Sustainable Development of Betel Nut Industry in Hainan Province

2016-01-12,,

, ,

Institute of Scientific and Technical Information, Chinese Academy of Tropical Agricultural Sciences, Danzhou 571737, China

1 Overview of betel nut cultivation in Hainan Province

The betel nut has become a cash crop second only to natural rubber in Hainan Province. In recent years, the low natural rubber prices severely affect farmers’ enthusiasm for planting rubber, but it improves farmers’ enthusiasm for planting betel nut. In the main producing areas of betel nut, the betel nut is planted in some regeneration rubber forests and flawed rubber plantations. The plan-ting area is increasing and fresh fruit processing is receiving much attention, but it lacks emphasis on the sustainable development of betel nut industry.

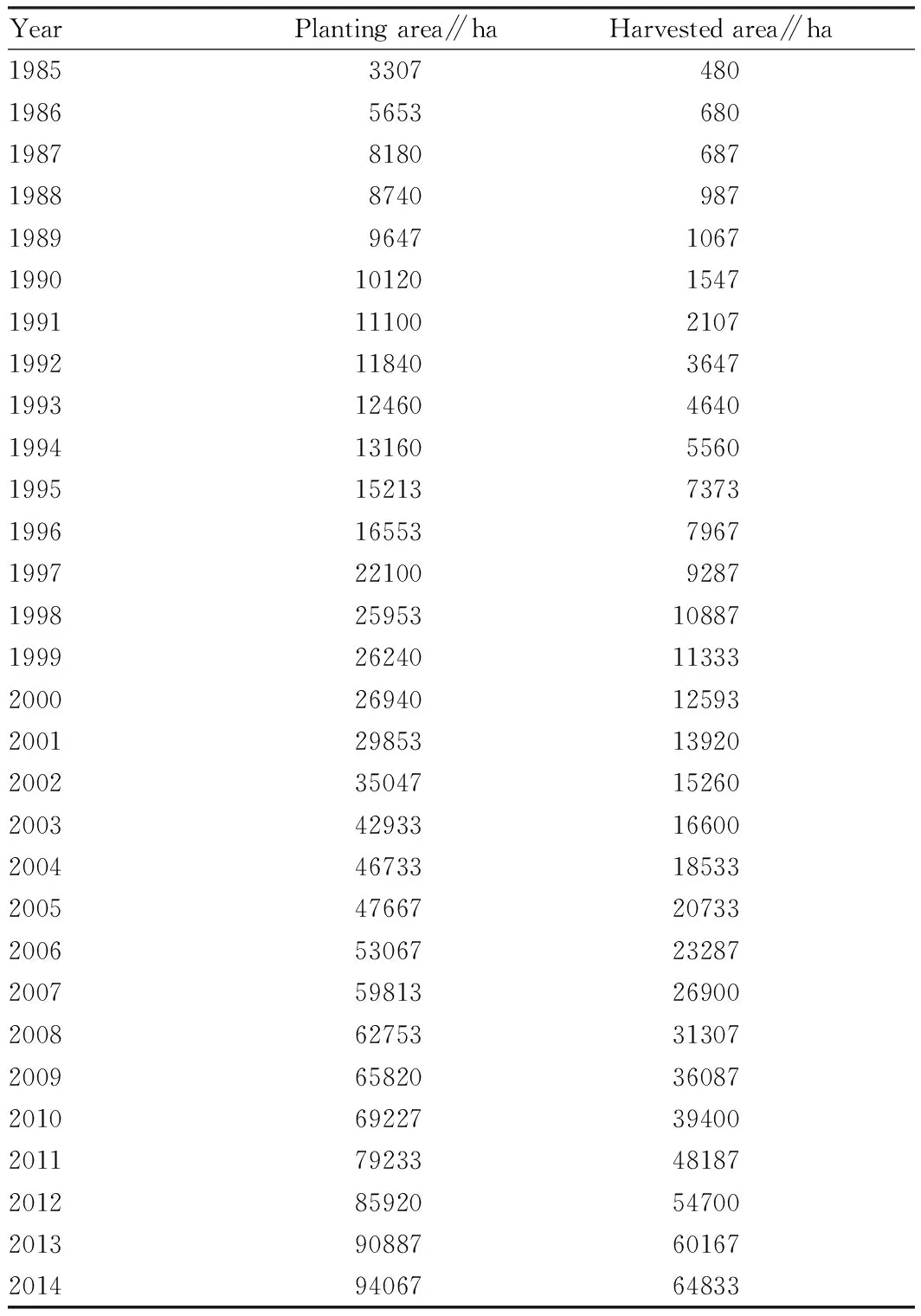

1.1PlantingareaThe betel nut planting area in Hainan was 94000 ha in 2014. The betel nut planting in Hainan during 1985-2014 can be shown in Table 1. From Table 1, it is found that the betel nut planting area in Hainan continues to increase, and the harvested area is also increasing. The betel nut planting is rapidly developed in Hainan, mainly because the betel nut is extensively planted, the investment is not sufficient, and the economic efficiency of betel nut is high under normal management.

