Embedded Programmable Single Point Multiple Output Intelligent Data Acquisition and Transmission System

2016-01-12,,,

, , ,

1. Zibo Environmental Monitoring Station, Zibo 255000, China; 2. Jiangsu 3C Technology Inc., Nanjing 210002, China

1 Introduction

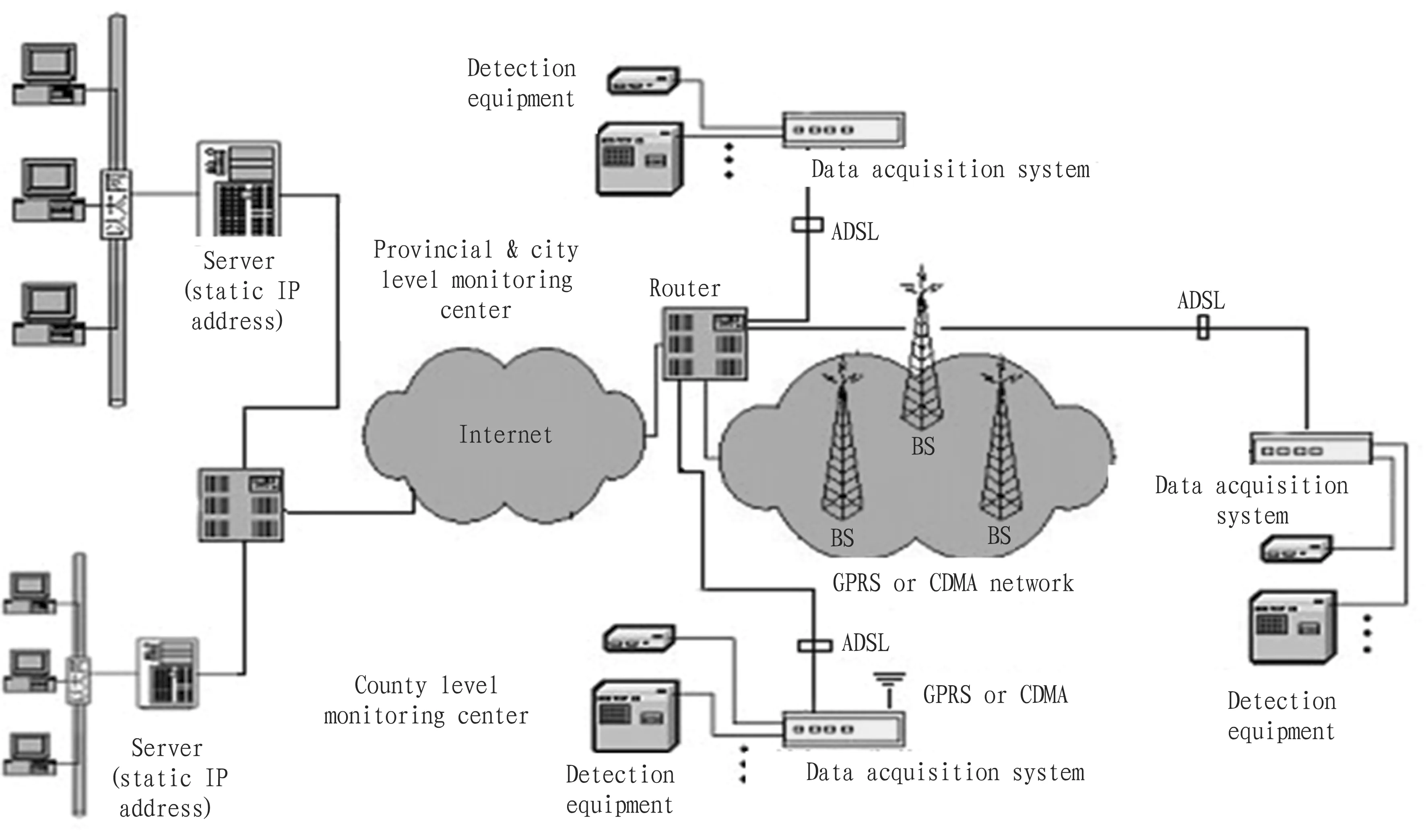

Generally, environmental monitoring stations are separate and the distribution range is wide, and most environmental stations are set up in regions with hostile environment. Ordinary (none online) monitoring fails to realize data sharing, online measurement and remote control, and fails to grasp deterioration of environmental quality, excess emission of pollution sources and pollutants, so it has obvious drawbacks[1]. The data acquisition and transmission equipment is an instrument connecting field instrument and master system. It can acquire monitoring data and status of monitoring instrument through digital channel, simulation channel, and switching channel, then transmit the data and status information to the master system through the transmission network; at the same time, it can receive control instructions sent by the master system through the transmission network, and control the work of monitoring instrument, thus, it plays an utmost important role in modern environmental monitoring system[2-5]. Development of data acquisition and transmission system is generally faced with two problems: (i) inconsistent communication protocols in automatic monitoring equipment, and (ii) limited data acquisition transmission and monitoring equipment. There are numerous manufacturers of automatic monitoring equipment, but there is no uniform communication protocol. As a result, it is necessary to develop equipment with different communication protocols for equipment networking, which will increase development difficulty and system instability. Remote operation functions of existing automatic monitoring system are too weak, and automatic monitoring system remains unattended for a long time, and it merely can realize transmission of monitoring data and simple reverse control.

To solve these problems and satisfy application demands of data acquisition and transmission in automatic system, it is necessary to research and develop a new generation intelligent data acquisition and transmission system. In line with non-standardized communication protocols and difficult interaction of communication information for existing pollution source automatic monitoring equipment, we developed and integrated a variety of online monitoring system communication protocols, which can automatically convert various protocols to information format required by the national standard, allow access of many types of environmental element monitoring equipment, support a variety of data