Optimization of volume to point conduction problem based on a novel thermal conductivity discretization algorithm☆

2015-11-02WenjingDuPeiliWangLipengSongLinCheng

Wenjing Du ,Peili Wang ,Lipeng Song ,Lin Cheng ,*

1 Institute of Thermal Science&Technology,Shandong University,Jinan 250061,China

2 Department of Energy and Power Engineering,Shandong University,Jinan 250061,China

Keywords:Volume to point conduction Principle of minimum entropy generation Algorithm of thermal conductivity discretization Optimization

ABSTRACT A conduction heat transfer process is enhanced by filling prescribed quantity and optimized-shaped high thermal conductivity materials to the substrate.Numerical simulations and analyses are performed on a volume to point conduction problem based on the principle of minimum entropy generation.In the optimization,the arrangement of high thermal conductivity materials is variable,the quantity of high thermal-conductivity material is constrained,and the objective is to obtain the maximum heat conduction rate as the entropy is the minimum.A novel algorithm of thermal conductivity discretization is proposed based on large quantity of calculations.Compared with other algorithms in literature,the average temperature in the substrate by the new algorithm is lower,while the highest temperature in the substrate is in a reasonable range.Thus the new algorithm is feasible.The optimization of volume to point heat conduction is carried out in a rectangular model with radiation boundary condition and constant surface temperature boundary condition.The results demonstrate that the algorithm of thermal conductivity discretization is applicable for volume to point heat conduction problems.

1.Introduction

Problems of volume to point heat conduction are widely encountered in various engineering fields.“Volume”generally refers to the substrate with various shapes and boundary conditions,and “point”is various heat sources in the substrate.The objective of such problems is generally to increase heat dissipation from points to certain boundaries.In the aerospace field,spacecraft works in a harsh outer space environment,such as over-cold or over-heat.How to control the spacecraft temperature distribution in an acceptable range is one of the most important tasks[1].In the field of microelectronics,the volume of electronic chips is becoming smaller and smaller,and the corresponding power is getting larger and larger.The heat dissipation per unit volume increases greatly,which makes the chip cooling difficult[2].Chip heat dissipation can not rely on the application of monocry stalline silicon only, filling a high thermal conductivity material in the substrate is also a solution.A reasonable layout of high thermal conductivity material will greatly increase the chip heat dissipation capability.The cost and characteristics of the chip are related to the quantity and thermal conductivity of filling material.An optimized filling method is important for high power heat dissipation.

Bejan[3,4]has put forward the constructal theory to deal with the volume to point heat conduction problem.Based on the theory,the best shape is first sought for a given minimum volume unit.Then the optimized minimum thermal conductivity units are combined to minimize related thermal resistance.The evolution is performed for several assembly and optimization processes.Once the high thermal conductivity material covers prescribed substrate space,the heat dissipation process is optimized with the minimum thermal resistance.Bejan[5–7]has also used the principle of minimum entropy production for the optimization of volume to point conduction problem.Starting from the irreversible thermodynamics,the total process entropy production is set as the objective function in the optimization.This method is also named as thermodynamic optimization.Guo et al.[8,9]have put forward the concept of entranspy,which can be used to solve volume to point conduction problems.Based on the analogy between thermodynamics and electricity,the entranspy describes the capability of heat transfer.With the principle of minimum entranspy dissipation,the heat transfer process can be optimized to enhance heat transfer or heat dissipation.Cheng et al.[10–12]have used the evolution algorithm in the principle of bionic optimization to deal with the layout of high thermal conductivity materials.Xia and Guo[13]have optimized heat conduction by using life evolution process.The principle of minimum entropy production can also be used to determine the population locations of high thermal conductivity materials.Find the points with maximum and minimum entropy production, fill the maximum entropy production points with high thermal conductivity material,and replace the minimum points with the substrate material.The evolution process terminates when the quantity of high thermal conductivity material meets the requirements.Chen et al.[14]have presented a more complex algorithm,named the continuous thermal conductivity algorithm,to search the global optimal solution on the basis of bionic optimization algorithm.The global optimization ability is better,but it needs a large amount of calculations because of traversal search.Therefore,it is difficult to apply the continuous thermal conductivity algorithm in practice and its results are often regarded as the theoretical optimum solution in a volume to point conduction problem.

