Effect of urban symbiosis development in China on GHG emissions reduction

2016-02-23HUANGWeiGAOQingXinCAOGuolingMAZhnYunZHANGWeiDingCHAOQingChen

HUANG Wei,GAO Qing-Xin,CAO Guo-ling,MA Zhn-Yun,*,ZHANG Wei-Ding, CHAO Qing-Chen

aXi'an University of Architecture and Technology,Xi'an,710055,China

bChinese Research Academy of Environmental Sciences,Beijing,100012,China

cPoznan University of Economics and Business,Poznán,61-875,Poland

dNational Climate Center,China Meteorological Administration,Beijing,10081,China

Effect of urban symbiosis development in China on GHG emissions reduction

HUANG Weia,b,GAO Qing-Xianb,CAO Guo-lianga,MA Zhan-Yunb,*,ZHANG Wei-Dingc, CHAO Qing-Chend

aXi'an University of Architecture and Technology,Xi'an,710055,China

bChinese Research Academy of Environmental Sciences,Beijing,100012,China

cPoznan University of Economics and Business,Poznán,61-875,Poland

dNational Climate Center,China Meteorological Administration,Beijing,10081,China

This paper analyzes current urban symbiosis development and application in China,and then conducts a statistical analysis of the emissions reduction of CO2and CH4in relation to recovery of iron and steel scraps,waste paper,and waste plastics from 2011 to 2014 using the greenhouse gas(GHG)emission inventory calculation method provided by the IPCC.Results indicate that the cumulative recovery of renewable resources during China's main urban symbiosis development in 2011-2014 was 803.275 Mt,and the amount of iron and steel scraps,waste paper,and waste plastic recovery was the largest,respectively accounting for 62.2%,18.0%,and 8.2%of total recovery in 2014.In addition,the cumulative emissions reduction of GHGs in relation to recovery of iron and steel scraps,waste paper,and waste plastics in 2011-2014 was 27.962 Mt CO2-eq,954.695 Mt CO2-eq,and 22.502 Mt CO2-eq,respectively,thereby totaling 1005.159 Mt CO2-eq.Results show a remarkable GHG emissions reduction during 2011-2014.

Urban symbiosis;Recovery of renewable resources;GHG emissions reduction

1.Introduction

Urban symbiosis aims to achieve development on an industrial scale while utilizing urban waste resources.These resources include recyclable resources(Zhou et al.,2014)such as iron and steel,non-ferrous metals,noble metals,plastics and rubber generated and contained in waste and discarded electromechanical equipment,family appliances,electronic products,wires and cables,automobiles,communication tools, metals,and plastic wrapping.The meaning of urban symbiosis has now expanded in line with technological and economic developments,and it should include both energy and materials recycling according to Peter et al.(2013).The concept of urban symbiosis development has gradually shifted to encompass the idea of environmental-friendly development that makes use of waste and transforms potentially harmful substances into something advantageous.This concept has not only become used as an effective approach for alleviating bottleneck restrictions on resources and reducing environmental pollution,but it is also important in developing a circular economy and realizing sustainable development.

Over 300 years of exploitation and utilization,80%of global mining resources that could be utilized on anindustrialized basis have been transferred from under ground to above ground.These resources are now accumulated around us in the form of garbage,and their total quantity has reached hundreds of billions of tons with the increasing rate of 10.0 billion tons per year.Many studies have been conducted on the tremendous above-ground resources that are currently abandoned and neglected by the society.And in this respect the idea of urban symbiosis proposed by Jane(1961)has comprehensively deepened.