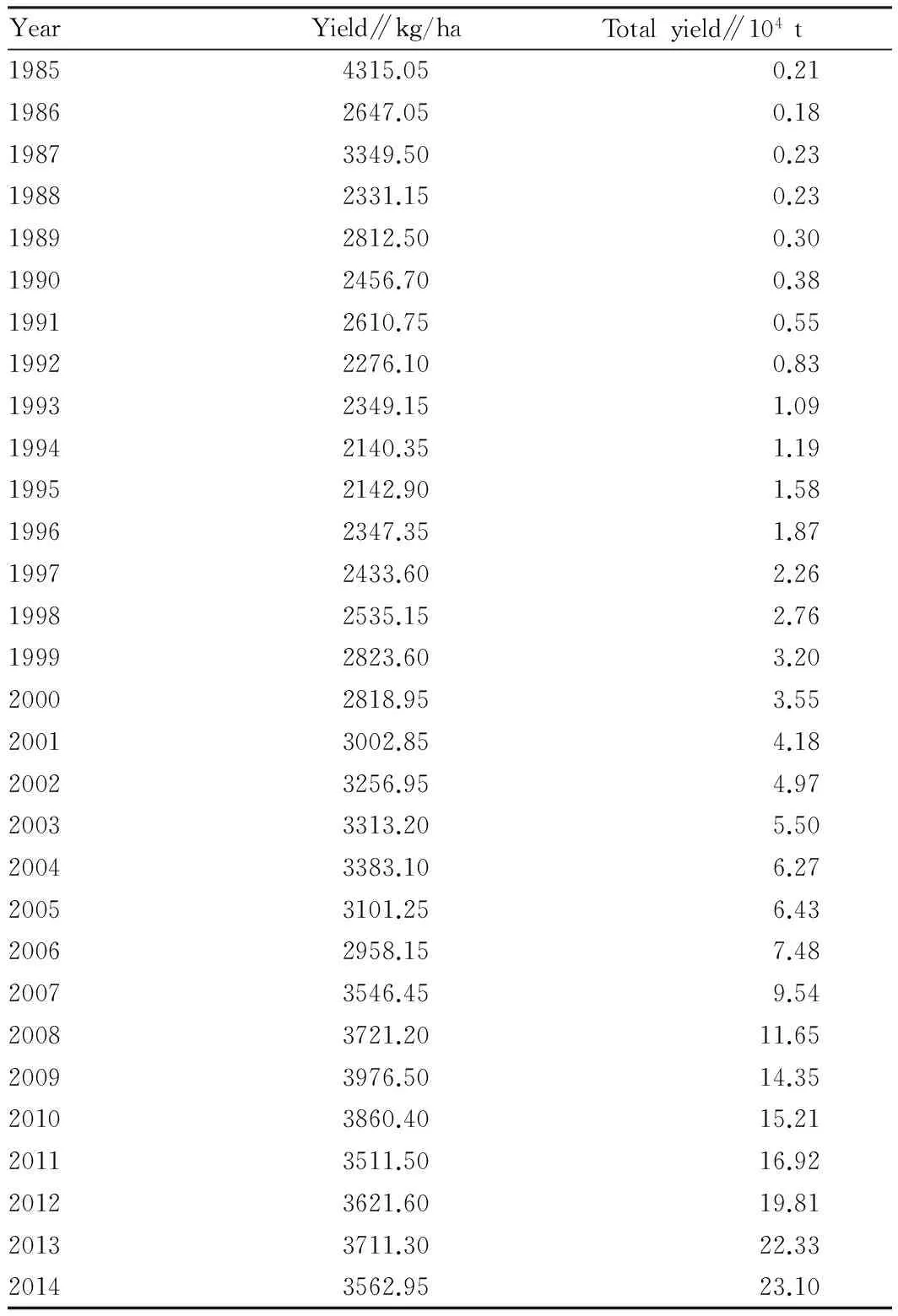

1.2YieldChina’s betel nut yield increases year by year, and the betel nut yield was 231000 t in 2014. The betel nut yield in Hainan during 1985-2014 can be shown in Table 2. From Table 2, it is found that during 1985-2014, the total yield of betel nut continuously increased, but the betel nut yield has decreased in recent years.

1.3CultivationmodeThe continuous rise of betel nut prices during 2014-2015 increased farmers’ enthusiasm for planting betel nut, and the planting development trend is good. However, the betel nut cultivation lacks scientific planning, and it is basically the traditional cultivation method. The betel nut is mostly planted spontaneously by farmers while few businesses plant it. When farmers plant betel nut, they often overemphasize planting, harvesting, but neglect management, and in most betel nut plantations, the soil improvement, water and fertilizer management is poor, so the betel nut plant can not get sufficient nutrients, the harvest period gets short, and the yield becomes low. The betel nut plantations with normal management can achieve 50 to 60 years of harvest, while some betel nuts in Hainan degenerate after 20 years of planting. In recent years, the betel nut yield has decreased.

Table1ThebetelnutplantinginHainanduring1985-2014

YearPlantingarea∥haHarvestedarea∥ha19853307480198656536801987818068719888740987198996471067199010120154719911110021071992118403647199312460464019941316055601995152137373199616553796719972210092871998259531088719992624011333200026940125932001298531392020023504715260200342933166002004467331853320054766720733200653067232872007598132690020086275331307200965820360872010692273940020117923348187201285920547002013908876016720149406764833