transmission modes, support multi-protocol multi-target parallel data communication, support reverse control, display operating conditions and processes of equipment, support data reissue, and conform to national environmental protection standard, so as to provide authoritative, scientific and objective basis for environmental management works including energy saving, consumption reduction, emission reduction, and total amount control, assist enterprises and all levels of environmental protection departments in implementing the targets of total amount control and emission reduction work, and meet increasing requirements of all levels of environmental management and competent authorities for monitoring data.

2 Hardware design

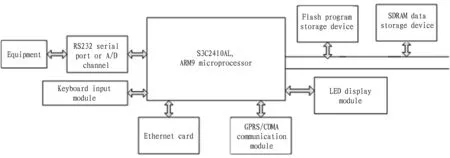

Hardware design includes selection of type for embedded processors, extension of peripheral storage device, and design of keyboard, and LCD human-machine interface, design of Ethernet card port, and design of GPRS/CDMA modules[6]. Motherboard adopts core board plus base board. The core board is six-layer high speed PCB, considering extension of interfaces, integrating power supply, CPU, SDRAM, NandFlash, network port, reset circuit, and JTAG debugging interface. Through four double row 68-pin connector, it outputs all data, address bus, peripheral interfaces, and IO information. Two layer PCB base board leads out main interface of CPU and other necessary interfaces, for convenience of product development and design. The overall framework of hardware platform is illustrated in Fig. 2.

Fig.1Applicationofdataacquisitionsysteminonlinemonitoringsystem

Fig.2Overallframeworkofhardwareplatform

For product development, the development of embedded hardware should first consider the selection of embedded processor. It is necessary to select chips with high integration from price and stability. ARM company provides a series of kernel, system extension, microprocessor, system chip scheme, and internal function configuration combination. In this study, we selected Samsung S3C2410AL industrial ARM9 microprocessor. It is an ARM920T kernel based 32-bit RISC embedded microprocessor, mainly oriented towards terminal device and high cost performance, and low power consumption, and the operating frequency is up to 400 MHz.

Extension design of peripheral storage device is very important in design of embedded system. Some processors are provided with in-built storage device, but the storage capacity is too small to satisfy demands for complete functions of embedded system. Proper capacity selection is very necessary. Too high capacity will lead to increase of cost and waste of resources. The memory consists of 32 Mb chip and 32 bit wide 64 Mb memory, and storage chip adopts 64 Mb NAND type flash chip.

