学生公寓,圣库加特·德尔·瓦莱斯,巴塞罗那,西班牙

2015-12-22建筑设计H建筑事务所DATAAE建筑事务所

建筑设计:H建筑事务所 + DATAAE建筑事务所

学生公寓,圣库加特·德尔·瓦莱斯,巴塞罗那,西班牙

建筑设计:H建筑事务所 + DATAAE建筑事务所

1 局部立面/Partial elevation

这栋新建的学生公寓与巴塞罗那瓦莱斯高等建筑技术学院校区的基地一致,都位于圣库加特·德尔·瓦莱斯的一块低密度住宅区内。该项目由巴塞罗那瓦莱斯高等建筑技术学院和加泰罗尼亚理工大学共同组织竞标,他们提出了3个雄心勃勃的挑战:为建筑系学生建造一个住宅区域,符合瑞士迷你能源标准(38kWh/(m2·a)以下),采用一项新的工业施工系统(Compact Habit公司的工业化集成模数系统)。

原有地形及2条平行的体块组织使得这栋公寓更贴近地面,且易于形成一个巨大的中央庭院,为集体生活提供起居空间。

这座建筑系学生专用公寓可以引导住户进行深入交流,并且无论个人还是集体都得益于单元模块的灵活,中央庭院也具有作为社会活动空间的功能。

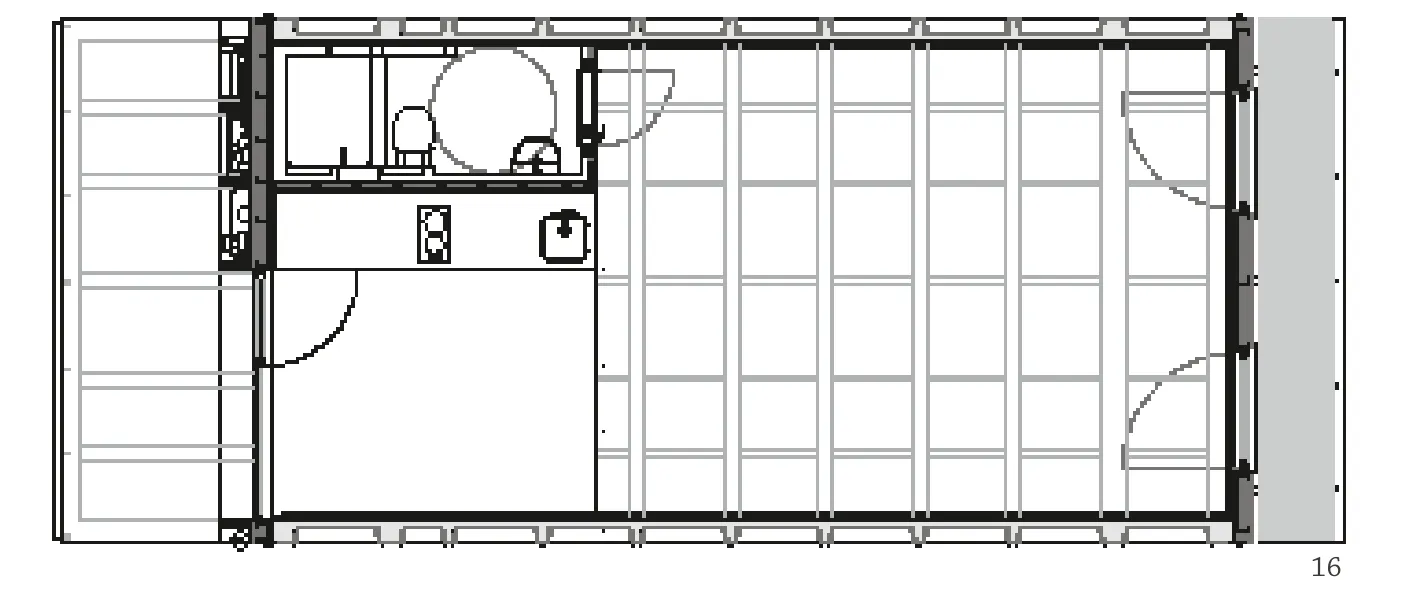

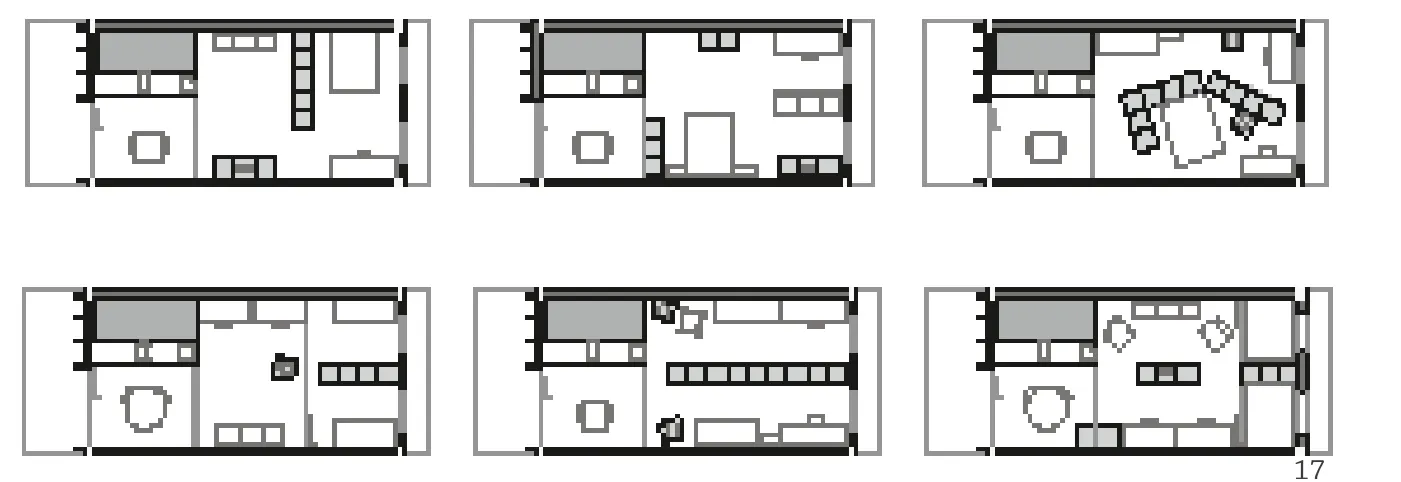