Human beings are concerned about global climate change and have achieved greenhouse gas(GHG)emissions reduction to eliminate such change.The Chinese government are paying attention to addressing climate change,and the actions are continuously increasing.Research has been conducted globally addressing GHG emissions from fossil fuel combustion, industrial production processes,agriculture and forestry, human society,and vehicles(Richard and Naomi,2016;Chen and Zhang,2010).For example,it has been indicated that 8 Mt of metals were recovered in the U.S in 2010,which directly reduced GHG emissions by a total of 26 Mt.This amount is equivalent to the GHG quantity generated by over 5 million motor vehicles driven on highways in one year(Zhou and Zhang,2013);the emissions reduction effect is therefore evident.In 1997,Berkel et al.(2009)began a comprehensive analysis of urban symbiosis development in Japan's Eco-Town program,and concluded that the program improved recycling legislation,government subsidies,and a recognition of environment issues.In addition,Dong et al.(2014)used a hybrid life cycle assessment(LCA)model to quantify the effect of carbon emissions reduction through a case study in Kawasaki Eco-town,Japan,and found that the carbon emission effciency was improved by 13.77%with the implementation of industrial mining and urban symbiosis.Geng et al.(2010)used a scenario simulation model based on the LCA approach and determined that by recycling mixed paper,mixed plastics,and organic wastes,and utilizing recycled materials in industrial production,potential emissions reduction of 69,000 t CO2-eq could be achieved and 8000 t incineration ashes could be landflled by 2015.Furthermore,Hashimoto et al.(2010) evaluated the potential of reducing CO2emissions through industrial mining in cement companies,and found that one cement producer reduced CO2emissions by 43,000 t per year when using recycled materials rather than virgin materials. Urban symbiosis development can reduce GHG emissions due to reducing the landfll quantity of solid urban waste which is an important source of GHG,especially in China,since Zhang et al.(2011)indicated that landfll will continue as the main method used in treating waste in China in the near future.

The direct beneft of strengthening urban symbiosis development is to reduce the amount of garbage generated.In addition,this so-called“garbage”can be restored as constituent raw materials that can be re-used and reduce exploitation and processing of natural raw materials.In China,studies on urban symbiosis have focused on recycling and gaining knowledge from experience and practice gained overseas(Yu et al.,2015;Li et al.,2015).However,this paper focuses on the effect of urban symbiosis development on GHG emissions reduction.China's urban symbiosis development is mainly focused on the development of renewable resource industries. Therefore,three types of renewable resources(iron and steel scraps,waste paper,and waste plastics)are selected in this paper,which were determined to be the most recovered resources in China in 2011-2014.The study aims to estimate the emissions reduction in CH4and CO2in relation to recovery of these three types of resources.The effect of urban symbiosis development on GHG emissions reduction are also analyzed.

2.Material and methods

2.1.Data

Data of China's renewable resources recovered in 2011-2014 were collected for analysis of GHG emissions reduction(DCID,2011,2012,2013,2014),with a particular focus on amounts of recovered iron and steel scraps,waste paper,and waste plastics.

2.2.Methods

Methods for calculating GHG emissions provided by IPCC Guidelines for National Greenhouse Gas Inventories(IPCC, 2006)are widely used(Chen and Zhang,2010;Peters,2008; Hertwich and Peters,2009).The basic principles involved in calculating GHG emissions and associated methods for sectors given by IPCC can also be applied to area and enterprise levels.These methods are more appropriate than other methods such as LCA and economic beneft analysis,because detailed operational data are diffcult to obtain from both government run and private factories.To correspond with the actual situation in China,the localized emission factors and parameters used in this article refer to the values recommended by China's National Greenhouse Gas Inventory 2008 (DCC,2014).In addition,the results were compared with those of other studies to obtain a verifed and superior assessment.

2.2.1.Calculation methods for waste paper

GHG emissions reduction from waste paper recovery is equal to the difference between GHGs emissions from the equivalent recovery of paper from wood and that generated by pulping paper using recovered waste paper,and plus the emissions saved in relation to the reduction in wood consumption and waste paper landflling.The emissions from the equivalent recovery of paper from wood and waste paper pulping is calculated by referring to a LCA inventory analysis of a typical product used in China's paper-making industry (Chen et al.,2014).According to GHG emission from the production of 1 kg wood pulp and 1 kg recovered waste pulp, the GHG emissions in the paper-making stage are identical for both types of paper production.On the assumption that an equivalent amount of recycled waste paper is produced completely with wood pulp rather than waste paper pulp,and based on the global warming potential of CH4being 21 timesthat of CO2(Pattharathanon et al.,2012).The amount of emissions reduction by producing 1 kg pulp from waste paper recycling and from wood is 584.40 g CO2-eq and 117.30 g CO2-eq respectively.Therefore,producing paper using waste paper recycling pulp does not reduce GHG emissions (-431.1 g CO2-eq).In addition,the amount of GHGs generated by wood consumption is related mainly to the difference from forest planting management and wood carbon storage. The emissions reduction from forest planting management is negative,and emissions are mainly indirect emissions from machines use,electric power,and manual work.However,the emissions reduction from wood carbon storage is positive,and is the CO2absorption during forest biomass growth.