The objective in this paper is the optimization of volume to point heat conduction.Numerical simulations and analyses are based on the principle of minimum entropy generation.The software MATABLE is used for numerical calculation.The emphasis is to search a practical and useful algorithm for appropriate layout of high conductivity materials,enhancing heat dissipation efficiently.

2.Physical Model of Volume to Point Conduction Problem

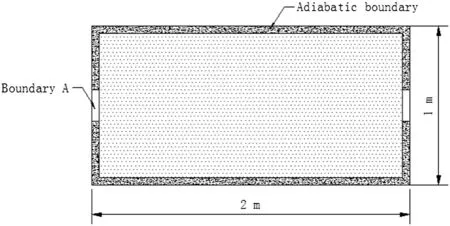

As shown in Fig.1,the two-dimensional rectangular plate with 2 m length and 1 m width is defined as the volume,and internal heat source qi,namely points,are distributed uniformly in the substrate.Border A with the length 0.2 m locates in the middle of left and right boundaries of the plate,serving as heat outlets.The boundaries except A are adiabatic.Thermal conductivities of substrate and high thermal conductivity material are assigned based on practical situations.The filling rate of high thermal conductivity material can be selected by the designer.10% filling rate is set in this study if it is not specified.Such physical model is typical among common volume to point conduction problems.

Fig.1.The physical model of volume to point conduction problem.

In the calculation the substrate is divided into grids,which are 200 grids in length and 100 grids in width in this physical model.Therefore,there are 20 thousand girds in the volume.In the filling process,the quantity of high thermal conductivity material is set,but its arrangement varies.The heat dissipation rate of the volume is mainly dependent on the layout of the filling material.The principle of minimum entropy production is used and the objective function is written as

where Sgis the total entropy production in the volume and is the function of thermal conductivity in each grid,and n is the total grid quantity.The objective is to calculate the volume heat dissipation rate corresponding to the minimum entropy generation Sg.The variables are set as

where kiis the thermal conductivity in the i th point,λLand λHare the lower and higher thermal conductivities,respectively,referring to the substrate and embedding material,respectively.

The filling process subjects to the prescribed quantity of high thermal conductivity material,

where m is used to calculate the grid quantity occupied by the high thermal conductivity material,defined as

3.The Algorithm of Thermal Conductivity Discretization

In order to obtain the layout of high thermal conductivity material,proper algorithms should be selected.In this paper,the algorithm of continuous thermal conductivity is used to obtain the theoretical arrangement of high conductivity material in the substrate.The thermal conductivity of material can be defined by the designer,regardless of its value of true materials.Based on the theoretical layout,a new algorithm of thermal conductivity discretization is proposed.

3.1.The algorithm of continuous thermal conductivity

For the problem of volume to point conduction,the integral of thermal conductivity for both substrate and high conductivity material is set as the constraint condition.The initial value of the continuously variant thermal conductivity k0is defined as

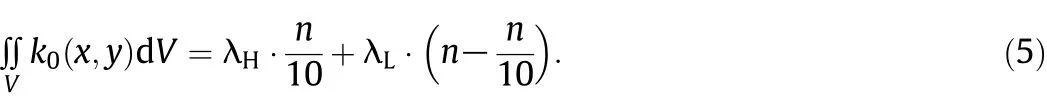

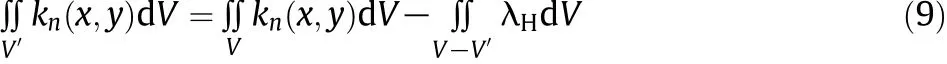

With the algorithm of continuous thermal conductivity,based on the principle of the minimum entropy production,numerical calculations are explored to solve the layout of high thermal conductivity material in the volume to point problem as follows.

(1)Initializing the thermal conductivity in the whole substrate,namely,calculating the initial value k0of thermal conductivity based on Eq.(5).

