Effects of Bi and rare earth metal on theMicrostructure and properties of Zn-based high-tem perature solder*

2015-09-05XingFeiQiuXiaomingWuAimingandWenYuhang邢邱小明吴爱明温宇航

Xing Fei,Qiu Xiaoming,Wu Aiming and Wen Yuhang邢 飞,邱小明,吴爱明,温宇航**

Effects of Bi and rare earth metal on theMicrostructure and properties of Zn-based high-tem perature solder*

Xing Fei,Qiu Xiaoming,Wu Aiming and Wen Yuhang

邢 飞,邱小明,吴爱明,温宇航**

A novel Zn-based high-temperature solderwas developed to join copper/steel atmoderate temperature.The effectsof Bi and rare earth metal on themicrostructures,wettability of solders aswell as themechanical properties of solder jointswere investigated.The results indicated that with the addition of Bi into Zn-Cu-Sn(ZCS)alloy,significant improvement in wettability is realized.When the content of Bi element is 1.5 wt.%in the solder,the spreading area researched over 200 mm2.Furthermore,with the addition of RE,refined primaryε-CuZn5phaseswere formed and the shear strength of the solder jointwas largely improved.

solder,high-temperature solder,wettability,mechanical properties,microstructure

0 Introduction

The development of innovative materials has been putting new request to the soldering technology and solders,especially functional materials whose microstructures and properties are sensitive to the changing of temperatures[1-3].When brazing thesematerials,the severe joining temperatures(>500℃)are always above the transition temperatures and will lead to themagnetic transformation and reduction of shape memory properties[3-4].In comparison with brazing,when soldering these functional materials(<350℃),the joining temperature and mechanical properties are usually far beyond the reach of the basic needs in production.Therefore,a novel high-temperature solder with melting temperature lies between 350 -500℃is urgently needed in soldering functionalmaterials.Furthermore,the multi-step joining of complicated parts,e.g.heavy truck copper radiator,also need various melting temperature solders to avoid the re-melt of seams.

In recent years,though a series of Zn-based hightemperature solders,which have a strong reaction with Cu in moderate temperature,have been investigated by some researchers,theworksmainly focus on the basic properties of high-temperature solders[5].The potential for further improvement in properties via micro alloying additions of Zn-based alloys is seldom researched in the literature.It is well know that Bi is a traditional active element,which is widely used in lead-free solders for depressing the melting temperature and bringing a pronounced improvement in wettability of solder joints[6-7].And rare earth metal (RE)is also used as alloying and purification ofmaterials and metamorphosis of inclusions[8-9].In this paper,Bi element and rare earth metal(RE)were selected to enhance the properties of Zn-based high-temperature solders.Thus,the aim of this study is to investigate the effects of Bi and RE alloying elements on the microstructures,wettability of solders as well as the mechanical properties of solder joints.

1 Experimental

Zn-based high-temperature solders were fabricated in nominal weight percent compositions.Pure zinc,copper,tin and bismuth weremelted in a vacuum arc melting furnace to produce Zn-based high-temperature solders,and they were subsequently cast into a quartzmolds for cooling.The weight lossesweremeasured to be less than 0.3wt.%.

Differential scanning calorimetry was used to determine the solidus temperatures and liquidus temperatures of solders.The samples were examined under a nitrogen atmosphere.The kinetic curing profilewas obtained by heating the formulated sample to a temperature of 500℃at a rate of 10℃/min.

The microstructures of Zn-based high-temperature solderswere examined by opticalmicroscopy and scanning electronmicroscopy.And the sampleswere etched in solutions(CrO3∶Na2SO4∶H2O=20 g∶1.5 g∶100 g)for five seconds.X-ray diffraction was used to determine phase composition.

Wetting tests were carried out in accordance with the Chinese national standard GB/T 11364-2008.The sampleswere cut into0.30 gweight,while the substrateswere high conductivity Cu of 40 mm×40 mm×0.3 mm.The spreading areaswere calculated using Auto CAD software,and the data after averaging valuewas used as the final results.In addition,a video-based contact anglemeter was used to measure the contact angle of solders on Cu substrate.After soldering,the shear strength of joints was carried out in an electronic universal testerwith a constant cross-head displacement rate of0.5mm/min,according to Chinese national standard GB/T 11363-2008.At least three samples were tested under each experimental condition.

