Study on the Aromatic Components of Green Plum Wine by HS-SPME-GC-MS

2016-01-11,,,,,,

, , , , , ,

College of Bioengineering, Sichuan University of Science & Engineering, Zigong 643000, China

StudyontheAromaticComponentsofGreenPlumWinebyHS-SPME-GC-MS

YingyingMA,HechuanWU,QingbinLIU,LingyunWANG,XiaoDOU,LinYANG,JiangangYANG*

College of Bioengineering, Sichuan University of Science & Engineering, Zigong 643000, China

In order to better blend green plum wine and study aromatic components of green plum wine, a qualitative analysis on aromatic components of soaked base liquor, green plum soaked wine, green plum juice, and fermented wine of green plum juice by Head Space Solid-phase Microextraction (HS-SPME) and Gas Chromatograph Mass Spectrometer (GC-MS) was studied in this paper. Experiment results indicated that 14,32,17,and 46 kinds of aromatic components were identified respectively from four samples. Different aromatic components determined the special flavor and taste of green plum wine. Unique aromatic components generated in soaking process include benzaldehyde, 1-butanol, 2-methyl-, S-(-), benzoic acid ethyl ester, and 5-(hydroxymethyl). Special aromatic components in green plum juice were furfural, phenylethyl alcohol, and benzyl alcohol. The aromatic components in fermented wine of green plum juice mainly included phenylethyl alcohol (6.941%, relative content of peak area, same below), 1-butanol, 3-methyl- (6.940%), octanoic acid, ethyl ester (3.734%), decanoic acid, ethyl ester (2.590%), hexanoic acid, ethyl ester (2.479%), ethyl 9-decenoate (2.080%), and 5-hydroxymethyl (1.756%). This study was expected to provide scientific basis and data reference for quality improvement of green plum wine.

Green plum wine, Aromatic components, Head Space Solid-phase Microextraction (HS-SPME), Gas Chromatograph Mass Spectrometer (GC-MS)

1 Introduction

China is home of green plum. It is mainly distributed in Changjiang Delta Area, South China, and southwest of China, including Guangdong, Guangxi, Fujian, Zhejiang, and Yunnan[1]. According to reports[2-4], fruit of green plum is rich in citric acid which can improve appetite, restore physical strength, and remove fatigue; besides, green plum can improve constipation, soothe the nerves, alleviate vexation, and promote tricarboxylic acid cycle, rapidly remove fatigue elements out of body, and generate energy to the maximum extent, and make foods completely burn. This is of significant realistic value for athletes and hot workers to restore physical strength. These organic acids can not only remove lactic acid accumulated in blood, but also inhibit generation of new lactic acid, to reach the function of cleaning blood. Also, the rich Vitamin B2 has function of anti-cancer. In addition, green plum is favorable for absorption of calcium, so it is an optimum fruit helping children and elderly people enriching the calcium. Processed products of green plum mainly include salted green plum, candied green plum, green plum drink, and green plum wine. In recent years, a lot of green plum wine products appear, but there are few products with special flavor and taste. Therefore, it is necessary to further study making of green plum wine.

Aroma is an essential indicator for wine products. Head Space Solid-phase Microextraction and Gas Chromatograph Mass Spectrometer (HS-SPME-GC-MS) combined method has been widely applied in analysis and detection of aromatic components of wine products[5]. Solid-phase microextraction (SPME) technology, developed in 1990, has been widely applied in study of aromatic substances of food[6]. HS-SPME method features short operation time, few samples, rapid and easy use, reagent not needed, and high repeatability[7-9], so we adopted this method to make preliminary treatment of samples. Besides, to better blend green plum wine, it becomes particularly important to know aromatic components of green plum soaked wine, green plum juice, and green plum juice fermented wine, to provide scientific basis and data reference for improving quality of green plum.

2 Materials and methods

2.1Materials

2.1.1Raw materials for experiment. Green plum wine, green plum soaked wine, and green plum juice were kept by laboratory. Soaked base liquor adopted Sichuan sorghum wine (suitable for medicated wine and soaking fruit wine), strong fragrant spirit, 60% Vol, produced by Luzhou Hong Man House Wine Co., Ltd.

2.1.2Main instruments. Angilent 6890 GC gas chromatograph and 5975 MS mass spectrometer; chromatographic column DB-WAX (60 m × 250 μm × 0.25 μm); SPME manual sampling handle and extractor, produced by ANPEL Laboratory Technologies (Shanghai) Inc, and extractor was 50/30UM DVB/CAR on PDMS and made by American Supelco Company.

2.1.3Main reagents. Sodium chloride (purity above 99.5%) was produced by Chengdu Kelong Chemical Co., Ltd; pure water was taken from Mount Emei drinking natural mineral water produced by Emeishan Emeisnow Mineral Water Co., Ltd.