我们的目标是尽可能少地决定单元模块的类型,仅提供规范要求的部分,以降低对居住可能性的限制。在这个方式下,我们尝试不完全建成这座建筑,以开启新的可能性:我们给予建筑系学生更多自由来挪用空间,在能源效率上进行再投资以节省建材开销,并且提供一种更身临其境且有教学意义的建造方式。

这个工业化系统对于该项目的开展具有决定性意义,它明确地提出了很多关于工业过程的最优化和合理化决定。工业化可以节省时间,更好地保证操作实施,能移植新的干燥施工系统,并减少施工过程中的材料浪费。这个系统在设计及可持续性中是一个很大的机会。

施工时间按照以下阶段发展。2个月:基地作业(地基、下水系统、整体安装等);2个月:在加工车间制造单元模块;2周:运输单元模块并在基地装配;3个月:整体完成(屋顶、立面细节、城市化等)。

这种“未完成”的建筑思想对于建筑材料的结局具有决定性的影响。由于初期的混凝土模块大部分都是裸露的,因此能够得益于它的可塑性、纹理及热惯性。仅有的室内装饰成品来自常被用于制作混凝土模板的胶合板,其优势在于这种接头材料可更新且干燥,因此也没必要彻底完成室内装饰。安装过程是公开的,可能在某种方式上也完成了教学。立面技术采用一种轻型且可逆的干燥施工方法,在绝热的厚壁上覆盖一层透气防水的薄膜,形成占主导地位的通风立面系统。由于这种方法可以节约能耗经费,现已被投资于一项能效改进工程(更隔热、更优质的玻璃、木窗框等)。

