气泡微细化沸腾传热特性

2015-12-23朱光昱于方小稚田齐伟

朱光昱 高 力 于方小稚 田齐伟

气泡微细化沸腾传热特性

朱光昱1高 力1于方小稚2田齐伟1

1(中国核电工程有限公司 总体所 北京 100084)

2(北京理工大学 自动化学院 北京 100081)

气泡微细化沸腾(Micro-bubble Emission Boiling, MEB)是一种特殊的过冷沸腾现象,当其发生时加热面的热流密度会远高于临界热流密度(Critical Heat Flux, CHF)。根据采集到的可视化沸腾资料,对MEB的传热机理进行了分析。结果表明,MEB发生时,加热面上不稳定气膜的周期性破裂,破坏了过热液层,导致了良好的气液置换对流换热。考虑MEB的特殊传热过程,对Rohsenow关系式中部分项进行修正,并根据最小二乘法对实验数据进行拟合,得到了适用于10 mm铜加热面上的MEB沸腾关系式,误差不超过±15%,可满足一般的工程计算要求。

气泡微细化沸腾,临界热流密度,最小二乘法

近几十年内,很多核能装置的发热元件热通量已经远超1 MW·m-2,国际热核聚变实验堆(International Thermonuclear Experimental Reactor, ITER)滤偏器上的最大热负载达到了30 MW·m-2;在托卡马克第一壁上,当等离子体破灭时,其局部功率也达到500 kW·m-2。

常见的空冷、水冷技术已无法满足这些设备的制造或改进要求。由Suzuki等[1-2]发现了气泡微细化沸腾(Micro-bubble Emission Boiling, MEB),因其可获得远高于临界热流密度(Critical Heat Flux, CHF)的热流,被认为是换热器设计优化和提升换热极限的理想手段之一。

Zhu等[3]绘制了15-85 K过冷度下的池式沸腾特性曲线,分析了加热面上的气泡脱离和破裂频率,总结了过冷度对MEB沸腾以及偏离泡核沸腾点(Departure from Nuclear Boiling, DNB)的影响。Shoji等[4]在过冷度高于40 K的铂加热丝的池沸腾实验中实现了MEB,他们获得的最高热流密度达到了10MW·m-2。Kumagai等[5]研究了15 mm×6 mm矩形管道内的过冷流动沸腾现象,并根据实验条件和现象将MEB区分为:(1) 壁面过热度较低、过冷度较高、液体流速较高条件下的Stormy-MEB I;(2) 壁面过热度较高、过冷度较低、液体流速较高条件下的Stormy-MEB II;(3) 壁面过热度较高、热流密度增长缓慢的Calm MEB。本文根据采集到的可视化资料,分析了MEB的传热机理,给出了MEB沸腾换热关联式。为MEB的工程化应用和发生机理研究提供了基础。

1 实验装置

图1所示为过冷池沸腾实验装置,详见文献[6]。加热元件为4个硅碳棒,导热铜芯上部为直径10mm的加热面。导热铜芯中轴上装有3个直径1mm的T分度号铜-康铜铠装热电偶,距离加热面分别为3 mm、5.75 mm和8 mm,并依次间隔30º,以减少热电偶对铜芯导热的影响。加热面的壁温数据可以根据铜芯中轴的温度通过Fourier导热定律求得。水箱中的水温由在加热面上方5 mm处的热电偶测量,水的过冷度由一个电加热器和一个冷却器共同控制。

2 结果和分析

图2为30 K和50 K过冷度下热流密度为6.3MW·m-2和5.7 MW·m-2时的MEB沸腾现象。当MEB发生时,加热面上周期性的生成不稳定气膜,在气膜完成生长后,由于气液界面不稳定而发生剧烈破碎。如图2(a)中2.75 ms和图2(b)中1.2 ms处所示,气膜破损产生的冲击横扫加热面,使加热面可以直接与过冷水接触,并迅速生成新的气膜。整个变化周期约在3 ms,这种由气膜破碎导致的气液置换是MEB可以达到极高热流密度的原因。而当加热面低于隔热陶瓷0.5 mm时,气液置换过程受到阻碍,MEB不会发生[3]。

图1 过冷池沸腾实验装置Fig.1 Experimental setup for subcooled pool boiling.

图2 30 K (a)和50 K (b)过冷度下热流密度为6.3 MW·m-2(a)和5.7 MW·m-2(b)时的MEB 沸腾现象Fig.2 Bubble behavior of MEB at liquid subcooling of 30 K (a) and 50 K (b) with q=6.3 MW·m-2(a), 5.7 MW·m-2(b).