The serial port is designed with 5 three-wire asynchronous serial ports with baud rate up to 1.5 Mbps. There are 3 serial ports in CPU, which can not meet product requirement, so 5 serial ports are extended for interconnection of devices. ST16C554 is a chip with 4 serial ports, extension is made through CUP bus, and the bus is 16 bit wide. The product is designed with a 10 M network port, network chip is extended through 16 bit data bus, network port is provided with connection light and transmission light, for convenience of troubleshooting for network data transmission.

Keyboard and LED graphic display HMI can realize better information interaction with users, for convenience of operation of embedded system. This product is designed with a resolution 4096*4096 touch screen, to display various data and status of system operation and control the backlight of touch screen to satisfy demands of low consumption.

3 Software architecture and principle

The software system of data acquisition and transmission system employs advanced computer, network communication, database, and data processing technology, has reliable performance, mature technology, complete functions, and operating conditions satisfying industrial application demand, and also has automatic data processing and analysis, data transmission automation, remote control functions and exception handling capability. Data acquisition and communication network is shown in Fig. 3.

Fig.3Structuraldiagramfordataacquisitionandcommunicationnetwork

3.1DistributeddatabasetoensuredataconsistencyWe established a uniform distributed automatic monitoring database. Together with the monitoring database of the enterprise, it forms a distributed database system with automatic monitoring system. It adopts the same database management system to keep data consistency. It uses a complete set standardized and uniform automatic environmental monitoring data transmission, processing, and analysis software and uniform automatic environmental monitoring data acquisition and transmission system, to ensure data consistency.

3.2SafeandreliabledatatransmissionIn the data transmission network system of existing environmental monitoring system, the data communication methods of most monitoring stations support CDMA/GPRS wireless network technology. Transmitted data are encrypted and have validation mechanism. The data acquisition and transmission system stores 12 months of field data, has automatic data reissue mechanism, master data calling mechanism, and manual data adjustment mechanism, and is not subject to influence of power failure or accidental fault of the control center.

Besides, environmental protection business data rule constraint strategy is used as guide to automatically identify and separately store data, for maintenance and inquiry.

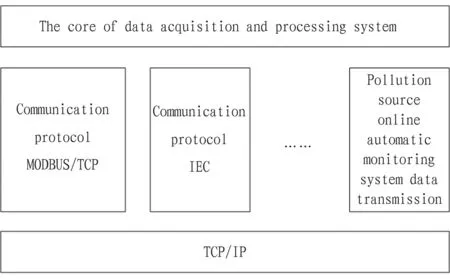

3.3DevelopmentofcommunicationprotocolThe protocol driving program of data acquisition and transmission system adopts open design and supports most existing automatic online monitoring system communication protocols. Communication protocols employed by the data acquisition and transmission system adopt ISO/OSI 7-layer protocol architecture, as shown in Fig. 4.

Fig.4Layersofdataacquisitionsystemcommunicationprotocols

The data acquisition and transmission system is programmable, thus it can support communication protocol of any monitoring equipment, and each communication protocol program is realized through dynamic link library. And the system calls corresponding dynamic link library according to actually selected protocol. Once there is new monitoring equipment and new protocol, as long as dynamic link library of new protocol is realized, it is able to realize communication with new monitoring equipment without any change in main program for software system of the data acquisition and transmission system.

3.4RealizationofreversecontrolofmonitoringequipmentReverse control of the equipment includes local control and remote control. It can perform local or remote setting of various parameters of monitoring equipment and system, to realize data calling acquisition and validation.

For local control, it can perform calibration, cleaning, shutdown, and equi-proportional sampling of monitoring equipment locally. In the monitoring center, it can realize remote control of monitoring equipment and perform calibration, cleaning, shutdown, and equi-proportional sampling of monitoring equipment remotely.

Data acquisition of online monitoring equipment can realize timed sampling function, real-time direct sampling function, and event trigger sampling function. Data acquisition equipment can automatically control automatic sampler for event sampling, to provide manual comparison test or other detailed analysis.