The amount of CH4emissions from waste paper landfll treatment is calculated using the frst order decay(FOD) method recommended by the IPCC(2006).The amount of CO2generated from waste paper incineration treatment is from biogenetic emissions and is not included in the calculation of national total emissions.In China,31.44%of the recovered waste paper is annually treated as landfll,and waste paper treated in other ways is considered to be unmanaged shallow landfll and accounts for 3.21%of the recovered waste paper(Chen et al.,2014).

2.2.2.Calculation methods for iron and steel scraps

In this study,the emissions reduction from the recovery of iron and steel scraps is defned as the difference between the emissions generated by production of the equivalent recovery of iron and steel and that emitted by producing crude steel from recovered iron and steel scraps.As verifcation of GHG emissions from iron and steel production enterprises is new in China,the data provided are unfortunately be inaccurate. Therefore,in this paper we refer to the GHG emissions per ton of steel issued by the World Steel Association in 2003-2014 (WSA,2014).CO2emissions from the production of 1 t crude steel are,on average,around 1.8 t CO2.Due to advances in production technology of domestic iron and steel production enterprises and national policy requirements,Zhang et al. (2012)indicated that there was a direct emissions reduction from the production of 1 t crude steel in China,from 3.29 t in 1991 to about 1.92 t in 2008.In addition,the Chinese Academy of Engineering(CAE,2008)indicated that the amount of CO2emitted from energy(fuel)consumption accounts for over 95%of total CO2emissions from China's iron and steel industry,which is consistent with the global average level. This paper uses the value conforming to actual values in China,which is 1.9 t CO2per ton crude steel.

The national GHG inventory for the iron and steel sector includes the CO2emissions relating to carbon reduction in the steel-making process and electrode consumption in the electric furnace steel making process.CO2emissions from energy activities such as fossil fuel combustion etc.,reducing agents, and high temperature decomposition of solvents in the iron and steel production process,is reported by the energy sector. The industrial production process part are only calculated in this study.On the assumption that recovered iron and steel scraps are calculated as pig iron,the CO2emission in the process of producing crude steel from scraps is calculated using the method described in China's National Greenhouse Gas Inventory 2008(DCC,2014).

2.2.3.Calculation methods for waste plastics

Most waste plastic is treated as landfll in China,although the incineration treatment mode is currently supported by the local governments and is developing quickly(Gao et al., 2009).However,these simple treatment modes not only emit large amount of GHG but also pollute the environment,and are not beneft to recycling of waste plastics.Therefore,the GHG emissions reduction related to the recovery of waste plastics can only be estimated as a reduction generated by landfll and incineration processes for waste plastics.It is diffcult for organic carbon in waste plastics to degrade in the landfll process,and thus the amount of GHG generated can be neglected.In addition,CH4and N2O generated by incineration of waste plastics are currently not calculated in China due to diffcultly in determining emission factors and incomplete data.Therefore,the GHG emissions reduction related to the recovery of waste plastics is calculated using the method for CO2emissions from the incineration treatment of wastes,as described in China's National Greenhouse Gas Inventory 2008 (DCC,2014).