(2)Solving the conduction differential equation in the substrate and obtaining the distribution characteristics of both temperature and temperature gradient fields.

(3)Obtaining the field of thermal conductivity distribution based on the following equations

where k′n+1(x,y)is the intermediate variable at grid coordinate(x,y)and knis the thermal conductivity in the n th iteration.

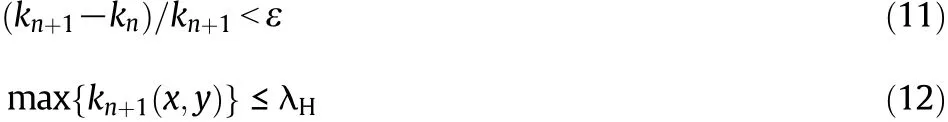

(4)In order to prevent the appearance of singularity and to control

the thermal conductivity of materials within the given scope,some determinations are performed on kn+1(x,y).If kn+1(x,y)<λH,go to Step(6)directly;if kn+1(x,y)≥λH,

(5)In order to satisfy the integral of thermal conductivity,the calculation of practical thermal conductivity integral is redone in the area of V′,i.e.,and recalculate the distribution of thermal conductivity field in the region V′as

(6)Go back to Step 2 until Eqs.(11)and(12)are satisfied

where ε is the error controlling factor for convergence,10-6in this paper.Here Eq.(12)is set to ensure that the thermal conductivity satisfies the requirements.

3.2.The algorithm of thermal conductivity discretization

The arrangement of high thermal conductivity material based on the principle of minimum entropy production can be optimized to the best level[15–17].In this situation,the substrate heat dissipation rate is best enhanced with the continuous thermal conductivity algorithm.To the problem of long calculation time and difficulty in finding suitable materials with continuous thermal conductivity,a novel algorithm of thermal conductivity discretization is put forward in this paper.The continuous thermal conductivity is discretized into prescribed and practical values of thermal conductivity.Two types of thermal conductivity are used to demonstrate the new algorithm.The heat dissipation rate is less with this algorithm,but it is more feasible and efficient compared with the continuous thermal conductivity algorithm and the evolution algorithm.

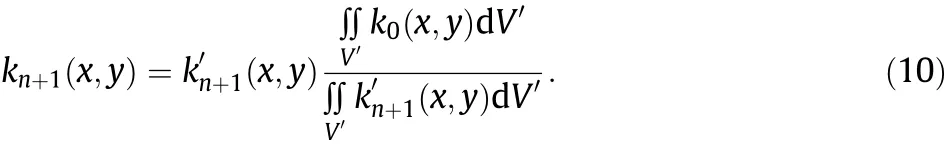

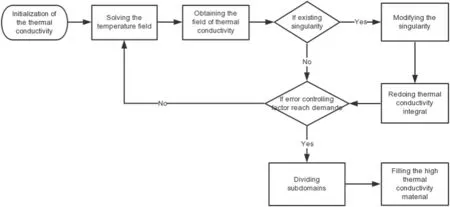

In the application of the new algorithm,the first step is to achieve the thermal conductivity distribution in the substrate based on the continuous thermal conductivity algorithm.Then,two sets of thermal conductivities are assigned to the substrate and the embedded high thermal conductivity material.The substrate region is divided into an appropriate quantity of subdomains.The layout of high thermal conductivity material is achieved in each subdomain and further the whole substrate.The flow chart of the novel algorithm is briefly illustrated in Fig.2.

For the rectangular plate and boundary conditions,the flat plate is divided into a certain quantity of subdomains.In each subdomain,the arrangement of high thermal conductivity material is solved with the continuous thermal conductivity algorithm.In each sub-area,the integral of continuous thermal conductivity is equal to that of high thermal conductivity material,

where Niis the grid numberin subdomain i,and Miis the gird numberin subdomain i occupied by the high thermal conductivity material.The calculation equation of Miis deduced as

The filling rate of high thermal conductivity material in each subdomain can be calculated after being rounded.Errors appear in the process of both numerical simulations and rounding off.The division of subdomains also affects the final calculation result and precision.Therefore,the preliminary layout of high thermal conductivity material based on the algorithm of thermal conductivity discretization is generated and the evolution algorithm can be used to form the final arrangement of the high thermal conductivity material.