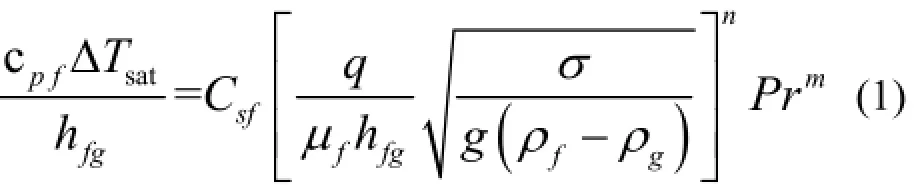

式中,cpf为水的比热容,J·kg-1·K-1;ΔTsat为壁面过热度,K;hfg为水的汽化潜热,J·kg-1;Csf为流体加热面组合的特性函数;μf为水的动力粘度系数,N·s·m-2;σ为水的表面张力系数,N·m-1;g为重力加速度,m·s-2;ρf和ρg为水和蒸汽的密度,kg·m-3;Pr为普朗特数。

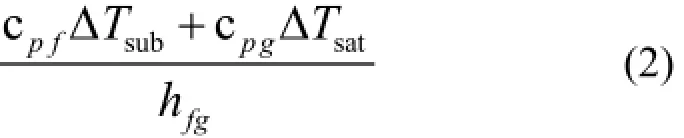

在大容积饱和沸腾过程中,水温为饱和温度,为防止达到CHF,壁温通常也不会太高。而当MEB发生时,水的过冷度都在20 K以上,加热面的过热度可以超过180 K[1]。所以式(1)中等号左侧项需要改写将过冷水加热至饱和,以及将蒸汽加热至过热两个部分:

式中,ΔTsub为水的过冷度;cpg为水蒸汽的比热容,J·kg-1·K-1。

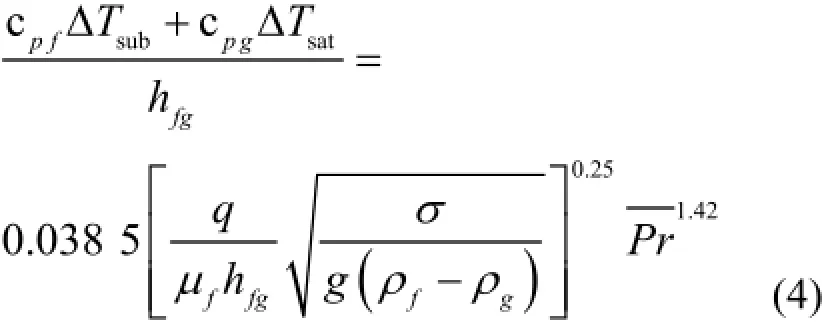

在式(1)中,工质为水时Pr数的系数m=1。而在MEB沸腾过程,需要考虑蒸汽过热度和水的过冷度对Pr数的影响,所以需对Pr数进行如式(3)修正并重新拟合其系数m。

式中,Prf和Prg分别为过冷水和过热蒸汽在物性温度下的Pr数。

对于核态沸腾来说,Csf一般在0.0027-0.013。对于MEB而言,流体与加热面的相互作用方式与核态沸腾有一定差别,所以Csf需重新拟合。据实验数据使用最小二乘法拟合,可以得到Csf=0.0385,m=0.25,n=1.42。MEB换热关联式为:

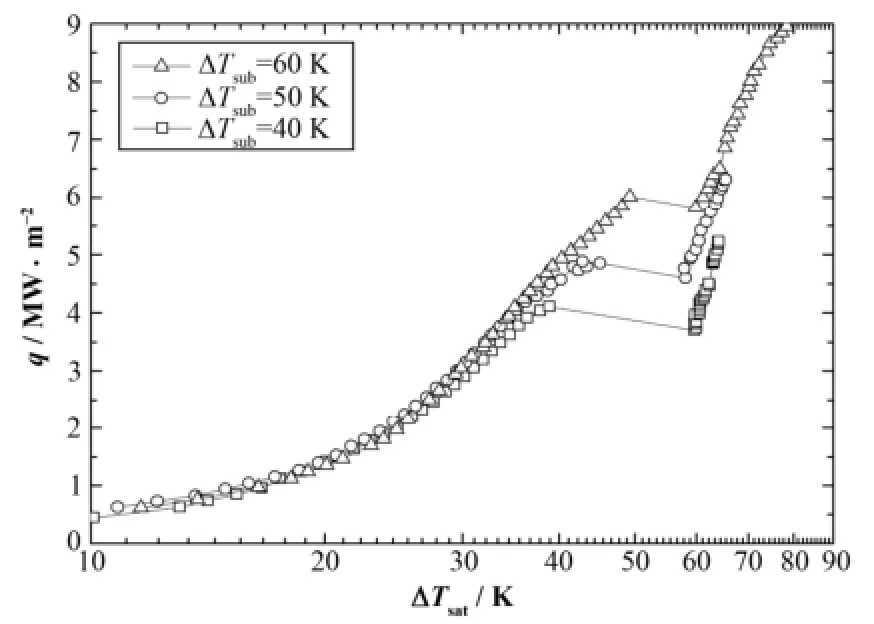

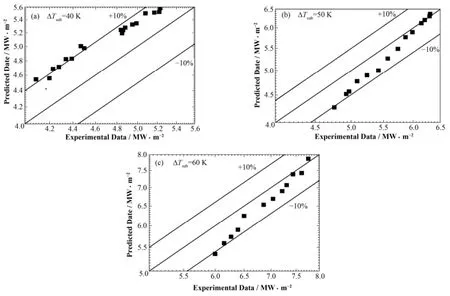

图3为实验获得的40 K、50 K和60 K过冷度下的沸腾特性曲线。图4(a)、(b)、(c)分别为40 K、50 K、60 K过冷度下,热流密度的实验值和计算值的对比。可以看出,该关系式与实验值吻合较好,误差不超过±15%。

图3 过冷度对MEB的影响Fig.3 Effect of subcooling on MEB.