2.2Methods

2.2.1Gas chromatograph and mass spectrometry conditions. Chromatographic column was DB-WAX (60 m × 250 μm × 0.25 μm), sample injection port temperature 250℃; column oven temperature rise process kept 35℃ for 5 minutes, then rose to 100 ℃ at 5 ℃ /min to hold 2 minutes, finally rose to 230℃ at 15 ℃ /min and held 10 minutes, the operation time was 38.667 minutes. Carrier gas: high purity nitrogen, flow rate of carrier gas: 1 ml /min. Mass spectrometry conditions: EI ion source, ion source temperature 230 ℃, interface temperature 250 ℃, ionization voltage 70 eV, quadruple pole temperature 150 ℃, and mass scan range 30-500 m/z. Qualitative determination of aromatic components: comparing with NIST05a.L spectrum library.

2.2.2Operation method of Head Space Solid-phase Microextraction (HS-SPME). Put 9 ml samples and 1.8 g sodium chloride into 20 ml head space vial, and place it on 45℃thermostatic water bath for 30 minutes, insert the aged extractor (aging temperature 230℃ and aging time 30 minutes) into the head space vial, extract 30 minutes, the extractor is 1 cm from the liquid level, and finally manually feed samples onto GC-MS to make chromatographic analysis.

3 Results and analyses

3.1GC-MSresultanalysisUsing Head Space Solid-phase Microextraction (HS-SPME), we extracted aromatic components of green plum soaked wine, green plum juice, and green plum juice fermented wine and made GC-MS analysis. Total ion of 4 samples was illustrated in Fig. 1. From Fig. 1, peaks of ions in green plum soaked wine (Fig. 1B) are more than in green plum soaked base liquor (Fig. 1A), showing that long time soaking of green plum in base liquor gives out new aromatic components. From Fig. 1C and Fig. 1D, we know that green plum gives out a lot of aromatic components through fermentation of yeast. Through NIST05a.L library search, 4 samples (A, B, C and D) had 14, 32, 17, and 46 aromatic components, we calculated peak area relative content of aromatic component using area normalization method and results were listed in Table 1, 2, 3, and 4.