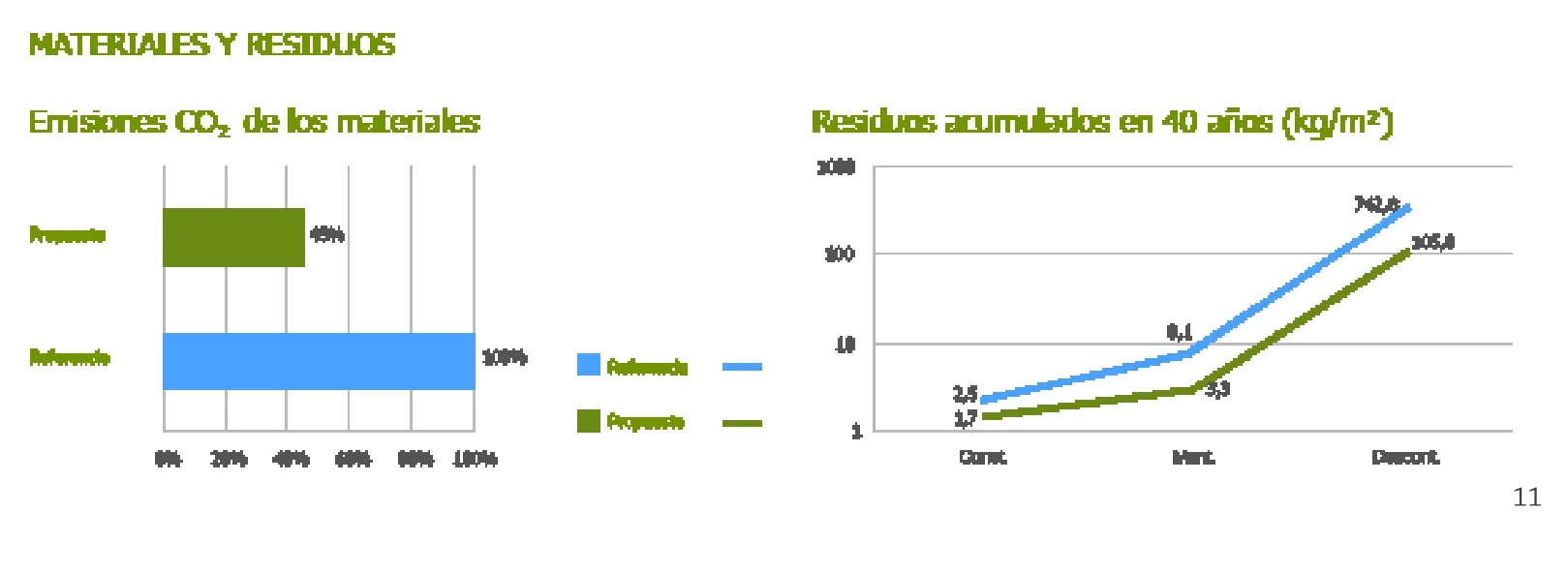

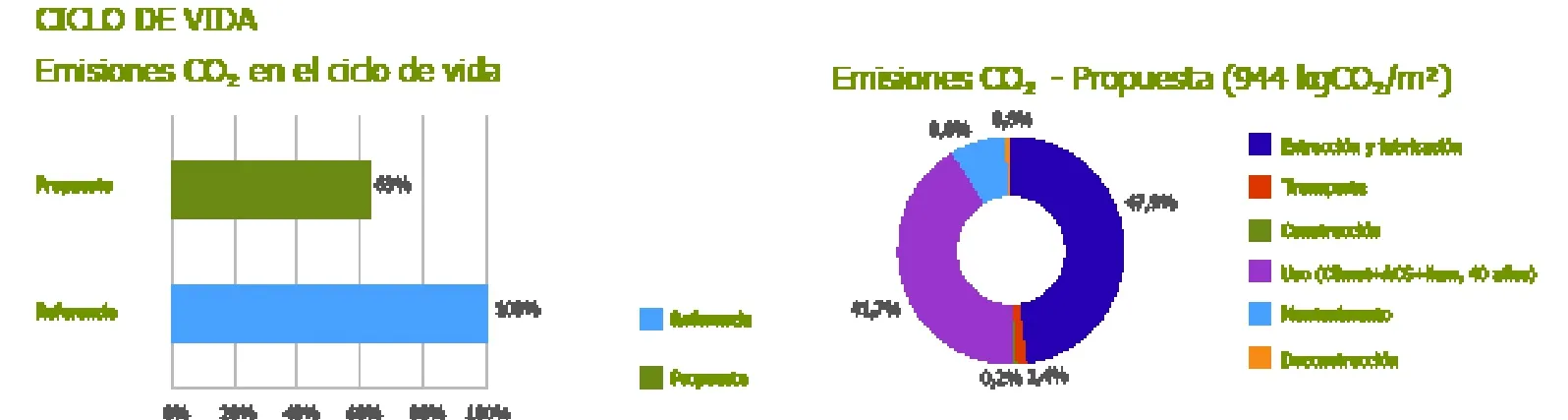

一些工业化系统比传统施工(在能源消耗、废渣废料及CO2的产生方面)更加环保。但这个项目使用一种封闭生命循环的材料准则(材料用量小的服务单元、可循环利用的材料、干燥可逆的接头、更耐久的结构),经证实可以显著减小对环境的影响:该项目在制造阶段减少排放CO225%,在装配阶段减少排放废物废渣50%,在拆解阶段减少材料浪费75%。

一旦建筑达到使用寿命就可以将其完全拆解,混凝土模块以及几乎全部的零件和系统都可以被再利用。于是这个建筑将不再是产品,而是重新成为资源。可循环与再利用过程是这种模块系统最强有力的概念。没有固定或完全拆卸的关节,这种装配系统使我们能够畅想可循环混凝土模块被用于其他建筑及环境的未来图景。

这个项目并不试图表达一种工业模块系统,而是把模块逻辑优化并融合于技术性与适居性的一种混合式思维。□(辛梦瑶 译)

2 外景/Exterior view

3 首层平面/Floor 0 plan

项目信息/Credits and Data

客户/Client: UTE d'Aro Compact-Habit Campus de Sant Cugat主持建筑师/Principal Architects: 大卫·洛伦特·伊瓦涅斯,何塞普·里卡特·乌利德莫林斯,泽维尔·罗斯·马霍,罗杰·图多·加利/H建筑事务所+克劳迪·阿吉洛,阿尔伯特·多明戈/DATAAE建筑事务所/David Lorente Ibáñez, Josep Ricart Ulldemolins, Xavier Ros Majó, Roger Tudó Galí/H ARQUITECTES+ Claudi Aguiló, Albert Domingo/DATAAE

合作者/Collaborators: Toni Jiménez, Montse Fornés, Anna Tamayo (H ARQUITECTES); Anne Hinz, Letizia Dipasquale, Catarina Marques (DATAAE)

设计团队/Project Team: Societat Orgànica (环境/ consultoria ambiental), DSM arquitectes (结构/estructura), ÀBAC enginyers (设备/instal·lacions)

建筑面积/Floor Area: 3101m²

设计时间/Design Period: 2009-2010

建造时间/Construction Period: 2010-2011

摄影/Photos: Adrià Goula

4-8 内景/Interior view

The new dwelling house for students is placed in the same plot as the University of Architecture (ETSAV), in a low density residential area in Sant Cugat del Vallès. The competition, organized by the ETSAV and the UPC, considered three ambitious challenges: to build a housing area for architecture students, to comply with the Swiss energetic certification Minergie (below 38 kwh/m2a) and to use a new system of industrialized construction (EMI System by Compact Habit).