4.Numerical Calculation Results and Discussion

4.1.The effect of subdomain quantity on numerical calculation results

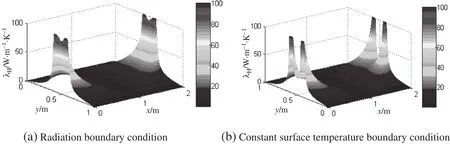

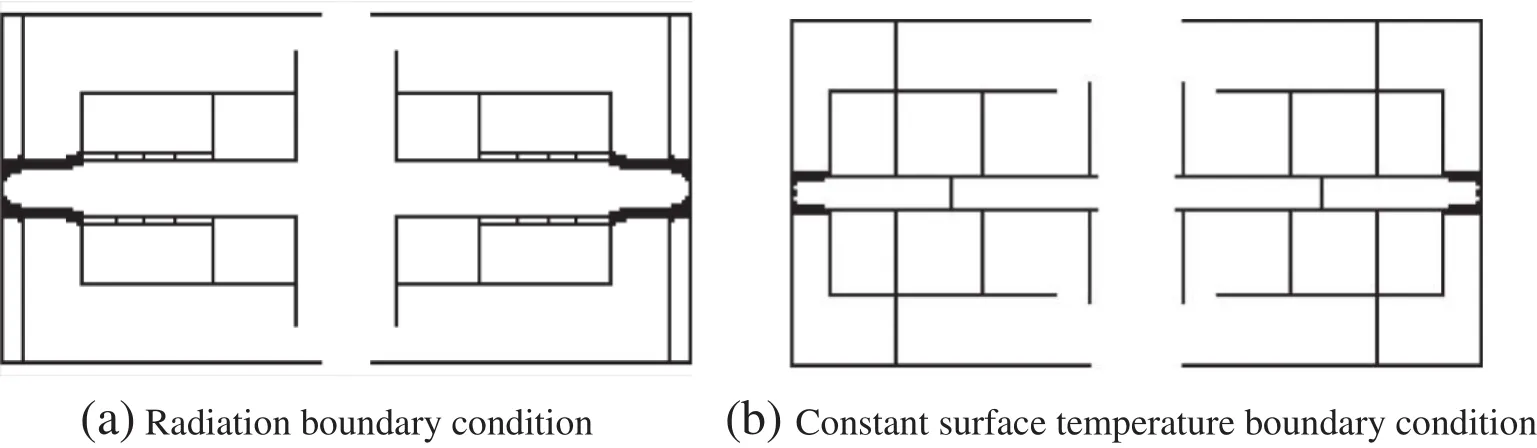

In the physical model,the substrate is divided into 20 thousand grids,with the thermal conductivity of substrate λL=1 W·m-1·K-1.For the high thermal conductivity material λH=100 W·m-1·K-1.Two kinds of boundary conditions are considered in this paper.In the first case,border A has radiation boundary condition with deep space,which is set as 3 K,and its emissivity is 0.8[20].In the second case,border A is set at constant surface temperature TA=300 K.Characteristics of internal heat source distribution change with boundary conditions.Numerical simulations on the continuous layout of high thermal conductivity material are shown in Fig.3,presenting the layout results for different boundary conditions.

Fig.2.The flow chart for the novel algorithm.

Fig.3.Continuous thermal conductivity layout for two kinds of boundary conditions.

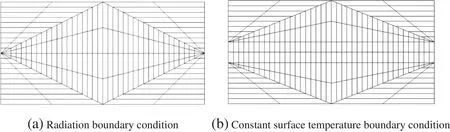

On the basis of the continuous distribution of thermal conductivity,the rectangular plate is divided into subdomains.The dividing method is different for different boundary conditions.As shown in Fig.3,thermal conductivity fluctuation on the border is not so obvious when border A has radiation boundary condition.Therefore,the subdomain is divided from the center of border A to the substrate center.When border B presents constant surface temperature boundary condition,thermal conductivity in the border changes violently,so the subdomain is divided from the location with the maximum thermal conductivity.And the area with a steady thermal conductivity is divided into rectangular region,as shown in the middle section of the substrate.Fig.4 describes the subdomain division for the two boundary conditions.

