How to Develop Rubber Production in Xishuangbanna Dai Autonomous Prefecture?

2015-02-06HuideHUANGHaolunHUANGWanzhenZHANG

Huide HUANG,Haolun HUANG,Wanzhen ZHANG

1.Institute of Scientific and Technical Information,CATAS,Danzhou 571737,China;2.CATAS,Haikou 571101,China

1 Current situation of rubber production in Xishuangbanna Dai Autonomous Prefecture

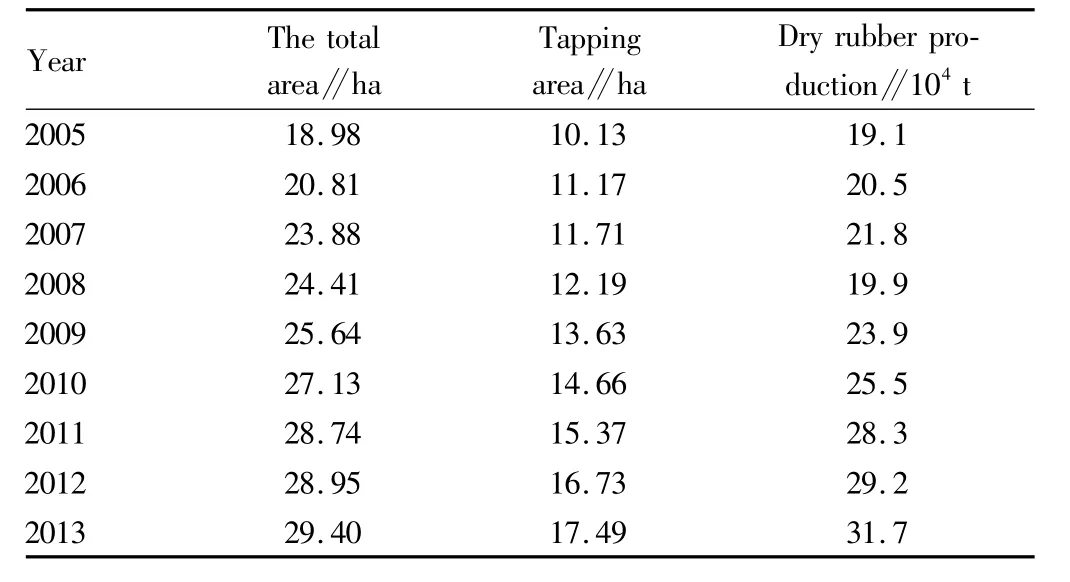

1.1 Rubber cultivationChina's main rubber growing areas are in Hainan Province and Yunnan Province.In 2011,the rubber planting area of Yunnan Province was largest in China,exceeding that of Hainan Province[1],and the rubber planting area of Xishuangbanna Dai Autonomous Prefecture was largest in Yunnan Province.The rubber planting of Xishuangbanna Dai Autonomous Prefecture is distributed in 12 farm management committees,27 towns and 1302 village groups in the prefecture.There are more than 120000 rubber growersand 150000 people directly engaged in the rubber industry,involving agricultural population of about 500000.The natural rubber planting area in Xishuangbanna Dai Autonomous Prefecture accounts for about30%of rubber planting area in China.At the end of 2013,the rubber planting area was 29.4 ha in Xishuangbanna,the tapped rubber plantation area was 17.49 ha,and the dry rubber production was 317000 t.In farmers' per capita net income of 7107 yuan in the prefecture,2413.4 yuan is from natural rubber,with the contribution rate of 34%.The rubber area and production in Xishuangbanna Dai Autonomous Prefecture during 2005-2013 are shown in Table 1.

1.2 Rubber productionIn 2008,there were 136 initial processing factories of natural rubber in Yunnan Province,including 54 state-owned land-reclamation factories and 82 private factories[2].In 2013,there were 57 enterprises engaged in the production and operation of rubber in the prefecture,and 98 rubber factories,with the annual production capacity of650000 t.The main production varieties include standard rubber series,special rubber tire series and so on.There were 7 tire rubber production and processing enterprises,1 smoked sheet factory,20 quality control offices,and 11 registered trademarks.Currently,the rubber production and processing enterprises in Xishuangbanna include Xishuangbanna Zhonghua Rubber Co.,Ltd.,Jingyang Rubber Co.,Ltd.,Guangken Group,Haijiao Group,Shunda Co.,Ltd.,Jingmeng Rubber Co.,Ltd.,Gaoshen Rubber Co.,Ltd.,and Longxin Co.,Ltd.