The existing topography and its own double parallel block organization allows dwelling to be closer to the ground level and to favour a big central atrium, where, as a living room, the community life will take place.

The residency program for architecture students allows for imagination of deep relationships between users, both individual, due to the housing unit flexibility, and collective, thanks to the potential use of the central atrium as a social event space.

Our proposal tries to determine as little as possible the unit typology bordering the habitability limits and only offer those elements required by regulation. In this way we try not to completely finish the housing, opening new fields of opportunity: more freedom in the students' appropriation of the space, material cost saving in finishing reinvested in energy efficiency, and a more real and pedagogical expression of construction.

The use of an industrialized system has been decisive for the project development and it has positively conditioned many decisions related to optimization and rationalism of the industrial process. Industrialization helps to save time, to guarantee a better execution control, to implant new dry construction systems and to minimize the production of waste materials during the construction process. It was a great opportunity in design and sustainability terms.

The construction time was developed in the next stages: 2 months of on-site works (foundations, sewage, general installations…), 2 months of units manufacturing in workshop, 2 weeks of transporting and assembling the units on site, and 3 months of general finishing (roof top, façade details, urbanization…)

The idea of a 'none finished' building has a decisive influence on the material result of the building. The original concrete module appears mostly naked, taking positive profit of its materiality, texture and thermal inertia. The few interior finishings added are mainly formed by plywood panels often used for the concrete framework, which have the advantage of being a renewable and dry joint material and with no finishing need. Installations are exposed, when possible, as a way to implement teaching. The façade technology uses a dry construction logic, light and reversible, which are predominated by a ventilated facade system and an important thermal isolation combining thickness with a breathable and watertight membrane. The economic savings achieved by using this kind of material have been invested in energy efficiency improvements (more isolation, better glazing, wooden windows...).

Some of the industrialized systems have a greater environmental impact (energy consumption, generation of waste materials and CO2emissions) than conventional construction. But in this case, using a closed life-cycle materials criteria (less material used by service unit, recycled and recyclable materials, dry and reversible joints, more durability of the structure, etc.), a significantly lower environmental impact has been verified: this project saves up to 25% CO2emissions in manufacturing process, 50% waste materials in the assembly stage and 75% waste materials in the deconstruction stage.

Once the lifetime of the building is over it could be completely disassembled, concrete modules as well as almost all elements and systems could be reused, and the building will no longer be a product, but to become a resource once again. Possibly, recyclable and reuse processes are the strongest concept of the modular system. Its assembly system, without rigid or completely disassembled joints, allows us to imagine a future reuse of the concrete module in other buildings and situations.

The project does not try to show an industrial modular system, but to optimize and integrate a modular logic within a technology and habitability collage.□