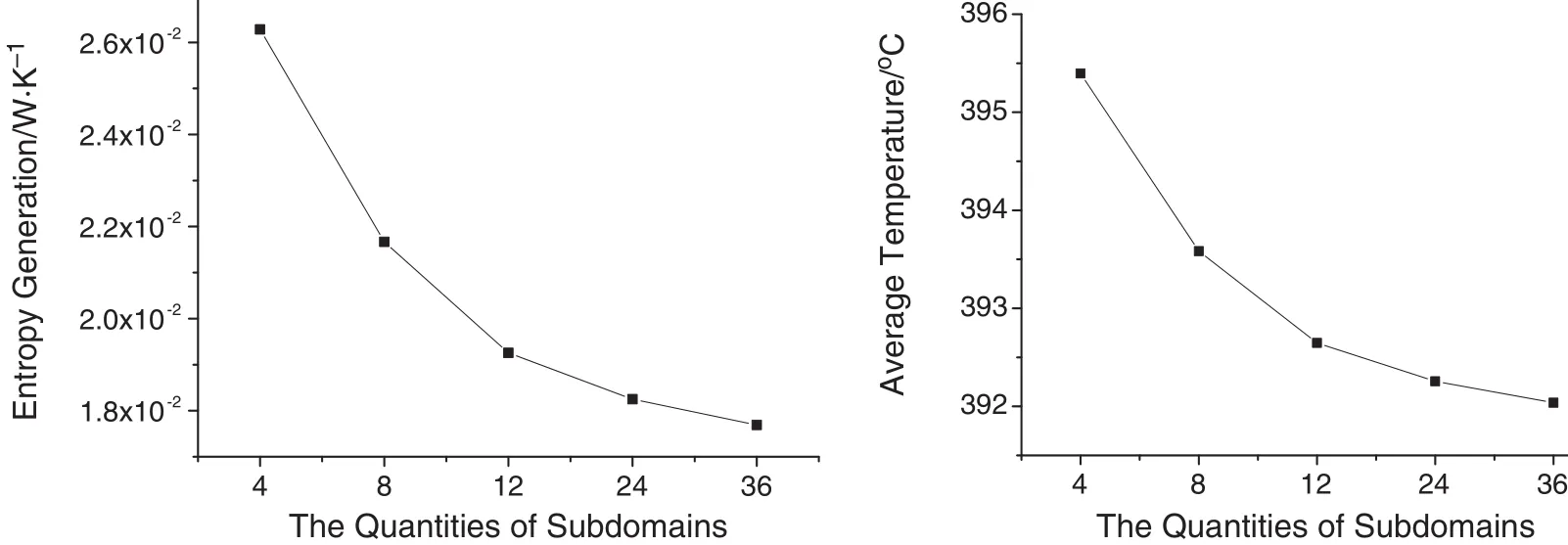

It is deduced that the subdomain division affects greatly the heat conduction rate optimization results.A smaller quantity of subdomains causes a coarse layout of materials and the heat dissipation cannot be optimized efficiently.A larger quantity of subdomains will generate an obvious rounding off error,so that the arrangement of material is far from the theoretically continuous layout.Therefore,the relationship between substrate optimization and subdomain quantity is studied.Fig.5 depicts the layout of materialin different subdomain quantity with radiation boundary conditions.The shape of high thermal conductivity material is different for different subdomain quantity.When the entropy generation in the substrate is compared,the difference between cases(4)and(5)is less than 2.8%,with the subdomain quantity of 24 and 36,respectively.The difference in average temperature is less than 1%,as shown in Fig.6.