3.Results

3.1.Analysis of recovery data

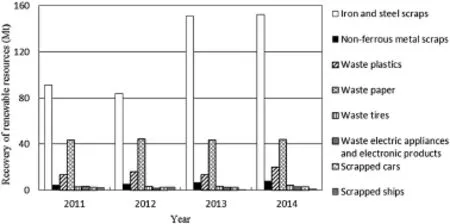

There has been a steady development in the recovery of renewable resources in China since the country proposed the construction of urban symbiosis demonstration bases in 2010. The total amount of renewable resources recovered in 2011 and 2012 was 164.6 Mt and 160.7 Mt,respectively,and this amount then greatly increased to 233.1 Mt in 2013.Until the end of 2014,a total weight of 0.245 Gt was recovered in China in 10 major types of renewable resources,e.g.,iron and steel scraps,non-ferrous metal scraps,waste plastics,waste tires, waste paper,waste electric appliances and electronic products, scrapped cars,scrapped ships,waste glass and used batteries, with an annual growth rate of 5.0%.In addition,the iron and steel scraps recovered by medium and small iron and steel enterprises,together casting and forging industry since 2014, has now been included within the statistical scope,therefore the statistical data presented here are considered relatively to be accurate.According to Fig.1,the amount of iron and steel scraps recovered in 2013 was 1.8 times of that in 2012,and this level was basically retained in 2014.The recovery of waste paper and waste plastics also remained at a relatively stable level within the four years,and was respectively around 44 Mt and 16 Mt per year.As shown in Fig.1,the amount of iron and steel scraps,waste paper,and waste plastics recovered to the total recovery in 2011-2014 was 89.9%,90.1%, 89.3%,and 88.4%,respectively.The recovery of iron and steel scraps,waste paper,and waste plastics in 2014 accounted for 62.2%,18.0%,and 8.2%of the total recovery,and the recovery of the three types accounted for 88.4%.At present,China's urban symbiosis development focuses on recycling of renewable resources,so the recovery of iron and steel scraps, waste paper,and waste plastics therefore represents the main status quo and growth trend of China's urban symbiosis development.

3.2.Emission factors and parameter selection

3.2.1.Waste paper substitution and landflling

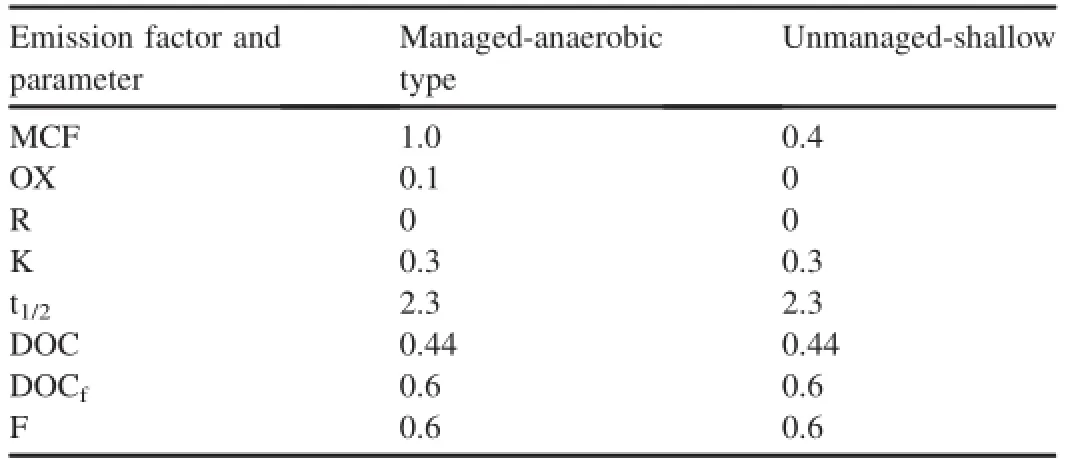

The difference between GHG emissions of 1 kg recovered paper made from wood and recovered waste paper pulp is 431.1 g CO2-eq.GHG emissions from the production of 1 kg dry round timber in China's forest planting management are considered to be 150.8 g CO2-eq(Sara et al.,2009).According to the IPCC(2006),GHG emissions can be fxed as 1.6892 kg CO2-eq from the production of 1 kg dry round timber in the forest planting stage.The emission factors required for the CH4emissions reduction from waste paper landflling treatment due to the recovery of waste paper include the methane correction factor(MCF),the fraction of degradable organic carbon in the waste(DOC,by C,Gg),fraction of degradable organic carbon that decomposes under anaerobic conditions(DOCf),fraction of methane in generated landflling gas(F),methane recovery (R),oxidization factor(OX),half-life time(t1/2),and the reaction constant(K).In view of China's actual domestic waste treatment and with reference to the IPCC(2006)in combination with China's National Greenhouse Gas Inventory 2008 (DCC,2014),these factors are determined in Table 1.