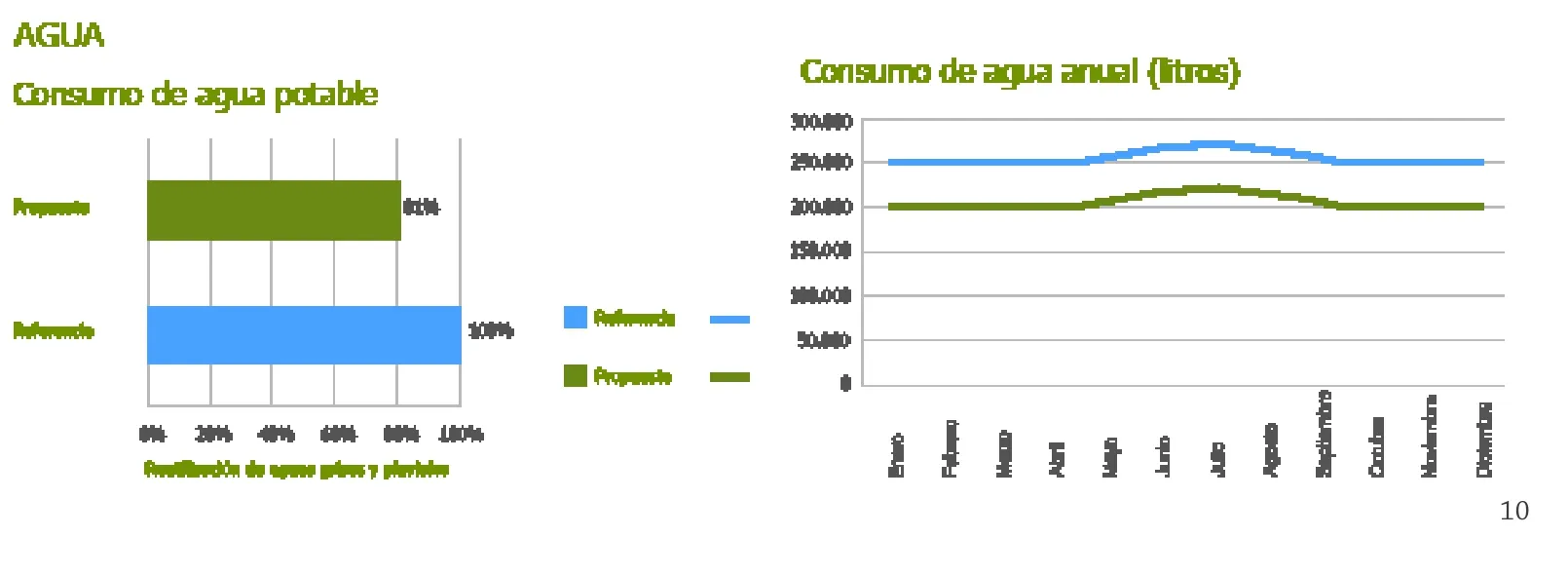

10 水消耗/Water consumption

11 材料与废物/Materials and waste

12 生命周期/Life cycle

13 外景/Exterior view

评论

丁力扬:这是一个貌似简单直白的建筑,但它实际上不仅蕴含模数化的设计思路,还呈现出一种有趣的复杂性。具体来说,从模数化的角度来看,这个建筑中的每个宿舍空间具有上下双层楼板和左右双层隔墙,意味着每一个宿舍房间本身就是一个完整的结构单元。模数化构件的使用贯彻到了从建筑到景观铺装的不同区域。除了模数化和工业预制,建筑师对“未完成”思路的贯彻,也为这座学生公寓带来了增加复杂性的可能。首先,这种复杂性不仅来自设计师的构想,同时也来自学生们在使用时的实际操作,具体说,就是学生们对房间内部功能格局的自由调整。其次,建筑立面通过增加垂直绿化和附着的铁丝网所创造的界面,加厚了建筑的“墙体”,也随之将建筑与环境两者之间看似常规的关系变得不那么简单。美中不足的是,中庭里的两组清水混凝土楼梯略显“粗暴”,和其他部分看似随意、实则微妙的材料应用比起来,并不太协调,尤其不如有意暴露的设备管道以及镀锌钢板的局部应用来得匠心独到。

姜涌:乍看以为是一个集装箱或者某种工业化制品废料堆积而成的建筑,细看才知道是刻意未完成状态的、预制清水混凝土的学生宿舍。简单而坚硬的外壳和设施、柔性的绿化和内院、奢侈的空间尺度为生活提供了最大的可能和最小的干扰:超过4m的面宽、3m左右的厨房台面和卫生间、可供一人独居的极简生活。唯一遗憾的是,空间和设施的固定无法提供给居住者更多的可能。

