Comparative Study of the Impact of Two Types of Natural Dyes and Synthetic Dyes on the Fabric Comfort Level

2015-06-27FirstAuthorLiuYushiWangYuqiu

First Author: Liu Yushi, Wang Yuqiu

(Culture Club of Beijing No.4 High School)

Advisor: Yun Song

Second Author: Deng Ruoyu, Pan Yuan Li Tianxue, Li Xiuzhi, Chen Yueting, Wang Ruowei, Yao Jingyu, Qian Yangyang

Comparative Study of the Impact of Two Types of Natural Dyes and Synthetic Dyes on the Fabric Comfort Level

First Author: Liu Yushi, Wang Yuqiu

(Culture Club of Beijing No.4 High School)

Advisor: Yun Song

Second Author: Deng Ruoyu, Pan Yuan Li Tianxue, Li Xiuzhi, Chen Yueting, Wang Ruowei, Yao Jingyu, Qian Yangyang

In order to research whether the Natural Dyes areremarkably different from the chemical dyes in practical application, four experiments relating to the fabric comfort degree were selected for operation and a social survey experiment was also conducted. The research was conducted from the two perspectives of scientific tests and subjective judgments. Through the scientific tests and social survey, it was concluded that the impact of Natural Dyes and that of Synthetic Dyes have little difference towards the fabric comfort degree, but there are still some findings need to be noticed through the conclusion.

Synthetic Dyes; Natural Dyes; Comfort Level; Color Fastness; water repellency; sustainable development

Preface

The environmental problems have been affecting the life quality of people in the world nowadays. As a result, a large number of people have been paying more and more attention to the sustainable development. The increase of attention drives more people consider to use natural dyes, which sounds conform to the sustainable development concept, to take the place of synthetic dyes, which can greatly affect the nature. D J Hill pointed that the reason people prefer to select natural dyes might be resulted from the comprehensive consideration of many advantages of natural dyes including that they might sound more green and environment protective or look more comfortable or that only because the idea is innovative1. However, azo dyes, a kind of synthetic dyes, is the kind with the most diversified categories and its aspects of color distribution and Color Fastness are considered more superior than those of natural dyes2. The differences of performances, of course, is the conclusion resulted from laboratory tests, and whether it could have remarkable impact in its practical application in life still remains unknown. The objective of this experiment was to, by comparison of the differences of natural dyes and synthetic dyes on color fastness and water repellency performance the differences of these two dyes on their actual comfort level performances, further research the necessity of inheritance and the development prospect of natural dyes.

To quantify the concept of “Comfort Level,” the project studied the difference between Synthetic Dyes and Natural Dyes from the two aspects of chemical experiment and social survey. In accordance with the relevant national standard and other scientific datas, the experiment mainly focused on the study of five aspects including the color fastness (Color Fastness to washing with soap, Color fastness to water and Color fastness to rubbing) of dyeing of fabrics, water repellency, staining degree, softness degree and static electricity resistance. Make scientific analysis of the achieved data with application of statistics after the normative experiment operation, and then study the impact of the two dyes toward fabric comfort level from two perspectives of objective and subjective aspects.

Color fastness to soaping of the fabric means the color fastness of printed and dyed cotton pieces against washing with soap solution, i.e. emulsification and Color stripping effect generated by soap solution towards dyes on printed and dyed cotton pieces, including the color fading of original sample and staining on white cloth. Evaluate the tested specimen according to the Grey Scale for Assessing Staining3, make comments on the color fastness to soaping of the fabric. Color fastness to water means the degree of change in color and the degree of staining of the diversified fiber cloths caused by the process that colored fabric be soaked in water together with diversified fiber cloths for a certain period of time and then be processed under certain conditions. When we say“losing color” in daily life, it usually means that the color fastness to water of dyed fabric is inferior. Therefore the color fastness to water of the printed and dyed cotton pieces is also a key index to evaluate the performance of a fabric. Color fastness to rubbing means the degree of the fabric color staining on other fabrics after rubbing. Since the friction would always be generated between the clothing and different materials during daily wearing, therefore the color fastness to rubbing of clothing is a significant index to evaluate the fabric performance. Water repellency performance means the capacity of fabric to prevent the water molecule from passing through. Comments on water repellency performance can be made through comparison of the specimen appearance and description of wetting phenomenon the wetting degree of the fabric can be determined. Water repellency of the fabric is also very important to evaluate the fabric performance. On the other hand, in order to study the impact of synthetic dyes and natural dyes toward the comfort degree of fabric from the perspective of subjectivity, a survey of fabric comfort level by human body practical senses was conducted. Compare the differences between naturally dyed fabrics and chemically dyed fabric on comfort degree using the data obtained in the survey of subjective feeling from survey takers. The combination of subjectivity of the social survey objectivity of chemical experiment section made the conclusion more convincing.