3.2.2.Iron and steel scraps

GHG emissions from production of the equivalent recovery of iron and steel were calculated according to 1.9 t CO2from the production of 1 t crude steel.The emission factors required for GHG emissions from the production of recovered iron and steel scraps into crude steel are determined according to DCC (2014),and the carbon ratio of pig iron is 4.1%and the carbon ratio of steel is 0.2426%.In addition,the CO2emission factor from electrode consumption by electric furnace steel is 0.00883 t CO2per ton of electric furnace steel.

3.2.3.Incineration of waste plastics

Emission factors required for CO2emissions reduction when incinerating waste plastics after recovery include the following:the carbon content ratio in waste(CCW),the fraction of fossil carbon in total carbon(FCF),and the complete combustion effciency of waste incinerators(EF).According to the recommended values in IPCC(2006)and DCC (2014),the following values hold for waste plastics: CCW=0.75,FCF=1,EF=0.95.

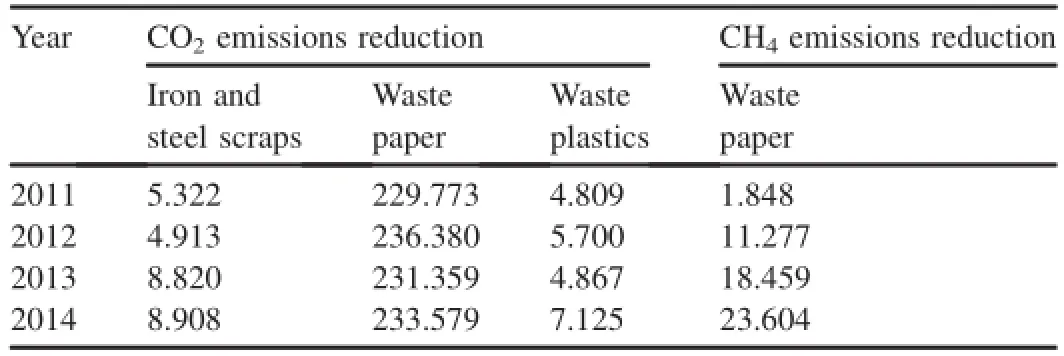

3.3.GHG emissions reduction

Table 2 shows the emissions reduction in CO2and CH4from the recovery of iron and steel scraps,waste paper,and waste plastics in China from 2011 to 2014.There shows a large GHG emissions reduction;the emissions reduction from the recovery of iron and steel scraps,waste paper,and waste plastics in 2014 was 8.908 Mt,233.579 Mt,and 7.125 Mt CO2-eq,respectively, which increased by 67.36%,1.66%,and 48.15%,respectively, compared with 2011.A large amount of indirect GHGs are emitted when producing waste paper pulp,4.68 times of that from the wood pulp production process,and thus the emissions reduction from the paper pulp production process in 2011-2014 was-60.751 Mt CO2-eq.However,the consumption of trees was reduced and the carbon sink increased during paper production with waste paper pulp;therefore,the cumulative emissions reduction in 2011-2014 was 991.842 Mt CO2-eq.This implies that the recovery of waste paper is favorable for emissions reduction.However,the calculation is based on the assumption that all paper pulp is made of wood, whereas in actual paper pulp is produced with wood pulp, waste paper pulp,and other pulp.Therefore,the calculated value is higher than the actual value.In addition,the cumulative emissions reduction in 2011-2014 due to a reduction in the quantity of waste paper landfll was 23.604 Mt CO2-eq.

Fig.1.Recovery of renewable resources in China from 2011 to 2014.

Table 1Waste paper landflling CH4emission factors and parameter selection.

Table 2CO2and CH4emissions reduction from the recovery of iron and steel scraps, waste paper,and waste plastics in China from 2011 to 2014(unit:Mt CO2-eq).