Comments

DING Liyang: This project seems very simple at first, yet it actually displays an architectural modular philosophy with a significant level of complexity. Specifically, regarding the modular design strategy, each dorm unit is composed of double floor slabs and double partition walls, which implies that each individual dorm room is a self-complete structural unit. Modular components are also applied to various aspects of the whole project from construction to landscaping. Apart from modular design and prefabrication, the implementation of the architect's "incompleteness" concept also adds to the project's complexity. Moreover, students who literally inhabit this dorm building also contribute to its complexity through free adaptation of the interior functional layout. On the other hand, vertical landscape on the exterior façade helps to thicken the wall, an approach that renders more complex the seemingly ordinary relationship between architecture and nature. The only defect, in my opinion, consists in the treatment of the courtyard staircases, which seems a little rough as compared to the delicate treatment of other materials and elements, in particular the intentionally exposed wall pipes and galvanized steel plates.

JIANG Yong: on the first sight, it may easily be mistaken for a container or a building piled up with some sort of industrial wastes. Only on closer look can one realize that it is a student dorm built of precast concrete and deliberately left in an unfinished status. Simple yet firm shells and facilities, courtyard with soft greening, and luxurious spacial scale, all provide maximum living potential and minimum disturbance: the 4-meterwide room, the 3-meter kitchen counter and toilets are designed for the simplistic life of individual student. The only pity lies in the immobility of spaces and facilities, which failed to provide more possibilities for the inhabitants.

Student Housing, Sant Cugat del Vallès, Barcelona, Spain, 2011

Architects: H ARQUITECTES + DATAAE

14 外景/Exterior view

18 细部/Detail

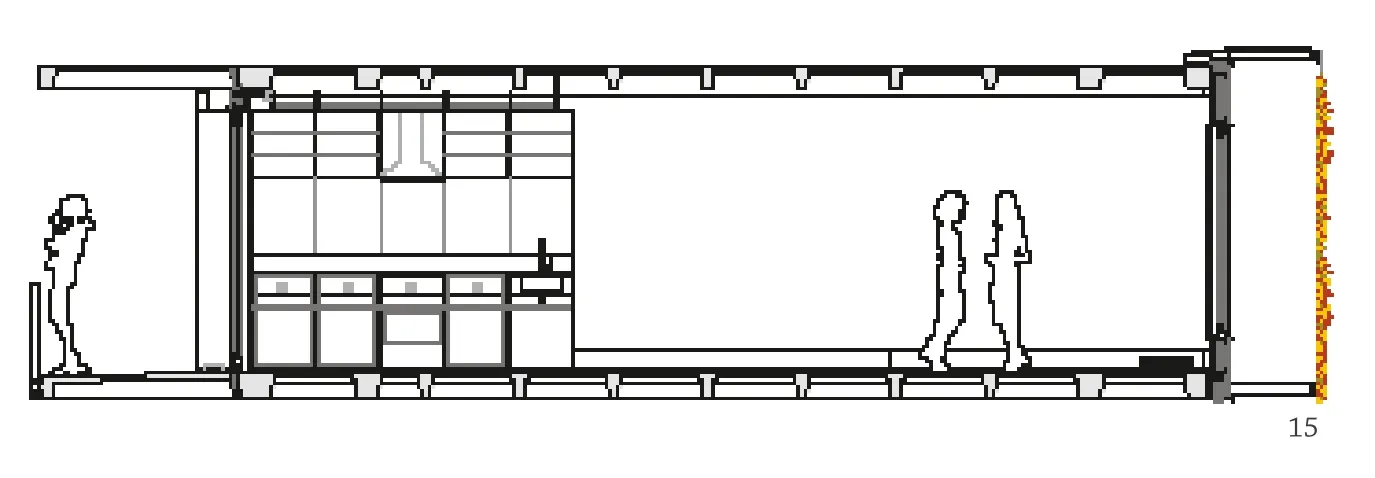

15 单元剖面/Unit section

16 单元平面/Unit plan

17 单元示意/Unit diagram