Assessment of neutron-irradiated 3C-SiC implanted at 800 ℃

2015-06-09EngelbrechtDeyzelMinnaarGoosenVanRooyen

J. A. A. Engelbrecht,G. Deyzel,E. G. Minnaar,W. E. Goosen,I. J. Van Rooyen

(1.Physics Department,Nelson Mandela Metropolitan University, Port Elizabeth 77000,South Africa; 2.High Resolution Electron Microscopy Facility,Nelson Mandela Metropolitan University, Port Elizabeth 77000,South Africa; 3.Fuel Performance and Design Department,Idaho National Laboratory, Idaho Falls 1625,USA)

Assessment of neutron-irradiated 3C-SiC implanted at 800 ℃

J. A. A. Engelbrecht1,2,G. Deyzel2,E. G. Minnaar2,W. E. Goosen2,I. J. Van Rooyen3

(1.Physics Department,Nelson Mandela Metropolitan University, Port Elizabeth 77000,South Africa; 2.High Resolution Electron Microscopy Facility,Nelson Mandela Metropolitan University, Port Elizabeth 77000,South Africa; 3.Fuel Performance and Design Department,Idaho National Laboratory, Idaho Falls 1625,USA)

The favourable physical properties of SiC make it a potential material for use as containment layer in new generation nuclear reactors. The material will thus be exposed to high temperatures and fluences from fission products. The impact of increasing neutron fluence at constant irradiation temperature (800 ℃) on the properties of neutron-irradiated 3C-SiC was investigated, employing infrared reflectance spectroscopy and atomic force spectroscopy. A relation was found between the neutron fluence and the surface morphology of the irradiated 3C-SiC. The varying surface morphology also affected the dielectric parameters of the SiC.

3C-SiC; neutron-irradiation; infrared reflectance spectroscopy; morphology

Introduction

The threat of global climate change is forcing humankind to give more serious attention to alternative supplies of energy. In particular, such sources of energy should also reduce harmful carbon emissions[1]. Much attention has thus been focussed on generation processes termed “green” such as wind, solar, hydro and nuclear energy[2-3]. While safety concerns remain about nuclear energy plants, this source of energy has the best long-term solution in terms of both a low carbon footprint and sustainability[4-5]. Currently a new type of nuclear reactor, viz. the generation IV reactors, is being investigated. These reactors use triple-coated isotropic (TRISO) layers to contain the radioactive uranium nuclear kernel. 3C-SiC is considered to be one of the most suitable materials to use as containment layers in the TRISO particles[6]. As such, the material is expected to be subjected to high fluences of various nuclear fission particles, as well as to various temperatures during the operation of the nuclear reactor. Consequently, several investigations into the effects of nuclear fission products on SiC have been performed[7-15]. The research also included analysis of SiC material doped through implantation by various dopants such as Al, C, Ge[16-20]and implantation by particles such as electrons, protons and4He[21], but these investigations were mainly on 4H and 6H SiC.

This investigation reports on the analysis of 3C-SiC wafers irradiated with fast neutrons at an irradiation temperature of 800 ℃ with various fluences. Fourier transform infrared (FTIR) reflectance spectroscopy, nonlinear regression computer curve fitting procedures and atomic force microscopy (AFM) were employed in the assessment. The goal was to investigate the influence of the irradiation on the optical properties of the 3C-SiC samples.

1 Theoretical aspects

The theoretical expressions used in this study are based on the work by Holm, et al,[22]and Kroon[23], where the interaction of incident radiation with a solid is described by means of the complex dielectric functionε, given by

(n-ik)2=ε′+iε″

(1)

The reflectanceRis expressed in terms of this complex dielectric function as

(2)

ThedielectricparameterscontainedinEq. (1)canthusbeextractedbyobtainingabestfitbetweenanexperimentallyobtainedreflectanceandthetheoreticallysimulatedspectra.