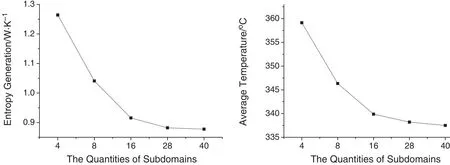

Fig.7 depicts the layout of high thermal conductivity material in different subdomain quantities with constant surface boundary conditions.The shape of material is clearly different for different subdomain quantity.When the entropy generation in the substrate is compared,the difference is less than 4.3%for subdomain quantity of 28 and 40.Their difference of the average temperature in the substrate between cases(3),(4)and(5)is less than 1%,as shown in Fig.8.

It is obvious that the shape of high thermal conductivity material is different for various boundary conditions.Substrate entropy generation and mean temperature decrease with the increase of subdomain quantity,while the heat transferrate is enhanced.In the numerical calculations,sufficient subdomains should be defined to enhance heat dissipation.However,excessive subdomains are not feasible in engineering and there is no obvious enhancement in the heat dissipation.Therefore,determination on the subdomain shape and quantity is necessary.With comprehensive consideration for optimization,the subdomain quantity in this paper is 24 for the radiation boundary condition and 28 for the constant surface temperature boundary condition.Proper subdomain quantity should be defined for different physical models and boundary conditions before further developments.

4.2.Comparison between the new algorithm and other algorithms

The evolution algorithm,which is widely accepted in the volume to point conduction problem,is also used in this paper for our physical model[18–20].The layout of high thermal conductivity material is shown in Fig.9.Since the layout for two kinds of boundary conditions is similar,the layout in Fig.9(a)is used here for the following comparison and analyses.

Fig.10 depicts entropy generation and temperature distribution with the variation of internal heat source for radiation and constant surface temperature boundary conditions.Here subscripts c,d,and e signify the continuous thermal conductivity algorithm,the algorithm of thermal conductivity discretization,and the evolution algorithm,respectively.T denotes the highest temperature and t is the mean temperature in the substrate.With the boundary conditions of radiation and constant surface temperature,the entropy generation from the algorithm of thermal conductivity discretization is smaller than that from the evolution algorithm and much closer to that from the continuous thermal conductivity algorithm.The maximum and average temperatures from the algorithm of thermal conductivity discretization are much lower than those from the evolution algorithm,so that this new algorithm is advantageous in the global optimization for volume to point conduction problems.

Fig.4.Subdomain division in two kinds of boundary conditions.

Fig.5.The layout of high conductivity material in different subdomains with radiation boundary conditions.

Fig.6.Variation of entropy generation and average temperature in the substrate with the quantity of subdomains for radiation boundary condition.

In the practical calculation,the iteration steps with the continuous thermal conductivity algorithm are much less than that with the evolution algorithm.For example,in the above-mentioned physical model,the filling rate of high thermal conductivity material is 10%and the grid number is 20 thousand.The iterative steps with the evolution algorithm are more than 2000 and those with the continuous thermal conductivity algorithm range from decades to hundreds depending on the error controlling factor.With the algorithm of thermal conductivity discretization,the iteration steps are same as those for solving continuous thermal conductivity layout.As for the calculation time,the continuous thermal conductivity algorithm requires several minutes,and the thermal conductivity discretization algorithm needs around 30 min,while the evolution algorithm needs about 40 h.Therefore,the new algorithm of thermal conductivity discretization shows great advantage in the calculation time.Such advantage is more obvious with the increase of grid number.It is favorable for determining practical layout of high thermal conductivity material with the new algorithm of thermal conductivity discretization.

Fig.7.The layout of high conductive materials in different subdomains with constant temperature boundary conditions.

Fig.8.Variation of entropy generation and average temperature in the substrate with the quantity of subdomains with constant surface boundary conditions.

Fig.9.The layout of high thermal conductivity material with the evolution algorithm.