Besides, it can realize monitoring and report of environmental parameters of monitoring station room, including access, room temperature, air conditioner, and power supply.

In addition, it can realize clock synchronization, has self-checking and complete power failure self-protection and crash automatic recovery functions, and data before failure can be fully stored for convenience of access.

3.5DatacommunicationtransmissionThe data communication system of data acquisition and transmission system is mainly wireless CDMA/GPRS. In positions needing continuous image monitoring, it is provided with ADSL and optic fiber broadband access mode. The monitoring system in environmental monitoring center is compatible with these communication methods which can smoothly perform transition between each other. Data communication system meets following requirements:

(i) Security of data transmission:

To ensure security of data transmission in public wireless data network, we made following treatment in the data acquisition and transmission system and data transmission software system.

Self-defined data frame format, to ensure that the data are transmitted in accordance with requirements ofStandardforDataCommunicationofPollutionEmissionAutoMonitoringSystemissued by State Environment Protection Administration;

In data frames, it adopts cyclic redundancy check, which is a typical data checking method. Cyclic check code adopts standard CRC16,i.e. 16 bit cyclic redundancy code check mode, to ensure accuracy of received data.

Before data frames are sent, it adopts Data Encryption Standard (DES) to encrypt data, and the communication server in the control center is configured with firewall for separation to prevent malicious interference.

(ii) Reliability of data transmission:

To ensure reliability of data transmission in public wireless data network, we made following treatment in the data acquisition and transmission system and data transmission software system.

Once the power fails in the data acquisition and transmission system, it can ensure automatic reset after power restoration, and automatically builds communication link with the communication server. In the data transmission process, once the communication link is disconnected, it can automatically build communication link with the communication server when the communication is restored, it will automatically reload data received, to ensure no loss of data.

As to the protocol, the sender sends out the data, the receiver receives the data and sends a confirmation message to the sender to tell the sender that the data have been correctly received, then the receiver marks the data already sent. After a certain time-out, if the confirmation message is not received, it will automatically re-send the data, thus ensuring the reliable transmission of data.

The heartbeat connection is set up between the data acquisition and transmission system and the communication server of the monitoring center, and there is a heartbeat message in the protocol. When there is no data transmission on the communication link, the sender periodically sends heartbeat message, to actively monitor if the communication link is dropped; when the receiver receives the heartbeat message, it answers "heartbeat" confirmation message, to ensure that the sender confirms the connection status of communication link.

The data terminal of the monitoring center checks whether the terminal equipment is online through IP, to determine which side the dropped line fault comes from. Also, it can check when the terminal equipment is connected and when it is disconnected, and count the connection time and the disconnection time, to determine the communication status of communication network, so that users can determine the problem.

In communication software, it determines if the data judgment is correct through cyclic check code. The cyclic check code adopts standard CRC16 code,i.e. 16 bit redundancy cyclic code check mode. In the sender, it generates CRC16 check code according to the data sent, and it is put in the last two bytes of the packet; the receiver performs the same operation for the entire packet. If the transmission is normal, it will get consistent results; if results are inconsistent, it indicates transmission error, the entire packet will be ignored, and the receiver will require the sender to re-send the data.

(iii) Adaptation of data transmission:

Data transmission adopts the protocol specified inStandardforDataCommunicationofPollutionEmissionAutoMonitoringSystem, and the entire layer protocol is not related with specific transmission network. Standardization manifests communication medium independence, and realizes adaptation to various communication (data transmission) methods, including wireless, wired, and wired broadband methods, to realize communication software independent from hardware and medium.

4 Main functions and technical parameters

4.1Standardizedmulti-channelinputendC&M data acquisition and transmission system supports standard RS-232 signal and RS-485 signal input, can realize data communication of many sets of field monitoring equipments using different communication protocols. Besides, it is provided with common industrial signal acquisition function. Without any change, it can add acquisition of monitoring equipment or item at any time, and can connect with instrument, meter, PLC, and industrial personal computer (IPC). Each input channel can connect with monitoring equipment using different communication protocols and has excellent extensible performance.