2 Experimental procedure

Samplesof3C-SiCintheshapeofdiscswereirradiatedatanirradiationtemperature800 ℃;atfluencesrangingfrom5×1019n/cm2to7.7×1021n/cm2.IrradiationofsampleswasdoneattheOakRidgeNationalLaboratory(ORNL),USA.ABruker80VFTIR/Ramanspectrometer,fittedwithaPike10Specspecularreflectionunitenablingnear-normalincidence,wasemployedtoobtaininfraredreflectancespectrafromsamplestaking100scansataresolutionof8cm-1.ExpressingthereflectivityRintermsofthecomplexdielectricfunctionε (Eqs. (1)and(2)),oneisabletoextractsixdielectricparametersrelatedtothematerialanalysed.Anonlinearregressionstatisticalsoftwarepackage,BMPD®,wasemployedforcomputercurvefittingtoobtainthebestfitbetweentheoryandexperiment.SurfaceroughnessofthesampleswasmeasuredusingaCSMinstrumentsnano-indenter,fittedwithanatomicforcespectroscope.Sampleareasofsize25×25μm2wereanalysedbyatomicforcemicroscopyonthenano-indenter,whichyielded,interalia,therootmeansquare(RMS)ofthesamplesurfaceroughness.

3 Results and discussion

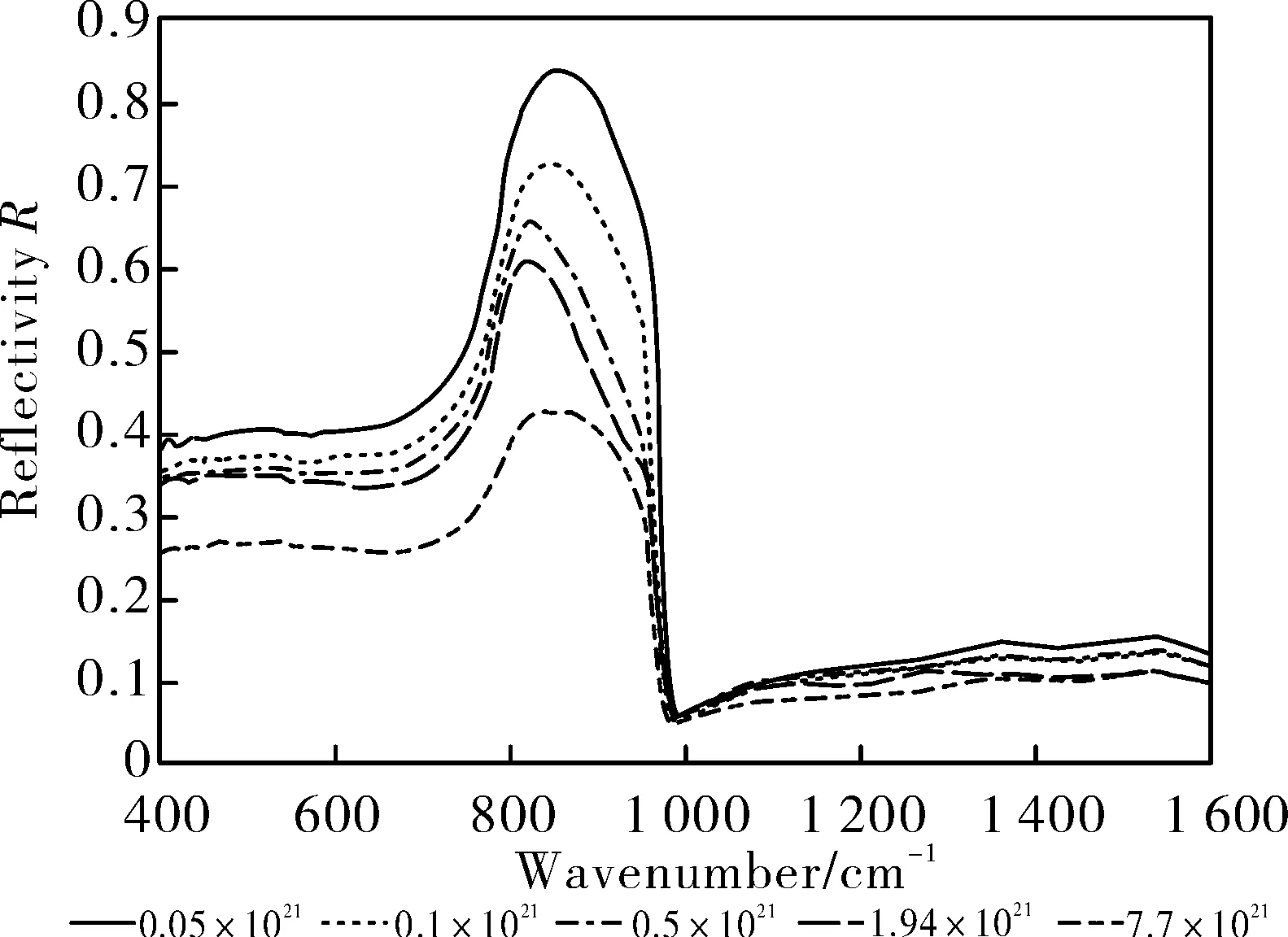

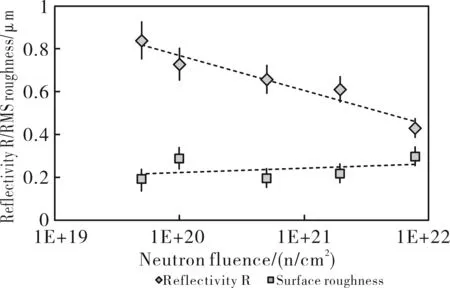

ThevariationofinfraredreflectivityasfunctionofirradiationfluenceisdepictedinFig.1,indicatingthatthereflectivitydecreasesastheirradiationfluenceincreased.

Fig.1 Change observed for infrared reflectivity of samples subjected to increasing irradiation fluence