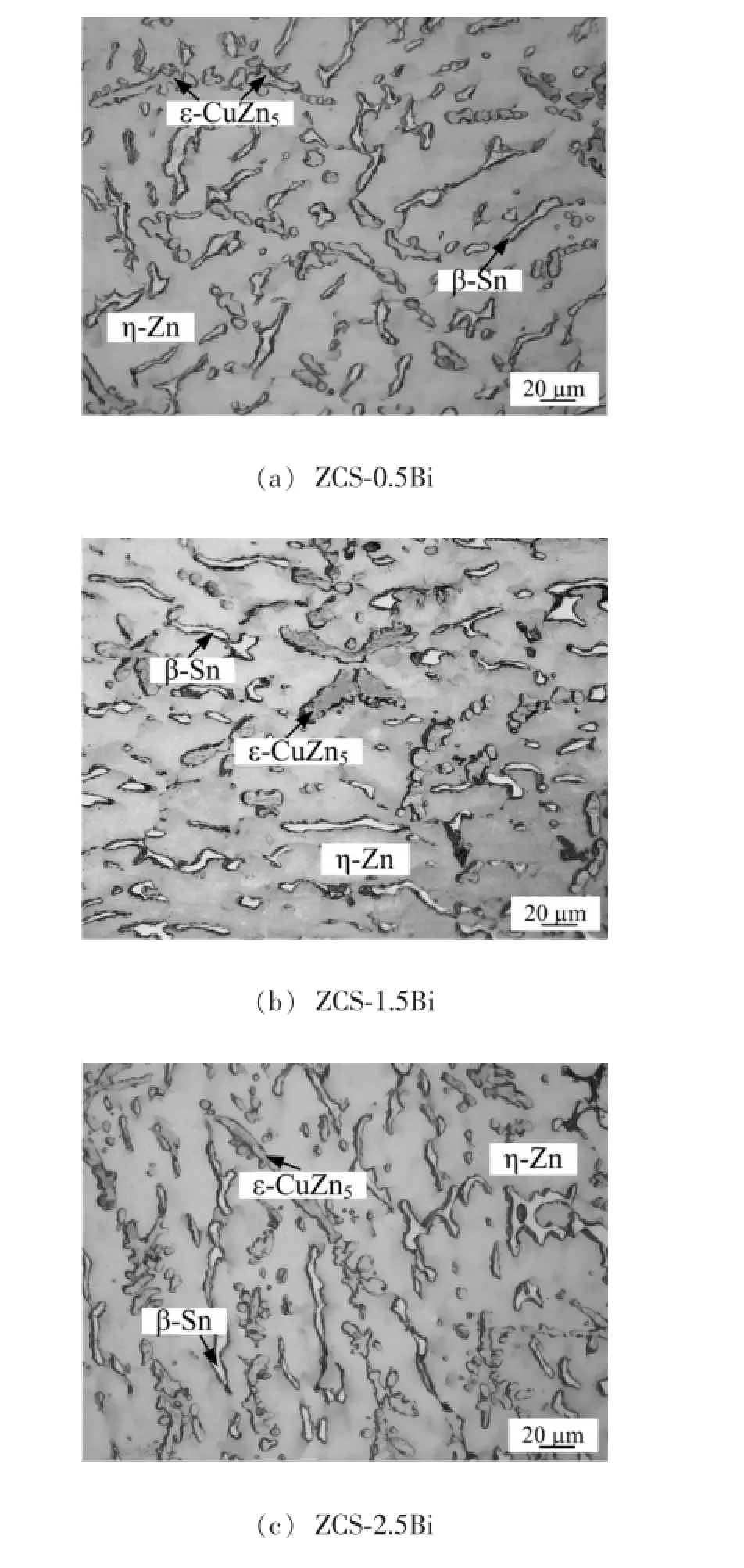

Fig.1 Microstructure of Zn-based high-temperature solder

2 Results and discussion

2.1Microstructure of Zn-based high-tem perature solder

Fig.1 shows the representativemicrograph of Zn-2Cu-5Sn-Bi(ZCS-Bi)high-temperature solders.And the X-ray analyses of corresponding Zn-based high-temperature solders are presented in Fig.2.