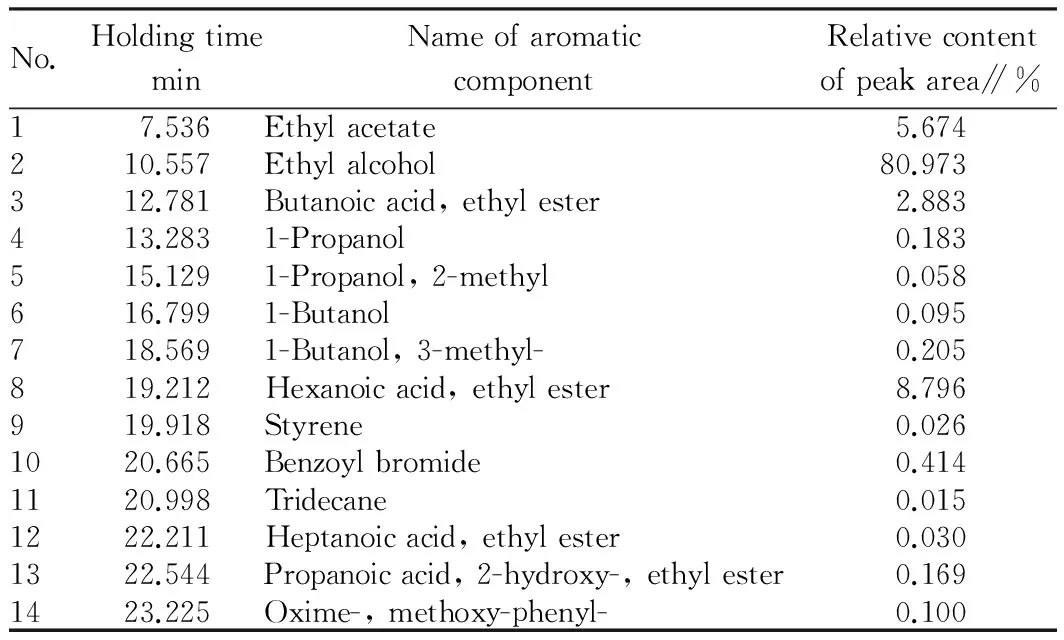

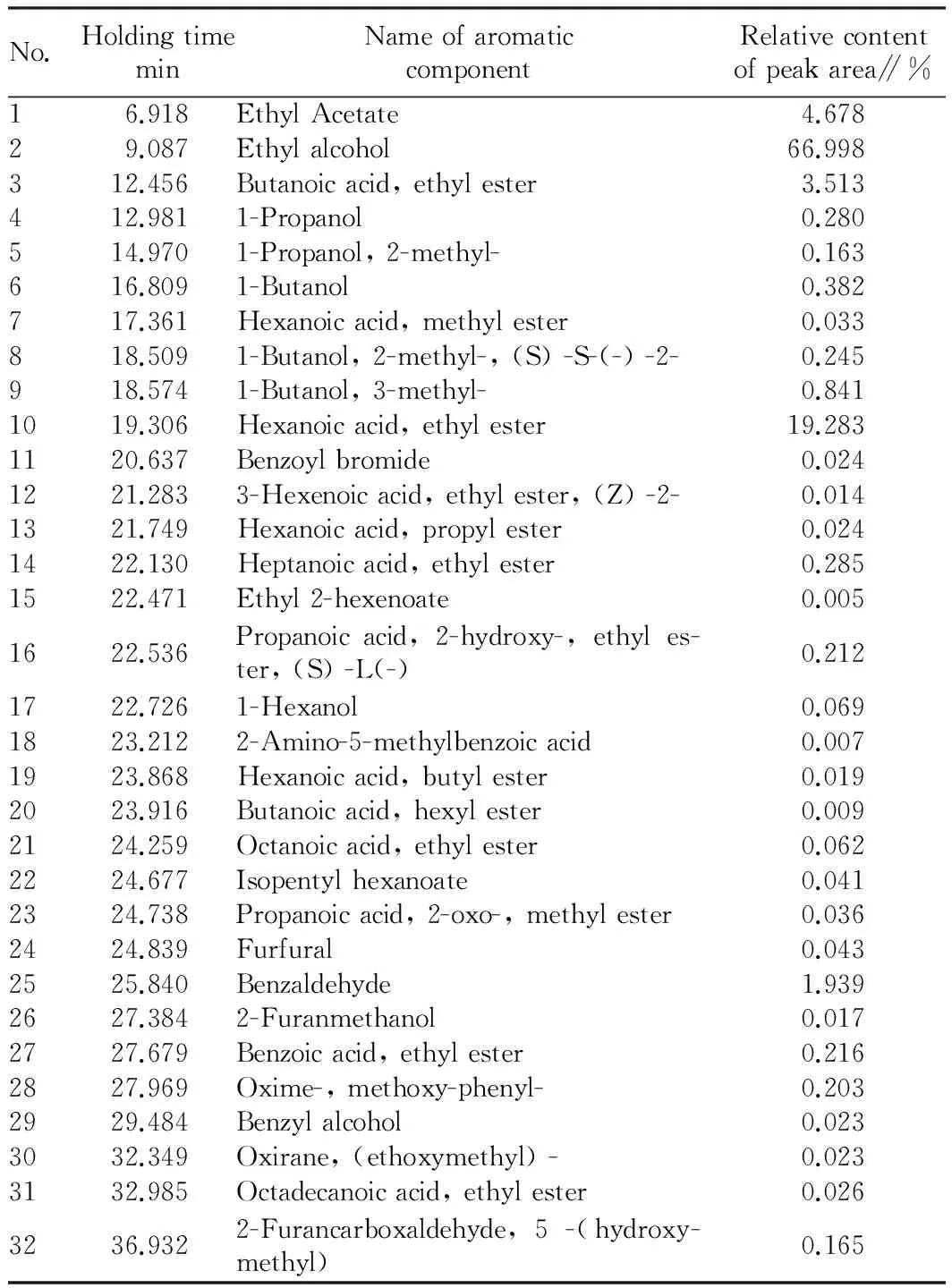

Fig.1 Total ions of GC-MS

3.2Aromaticcomponentsofsoakedbaseliquor,greenplumsoakedwine,greenplumjuice,andgreenplumjuicefermentedwineFrom Table 1, we can see that soaked base liquor had 14 types of aromatic components, including 5 esters, 5 alcohols, and 4 others. These are mainly hexanoic acid, ethyl ester (relative content of peak area 8.796%, the same below), ethyl acetate (5.674%), butanoic acid, ethyl ester (2.883%), benzoyl bromide (0.414%), 1-Butanol, 3-methyl- (0.205%), 1-Propanol (0.183%), and propanoic acid, 2-hydroxy-, ethyl (0.169%), etc. This soaked based liquor has relative few aromatic components, so it is suitable for making fruit wine and medicated wine. From Table 2, we can see that green plum soaked wine had 32 types of aromatic components, including 16 esters, 9 alcohols, 3 aldehydes and 4 others. Aromatic components are mainly hexanoic acid, ethyl ester (relative content of peak area 19.283%, the same below), ethyl acetate (4.678%), butanoic acid, ethyl ester (3.513%), benzaldehyde (1.939%), 1-Butanol, 3-methyl- (0.841%), 1-Butanol (0.382%), heptanoic acid, ethyl ester (0.285%), 1-Propanol (0.280%), 1-Butanol, 2-methyl-, (S) - (0.245%), benzoic acid, ethyl ester (0.216%), Propanoic acid,2-hydroxy-, ethyl ester, (S) -L(-) (0.212%), Oxime-, methoxy-phenyl- (0.203%), 2-Furancarboxaldehyde, 5 -(hydroxymethyl) (0.165%), and 1-Propanol, 2-methyl- (0.163%).