Experiment Section

I.Process and Result of the Experiment

1.Test of Color fastness to soaping

Four types of printed and dyed cotton pieces were selected for the test of Color fastness to soaping: Cape jasmine dyed fabric (Naturally Dyed Yellow Fabric), Indigo dyed fabric (Naturally Dyed Blue Fabric), Azo dyed Yellow fabric (Synthetic Dyed Yellow Fabric), and Azo dyed Blue fabric (Synthetic Dyed Yellow Fabric) with each type for 2 pieces with the size of 100mm*40mm to conduct the experiment. Two sides ofthe Specimen were stitched with white wool fabric and white cotton fabric with the same size of the Specimen. Weight the quality of Specimen, calculate the quality of soap solution needed as per the proportion of 1:5 (soap solution is similar to be affirmed to be equal with the water density), and deploy 1 liter of solution with 5g soap flakes. Weight 5g soap flakes and pour them into a beaker with 1 liter of water to heat up and stir until they are totally dissolved. After that, put the specimens into 8 small steel cylinders respectively and put the steel cylinders into testers for dye color fastness to soaping for 30 minutes. 30 minutes later, get the specimens out and wash them in deionized water and squeeze out the excessive water. And then put the specimens between two pieces of filter paper to squeeze out the water and hang them in indoor normal pressure and temperature for airing; remove the stitches, evaluate the color fading of original sample and the color change of white cloth4.

Fabric Quality (g) Staining (White Cotton Fabric)Staining (Wool Fabric)Color Change (Specimen )Naturally Dyed Blue Fabric #12.166108.31 4 4-5 1-2Naturally Dyed Blue Fabric #22.200110.02 4 4-5 1-2Naturally Dyed Yellow #12.160108.03 4 4-5 1Naturally Dyed Yellow #22.300115.04 4 4-5 1Synthetic Dyed Yellow #12.275113.85 2-3 4-5 4-5Synthetic Dyed Yellow #22.173108.76 2 4-5 4Synthetic Dyed Yellow #12.070103.57 1-2 4-5 2-3Synthetic Dyed Yellow #22.225110.38 1-2 4-5 2-3

