光纤光栅在线写入系统

2016-03-25吴飞李从军李瑞涛陈祥坡

吴飞 李从军 李瑞涛 陈祥坡

1Wuhan University of Technology 430070; 2National Engineering Laboratory for Fiber Optic Sensing Technology 430070)

Abstract: With the development of science and technology, new sensors continuously emerge. Among them, research on the fiber grating has become the hot spot. According to the characteristics of existing production method of fiber Bragg grating, demand of new technologies adapted to the fabrication of fiber Bragg grating becomes urgent. This paper mainly research on fiber grating written online system. Based on the study of online writing method of optical fiber drawing tower, phase mask plate automatic replacement online and fiber grating automatic writing online were achieved through the design of a mechanical and control system for online of fiber Bragg gratings written.

Key words: fiber grating;phase mask plate;automatic replacement;written online

1.Fiber grating written online and some problems

Fiber Bragg grating online writing is the organic combination of holographic technique and point-by-point method[1]. In the optical fiber drawing process, fiber grating is written before the formation of core cladding. The method has important applied value for fiber Bragg grating mass production and fabrication of fiber grating array in a single fiber.

The traditional phase mask plate online writing is to firstly place and fix a phase mask plate, and then start written grating [2]. But a phase mask plate can only write a type of Bragg wavelength of the grating. If there are several different Bragg wavelength gratings to be written, replacement of the phase mask plates is required [3]. The tradition method of the replacement has to stop the machine, and then to manually replace the phase mask plates. This method not only consumes a large amount of manpower and material resources, but also prolongs the production period. And hence it is unable to realize automatic processing.

2.Fiber grating written online machine and control system

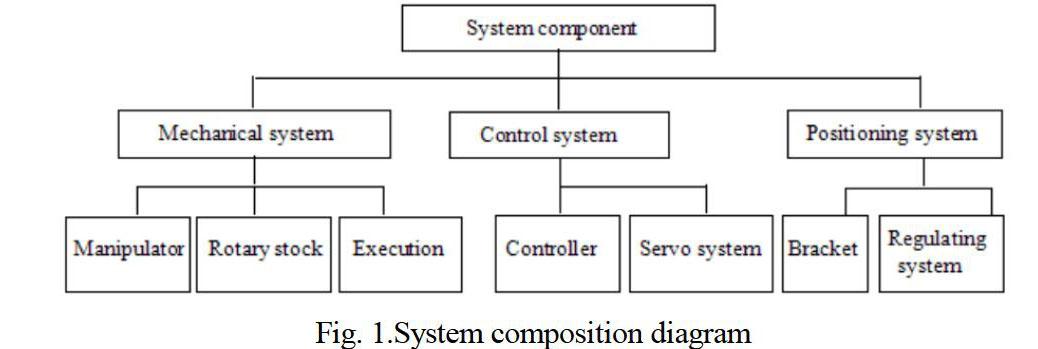

In view of the existing optical fiber grating online writing problems, this paper mainly studies a kind of automatic replacement of the mask plate writing online system. Based on the study of the writing online method of optical fiber drawing tower, we designed phase mask plate turntable stock to fabricate of fiber Bragg gratings online and replace mask plate online. The designed system overcomes the defects of the phase mask plate method only for production of fixed period Bragg grating, thereby system can produce gratings containing different Bragg wavelength for meeting the requirements of different application occasions. The online writing system have following requirements: the mask plate rotary stock can deposit ten different types mask plate at least; the turntable is capable of accurate positioning to manipulate the clamping of the mask plate; the time for replacing the mask plate online must be exactly same; and the mask plate in the machining position is perpendicular to the fiber, so that gratings can be written with high accuracy. The system components are shown in Fig 1.

Fig. 1.System composition diagram

2.1Mechanical system design

The design of phase mask plate rotary stock achieved the arrangement of a number of mask plates in one rotary stock. The bottom plate is connected with the servo motor, to ensure the machining accuracy, by absolute positioning of the mask plate. Thus the design can realize a plurality of mask plate cycle change.

After the completion of rotary stock positioning, the manipulator clamps a mask plate by using pneumatic actuator. The pneumatic actuator is the key part of the mechanical system for fiber Bragg grating writing online. The actuator is required to be parallel with manipulator and induction switches or electronic switches can be mounted on to perform convenient electric control.

Two-dimensional transport platform moves the mask plate from the rotary stock position to the fiber grating processing position. By controlling the manipulator to open and close, the pneumatic manipulator clamps the mask plate, and the phase mask plate is transmitted through the mask plate X-Y two-dimensional transmission platform.

2.1 Control system design

2.2.1 The control scheme of theoretical analysis

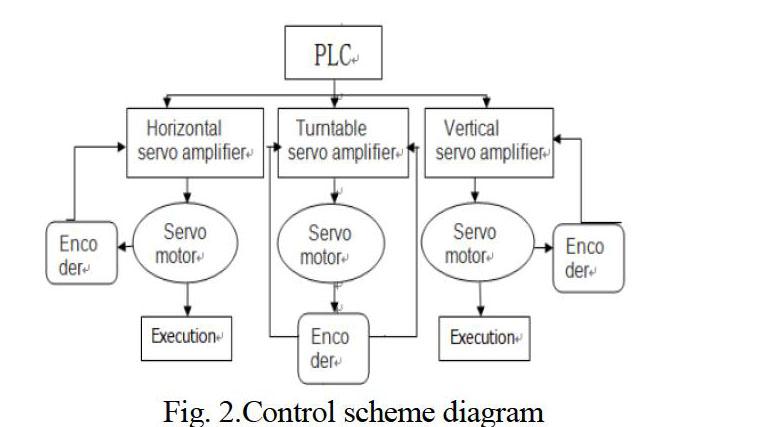

Fiber Bragg grating machinery control system of online processing integrates the optical fiber writing online method and the improved phase mask method, which can write gratings with different period of the Bragg wavelength of FBG in a single fiber, and achieve non-stop and continuous production. Fiber Bragg grating online processing scheme of control system is shown in figure 2.