Table1Aromaticcomponentsofsoakedbaseliquorandtherelativecontentofpeakarea

No.HoldingtimeminNameofaromaticcomponentRelativecontentofpeakarea∥%17.536Ethylacetate5.674210.557Ethylalcohol80.973312.781Butanoicacid,ethylester2.883413.2831-Propanol0.183515.1291-Propanol,2-methyl0.058616.7991-Butanol0.095718.5691-Butanol,3-methyl-0.205819.212Hexanoicacid,ethylester8.796919.918Styrene0.0261020.665Benzoylbromide0.4141120.998Tridecane0.0151222.211Heptanoicacid,ethylester0.0301322.544Propanoicacid,2-hydroxy-,ethylester0.1691423.225Oxime-,methoxy-phenyl-0.100

Table2Aromaticcomponentsofgreenplumsoakedwineandtherelativecontentofpeakarea

No.HoldingtimeminNameofaromaticcomponentRelativecontentofpeakarea∥%16.918EthylAcetate4.67829.087Ethylalcohol66.998312.456Butanoicacid,ethylester3.513412.9811-Propanol0.280514.9701-Propanol,2-methyl-0.163616.8091-Butanol0.382717.361Hexanoicacid,methylester0.033818.5091-Butanol,2-methyl-,(S)-S-(-)-2-0.245918.5741-Butanol,3-methyl-0.8411019.306Hexanoicacid,ethylester19.2831120.637Benzoylbromide0.0241221.2833-Hexenoicacid,ethylester,(Z)-2-0.0141321.749Hexanoicacid,propylester0.0241422.130Heptanoicacid,ethylester0.2851522.471Ethyl2-hexenoate0.0051622.536Propanoicacid,2-hydroxy-,ethyles-ter,(S)-L(-)0.2121722.7261-Hexanol0.0691823.2122-Amino-5-methylbenzoicacid0.0071923.868Hexanoicacid,butylester0.0192023.916Butanoicacid,hexylester0.0092124.259Octanoicacid,ethylester0.0622224.677Isopentylhexanoate0.0412324.738Propanoicacid,2-oxo-,methylester0.0362424.839Furfural0.0432525.840Benzaldehyde1.9392627.3842-Furanmethanol0.0172727.679Benzoicacid,ethylester0.2162827.969Oxime-,methoxy-phenyl-0.2032929.484Benzylalcohol0.0233032.349Oxirane,(ethoxymethyl)-0.0233132.985Octadecanoicacid,ethylester0.0263236.9322-Furancarboxaldehyde,5-(hydroxy-methyl)0.165