The microstructure of ZCS-0.5Bi solder consists of light grayη-Zn matrix,primary dendriticε-CuZn5,fiberlikeβ-Sn and white spherical Bi phases.With the addition of Bi increased from 0.5 wt.%to 1.5 wt.%in the ZCSB solder,the solidifiedmicrostructure exhibitsmore uniform microstructure,as shown in Fig.1b.

With the increase of Bi,the amounts andmorphology of Bi change obviously,while those of large spherical Bi phases increase.However,with the excessive addition of 2.5 wt.%Bi in the solder,Biphases become coarser and turn to chain shape,which needs to be on the alert.

The microstructure of Zn-2Cu-5Sn-1.5Bi-RE(ZCSBRE)is shown in Fig.3.In order to precisely determine the influence of rare earth metal(RE)on themorphology of grains,we analyzed themulti-phase number per area in randomly chosen locations of the fabricated ZCSB-RE solders.The average quantity percentages ofβ-Sn and refined ε-CuZn5crystals in solders were calculated.Comparedwith the presentofβ-Sn in ZCSB high-temperature solder,the percentages ofε-CuZn5crystals increased dramatically,almost twice the amount in ZCSB solder,from 20.8% to 52.5%.With the increase of RE,the amount ofε-CuZn5increase,which will directly affect the properties of the solders and joints.

Fig.2 XRD analysis of(a)ZCSB-0.05RE and (b)ZCSB high-tem perature solders

Fig.3 Microstructure of ZCSB-RE high-tem perature solder

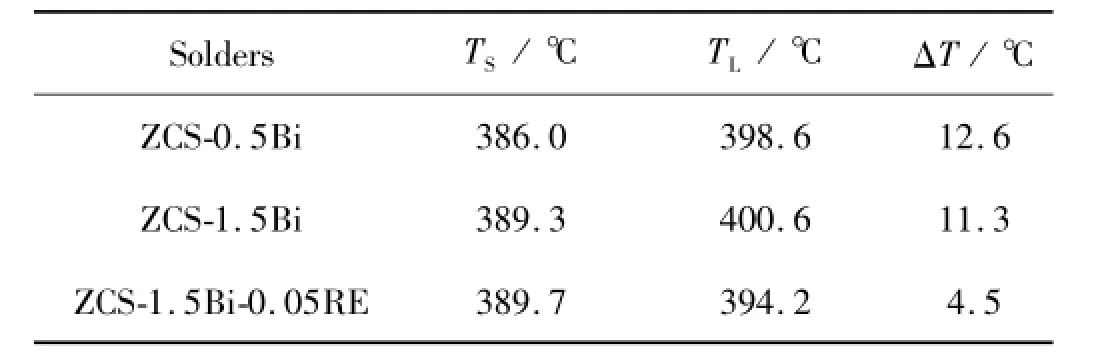

Fig.4 shows the DSC heating curves of Zn-based high-temperature solders.And the solidus temperatures (TS)and liquidus temperatures(TL)of Zn-based hightemperature solders are listed in Table 1.It is observed that the curves are similar,withmainly two peaks at about 180℃and 400℃,respectively,corresponding to the remelting ofβ-Sn andη-Znmatrix transformations.

Fig.4 The DSC curves and spread ing area of Zn-based high-temperature solders

Table 1 Thermal properties of Zn-based high-temperature solders

2.2 W ettability

Wettability of Zn-based solders with various Bi and RE were studied on Cu substrates.Without Bi in the ZCS alloys,the solders spread slowly in the soldering process,with the wetting area as small as102mm2.With the addition of small amount of Bi in the Zn-based solder,the wettability increased dramatically,with a clear wetting ring and the contact angle wasmeasured to be about7°.With the increase of Bi from 0 to 1.5 wt.%,the spreading area of ZCSB solders increased gradually,from 102mm2to 220 mm2.However,with the further increase of Bi,the spreading area decreased(Fig.4b).The addition of small amount of RE in ZCSB-RE solder greatly improved the spreading speed and it took only 5-10 s to reach wettability equilibrium.However the adding of RE has little effect on the spreading area.