Data source: Hainan Provincial Department of Agriculture.

Table2ThebetelnutyieldinHainanduring1985-2014

YearYield∥kg/haTotalyield∥104t19854315.050.2119862647.050.1819873349.500.2319882331.150.2319892812.500.3019902456.700.3819912610.750.5519922276.100.8319932349.151.0919942140.351.1919952142.901.5819962347.351.8719972433.602.2619982535.152.7619992823.603.2020002818.953.5520013002.854.1820023256.954.9720033313.205.5020043383.106.2720053101.256.4320062958.157.4820073546.459.5420083721.2011.6520093976.5014.3520103860.4015.2120113511.5016.9220123621.6019.8120133711.3022.3320143562.9523.10

Data source: Hainan Provincial Department of Agriculture.

1.4BetelnutyellowsThe betel nut yellows disease in Hainan was first found in Tunchang in 1981, and now it has spread to Qionghai, Wanning, Lingshui, Sanya, Wuzhishan, Qiongzhong, Baoting, Ledong and Danzhou in Hainan. The disease incidence is usually 10% to 30%, and in the severely afflicted area, the disease incidence reaches as high as 90%, resulting in production reduction of 70% to 80%, or even total loss. So far, many diseased betel nut plants have been felled in production[1]. The 2012 survey results show that in the main betel nut plantations in the eastern and western regions of Hainan, the average disease incidence is 41.38% and 37.67%, respectively. The survey results also show that the older the betel nut plantations, the severer the betel nut yellows, and the betel nut mortality increases with increasing incidence of betel nut yellows[2]. In recent years, it has been found that the betel nut yellows in the main producing areas are severe, and the yellows occur frequently especially for the betel nut planted in mountain slope.