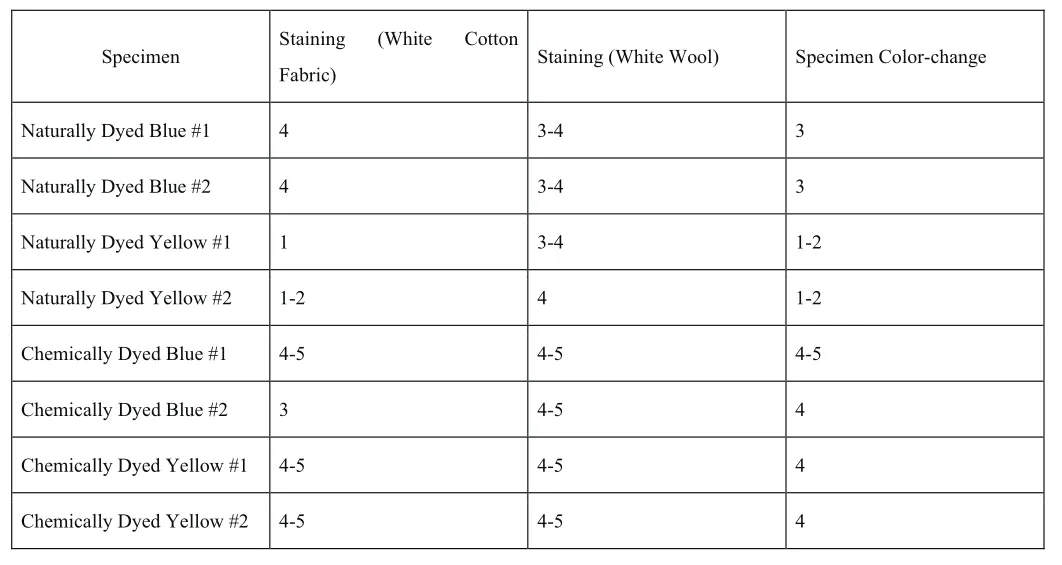

2.Test of Color fastness to Water

Four types of printed and dyed cotton pieces were selected for the color fastness to water: Cape jasmine dyed fabric (Naturally Dyed Yellow Fabric), Indigo dyed fabric (Naturally Dyed Blue Fabric), Azo dyed Yellow fabric (Synthetic Dyed Yellow Fabric) and Azo dyed Blue fabric (Synthetic Dyed Yellow Fabric) with each type for 2 pieces to conduct the experiment. After stitching the test sample fabrics (40mm*100mm) to be tested together with accompanying fabric (a piece of white wool fabric and a piece of white cotton fabric with the same size of the test sample fabrics), put 8 pieces of specimens into different metal cans respectively, and add defined amount of deionized water into the cans respectively; use a glass rod to completely immerse them and turn them around. After that, use a tweezer to fetch out each specimen from each metal can and use two glass rods to squeeze out the water in the specimens and put them on the perspiration fastness tester; cover each specimen with resin and punch and press to fix it; keep the specimen on perspiration fastness tester with a pressure of 12.5kPa. Then, put this device into the Electric drying oven with a temperature of 37°C for 3 hours. Finally, spread the specimen to air them ensuring the specimens are connected with the accompanying fabrics stitched on two sides by only a thread5. After the desiccation, according to the judgment standard of ISO105/A02-1993 Grey Scale for Assessing Staining2, the smaller the color change grade value obtained from the comparison of the fabric and the accompanying fabric is, the severer color change and staining degree will be, and this will indicate the worse the color fastness to water of its corresponding dye type.

Specimen Staining (White Cotton Fabric) Staining (White Wool) Specimen Color-change Naturally Dyed Blue #1 4 3-4 3 Naturally Dyed Blue #2 4 3-4 3 Naturally Dyed Yellow #1 1 3-4 1-2 Naturally Dyed Yellow #2 1-2 4 1-2 Chemically Dyed Blue #1 4-5 4-5 4-5 Chemically Dyed Blue #2 3 4-5 4 Chemically Dyed Yellow #1 4-5 4-5 4 Chemically Dyed Yellow #2 4-5 4-5 4

3.Test of Color Fastness to Rubbing

Four types of Printed and Dyed Cotton Pieces were selected for the test of color fastness to rubbing: Cape jasmine dyed fabric (Naturally Dyed Yellow Fabric), Indigo dyed blue fabric (naturally dyed blue fabric), chemically dyed fabric (chemically dyed yellow fabric), chemically dyed blue fabric (chemically dyed blue fabric), each type for a dry and a wet piece for the experiment. Firstly, prepare 2 groups of 80mm*250mm specimen fabrics and take the dry fabric group for experiment first. After wetting for 4 hours under standard atmosphere, fix the specimen on the platform, and make the length direction of the specimens in line with the friction head motion direction; place a piece of abrasive paper between the platform and the specimen. Spread the cotton friction fabric (50mm*50mm) which was also wetted on the friction head with a weight of about 10N on it, and make the warp direction of the friction fabric in line with the motion direction of the friction head, and then rub the specimen with a speed of one/second for circulation. Then take the other group of wetted friction fabrics and completely immerse them into distilled water to make water content of them reach 95%-100%, and repeat the above steps of the dry fabrics. Put each group of specimens after the experiment together with friction fabrics, evaluate the staining or color change friction fabric or specimen with the grey scale for color assessment6.

Specimen Staining Degree Naturally blue wet 1-2 Naturally blue dry 3 Naturally yellow wet 2-3 Naturally yellow dry 5 Synthec blue wet 3 Synthec blue dry 4-5 Synthec yellow wet 2-3 Synthec yellow dry 4-5

4.Water Repellency Test

Four types of Printed and Dyed Cotton Pieces were selected for the experiment of water repellency analysis test: Cape jasmine dyed fabric (Naturally Dyed Yellow Fabric), Indigo dyed blue fabric (Naturally Dyed Blue Fabric), Azo dyed yellow fabric (chemically dyed yellow fabric) and Azo dyed blue fabric (chemically dyed blue fabric) with each type for 1 piece to conduct the experiment with the minimal size of 180mm*180mm.