The emissions reduction in relation to recovery of the three wastes(iron and steel scraps,waste paper,and waste plastics) was 1005.159 Mt CO2-eq in 2011-2014.The largest was fromthe recovery of waste paper,954.695 Mt CO2-eq.Waste paper has the highest emissions reduction effciency out of the three wastes analyzed,with a reduction of 5.42 t CO2-eq per ton of waste paper,which is higher than the results by Dong et al. (2014)in the case of Kawasaki with reduction values of 4.40 t CO2-eq per ton of waste paper.The reason for the higher value in this paper is that we considered CH4emissions generated by waste paper landfll.After recovery,waste plastics are used for a variety of purposes,and in this respect statistical data are incomplete;therefore the emissions reduction effciency from the recovery of waste plastics may be underestimated in this paper.The reduction is 0.36 t CO2-eq per ton of waste plastics,which is much less than that of Chen et al.(2011)in the Shenyang case,1.66 t CO2-eq per ton of waste plastics.The emissions reduction effciency of waste iron and steel scraps was 0.15 t CO2-eq per ton of waste iron and steel scraps,which is close to the results of DCC(2014), 0.14 t CO2-eq per ton of waste iron and steel scraps.

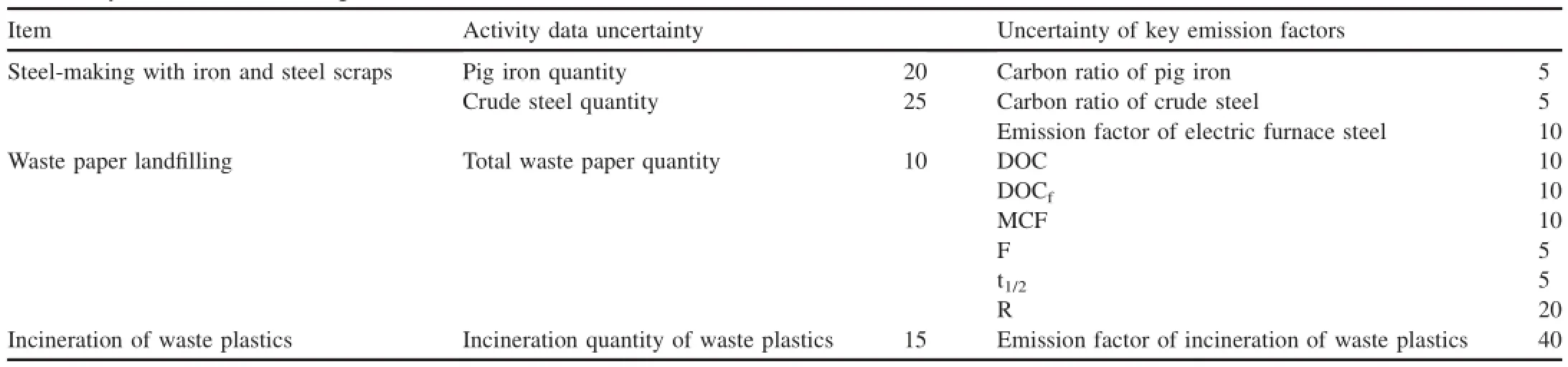

3.4.Uncertainty analysis

The uncertainty involved in the reduction estimation is calculated according to the error propagation method provided by the IPCC(Ma and Gao,2011).With reference to the default value and the uncertainty estimation value of relevant parameters in the 2006 IPCC Guidelines for National Greenhouse Gas Inventories(IPCC,2006),Table 3 shows the uncertainty estimation value of steel-making using iron and steel scraps, waste paper landflling,and the incineration of waste plastics. The percentage uncertainty of CO2emissions from steelmaking with iron and steel scraps is 34%;that of CH4emissions from waste paper landflling is 29%;that of CO2emissions from the incineration of waste plastics is 43%.The total percentage uncertainty is 21%.This uncertainty relates only to the uncertainty of the data.The uncertainty caused by simplifcation of the calculation method may be large.

Table 3Uncertainty involved in calculating GHG emissions(unit:%).

4.Conclusions and discussion

The total amount of waste recovery illustrated an increasing trend in China from 2011 to 2014 and reached 244.706 Mt in 2014,which was 2.7 times of that in 2011.The cumulative recovery of renewable resources from China's main urban symbiosis development in 2011-2014 was 803.275 Mt,where recovery of iron and steel scraps,waste paper,and waste plastics represented the largest values and were 478.100 Mt, 176.150 Mt,and 63.162 Mt,respectively.