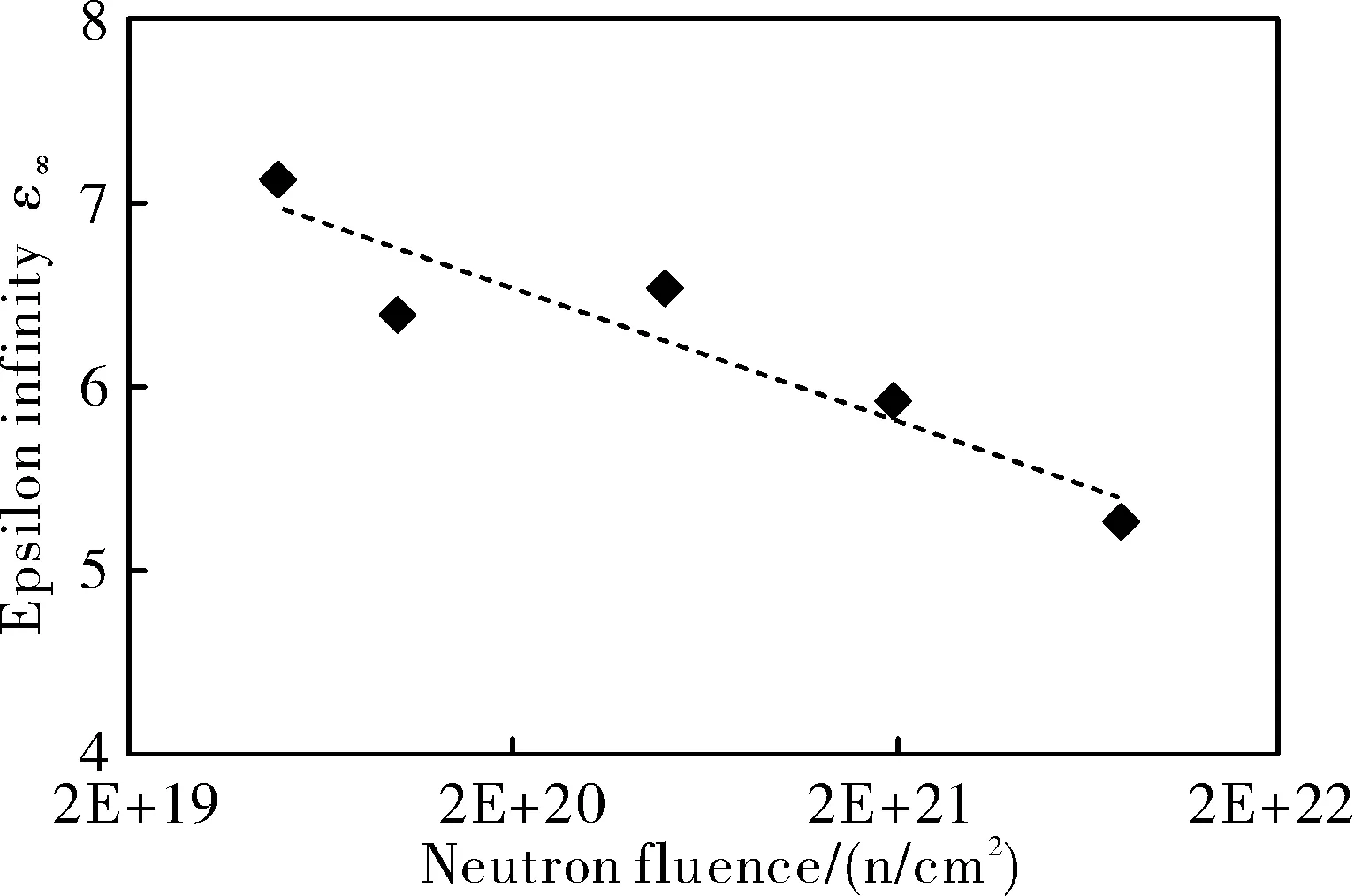

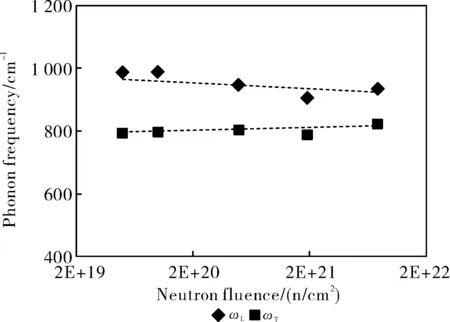

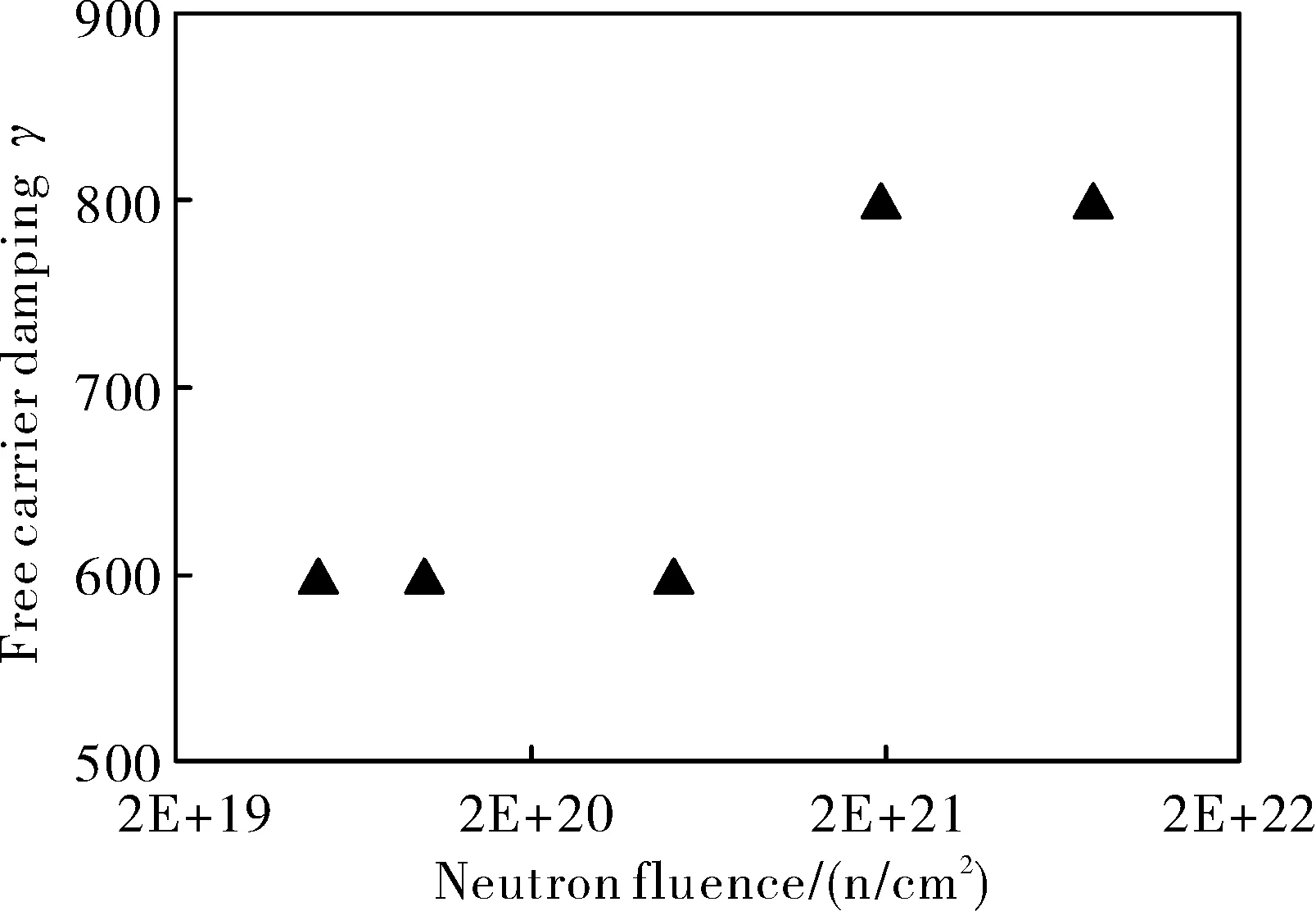

This implies that radiation was scattered from the sample surfaces, as the reflectivity decreases, as was observed earlier for single-side polished Si wafers[24]and GaAs samples with intentionally damaged surfaces[25]. Variations in the obtained dielectric parameters with irradiation fluence further confirmed the observation, as is clear from Figs. 2 ~6.

Fig. 2 Variation of high frequency dielectric constant ε∞ with increasing fluence. (Dotted line is a guide to eye)

Fig.3 Changes in phonon damping constant Γ with fluence

Fig.4 Mininal variation for longitudinal (ωL) and transverse (ωT) phonon frequencies