4.2Standardizedmulti-channeloutputendC&M data acquisition and transmission system supports standard RS-232 signal and RS-485 signal output, supports CDMA/GPRS wireless communication mode, broadband/ADSL/optic fiber wired communication mode. It also supports the combination of any wireless and wired communication methods, to increase data upload rate.

4.3Analog/digitalsignalacquisitionandsettingfunctionsC&M data acquisition and transmission system supports analog signal (AI) and digital signal (DI) acquisition modules, and the A/D conversion accuracy of analog signal is 16 bit. It can realize acquisition and setting of analog/digital signals.

4.4ConfigurationofbasicinterfacesandwirelesstransmissionmodulesThe interface of C&M data acquisition and transmission system is configured as follows: 6-8 way RS232/485 standard port for connecting various monitoring equipment; 8-way analog port for connecting 8-way 4-20 mA or 0-5 V analog; 8-way digital input (with photoelectric isolation) for measuring equipment status; 8-way digital output for equipment control; one 100 M network port for connecting Ethernet; one Console debugging port for field debugging; 2 USB ports.

C&M data acquisition and transmission system supports CDMA and GPRS wireless communication modules. The equipment is provided with CDMA or GPRS wireless communication module (configured as required by users). Users can realize wireless communication through simply replacing CDMA or GPRS module and data communication card, without the need of changing circuit or software. Therefore, without changing existing transmission method and impairing the quality of data acquisition and transmission, it is able to realize distribution of digital signal in more than two ways, to ensure existing transmission method and simultaneous data upload of data acquisition and transmission system.

4.5ManymethodsofdatasendingC&M data acquisition and transmission system supports following 4 methods of sending data to the monitoring center:

Timed transmission: in this mode, when it reaches the specified time, the forward module will send the data collected before the sending time to the server control center.

Sampled transmission: data processing module first processes data, then sends to the sending data list, and the forward module sends the data to the server control center in the first time.

Called transmission: after receiving the calling instruction from the server, the forward program will send the called data to the server control center.

Transparent transmission: equipment is connected with the server control center through transparent transmission module, for direct transmission of data.

4.6Multi-terminaldatasendingfunctionC&M data acquisition and transmission system actively locates the target end, supports "one to one" and "one to many" communication with the monitoring center. In other words, it supports many IP addresses of the central end, and it can communication with 8 systems adopting different communication protocols in the monitoring center.

4.7HistoricaldatastoragefunctionC&M data acquisition and transmission system is provided with large capacity memory and flash memory, can store historical monitoring data up to 12 months, and the storage interval may be set at 1-24 h. Historical data can adopt lossless compression format for called transmission.

4.8DatareissuefunctionC&M data acquisition and transmission system stores records of data transmission between each monitoring control center. When the data acquisition and transmission system loses communication with a certain monitoring control center and it leads to missing, the data acquisition and transmission system will automatically reissue the missing data to the corresponding monitoring center after communication recovery. Besides, operator may ask the data acquisition and transmission system to reissue data of certain time through reverse control instruction in the monitoring center.

4.9RemotemaintenancefunctionC&M data acquisition and transmission system has remote maintenance function and supports Telnet remote login function, maintenance personnel can perform following operations remotely in wired or wireless manner: setting of the data acquisition and transmission parameters; inquiry of running state of the data acquisition and transmission system; inquiry of data stored by data acquisition and transmission system; replacement and upgrade of communication protocol or program for the data acquisition and transmission system; start and stop of the data acquisition and transmission system.

4.10DisplayfunctionC&M data acquisition and transmission system has built-in 7" TFT color LCD touch screen, external standard VGA interface which can connect computer display. Display resolution 800*480, display backlight LED, display backlight brightness 200 cd/mm. It can display the monitoring data list, line graph, bar graph, pie chart, alarm information, process flow chart and other monitoring information. Besides, it can enhance dynamic display effect by means of size change, color change, blink, flip and other means.