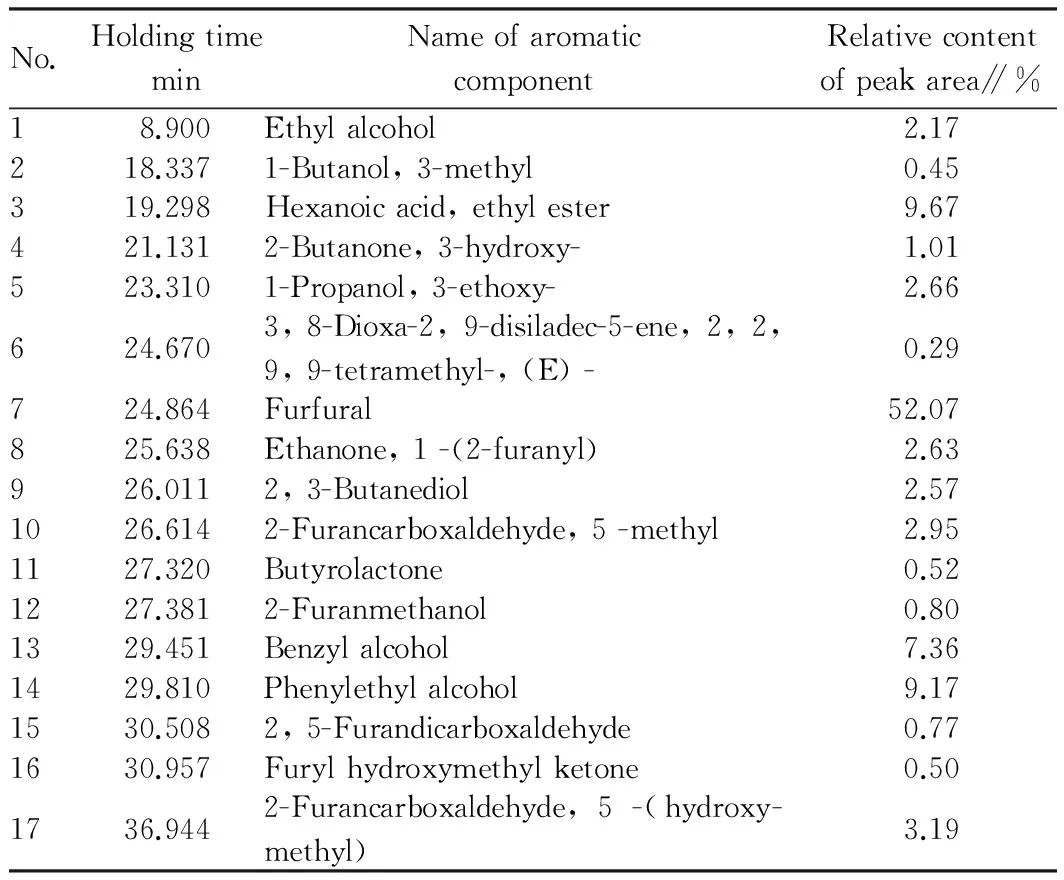

From Table 3, we can see that green plum juice had 17 types of aromatic components, including 2 esters, 8 alcohols, 4 aldehydes and ketones and 3 others. The aromatic components are mainly furfural (relative content of peak area, 52.07%, the same below), hexanoic acid, ethyl ester (9.67%), phenylethyl alcohol (9.17%), benzyl alcohol (7.36%), 2-Furancarboxaldehyde, 5-(hydroxymethyl) (3.19%), 2-Furancarboxaldehyde, 5 -methyl- (2.95%), Ethanone, 1-(2-furanyl) (2.63%), 2, 3-Butanediol (2.57%), ethyl alcohol (2.17%), 1-Propanol,3-ethoxy- (2.66%), and 2-Butanone, 3-hydroxy- (1.01%).

Table3Aromaticcomponentsofgreenplumjuiceandtherelativecontentofpeakarea

No.HoldingtimeminNameofaromaticcomponentRelativecontentofpeakarea∥%18.900Ethylalcohol2.17218.3371-Butanol,3-methyl0.45319.298Hexanoicacid,ethylester9.67421.1312-Butanone,3-hydroxy-1.01523.3101-Propanol,3-ethoxy-2.66624.6703,8-Dioxa-2,9-disiladec-5-ene,2,2,9,9-tetramethyl-,(E)-0.29724.864Furfural52.07825.638Ethanone,1-(2-furanyl)2.63926.0112,3-Butanediol2.571026.6142-Furancarboxaldehyde,5-methyl2.951127.320Butyrolactone0.521227.3812-Furanmethanol0.801329.451Benzylalcohol7.361429.810Phenylethylalcohol9.171530.5082,5-Furandicarboxaldehyde0.771630.957Furylhydroxymethylketone0.501736.9442-Furancarboxaldehyde,5-(hydroxy-methyl)3.19