Fig.5 Changes in free carrier damping constant γ with fluence

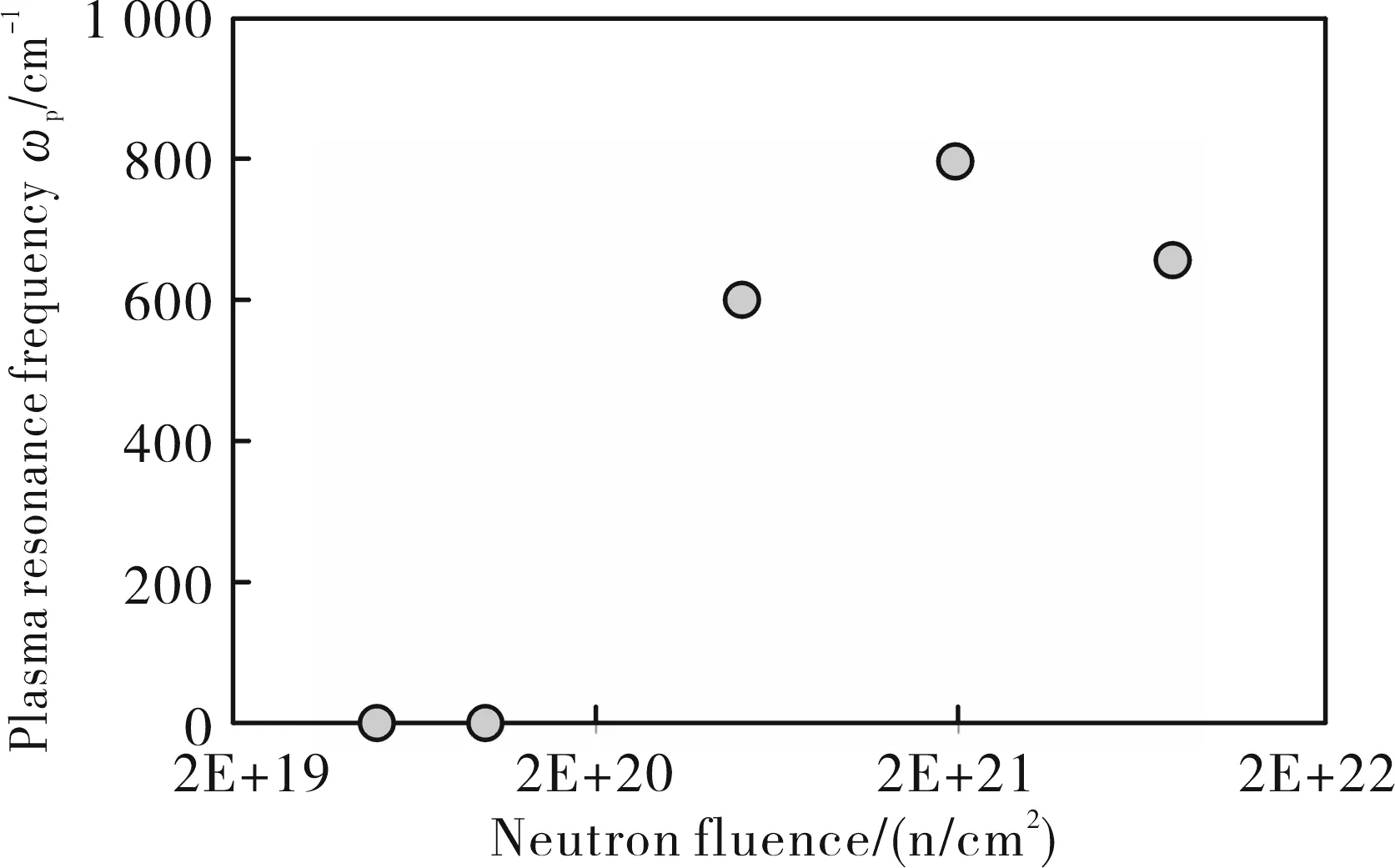

Fig.6 Variation of plasma resonance frequency ωp

The variation in the free carrier concentrationγand the plasma resonanceωp(Figs. 5 and 6) could be expected that with higher fluences the free carriers might increase and hence thatωpwill change accordingly. However no proof of similiar observations could be found in previous research in this field. More work is hence required on these observations.

