofvelocityflyer/m·s-1No.type2initiationcurrent/kAvelocityofflyer/m·s-1averageofvelocityflyer/m·s-11235.041373229373437001235.042384541433943724564.538353027343134314564.5431441374299425074.03128297774.039363986828268403693.52876287693.540114011

Fig.4 Curves of flyer velocity

The short-duration pulse initiation criterion value for solid heterogeneous explosive isP2τ=constant[10]. ForcePis dependent on velocity of flyer. Pulse durationτis dependent on thickness of flyer. It is indicated that the high flyer velocity is favorable for initiating explosive under the same thickness of flyer.

3.2 The Firing Test of Explosive

The initiation testing of ultrafine LLM-105 has been applied with two type flyer by D-optimal method. The result of initiation threshold has shown on Table 3.

Table 3 Initiation threshold of ultrafine LLM-105 and HNS-Ⅳ

No.initiationthresholdLLM-105HNS-Ⅳtype12.57-type22.141.96

The initiation threshold current is 2.14 kA based on type 2 flyer, which is almost equal to HNS-Ⅳ initiation threshold, namely 1.96 kA. But the initiation threshold is high (2.57 kA) of type 1 flyer, which is consistent with above analysis. It is found that the improvement of flyer velocity is benefit for explosive initiation.

4 Conclusions

In the present work, we proposed the initiation threshold of LLM-105 under two type of flyer. The conclusions indicated that:

(1) The flyer velocity is increasing as increasing pulse current. But it is sensitive for input current of large dimension flyer incomparision with small flyer.

(2) The flyer velocity consistency is bad of big size flyer, which has relationship with air resistancel.

(3) It is found that the initiation threshold is almost equal between LLM-105 and HNS-Ⅳ by firing test, which will offer fundamental data for slapper detonator.

[1] Hollands R, Barnes P, Moss R, et al. Explosive booster selection criteria for insensitive munitions applications[C]∥Insensitive munitions & energetic materials technology symposium, Bristol, UK, 2006.

[2] WANG Zhen-yu. Development on some new insensitive individual explosives abroad[J].ChineseJournalofEnergeticMaterials(HannengCailiao), 2003, 11(4): 227-230.

[3] DENG Ming-zhe, ZHOU Jie-wen, WANG Bo-zhou, et al. Preparation improvement of LLM-105 explosive[J].ChineseJournalofEnergeticMaterials(HannengCailiao), 2013, 21(3): 294-296.

[4] XU Wen-xin, LI Bi-hong, LI Wan-quan, et al. Application of LLM-105 based heat resistance explosive[J].Initiators&Pyrotechnics, 2012, 4: 40-43.

[5] Agrawal J P. Some new high energy materials and their formulations for specialized applications[J].Propellants,Explosives,Pyrotechnics, 2005, 30: 316-320.

[6] Tran T D, Pagoria P F,Hoffman D M,et al. Simpson. Characterization of 2,6-diamino-3,5-dinitropyrazine-1-oxide (LLM-105) as an insensitive high explosive material[C]∥Annual conference of ICT, karlsruhe, Germany, 2002.

[7] XU Wen-zheng, AN Chong-wei, WANG Jing-yu, et al. Preparation and properties of an insensitive booster explosive based on LLM-105[J].Propellants,Explosives,Pyrotechnics, 2013, 38: 136-141.

[8] XIANG Hong-liang, WANG Jian, BI Chong-lian, et al. Data processing of photonic doppler velocimetry system[J].Optics&OptoelectronicTechnology, 2012, 10(2): 52-56.

[9] Stanton P L. The acceleration of flyer plates by electrically exploded foils[R]. U.S: SAND 750221, 1975.

[10] GENG Chun-yu. Velocity analysis of a plastic flyer accelerated by an electrically exploded metal foil[J].ChineseJournalofEnergeticMaterials(HannengCailiao), 1995, 3(2): 37-43.

杂志排行

含能材料的其它文章

- Coatings of Activated Metal Hydride and Application in the Fuel-rich Propellant

- A Density Functional Theory Study on the Structures and Thermochemical Properties of Azo-bridged Azoles

- Constitutive Behavior of RDX-based PBX with Loading-history and Loading-rate Effects

- Synthesis and Characterization of a Novel Energetic Inner-salt 5,5′-Bis(3-diazo-1,2,4-triazole)

- 3,4-Bis(3-fluorodinitromethylfurazan-4-oxy)furazan: A New Thermally Stable Plasticizer with High Energy Density

- The Initiation Parameter of Detonation Wave Aiming Warhead