Fig. 2.Control scheme diagram

Process control system of optical fiber online using PLC as the control core, is connected with the three servo motors through signal cables. The servo motor encoders monitor servo motor speed and feed pulse signals back to the servo amplifiers, and servo amplifiers compare the control signal with the feedback signal to achieve half closed-loop control [4].

2.2.2 The control algorithm of PID

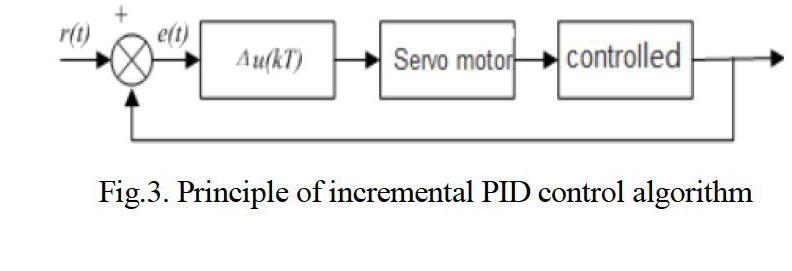

The PID control is the combination of three parts of proportion (P), integral (I), differential (D) to compose a controller. The controller adjusts the variable of a controlled system to be consistent with a predetermined value, which usually includes proportional, integral and differential [5].

In the control system, the servo motor functions as an integral component, and is used as the output holder which accumulates the output increment, and realizes. The principle of incremental PID control algorithm is shown in Fig 3.

Fig.3. Principle of incremental PID control algorithm

The system is respectively connected through the cable with three sets of servo motors. The speed of each servo motor is not the same, so each reference value r (t) of the servo motor is vary. According to the requirements of each servo motor working condition, r(t) sets in different and reasonable control parameter of PID can be calculated through many times debugging,. According to the control parameter of each servo motor of PID, parameters of each servo amplifier are respectively arranged in the servo amplifiers to optimize the overall scheme of the system. And then PLC controller is programmed to achieve the set function of the whole system.

2.3 The control object operation flow

By controlling the turntable servo motor, positioning the mask plate rotary stock can be realized. After the positioning is completed, the manipulator clamps mask plate, and the mask plate is transferred to the fiber grating processing position through the mask plate two-dimensional transport platform. When the fiber grating is processed, the two-dimensional transport platform transfers the mask plate to rotary stock to finish one operation cycle. The turntable of mask plate make positioning for another position, repeat the above process. Different cycle Bragg wavelength grating can be written in a single fiber, so that as automatic replacement of mask plate and to realize the writing different gratings on one fiber online. The control program flow chart is shown in Fig 4.

Fig.4.Control program flow chart

3.System realizations

In this paper, through the design of phase mask plate rotary stock, the different mask plate is stored in the rotary stock. The optical fiber grating written online control system controls the rotation of mask plate turntable and position of the mask plate. We built the experimental platform to realize the mask plate automatic replacement online, and write different fiber gratings in one fiber. The experimental verification indicates the stability, the safety, and the feasibility of the whole machine control system.

On the base of the existing optical fiber drawing tower, we set up the experimental platform of the whole system.

Fig. 5.The experimental platform system

Through the experiment, the mask plate can be accurately positioned in an arbitrary location. The time duration for clamping a mask plate from rotary stock and sending back to the stock can be controlled within 20 seconds. The system implemented the automatic mask plate replacement function. However, the mask plate in the optical fiber grating processing position has limited accuracy, and there is a certain error in fiber gratings written. Mask plate cycle is still too long in the process of the tower drawing, and if the higher operation speed is required, the mask plate period 18 - 25 seconds cannot be meet the actual demand.

4.Conclusions

This paper introduces the mechanical system and control system principle for fiber grating written online, and describes experimental processing for different Bragg wavelength fiber gratings. It has important significance to study the fiber grating with different production methods and highly automated production of fiber grating, for the production of high precision optical fiber grating and the improvement of production efficiency.

The verification of the fiber Bragg grating writing online system proposed in this paper has been made in theoretical and experimental study, and the feasibility of this system has been confirmed. However, further study should be made for solving the problems of long mask plate cycle and accuracy instability of gratings if rapid and efficient production of high precision grating is demanded.

References

[1] Wu,Z.X.,Wu, F., [Fiber grating sensing principle and application]. National Defence Industry Press, Beijing, 8-10(2010).

[2] Pu,T.,Zhang, Q. F.,Chen, P.,“Seminar on technology and application of fiber grating,” Military Communication Technology.29(3),97-104(2008).

[3] Yuan,L.B.,Farhad,A.N.,“Principle and application of optical fiber grating,” Optical Communication Technology, 22(4), 312 -319(1998).

[4] Huang,J.X.,Liu,J.Q.,Kuang, H.,“Servo motor control system composed of touch screen and PLC,” Instrument Technique and Sensor, 2 (2), 44-45(2005).

[5] Ogata, K., [Modern control engineering. Publishing House of Electronics Industry], Beijing, 633 -653(2011).