It has been reported that variations in dielectric parameters are linked to the surface morphology[24]. The current results agree with the previous findings on irradiated 3C-SiC samples at irradiation temperatures between 200 ℃ and 400 ℃[26]. The variation of the RMS surface roughness of these samples were determined, and are presented in Fig. 7 and Table 1, together with the variation in reflectivity R. The relation between maximum reflectance and fluence can be expressed in terms of the logarithmic fit between the two quantities as depicted in Fig.7, as

Reflectivity R=-0.701 ln(Fluence)+4.0383

(3)

Fig.7 AFM surface roughness and reflectivity as function of neutron fluence

Table 1 Fluences and RMS surface roughness of specimens analysed

SamplenumberFluence/(×1021n/cm-2)Totalbecquerel/BqRMSsurfaceroughness/μm150.05120.19160.1240.29180.51190.20201.94620.22197.76500.29

However, at this stage the reason for the change in surface morphology is not clear, and this aspect requires further investigation. It is possible that the sample surface is modified according to the inelastic thermal spike model[27], but this needs to be verified by electron microscopic investigations.

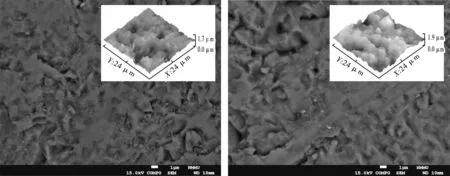

A more quantitative measure was obtained when analysing the sample surfaces with SEM and AFM, as shown in Fig. 8.

Fig.8 SEM micrographs of (L) lowest and (R) highest neutron fluence at 800 ℃, with insets of associated AFM measurements

It is concluded from assessment of results obtained from the whole set of samples that the variation in dielectric parameters can be linked to irradiation fluence, and is most likely due to increased surface damage with increasing fluence.

Acknowledgements

The financial assistance of the National Research Foundation (NRF), South Africa is most gratefully acknowledged. Any opinion, findings and conclusions or recommendations expressed in this article are those of the authors, and therefore the NRF does not accept liability in regards thereto. Technical assistance by E.G. Minnaar is greatly appreciated.

[1] Myles R A, Frame D J, Huntingford C, et al. Warming caused by cumulative carbon emissions towrds trillionth tonne [J]. Nature, 2009, 458:1163-1166.

[2] Lund H. Renewable energy strategies for sustainable development [J]. Energy, 2007, 32(6):912-919.

[3] Borchers A M, Duke M J,Parsons G R. Does willingness pay for green energy differ by source? [J]. Energy Policy, 2007, 35(6):3327-3334.

[4] Vaillancourt K, Labriet M, Loulou R,et al. The role of nuclear energy in long-term climate scenarios: An analysis with the World-TIMES model [J]. Energy Policy, 2008, 36(7):2296-2307.

[5] Menyah K, Wolde-Rufael Y. CO2emissions, nuclear energy, renewable energy and economic growth in the US [J]. Energy Policy, 2010, 38(6):2911-2915.

[6] Wacholz W. The present state of the HTR concept based on experience gained frm AVR and THTR [J]. International Working Group on Gas-Cooled Reactors, IWGGCAR, 1998, 19:61-70.

[7] Snead L L, Jones R H, Kohyama A,et al. Status of silicon carbide composites for fusion [J]. J. Nucl. Mater., 1996, 233-237:26-36.

[8] Snead L L, Zinkle S J, Hay J C,et al. Amorphization of SiC under ion and neutron irradiation [J]. Nucl. Instr. and Meth., 1998, B 141:123-132.

[9] Snead L L, Osborne M C, Lowden R A, et al. Low dose irradiation performance of SiC interphase SiC/SiC composites [J]. J. Nucl. Mater., 1998, 253(1):20-30.

[10]Snead L L, Hay J C. Neutron irradiation induced amorphization of silicon carbide[J]. J. Nucl. Mater., 1999, 273(2):213-220.

[11]Katoh K, Hashimoto N, Kondo S, et al. Microstructural development in cubic silicon carbide during irradiation at elevated temperatures [J]. J. Nucl. Mater., 2006, 351(1-3):228-240.