4.11PowerfulremotecontrolfunctionC&M data acquisition and transmission system can accept the instruction issued by the monitoring center software, to realize remote control of the connected automatic monitoring equipment. For field monitoring equipment that supports reverse control, it has following reverse control functions: acceptance of instructions issued by monitoring center software instructions; remote control of start and stop of the automatic monitoring equipment; remote and synchronous time calibration; uplink and downlink time synchronization between the monitoring center and the data acquisition and transmission system and between the automatic monitoring equipment and the data acquisition and transmission system, set and revision of the sampling time and period of the automatic monitoring equipment; set of the data acquisition frequency and data upload interval.

4.12ShortmessagefunctionC&M data acquisition and transmission system is provided with short message alarm function, short message data inquiry function, short message inquiry of equipment running state function, and short message equipment control function.

4.13WebpublishingfunctionC&M data acquisition and transmission system has inbuilt service program (BOA) and has IP address setting function, can realize Web publishing function as a Web website server. Users can directly view the data and parameters in the data acquisition and transmission system directly through IE browser after the authentication of the authority, and inquire the real-time sampling data, minute average data, hourly average data, and LOG information.

4.14PasswordsecurityvalidationfunctionC&M data acquisition and transmission system has password authentication function. Only after password is authenticated, may users log in the data acquisition and transmission system.

4.15SupportingnetsurfingoffieldworkersC&M data acquisition and transmission system supports surfing of field workers and authorized personnel can surf the net through wireless network, view remote platform data, obtain related technical support, promptly feed back field problems, and make judgment of strength of wireless signal.

4.16ConfigurationfunctionC&M data acquisition and transmission system is provided with object component library, so the configuration work is easy. The object component library is in fact storage of various configuration components by classifications. In configuration, objects (including graphical objects, window objects, policy objects, and even bitmap files) can be stored in library in the form of component, and various objects can be retrieved from the component library directly for current project. With accumulation of works, the object component library will be increasingly large and rich, which will solve the problem of accumulation and reuse of configuration results.

4.17RunningprocesscontrolC&M data acquisition and transmission system allows users to control the running process of field monitoring equipment through programming. Users can select and use strategy components of various conditions and functions provided by the system, establish multi-branch applications with graphical methods and simple control language structure, operate external equipment in accordance with the set conditions and sequence, control open or close of windows, exchange data in real-time with database, to achieve free and accurate control of the operating process.

4.18ProtectiondegreeofenclosureC&M data acquisition and transmission system is suitable for workplace with hostile environment and reaches industrial application requirement. Its enclosure has IP55 protection degree, and has dust prevention, moisture prevention and anti-seismic features. Besides, it can effectively shield electromagnetic radiation, anti-interference of fast transient electric impulse, anti-static, anti-voltage-sag, short-time interruption, and voltage change interference.

4.19BackuppowersupplyC&M data acquisition and transmission system is provided with UPS backup power supply, which can ensure more than 8 hours of continuous work after AC power failure.

4.20OthertechnicalparametersOperating voltage: AC220V ± 10%, 50Hz; CPU: ARM9 ≥200MHz; Memory: built-in 64M, external SD card storage device; electromagnetic compatibility: to IEC level three standard; rated power consumption: <10 W; operating temperature: -20℃-+65℃; operating humidity: 5% -95%, no condensation; MTBF (mean time between failures): more than 10000 hours.

5 Innovation points

5.1Intelligent(automatic)matchingavarietyofcommunicationprotocolsforenvironmentalmonitoringequipmentThe system adopts protocol management kernel based multi-protocol intelligent matching technology, and integrates more than 200 kinds of communication protocols for environmental monitoring equipment in environmental protection industry, so that the product can access to environmental monitoring equipment through intelligent matching communication protocol, without human intervention, to achieve the effect of plug and play, and can automatically convert all types of protocols to required by the information format required by national standard. It solves the problems of non-standardized communication protocols and difficult interaction of communication information for existing pollution source automatic monitoring equipment.