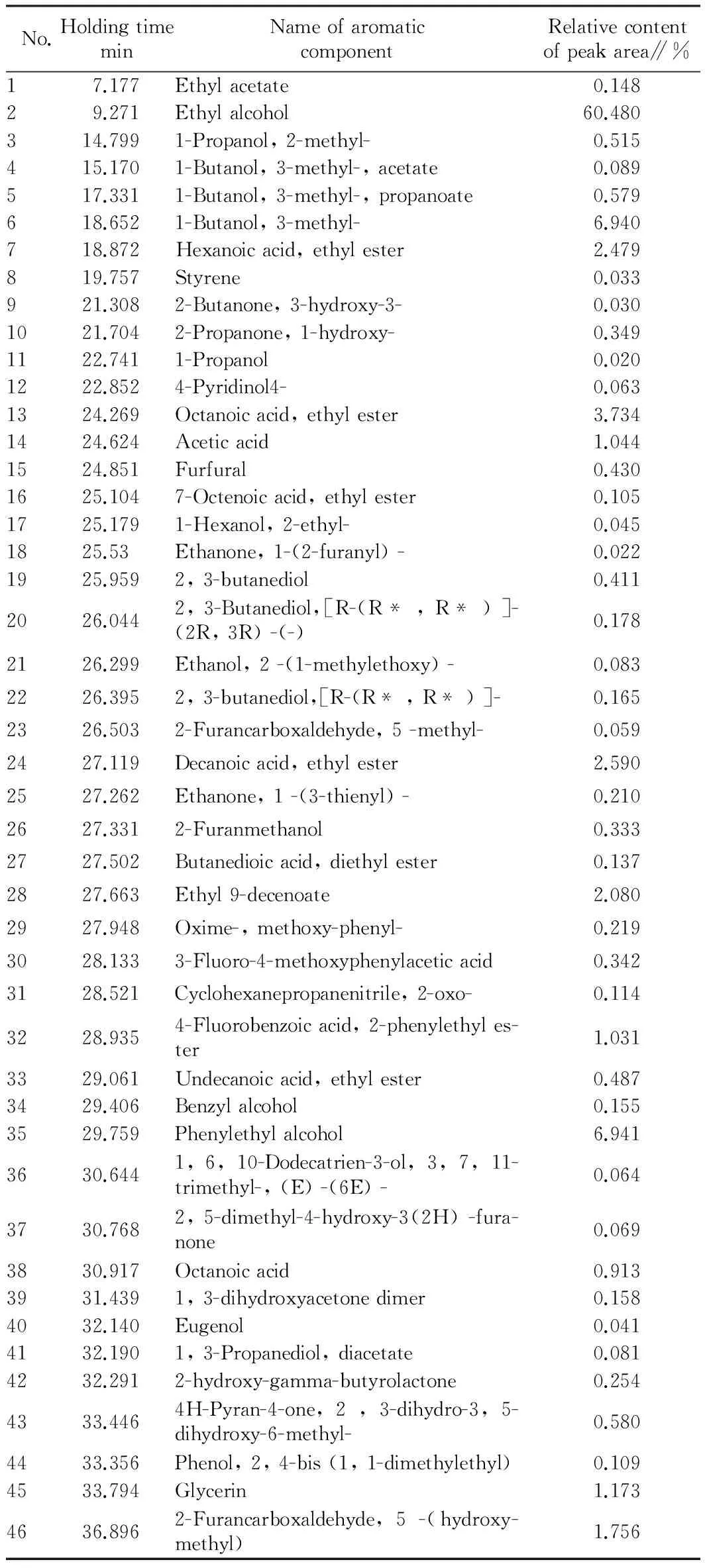

From Table 4, we can see that green plum juice fermented wine had 46 types of aromatic components, including 12 esters, 14 alcohols, 7 aldehydes and ketones and 13 others. Aromatic components are mainly ethyl alcohol (relative content of peak area, 60.480%, the same below), phenylethyl alcohol (6.941%), 1-Butanol, 3-methyl- (6.940%), octanoic acid, ethyl ester (3.734%), decanoic acid, ethyl ester (2.590%), hexanoic acid, ethyl ester (2.479%), Ethyl 9-decenoate (2.080%), 2-Furancarboxaldehyde, 5 -(hydroxymethyl) (1.756%), glycerin (1.173%), acetic acid (1.044%), 4-Fluorobenzoic acid, 2-phenylethyl ester (1.031%), etc.

3.3AnalysisonmajoraromaticcomponentsofgreenplumsoakedwineandgreenplumfermentedwineFrom Table 1 and Table 2, we can see that compared with soaked base liquor, there are 20 more aromatic components in green plum soaked wine. Major components are benzaldehyde (relative content of peak area, 1.939%, the same below), 1-butanol, 2-methyl-, (S) - (0.245%), benzoic acid, ethyl ester (0.216%), and 2-Furancarboxaldehyde, 5-(hydroxymethyl) (0.165%). Benzaldehyde has pleasant almond flavor and is unique aromatic component of green plum[10]. In the measurement of green plum soaked wine, Gao Minetal[11], Yang Hongyaetal[12], and Zheng Xinhuaetal[13]found there is benzaldehyde, the relative content of peak area is 4.740%, 10.870%, and 21.830% respectively, the volatile components in green plum soaked wine are high, which is consistent with results of our experiment. GC-MS experiment results of green plum soaked wine are consistent with sensory properties, proving that benzaldehyde is unique aromatic component of green plum.

Table4Aromaticcomponentsofgreenplumjuicefermentedwineandtherelativecontentofpeakarea

No.HoldingtimeminNameofaromaticcomponentRelativecontentofpeakarea∥%17.177Ethylacetate0.14829.271Ethylalcohol60.480314.7991-Propanol,2-methyl-0.515415.1701-Butanol,3-methyl-,acetate0.089517.3311-Butanol,3-methyl-,propanoate0.579618.6521-Butanol,3-methyl-6.940718.872Hexanoicacid,ethylester2.479819.757Styrene0.033921.3082-Butanone,3-hydroxy-3-0.0301021.7042-Propanone,1-hydroxy-0.3491122.7411-Propanol0.0201222.8524-Pyridinol4-0.0631324.269Octanoicacid,ethylester3.7341424.624Aceticacid1.0441524.851Furfural0.4301625.1047-Octenoicacid,ethylester0.1051725.1791-Hexanol,2-ethyl-0.0451825.53Ethanone,1-(2-furanyl)-0.0221925.9592,3-butanediol0.4112026.0442,3-Butanediol,[R-(R*,R*)]-(2R,3R)-(-)0.1782126.299Ethanol,2-(1-methylethoxy)-0.0832226.3952,3-butanediol,[R-(R*,R*)]-0.1652326.5032-Furancarboxaldehyde,5-methyl-0.0592427.119Decanoicacid,ethylester2.5902527.262Ethanone,1-(3-thienyl)-0.2102627.3312-Furanmethanol0.3332727.502Butanedioicacid,diethylester0.1372827.663Ethyl9-decenoate2.0802927.948Oxime-,methoxy-phenyl-0.2193028.1333-Fluoro-4-methoxyphenylaceticacid0.3423128.521Cyclohexanepropanenitrile,2-oxo-0.1143228.9354-Fluorobenzoicacid,2-phenylethyles-ter1.0313329.061Undecanoicacid,ethylester0.4873429.406Benzylalcohol0.1553529.759Phenylethylalcohol6.9413630.6441,6,10-Dodecatrien-3-ol,3,7,11-trimethyl-,(E)-(6E)-0.0643730.7682,5-dimethyl-4-hydroxy-3(2H)-fura-none0.0693830.917Octanoicacid0.9133931.4391,3-dihydroxyacetonedimer0.1584032.140Eugenol0.0414132.1901,3-Propanediol,diacetate0.0814232.2912-hydroxy-gamma-butyrolactone0.2544333.4464H-Pyran-4-one,2,3-dihydro-3,5-dihydroxy-6-methyl-0.5804433.356Phenol,2,4-bis(1,1-dimethylethyl)0.1094533.794Glycerin1.1734636.8962-Furancarboxaldehyde,5-(hydroxy-methyl)1.756