[12]Kondo S, Katoh Y, Snead L L. Microstructural defects in SiC neutron irradiated at very high temperatures [J]. J. Nucl. Mater., 2008, 382(2):160-169.

[13]Katoh Y, Kondo S, Snead L L. Microstructures of beta-silicon carbide after irradiation creep deformation at elevated temperatures [J]. J. Nucl. Mater., 2008, 382(2):170-175.

[14]Kondo S, Katoh Y, Snead L L. Unidirectional formation of tetrehedral voids in irradiated silicon carbide[J]. Appl. Phys. Lett., 2008, 93(16):163110-1 -163110-3.

[15]Katoh Y, Nozawa T, Snead L L, et al. Stability of SiC and its composites at high neutron fluence[J]. J. Nucl. Mater., 2011, 417(1-3):400-405.

[16]Satoh M, Miyagawa S, Kudoh T, et al. Annealing effect on characteristics of p+n 4H-SiC diode formed by Al ion implantation [J]. Mat. Sci. Forum, 2009, 600-603:023-1026.

[17]Nagano M, Tsuchida H, Suzuki T,et al. Formation of extended defects in 4H-SiC induced by ion implantation/annealing [J]. Mat. Sci. Forum, 2009, 615-617:477-480.

[18]Ottaviani L, Biondo S, Morata S, et al. Influence of heating and cooling rates of post-implantation annealing process on al-lmplanted 4H-SiC epitaxial samples[J]. Mat. Sci. Forum, 2010, 645-648:717-720.

[19]Lee K K, Laird J S, Ohshima T, et al. Current transient effect in N-channel 6H-SiC MOSFET induced by heavy ion irradiation[J]. Mat. Sci. Forum, 2010, 645-648:1013-1016.

[20]Kups T, Tonisch K, Voelskow M,et al. Structure and lattice location of Ge implanted 4H-SiC[J]. Mat. Sci. Forum, 2009, 600-603:623-626.

[21]Yan F, Devaty R P, Choyke W J, et al. New lines and issues associated with deep defect spectra in electron, proton and 4He ion irradiated 4H SiC[J]. Mat. Sci. Forum, 2010, 645-648:411-414.

[22]Holm R T, Gibson J W,Palik E D. Infrared reflectance studies of bulk and epitaxial-film n-type GaAs [J]. J. Appl. Phys., 1977, 48(1):212-223.

[23]Kroon R E. The classical oscillator model and dielectric constants extracted from infrared reflectivity measurements[J]. Infrared Phys. Technol., 2007, 51(1):31-43.

[24]Engelbrecht J A A, Kulkarni M V. Semi-quantitative measurement of wafer surface roughness via infrared spectroscopy [J]. IBM Tech. Discl. Bull., 1982, 24:6060-6034.

[25]Engelbrecht J A A, Hashe N G, Hillie K T,et al. The apparent effect of sample surface damage on the dielectric parameters of GaAs [J]. Physica B, 2007, 401(4):238-241.

[26]Engelbrecht J A A, Deyzel G, Minnaar E G, et al. The influence of neutron-irradiation at low temperatures on the dielectric parameters of 3C-SiC[J]. Physica B, 2014, 439(15):169-172.

[27]Toulemonde M, Dufour C,Paumier E. The ion-matter interaction with swift heavy ions in the light of inelastic thermal spike model [J]. Acta Physica Polonica A, 2006, 109(3):311-322.

1002-2082(2015)06-0937-05

2015-03-10;

2015-08-31

南非NRF基金

Jacobus Engelbrecht(1948-),男,南非人,博士,教授,主要从事红外反射光谱技术、材料光学表性等方面的研究工作。E-mail:Japie.Engelbrecht@nmmu.ac.za

TN304

A

10.5768/JAO201536.0604001

OCIS Codes:160.6000;230.3240;270.0270;300.6210