2 Processing of betel nut

The betel nut yield in Hainan was 231000 t in 2014. Currently, Hainan has built green environmentally-friendly betel standard drying equipment production line, and the annual processing capacity has reached 677400 t (344000 t in Wanning; 214000 t in Qionghai; 55000 t in Tunchang; 38000 t in Ding’an; 15000 t in Qiongzhong; 11000 t in Lingshui; 400 t in Baoting).

2.1PrimaryprocessingThe primary processing of fresh betel nut fruit includes primary processing of black fruit and primary processing of white fruit. The primary processing of black fruit: fresh fruit→fruit selection→smoking→black betel nut fruit. The processing of black fruit is to use the dense smoke generated by burning the wet wood chips to smoke the fresh betel nut fruit, and this process can remove most of the water inside the fruit, and make the dried fruit have a special scent favored by consumers[3]. A lot of smoke produced during the black fruit processing affects the processing personnel’s health and environment. The primary processing of white fruit: fresh betel nut→stewing→drying→fruit selection→re-drying→handpicking→packaging→finished product[4]. The production feature of white fruit lies in using the high-temperature steam to heat the cold air to about 60℃ hot air, and using hot air to bake the green betel nut fruit. The main problem in the processing of white fruit is that the waste water after cooking fruit is indiscriminately discharged into the environment, and the smoke from coal-fired boiler is discharged directly into the atmosphere. There is no primary processing enterprise of betel nut in Hainan effectively disposing of the exhaust gas and waste water from the production process.

2.2DeepprocessingAlthough betel nut is a kind of commonly used traditional Chinese medicine, it is only eaten as fresh fruit or processed into dry fruit of betel nut for chewing, and it seldom goes into medicine market. The dry betel nut fruit processing is deep processing, and now there are 7 deep processing enterprises of betel nut in Hainan (4 in Wanning City; 2 in Ding’an County; 1 in Chengmai County). The 7 enterprises carry out the deep processing of betel nut, and the processing materials account for about 10% of yield. There are 3 large and medium-sized edible refined betel nut processing plants in Hainan, the designed annual processing capacity is 22000 t, and the actual processing capacity is 8000 t. For example, the betel nut deep processing enterprise in Wanning City, Hainan Kouweiwang Technology Development Co., Ltd., invests 480 million yuan in building 2 deep processing plants of betel nut in Hou’an Town and Dong’ao Town, respectively, and 17.2 million kg of betel nut raw materials are processed annually. Hainan Kouweiwang Technology Development Co., Ltd. conducts the deep processing of betel nut, and the products are divided into three categories and six grades. Products are sold to Hainan and Guangdong, and the market share is over 80%. Kouweiwang betel nut is the industry’s first high-end brand, and known as "China’s first brand of betel nut fruit".

3 Conclusions and recommendations

3.1ConclusionsFor the development of betel nut industry, it is necessary to focus on the ecological environment for betel nut growth, create ecological betel nut plantations, and use nutritional analysis technology for nutritional analysis of betel nut leaf. The nutrient analysis indicators are used to guide the fertilization in betel nut plantations, to ensure normal growth and production of betel nut. The integrated betel nut processing plant is the development direction of betel nut processing industry, which can promote the development of betel nut planting, increase processing efficiency of betel nut, improve product quality, and reduce environmental pollution.

3.2Recommendations

3.2.1Establishing ecological betel nut plantation. Currently, it is necessary to focus on the prevention based on ecological improvement, and building of ecological betel nut plantations while attaching importance to prevention and control technology for betel nut yellows. The key to building ecological disease-resistant betel nut plantations lies in maintaining and using the ecological community in betel nut plantation, to prevent the occurrence of betel nut yellows. In betel nut plantations, the weeds and dwarf plants in the periphery of trunk are regarded as covering, to form a growth environment with sufficient sunshine on upper canopy and shade on the lower part. Ecological betel nut plantations can reduce soil erosion, increase species diversity, improve the soil environment in betel nut plantation, increase the surface shade, and reduce direct sunlight onto the ground, so as to maintain moisture and fertilizer and improve soil microbial environment for betel nut growth. The herbicides should not be used during weeding in the betel nut plantation, which can avoid damage of herbicides to betel nut root system.