From Table 3, we can see that relative content of furfural (relative content of peak area, 52.07%, the same below), hexanoic acid, ethyl ester (9.67%), phenylethyl alcohol (9.17%), and benzyl alcohol (7.36%) is high. Furfural is mainly generated through hydrolysis, dehydration, and distillation after reaction of pentose and vigabatrin. Pentose is isomerized to 1,2-alkene glycol, and further converted to deoxidized pentose, and finally forms furfural[14]. Since the formation process of furfural widely exists in plants and foods containing pentose type substances, it is reasonable that it also exists in green plum juice. Besides, extracts of green plum contain maleic acid and furfurtal substances, which have antibiotic and anti-inflammation effect[15]. Ethyl ester is aromatic component of strong fragrant spirit, like pineapple and banana flavor. The existence of ethyl ester in green plum can be understood that long time of soaking produces certain amount of ethyl ester which increases aroma of green plum. Benzyl alcohol has gentle sweet, fruit flavor, fragrance of flower, and aroma of oranges and tangerines. Benzyl alcohol is not fermentation product of common yeast. In the fermentation process, yeast has many reduction reactions, and many aldehydes and ketones can be reduced to alcohols[16]. Green plum contains benzaldehyde, and benzaldehyde can be reduced to benzyl alcohol through dehydrogenases. However, in the condition of oxygen, it firstly generates erythrose through pentose phosphate pathway, and then generates phenylethyl alcohol. The phenylethyl alcohol has sweet fragrance, rose and honey fragrance[12]. Therefore, furfural, benzyl alcohol and phenylethyl alcohol play important role in fragrance of green plum juice.

From Table 4, we can see that green plum juice produces a lot of aromatic components through fermentation of yeast. These aromatic components are mainly phenylethyl alcohol (6.941%), 1-Butanol, 3-methyl- (6.940%), octanoic acid, ethyl ester (3.734%), decanoic acid, ethyl ester (2.590%), hexanoic acid, ethyl ester (2.479%), Ethyl 9-decenoate (2.080%), 2-Furancarboxaldehyde, and 5 -(hydroxymethyl) (1.756%). 1-butanol, 3-methyl- and ethyl alcohol are generated in parallel and will bring fragrance of fruit. Ethyl ester, decanoic acid, ethyl ester, hexanoic acid, ethyl ester, and ethyl 9-decenoate separately have the aroma of pineapple, grape, banana, and pear. These aromatic components are closely related with fruit fragrance of green plum.

From Table 2 and Table 4, we can see that green plum fermented wine has more trace aromatic components than green plum soaked wine. The reason may lie in aromatic components of green plum are leached out and blended together with wine in the action of high concentration of spirit, forming unique aroma. High concentration of spirit also suppresses fermentation of natural yeast, leading to reduction of trace aromatic components in soaked wine. After dilution of green plum juice, sugar concentration drops to the level suitable for growth of yeast. Based on self substance of green plum, it generates important aromatic components, including 1-Butanol, 3-methyl- (6.940), octanoic acid, ethyl ester (3.734%), decanoic acid, ethyl ester (2.590%), hexanoic acid, ethyl ester (2.479%), ethyl 9-decenoate (2.080%). These contribute a lot to aromatic components of green plum wine.

4 Conclusions

Through HS-SPME-GC-MS sample analysis, there are 14, 32, 17, and 46 aromatic components in soaked base liquor, green plum soaked wine, green plum juice, and fermented wine of green plum juice . Unique aromatic components of green plum soaked wine include benzaldehyde (relative content of peak area, 1.939%, the same below), 1-Butanol, 2-methyl-, (S) - (0.245%), benzoic acid, ethyl ester (0.216%), and 2-Furancarboxaldehyde, 5-(hydroxymethyl) (0.165%). Aromatic components in green plum juice mainly include furfural (relative content of peak area, 52.07%, the same below), hexanoic acid, ethyl ester (9.67%), phenylethyl alcohol (9.17%), and benzyl alcohol (7.36%). The aromatic components in fermented wine of green plum juice mainly include phenylethyl alcohol (6.941%), 1-butanol, 3-methyl- (6.940%), octanoic acid, ethyl ester (3.734%), decanoic acid, ethyl ester (2.590%), hexanoic acid, ethyl ester (2.479%), ethyl 9-decenoate (2.080%), and 5-hydroxymethyl (1.756%). This experiment made a preliminary qualitative analysis on volatile substances in green plum fermented wine, green plum juice, green plum soaked wine, and base liquor. Analysis of special flavor components and principal components needs further study.