The emissions reduction from the recovery of iron and steel scraps,waste paper,and waste plastics was 27.962 Mt CO2-eq, 954.695 Mt CO2-eq,and 22.502 Mt CO2-eq,respectively, making a total reduction of 1005.159 Mt CO2-eq.

The potential in terms of reducing GHG emissions from the recovery of iron and steel scraps,waste paper,and waste plastics was 0.15 t CO2-eq per ton of waste iron and steel scraps,5.42 t CO2-eq per ton of waste paper and 0.36 t CO2-eq per ton of waste plastics,respectively.The recovery of waste paper has the greatest potential on GHG emissions reduction, whereas the potential in terms of reducing GHG emissions from the recovery of waste plastics may be underestimated due to incomplete statistic data.

Being in line with the Paris Agreement,the government should regard urban symbiosis development as a kind of strategy to control GHG emissions.In this respect,it is necessary to focus on the enormous potential of GHG emissions reduction,and thus,according to the analysis conducted in this article,the following are proposed:1)In China,waste generated amounts are numerous but recovery amounts of waste are less.The kinds of recovery waste are incomplete.For instance,recycle of electronic products,nonferrous metals,etc.,should be improved;2)Statistic data of recycle of waste are shortage,which is adverse to studying urban symbiosis;3)Waste paper recycling should be regard as a means of controlling GHGs due to its large emissions reduction potential.The production and consumption of paper is huge in China,but the recycling rate for waste paper and the landfll rate are currently at 43.8%and 43.31%, respectively.

Therefore there is considerable space for improvement. This study is incomplete and does not include all aspects of urban symbiosis due to lacking of data.A profound study should be needed.

Acknowledgments

This study was supported by the National Natural Science Foundation of China(4150050140)and the Special Fund for Environmental Protection Research in the Public Interest (201509004).

Berkel,R.V.,Fujita,T.,Hashimoto,S.,et al.,2009.Industrial and urban symbiosis in Japan:analysis of the Eco-Town program 1997-2006.J. Environ.Manag.90,1544-1556.

CAE(Chinese Academy of Engineering),2008.A Report on the Evaluation and Countermeasure of CO2 Emission of Main Process Industry in China. Chinese Academy of Engineering,Beijing(in Chinese).

Chen,G.-Q.,Zhang,B.,2010.Greenhouse gas emissions in China 2007:inventory and input-output analysis.Energy Policy 38(10),6180-6193.

Chen,S.,Yang,X.-G.,Li,Y.-P.,et al.,2014.Life-cycle GHG emission of paper in China.J.Beijing Univ.Technol.40,944-949(in Chinese).

Chen,X.-D.,Xi,F.-M.,Geng,Y.,et al.,2011.The potential environmental gains from recycling waste plastics:simulation of transferring recycling and recovery technologies to Shenyang,China.Waste Manag.31(1),168-179.

DCC(Department of Climate Change of National Development and Reform Commission),2014.The People's Republic of China National Greenhouse Gas Inventory 2008.China Planning Press,Beijing(in Chinese).

DCID(Department of Circulation Industry Development of Ministry of Commerce of the People’s Republic of China),2011.Renewable Resources Industry Analysis Report(in Chinese).

DCID(Department of Circulation Industry Development of Ministry of Commerce of the People’s Republic of China),2012.Renewable Resources Industry Analysis Report(in Chinese).

DCID(Department of Circulation Industry Development of Ministry of Commerce of the People’s Republic of China),2013.Renewable Resources Industry Analysis Report(in Chinese).

DCID(Department of Circulation Industry Development of Ministry of Commerce of the People’s Republic of China),2014.Renewable Resources Industry Analysis Rreport(in Chinese).

Dong,H.,Ohnishi,S.,Fujita,T.,et al.,2014.Achieving carbon emissions reduction through industrial&urban symbiosis:a case of Kawasaki.Energy 64,277-286.

Gao,T.,Zhang,Y.-J.,Pan,L.,2009.Review of present status and development on recycling in feld of waste plastics in China.Mech.Electr.Eng.Mag. 26,5-8(in Chinese).

Geng,Y.,Fujita,T.,Chen,X.-D.,2010.Evaluation of innovative municipal solid waste management through urban symbiosis:a case study of Kawasaki.J.Clean.Prod.18,993-1000.