5.2Realizingmulti-protocolandmulti-targetparalleldatatransmissionIt establishes data transmission protocol stack mechanism and protocol conversion mechanism, realizes the function of sending data to 8 target IP addresses (monitoring center) at the same time by different data communication protocols. It can provide synchronous but different forms of real-time and historical data for different fields and different levels of monitoring center. This way of data transmission ensures that the monitoring data of the enterprise end can be sent to the county, city, province and the state level platform at the same time, which avoids data falsification in the intermediate platform and ensures the truth and reliability of data.

5.3RealizingremotedynamicinputofcontrolinstructionsthroughwiredorwirelessnetworkThe system supports CDMA / GPRS / fiber-optic broadband / ADSL / VPN / serial wireless and wired communication methods. It not only can fully meet data acquisition and transmission of the different areas, different environments, different monitoring equipment, different communication interface and data format, but also can accept instructions to remotely control the field monitoring equipment through the wired and wireless communication. Monitoring personnel can realize the remote reverse control of the field equipment without being present in the field.

5.4Supportingconfiguration(process)simulationoffieldequipmentDCSconditionsThe system is provided with inbuilt configuration simulation function. Through the inbuilt 7" TFT color LCD touch screen, it can directly simulate DCS operating condition configuration diagram of an enterprise, display and update the monitoring data in real time on the configuration diagram. It also supports simulation of trend curve for monitoring data, which enhances application effect of the system.

6 Conclusions

In the context of various defects of both domestic and foreign data acquisition and transmission equipment, combined with environmental management requirements, business requirements, and macro control requirements of all levels of environmental departments, we developed a new data acquisition and transmission system. It solves the problem of non-standardized communication protocols and difficult interaction of communication information for existing pollution source automatic monitoring equipment, and integrates a variety of on-line monitoring system communication protocols. Besides, it can automatically convert various protocols to information format required by the national standard, allow access of many types of environmental element monitoring equipment, support a variety of data transmission modes, support multi-protocol multi-target parallel data communication, support reverse control, display operating conditions and processes of equipment, support data reissue, and conform to national environmental protection standard.

Our research can provide high performance intelligent data acquisition and transmission equipment for data acquisition and monitoring of environmental protection automatic monitoring equipment, play a great role in accurate and reliable grasp of various monitoring parameters, greatly reduce cost of monitoring system, assist enterprises and levels of environmental protection departments in realizing total amount control and emission reduction target, satisfy increasing requirements of levels of environmental management and competent authorities for monitoring data, and it will greatly promote building of conservation, environmental protection and harmonious society.

[1] XIANG Q. Research on remote data collection system based on ARM and its realization[D]. Changsha: Central South University,2007.(in Chinese).

[2] YANG M. Remote data sampling and transmission system based on ARM[D].Ji’nan: University of Jinan,2009.(in Chinese).

[3] CHEN JJ. Opinion for environmental automatic monitoring development in our country[J]. The Administration and Technique of Environmental Monitoring,2007,19(1) : 1-3.(in Chinese).

[4] XIONG JQ. Sudy on data collection transmission terminal and its application in environmental monitoring[D]. Hangzhou: Zhejiang University,2007.(in Chinese).

[5] XU XN, LIAO MD. Research on the multi-parameter auto-monitoring device for collecting and transmitting environmental data[J]. The Administration and Technique of Environmental Monitoring,2007,19(6) : 15-17.(in Chinese).

[6] LIU JG. Design and implementation of data collection model based on 3C2410[J]. Computer Engineering and Design,2008,29(13) :3345-3347.(in Chinese).

杂志排行

Asian Agricultural Research的其它文章

- Feasibility Analysis of Agricultural Product Price Index Insurance Based on Pilot Cases

- Forecast on Price of Agricultural Futures in China Based on ARIMA Model

- Model Building for Community Participating in Rural Tourism and Game Analysis of Core Stakeholders

- A Study of the Factors that Affect Farmers’ Willingness to Transfer Land in the Central Regions Based on a Survey of 180 Farmers in Suizhou City

- Comparative Study of Cotton Plant Height Difference in the Arid Areas Based on LandSat8 OLI Data

- How to Enhance the Brand Competitiveness of Ginseng Enterprises?