3.2.2Using nutrient adjustment to prevent betel nut yellows. According to the field survey in betel nut plantation, it is believed that the main cause of betel nut yellows may be the betel nut plant malnutrition. In recent years, due to the increase in labor costs and reduction of organic fertilizer source, the organic fertilizer input in betel nut plantation decreases, and the soil fertility declines in the betel nut plantations. With the considerable application of chemical fertilizer, the soil aggregate structure is damaged, causing soil compaction. Meanwhile, the extensive use of herbicides leads to serious soil contamination. The nutrient adjustment is used to prevent yellows, and the scientific fertilization is conducted mainly based on nutrition for betel nut. Based on the analysis of nutrients in betel nut plant leaf and betel nut plantation soil, the fertilizer type and fertilizer application rate are determined, to ensure the necessary nutrients for betel nut and promote betel nut growth. Excessive use of herbicides should be avoided during weeding in betel nut plantation, high bushes are cut and dwarf plants and weeds are retained to cover the ground and keep the soil moisture and nutrients and improve soil fertility in betel nut plantations.

3.2.3Developing the integrated betel nut processing plant. Currently, 80% of fresh betel nut fruits in Hainan are dried by farmers after primary processing, and the dried betel nut is mainly supplied to Hainan or Hunan betel nut processing enterprises for deep processing of products. Now there are nearly ten thousand processing plants of fresh betel nut fruits in Hainan, mostly concentrated in the main producing areas of betel nut such as Wanning, Qionghai, Tunchang and Ding’an. The traditional primary processing technologies and models are still widely used in Hainan. Now there are many processing plants of fresh betel nut fruits (3000 in Wanning; 2500 in Qionghai; 1000 in Tunchang; 1000 in Ding’an). The processing model is based on family workshop, and there are 2 to 3 people in small plants. There are generally 10-30 drying stoves, and tens of tons of fresh betel nut fruits are processed annually. There are about 200 people in large processing plants, and several thousand tons of fresh betel nut fruits can be processed annually. It is necessary to develop the integrated betel nut processing plants combining primary processing with deep processing, to continuously process betel nut. The processing plants complete the entire production process from dried betel nut fruit to edible products, and the primary processing form, dominated by family workshop or small processing plant, is gradually reduced, and the industrialized processing methods are adopted to replace the traditional processing methods. In the integrated betel nut processing plants, standard electric drying equipment is used to process dried fruits, which can save resources, reduce pollution, improve product quality and increase production efficiency. After the processing of dried fruits, it immediately enters the deep processing stage, which can reduce dried fruit marketing link, transportation costs, production and operation costs.

[1] DING XJ, TANG QH, YAN J,etal.Current pest status and key problems in areca nut palm industry in China [J]. Chinese Agricultural Science Bulletin, 2014,30(7):246-252.(in Chinese).

[2] YANG ZL, ZHOU YD, SHA LH,etal. Yellow leaf disease occurrence status of the major areca nut plantation in Hainan Province [J].Tropical Forestry,2013,41(l):49-51.(in Chinese).

[3] KANG XN, JI JB, LI L. Analysis of unsafe factors in baked craft of betel nuts [J]. Food and Machinery,2015(1):68-70.(in Chinese).

[4] ZHANG RH, DOU ZH. Investigation and analysis on the primary production of areca nut in Hainan Province [J]. Agricultural Development & Equipments, 2014(12):41-42.(in Chinese).

杂志排行

Asian Agricultural Research的其它文章

- Empirical Analysis on Financial Development, Urbanization, and Urban and Rural Resident Income in Jiangsu Province

- Farmer’s Perception on Supply-Demand Matching of New Variety and Its Influence Factors

- Vegetation Coverage Changes in the West Qinling Region from 2000 to 2010: A Case Study of Longnan City

- A Study of Estimation Model for the Chlorophyll Content of Wheat Leaf Based on Hyperspectral Imaging

- A Study of Virtual Museum Simulation Platform Based on 2.5D Architectural Modeling Technology

- The Value Insistence of the Cultural Production in the Big Data Era