According to the illustration of Spray System in Figure [3]assemble the experiment equipments; clamp the specimenwith the holder with the specimen right side up, and the warp direction of the fabric or length direction parallel with the water flow direction. Pour 250ml experimental water into the funnel to spray for 25-30 seconds. Take away the holder with the held specimen, put the fabric face down and horizontal, and tap the holder toward a solid object, and after the 180° horizontal rotation of the holder, tap the holder again. Finally, rate the wet degree of the front face of the specimen according to GB/T 4745-2012 National Standard Wetting Degree7, which states the wetting phenomenon with the levels 0-5 from totally wet of the specimen surface to no water drops or not wet on the specimen surface.

Note for the experiment equipments: Spray system is comprised by a funnel with a diameter of 150mm and a metal nozzle. There are 19 well distributed holes with the diameter of 0.86mm on the metal nozzle, after the infusion of 250ml water, continue the operation of the spray system between 25-30 seconds. The funnel is connected to the nozzle with a rubber test tube with a caliber of 10mm, and from the top of the funnel to the bottom of the nozzle is the 195mm specimen holder.

5.Social Survey

Fabric Weng Degree Naturally dyed blue fabric 1 Naturally dyed yellow fabric 1 Synthec dyed blue Fabric 1 Synthec dyed yellow fabric 1-2

In order to test the impact of different kinds of dyes on the comfort level of fabric, a social survey is carried out on campus. The questionaire includes five questions, which focus on color, static electricity resistance,and softness. Questionaires are filled in mainly by teachers and students. The respondents get four clean pieces of cloth, by which errors caused by pollution will be eliminated. Moreover, the respondents are required to make evaluation based on 10-point scale, a method may lead to a more precise result. Also, in the questionaire, illustrations are provided, which may help the respondents make more precise decision when filling in the questionaires. 76 pieces of questionaries are sent out, and 56 pieces are retrieved. The retrieved questionaires are analyzed by applying Pair T-test, using SAS9.2 operating system.

All the results from Pair T-test are below 0.5, which refers that the reponses of the respondents towards natually dyed and synethetic dyed cloth have no significant differences.

II. Data Analysis

III. Conclusion and Discussion

Integrate the four scientific tests and the social survey with 76 participants, the conclusion of the experiments is that natural dyes have little difference with synthetic dyes on practical application. In addition, there are still some findings need to be noticed: in the test of color fastness to water, by comparing the histogram it can be concluded that the synthetic dyed fabrics of the two colors are both superior to those of naturally dyed fabrics. However, in other two color fastness test experiments the synthetic dyed fabrics and naturally dyed fabrics have their own advantages respectively.

By observing the data obtained from the test of color fastness to soaping, thought synthetic dyed fabrics have obviously higher color change grade than naturally dyed fabrics of the same color, but as for the staining grade of white cotton fabric, naturally dyed fabrics is obviously higher than synthetic dyes. Generally, though natural dyes destain easily, in comparison with synthetic dyes it is hard to stain other fabrics. Additionally, fabrics of different colors resulted in different conclusions in the color fastness to rubbing experiment; the color fastness to rubbing staining grade of naturally dyed blue fabric is lower than that of synthetic dyed fabrics, but the color fastness to rubbing staining grade of the naturally dyed yellow fabrics is similar with synthetic dyed fabrics of the same color; because in test of color fastness to rubbing naturally dyed yellow fabric, in comparison with synthetic dyed yellow fabric, the staining grade of dry white cotton fabric is higher while that of wet white cotton fabric is low, and it can be concluded that the colors also havesomething to do with the fabric color fastness.

Beside the experiment findings, from the perspective of human health, natural dyes might be a better choice. It was reported by PhoenixNet that in November 2012, a latest survey by an international environmental agency named Greenpeace International shows that there are 20 global fashion brands applied poisonous and harmful coloring agents in their production process of garments, among them are international brands including Armani, CalvinKlein, Esprit, Gap, H&M, Marks&Spencer, Only, TommyHil-figer, Vancl, Veromoda, Victoria’s Secret, and Zara, etc. Abusive poisonous and harmful coloring agents will be gradually released to the skin of the wearer in daily wearing, and when the release amount exceeds a certain limit, the wearer will be infected with the upper respiratory tract inflammation and scytitis; and this is also a kind of allergen which might lead to skin allergy and even affect the internal organs and even might lead to cancer8. Therefore, it is with evidence to say that the synthetic dyes have certain toxicity and is possible to harm the human health. Synthetic dyes is toxic to a large extent because most of them are the extractive of coal tar; while to the contrary, most of the natural dyes are from plants and animals, e.g. the Cape jasmine dye applied in this experiment is obtained from immersed in water for 12 hours after the fruit of Cape jasmine is dried, therefore they are rarely toxic.