As known in physical chemistry,the lower surface tension element in the solution will gather together in the surface,which is so-called adsorption.Because of the effects of adsorption phenomenon,the surface and internal composition of alloys is different,leading to the changing of liquid tension.The adsorption elements in alloys satisfy the relation[7,10],

where XSAis the density of element A in surface atomic layer,XAis average density of A in solid solution,ΔHASis the solution heat of A dissolved in element B andΔHVis the latent heat of evaporation.

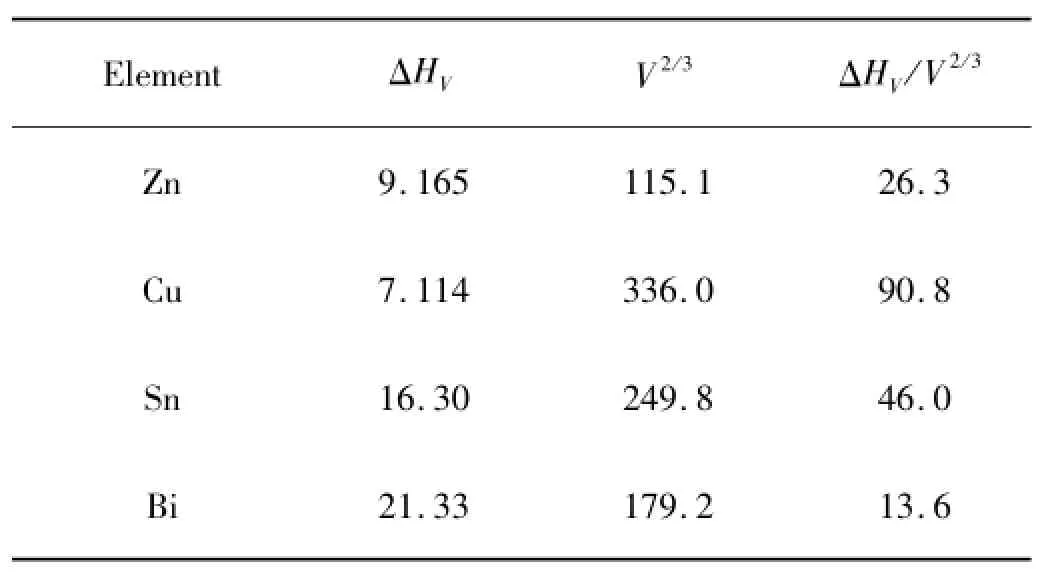

Based on the available thermodynamic data,ΔHV/V2/3of Zn,Cu,Sn and Bi elements is calculated and the results are listed in Table 2.

The elementwhich hassmallerΔHV/V2/3value is easier to gather in the liquid surface.As shown in Table 2,ΔHV/V2/3of Bi ismuch smaller than that of Zn,Cu and Sn.In addition,the diffusion of Bi is faster at moderate temperature in favor of the low melting point(231.89℃)of Bielement.So the addition of Bi to the solder alloy decreases the surface tension of the solders,which directly increases the wettability of ZCSB solder.Howeverwith the extensive increase of Bi content tomore than 1.5 wt.%in solders,the viscosity of alloys increase,leading to the decline of flowability of solders[12].As a result,thewettability of the high Bi content solders decrease.

Table 2 Thermal dynam ics parametersΔHV/V2/3[7,11]

2.3 Mechanical properties

The shear strength of ZCSB solder joint fluctuated with the increase of Bi.Differently,with the increase addition of RE,the shear strength of joints increased gradually,from around 28MPa to almost50MPa,as shown in Fig.5.Meanwhile,the elongation of the ZCSB-RE solder joints increased slightly compared with ZCSB solder joints.