The experiment results indicate that green plum soaked wine, green plum juice, and green plum juice fermented wine have unique aroma of green plum, but there are essential differences in aromatic components, which also proves results of sensory analysis. Green plum soaked wine is high in concentration and the flavor is not good enough; green plum juice is too sweet and too thick, so a certain dilution is necessary; green plum fermented wine has low concentration, but the aroma is not sufficient, so the optimization of fermentation process needs further study. In addition, proper blending of these three types of green plum wine to make up the shortage of each other and enrich aroma and flavor is an effective approach to improve market prospect of green plum alcoholic drink at present.

[1] ZENG FP, TAN YF. The production and processing technologies of green plum series products[J]. Science and Technology of Food Industry,1996(4): 65-66.(in Chinese).

[2] LI SF, LIU XM, WU JJ. Synthetical development and utilization of the sour plum resource[J]. Guangzhou Food Science and Technology,2004,20(3): 149-151.(in Chinese).

[3] XU YJ, XIAO GS, CHEN WD. Progresses in Prunus mume research[J].Science and Technology of Food Industry,2005,26(1): 185-187.(in Chinese).

[4] BAI WD, SHEN Y, LIU XY, et al. Status on processing technology and product features of plum wine[J].Nongchanpin Jlagong.Xuekan,2013,308(2): 10-14.(in Chinese).

[5] ZHAO XM, WU Q, CHEN Y. Changes of aromatic components of greengage during salt plume processing[J]. Modern Food Science and Technology,2013,29(4): 885-890.(in Chinese).

[6] ARTHUR C L,PAWLISZYN J. Solid phase microextraction with thermal description using fused silica optical fibers[J]. Analytical chemistry,1990,62(19): 2145-2148.

[7] FAN W,QIAN M C. Headspace solid phase microextraction (HS-SPME) and gas chromatography-olfactometry dilution analysis of young and aged Chinese “Yanghe Daqu” liquors[J]. Journal of Agricultural and Food Chemistry,2005,53(20): 7931-7938.

[8] WATTS V A,BUTZKE C E,BOULTON R B. Study of aged cognac using solid-phase mictroextraction and partial least-squares regression[J]. Journal of agricultural and food chemistry,2003,51: 7738-7742.

[9] FAN WL, XU Y. The chemistry of liquor flavor[M]. Beijing: China Light Industry Press,2014: 1-5.(in Chinese).

[10] GAO M, ZENG XA, XIAO LM. Determination of benzaldehyde content in plum fruit wine by high performance liquid chromatography (HPLC)[J].Liquor-making Science & Technology,2009,179(5): 110-112.(in Chinese).

[11] GAO M, ZENG XA, CHEN Y. Study on aroma components in plum wine[J]. Food Science and Technology,2010,35(3): 78-81.(in Chinese).

[12] YANG HY, WU SH, WANG XH,etal. Analysis of flavoring compositions in green plum fruit fermenting wine and in green plum fruit steeping wine by GC-MS[J]. Liquor-making Science & Technology,2005,135(9): 80-83.(in Chinese).

[13] ZHENG XH, ZHANG M, LIU YP. Analysis of aroma components by GC-MS and deacidification of plum wine[J].Journal of Food Science and Biotechnology,2014, 33(4): 432-437.(in Chinese).

[14] LIU Y. The rapid detection method of furfural and its application in liquor production[D]. Wuhan: Hubei University of Technology,2013.(in Chinese).

[15] ZHAO LR, ZOU PF, LU WC. The research progress of green plum extractive[J]. China Medicine and Pharmacy,2012,2(3): 41-43.(in Chinese).

[16] CAO YP. Food flavoring technology[M]. Beijing: Chemical Industry Press,2002.(in Chinese).

>EBSCO Publishing, headquartered in Ipswich, Massachusetts, is an aggregator of premium full-text content. EBSCO Publishing's core business is providing online databases via EBSCOhost to libraries worldwide. EBSCOhost is used by libraries, schools, academic institutions, medical institutions, and corporations. The company is a subsidiary of Birmingham, Alabama-based EBSCO Industries. EBSCO Industries is located at number 196 of the top 200 privately held companies in the United States by Forbes Magazine. The company's core business is providing online databases via its proprietary software, EBSCOhost, to libraries. EBSCO provides over 350 full-text and secondary databases. Content for these databases include full-text journals, magazines, books, monographs, reports, ebooks, business book summaries and various other publication types. It also provides databases for reference to the health and business sectors, such as DynaMed.

October 8, 2015 Accepted: November 24, 2015

Supported by Talent Introduction Project of Sichuan University of Science & Engineering (2012RC14; 2015RC14).

*Corresponding author. E-mail: xidaya@163.com

杂志排行

Asian Agricultural Research的其它文章

- Application and Residue Pollution of Mulching Films in Xinjiang

- Resource Dependence Relationship between Grass-roots Government and Farmers’ Specialized Cooperatives

- Urban Residents’ Consumption Risk Perception about the Dairy Products

- Effect of Vacuum Packaging on Storage Quality of Peanut

- Innovative Development of Fishery and Ecological Protection of Poyang Lake

- Effect of Silicon Application on Rice Growth and Production Structure