Finally, from the perspective of sustainable development, synthetic dye liquor process has always been criticized that the ingredient is complicated and the toxicity is hard to be clarified, therefore any pollution discharge or accidentally leakage will lead to the water pollution. In December 2012 an incident of human bodily injury of local residents was reported to be caused in large areas by household waterconsumption with water pollution, Shanxi Tianji Coal Chemical Industry Group Co., Ltd., which is located in Lucheng city, Changzhi City, Sanxi, was reported an aniline leakage accident caused by the broken conveying hose. And this accident led to the stop of drinking water for human and livestock along the watercourse of Shanxi and Hebei. Though after the urgent repair of nearly a month and the water pollution was temporally controlled, elements including aniline were still detected for exceeding standard in some part of water body including the Hongqi Canal. The aniline leaked in this incident is the raw material to manufacture many kinds of synthetic dyes9. Hence, any improper handling of toxic synthetic dye solution will result in irreparable damage to the nature and human body. While the natural dyes have superior advantage in this aspect, because they come from plants or animals, the natural dye solution does not need complicated treatment that most of them can be easily disposed by merely simple burying without damage the ecological environment.

It is widely believed that the natural dyes are hard to put into industrial production, therefore the efficiency is low and there would be hardly any possibility of future development; and if conversely, synthetic dyes will be put into industrial production massively, therefore it will be easier to use in nowadays. But the fact is far from this; recently, with the development, the manufacture and application of natural dyes have been greatly improved. Natural dyes are also put into industrial production, and have been manufactured and applied massively in Europe. And among them, natural dyes are greatly promoted in the application of textile. Rubia Pigmenta Naturalia in Netherlandish and Couleurs de Plantes in France will respectively extract liquid or powder coloring agents from natural plants for the manufacturing with the similar process of synthetic dyes10. As a result, the future development prospect of natural dyes is quite promising. In comparison with the current expensive manufacturing cost, the manufacturing process of natural dyes is gradually standardized and the manufacturing cost is gradually reduced annually. While from the prospective of ecological environment, the natural dyes also occupy the significance of long-term development with its non-pollution advantage.

Acknowledgement

This paper was accomplished under the guidance of my Advisor Yun Song. He devoted great attention and effort in the paper from the topic selection, experiment design to the composition. We hereby express our gratitude and respect.The success of accomplishment of this paper shall also thank to the support and help from Jiang Yuqiu, teacher of Beijing Institute of Clothing Technology, and teachers of the chemical laboratory for providing instruments, materials for the experiments of this paper and guidance in the operation. Thank all the classmates participated in our social survey and teacher Yang Qianlin who paid continuous attention to us.

Thanks again to all the teachers, parents and classmates who cared about and helped us!

Reference

1Hill, D. J. (1997), Is there a future for natural dyes?. Review of Progress in Coloration and Related Topics, 23 Oct. 2008. Web. 04 Aug. 2015.

2"Azo Dyes."Chemistry of Dyes. N.p., n.d. Web. 04 Aug. 2015.

3ISO 105/A02-1993. China Standardization Publishing House1993. n.d. Jul 30, 2015.

4ISO, CNS GB/T 3921-2008. China Standardization Publishing House 2008. n.d. Feb 12, 2015.

5ISO, CNS GB/T 5713-1997. China Standardization Publishing House1997. n.d. Feb 12, 2015.

6ISO, CNS GB/T 3920-2008. China Standardization Publishing House 2008. n.d. Feb 12, 2015.

7ISO, CNS GB/T 4745-2012. China Standardization Publishing House 2012. N.d. Feb 12, 2015.

8"Zara等20个品牌被曝含毒 专家解惑少穿亮色服装-时尚呼吸-北方网."北方网. Ed. Linsongzi Zhang. Enorth.com, 23 Nov. 2012. Web. 03 Aug. 2015.

9"山西长治苯胺泄漏."网易新闻. 网易, 31 Dec. 2012. Web. 04 Aug. 2015.

10Cardon, Dominique. "Natural Dyes, Our Global Heritage of Colors."Digitalcommons. University of Nebraska-Lincoln, 01 Jan. 2010. Web. 04 Aug. 2015.