Hashimoto,S.,Fujita,T.,Geng,Y.,et al.,2010.Realizing CO2emissions reduction through industrial symbiosis:a cement production case study for Kawasaki.Resour.Conserv.Recycl.54(10),704-710.

Hertwich,E.G.,Peters,G.P.,2009.Carbon footprint of nations:a global,tradelinked analysis.Environ.Sci.Technol.43(16),6414-6420.

IPCC(Intergovernmental Panel on Climate Change),2006.IPCC Guidelines for National Greenhouse Gas Inventory.IGES,Japan.

Jane,J.,1961.The Death and Life of Great American Cities.Random House, New York.

Li,H.,Dong,L.,Ren,J.-Z.,2015.Industrial symbiosis as a countermeasure for resource dependent city:a case study of Guiyang,China.J.Clean. Prod.87,339-347.

Ma,Z.-Y.,Gao,Q.-X.,2011.Guideline for Calculating GHG Emission of Waste Disposal.Science Press,Beijing(in Chinese).

Pattharathanon,T.,Towprayoon,S.,Wangyao,K.,2012.Greenhouse gas emission and economic evaluation from municipal solid waste landfll in Thailand.J.Int.Proc.Chem.Biol.Environ.Eng.42,79-85.

Peter,T.J.,Daneel,G.,Yves,T.,et al.,2013.Enhanced landfll mining in view of multiple resource recovery:a critical review.J.Clean.Prod.55, 45-55.

Peters,G.P.,2008.From production-based to consumption-based national emission inventories.Ecol.Econ.65(1),13-23.

Richard,H.,Naomi,O.,2016.Potential emissions of CO2and methane from proved reserves of fossil fuels:an alternative analysis.J.Glob.Environ. Change 36,12-20.

Sara,G.G.,Staffan,B.,Gumersindo,F.,2009.Environmental impacts of forest production and supply of pulpwood:Spanish and Swedish case studies.Int. J.Life Cycle Assess.14,340-353.

WSA(World Steel Association),2014.Sustainable Steel Policy and Indicators.http://www.worldsteel.org/dms/internetDocumentList/bookshop/ 2014/Sustainable-indicators-2014/document/Sustainable%20indicators% 202014.pdf.

Yu,F.,Han,F.,Cui,Z.-J.,2015.Evolution of industrial symbiosis in an ecoindustrial park in China.J.Clean.Prod.87,339-347.

Zhang,C.-X.,ShangGuan,F.-Q.,Zhang,S.-R.,et al.,2012.Discussion on GHG emissions reduction in the steel industry.J.Eng.Studies 4,221-230 (in Chinese).

Zhang,Y.-M.,Shang,X.-B.,Li,K.-M.,et al.,2011.Technologies status and management strategies of municipal solid waste disposal in China.J.Ecol. Environ.Sci.20,389-396(in Chinese).

Zhou,Y.-S.,Zhang,X.-F.,2013.Study of America's urban mines development. J.Rev.Econ.Res.15,59-64(in Chinese).

Zhou,Y.-S.,Wang,X.-P.,He,Z.-C.,et al.,2014.Experience and practices of urban minerals development in foreign and reference to China.Min.Res. Dev.34(6),89-94(in Chinese).

*Corresponding author.

E-mail address:mazyer@126.com(MA Z.-Y.).

Peer review under responsibility of National Climate Center(China Meteorological Administration).

http://dx.doi.org/10.1016/j.accre.2016.12.003

1674-9278/Copyright©2017,National Climate Center(China Meteorological Administration).Production and hosting by Elsevier B.V.on behalf of KeAi. This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Received 7 June 2016;accepted 6 December 2016

Available online 7 January 2017

杂志排行

Advances in Climate Change Research的其它文章

- Approaches to low carbon development in China and India

- The Five-Year Plan:A new tool for energy saving and emissions reduction in China

- China's low-carbon investment pathway under the 2°C scenario

- A modeling study of effective radiative forcing and climate response due to increased methane concentration

- Moving past the rhetoric:Policy considerations that can make Sino-African relations to improve Africa's climate change resilience and the attainment of the sustainable development goals