5.Experimental Verification

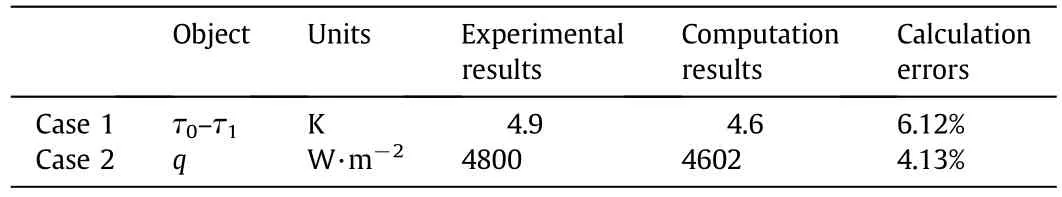

The experimental model in reference[21]is used here to verify the numerical simulation method.The volume to point heat conduction model in the experiment is shown in Fig.11(a).The length of the area is 0.2 m and the width is 0.1 m.There are one heat flux inlet and two heat flux outlets on the boundaries.Other place of the boundary is adiabatic.The thermal conductivity of high thermal conductivity material to be filled is 31 W·m-1·K-1,and the conductivity of substrate is 1 W·m-1·K-1.The electric conduction is introduced to simulate heat conduction in the experiment.Two boundary conditions are considered:in case 1,q0=2400 W·m-2,T1=T2=300 K;in case 2,T0=310 K,T1=T2=300 K.The filling rate of high conductivity material is 16%.The layout sketch of high thermal conductivity material in the experiment is shown in Fig.11(b).In the numerical simulations for verification,the substrate,high conductivity material layout,internal heat source distribution,and boundary conditions are identical with those in the experiment.The comparison between experimental results and numerical simulations with the new algorithm of thermal conductivity discretization is summarized in Table 1.For case 1,the item(T0–T1)is examined,and for case 2,the heat flux q is examined.As shown in Table 1,the numerical calculation results are close to experimental data and the calculation errors are in a reasonable range.Therefore,the new algorithm of thermal conductivity discretization proposed in this paper is acceptable and feasible.

6.Conclusions

(1)A novel algorithm of thermal conductivity discretization is proposed to deal with volume to point conduction problems.The comparison with the continuous thermal conductivity algorithm and evolution algorithm indicates that the new algorithm shows such advantages as high capability for global optimization,less calculation time,security and reliability.

(2)In the application of the thermal conductivity discretization algorithm,the division of subdomains plays an important role on the substrate optimization results.Therefore,it isnecessary to analyze and select appropriate quantity and shape of subdomains for different physical models and boundary conditions.

Table 1 Comparison between experimental results and numerical calculation results

(3)On the basis of the principle of minimum entropy production,optimized heat dissipation rate in the volume to point conduction problem is achieved for radiation boundary condition and constant surface temperature boundary condition.Related experimental results testify that the new algorithm is feasible and efficient in dealing with such volume to point conduction problems.

Nomenclature

A boundary

k thermal conductivity,W·m-1·K-1

M quantity of high thermal conductivity material in subdomain

m total quantity of high thermal conductivity material

N grid quantity in subdomain

n total grid quantity or the n th iteration

qiinternal heat source,W·m-2

Sgentropy generation,W·K-1

T temperature,K or°C

V volume of heat conduction

x,y gird coordinate in two dimensions

λ thermal conductivity,W·m-1·K-1

ε error controlling factor

Subscripts

c algorithm of continuous thermal conductivity

d algorithm of thermal conductivity discretization

e evolution algorithm

H material with high thermal conductivity

i index of point or subdomain

L substrate material with low thermal conductivity

n iterative step

Fig.11.Experimental physical model.

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- Effect of sub-layer thickness on magnetic and giant magnetoresistance properties of Ni–Fe/Cu/Co/Cu multilayered nanowire arrays☆

- Advanced nitrogen removal via nitrite from municipal land fill leachate using a two-stage UASB–A/O system☆

- A functional PES membrane for hemodialysis—Preparation,characterization and biocompatibility

- Comparison of steam-gasification characteristics of coal char and petroleum coke char in drop tube furnace☆

- Selective oxidation of methylamine over zirconia supported Pt-Ru,Ptand Ru catalysts☆

- Fabrication of superhydrophilic surface on copper substrate by electrochemical deposition and sintering process☆