图4 40 K (a)、50 K (b)和60 K (c)过冷度下实验结果与计算结果对比Fig.4 Comparison between experimental values and calculated values at liquid subcooling of 40 K (a), 50 K (b) and 60 K (c).

3 结论

本文研究了40-60 K过冷度下,10 mm铜加热面上除氧水的MEB沸腾传热特性,根据MEB的特殊传热过程,修改了Rohsenow关系式中部分项,并根据最小二乘法对实验数据进行拟合,得到了适用于10 mm铜加热面上的MEB沸腾关系式,误差不超过±15%。

1 Suzuki K, Inagaki F, Hong C. Subcooled boiling in the ultrasonic field-on the cause of microbubble emission boiling[J]. Heat Transfer Engineering, 2011, 32: 673-682. DOI: 10.1080/01457632.2010.509771

2 Suzuki K, Oshima A, Hong C, et al. Subcooled flow boiling in a minichannel[J]. Heat Transfer Engineering, 2011, 32: 667-672. DOI: 10.1080/01457632.2010.509770

3 Zhu G Y, Sun L C, Tang J G, et al. A visualized study of micro-bubble emission boiling[J]. International Communications in Heat and Mass Transfer, 2014, 59: 148-157. DOI: 10.1016/j.icheatmasstransfer.2014.10.003

4 Shoji M, Yoshihara M. Burnout heat flux of water on a thin wire[C]. Proceeding of 28thNational Heat Transfer Symposium of Japan, 1991: 121-123

5 Kumagai S, Kubo R, Kawasaki T. Microbubble emission boiling from horizontal and vertical surfaces to subcooled parallel flow water[J]. Heat Transfer-Asian Research, 2003, 32: 130-140. DOI: 10.1002/htj.10077

6 朱光昱, 孙立成, 唐继国. 气泡微细化沸腾的沸腾现象与沸腾音特性[J]. 核技术, 2014, 37(2): 020203. DOI: 10.11889/j.0253-3219.2014.hjs.37.020203

ZHU Guangyu, SUN Licheng, TANG Jiguo. Characteristics of phenomenon and sound in microbubble emission boiling[J]. Nuclear Techniques, 2014, 37(2): 020203. DOI: 10.11889/j.0253-3219.2014.hjs.37.020203

7 Rohsenow W M. Nucleate pool boiling[A]. Frost W. Heat transfer at low temperatures[C]. New York, US: Springer, 1975: 107-141. DOI: 10.1007/978-1-4899-1998-4_5

Heat transfer property of micro-bubble emission boiling

ZHU Guangyu1GAO Li1YU Fangxiaozhi2TIAN Qiwei1

1(General Design Division, China Nuclear Power Engineering Co., Ltd., Beijing 100084, China) 2(School of Automation, Beijing Institute of Technology, Beijing 100081, China)

Background:Micro-bubble Emission Boiling (MEB) is a special subcooling boiling phenomenon that the heat flux increases more highly than critical heat flux (CHF). Due to its extremely high heat transfer capability, many researchers have shown interest in it.Purpose:In this paper, we fit the heat transfer correlation of experimental data collected in visualized boiling experiments after deeply analyzing the heat transfer mechanism of MEB. Methods: Four Si-C heaters were employed for heating the copper block, which has a round heating surface with diameter of 10mm on its upper. Temperature data were measured by T-type sheathed thermocouples. The temperature of the heating surface was obtained by extrapolating the temperature distribution. Based on the heating surface temperature date in different subcoolings, least square method was used to fit Rohsenow relation to MEB. Bubble behaviors were captured by high-speed video camera with light system.Results:The experimental results showed that, when the subcooling exceeded 40 K, disturbance emerged at the liquid-vapor interface and the micro-bubble emission boiling occurred after the CHF was attained, thereafter the heat flux increased rapidly with the superheat increasing like that in typical nucleate boiling region. Based on Rohsenow relation, MEB heat transfer correlation is fitted according to the measured temperature data for heating surface of 10-mm copper in different subcoolings. The error of the relation is less than ±15%, which meets the requirement of general engineering. Conclusion: The efficient convective heat transfer of vapor-liquid replacement caused by periodic damage of the unsteady vapor film on the heating surface is the heat transfer mechanism of MEB.

MEB, CHF, Least squares

ZHU Guangyu, male, born in 1989, graduated from Harbin Engineering University in 2015, research areas is nuclear power plants operation and test technology

TL334

10.11889/j.0253-3219.2015.hjs.38.120602

国家自然科学基金(No.51376052)资助

朱光昱,男,1989年出生,2015年毕业于哈尔滨工程大学,研究领域为核电运行与调试技术

Supported by the National Natural Science Foundation of China (No.51376052)

2015-09-28,

2015-11-02

CLCTL334