The fracture surface of the shear test specimen is shown in Fig.6.As shown in Fig.6,cleavage plane is presented,which indicated the fracture surface had characteristics of brittle fracture(<3%).In the fracture of Cu/ZCSB-RE/Cu fracture surface,spherical particles having the brightest Z contrast can be seen in Fig.6a.The EDS analysis showed that large populations of disperse particles segregated in the grain and along grain boundaries are RE(including Ce and La elements)containing phases.It is known that the initiation ofmicro-cracks can be greatly influenced by the presence of second particles. However,if the particles are well bonded to the matrix,the resistance to crack of alloys can be largely improved. In the study,the ZCSB-RE containing small and spherical particles is more resistant to cracking.In addition,with the increase of RE in the solder,the primaryε-CuZn5was refined,which maybe the reason of higher shear strength of solder joints.

Fig.5 Effects of RE content on shear strength of solder joints

Fig.6 Fracture surface of ZCSB-RE and EDS analysis of ZCSB-RE high-tem peratu re solders joints

3 Conclusions

(1)The addition of Bi improved the wettability of ZCSB solders.When the content of Bi reached 1.5 wt.%, the spreading area is over 200mm2.

(2)The appropriate addition of RE favors the formation of refined primaryε-CuZn5phases.And significant improvement in themechanical properties of joints is realized.

References

[1] Rödel J,Jo W,Seifert K T P,et al.Perspective on the developmentof lead-free piezoceramics.Journal of the American Ceram ic Society,2009,92(6):1153-1177.

[2] Mathias B T,Remeika JP.Dielectric properties of sodium and potassium niobates.Physical Review,1951,82(5):727-729.

[3] Shirane G,Newnham R,Pepnsky R.Dielectric properties and phase transitions of NaNbO3and(Na,K)NbO3.Physical Review,1954,96(3),581-588.

[4] Li M G,Sun D Q,Qiu X M,et al.Effects of laser brazing parameters on microstructure and properties of TiNi shape memory alloy and stainless steel joint.Materials Science and Engineering A,2006,424(1-2):17-22.

[5] Qiu X M,Xing F Ma F,et al.A novel middle-temperature ranged Zn-based solders to joining copper/steel and their preparationmethods.ZL 201110341677.8,2013-10-16. (in Chinese)

[6] Liu Z L,Wang F,Qiu D,et al.The effect of solute elements on the grain refinement of cast Zn.Metallurgical and Materials Transactions A,2013,44(9):4025-4030.

[7] Wu W Y,Qiu X M,Yin SQ.Influence of Bi,Ag onmicrostructure and properties of Sn-Zn lead-free solder.The Chinese Journal of Nonferrous Metals,2006,16(1):158-163.(in Chinese)

[8] Guessoum K,Veys-Renaux D,Rocca E,et al.Corrosion behaviour of zinc-cerium alloys:role of intermetallic phases. Corrosion Science,2011,53(5):1639-1645.

[9] Aramaki K.Treatment of zinc surface with cerium(III)nitrate to prevent zinc corrosion in aerated 0.5 M NaCl.Corrosion Science,2001,43(11):2201-2215.

[10] Lin Q Z.Physical chemistry.Beijing:Beijing Normal University Press,2000.(in Chinese)

[11] Shi L.Thermodynamics of alloys.Beijing:China Machine Press,1992.(in Chinese)

[12] Iida T,Guthrie R IL.The physical properties of liquid metals.Oxford:Clarendon Press,1988.

*The research is supported by the Program for the Development of Science and Technology of Jilin Province(Grant No.20115003).

**Xing Fei,Qiu Xiaoming,Wu Aiming and Wen Yuhang,Key Laboratory of Automobile Materials of Ministry of Education,School of Materials Science and Engineering,Jilin University,Changchun,130025. Qiu Xiaoming,Corresponding author,E-mail:qiuxm13@163. com

猜你喜欢

杂志排行

China Welding的其它文章

- Stress-strain characteristics of linear friction welding of TC11 and TC17 alloys*

- Effects of C/B4C ratio on Microstructure and property of Fe-based alloy coatings reinforced w ith in situ synthesized TiB2-TiC*

- Numerical analysis of keyhole establishment time in keyhole p lasma arc welding*

- Effect of pulse frequency on hardness characteristics of Al-Cu alloy HPVP-GTAW joints*

- Automatic defect detection in ultrasonic TOFD D-scan data using image processing m ethods*

- Analysis of grain grow th in hybrid weld HAZ based on the coupled thermo-fluid model