Table 1 The area and yield of natural rubber in Xishuangbanna during 2005-2013

2 The problems in rubber production

2.1 Declining level of production and management in rubber plantationIn June 2010,Xishuangbanna Dai Autonomous Prefecture began territorial management reform,and the state owned farms were managed by local areas;subsequently,there was a gap in the management organization.Due to the negligence of managers at all levels in rubber plantation production technology management,the efficient production technology measures are not well implemented,leading to a decline in the rubber plantation production management level and yield.At the same time,the tapping technical inspection work can not be carried out properly,and various policies and measures are difficult to implement,especially for the fertilization management in the rubber plantation.If the farms do not offer fertilizers,employees will not fertilize the rubber plant,leading to lower and lower rubber production.

2.2 Backward tapping techniqueIn terms of tapping technique,it underwent an overall decline during the first half of 2014.The average score of tapping technique was-14.3;the lowest score of technique was-1177.0;the highest score was 91.5.The tapping techniques reaching 70 points or more accounted for only17.9%;the tapping techniques reaching more than 90 points accounted for only 2.4%;the tapping techniques reaching less than 0 point accounted for 63.1%.The extra-deep tapping was universal in the84 tasks surveyed,and ultra-deep tapping accounted for 72.6%.The cutting face was scarred and the trees were severely damaged,as shown in Table 2.In terms of bark consumption during tapping,the task with excessive bark consumption accounted for 85.7%among the 84 tasks,and the tapping depth and bark consumption can be seen in Table3.The cutting surface planning is universally in disorder and the flow area is overlapped.The upward and downward tapping lines are arbitrarily extended,and even the rubber trees are tapped in a single spiral or multiple spirals.The rubber trees are in a state of high-intensity rubber discharging for many years.In some tasks,even one rubber tree is tapped in multiple lines.

Table 2 Statistics of injuries to trees

Table 3 Tapping depth and bark consumption

2.3 Difficulties in implementing the tapping technology management systemAfter the reform on the state-owned farm in Xishuangbanna,the former state farm workers became residents,and most of the rubber plantations undertaken by residents now fail to implement the standard technology management system.The rubber plantation independently operated by farmers in Xishuangbanna lacks unified technical management systems,and there is great randomness in the planting management.Some use the cultivation and management techniques learned in the past state farms,while some conduct planting randomly or based on their experience.The tapping system is mostly traditional system of one knife two days.In the private tapping work,there are also some rubber farmers adopting"one knife one day"and other high intensity methods for tapping.Due to improper tapping technique,the rubber trees are badly scarred by some rubber farmers.According to a county's survey,it is found that the regenerated skin of about half of the rubber trees can not be tapped,eventually causing serious economic losses[3].

3 Recommendations for the development of rubber production in Xishuangbanna

3.1 Improving the operation and management level of rubber industryUnder the current management system,the management personnel of the production team and resident group tap the rubber trees that they contract every day,lacking time for the grass-roots management.Therefore,it is necessary to strengthen the production management theory and management practice training for the grass-roots management personnel of production team and resident group,and strengthen management work;make measures to ensure that the grass-roots management personnel implement various policies and management measures from higher authorities to improve the operation and management level of rubber industry.

3.2 Organizing the rubber production teamGood tapping technique can make the production period of rubber trees last for more than 30 years,while poor tapping technique will cause the production period to be less than10 years.Therefore,the Ministry of Agriculture and the relevant rubber management departments pay special attention to rubber tapping technique,and carry out the technical training and technical competition among the rubber workers,in order to improve the technical level of the rubber worker team,improve tapping efficiency and prolong economic life of rubber trees.It is necessary to improve the overall quality of the majority of rubber farmers,and organize a new well-educated and skilled rubber farmer team,to fully play the dominant role of rubber farmers in rubber industry development.There is also a need to develop effective policies and measures to encourage and support the migrant workers to return home to join rubber production team,and give full play to their important role in the construction of the rubber industry.

3.3 Developing new rubber farmer cooperativesThe new farmer cooperatives,the nonprofit rural organizations between government and the market,assume the functions of managing rural social and economic affairs.It is necessary to strengthen the professional skill training within cooperatives.The government should give special technical training funds and special subsidies for introduction and promotion of agricultural science and technology achievements;give subsidies and credit support for the production facility construction of cooperatives.It is also necessary to develop new rubber farmer cooperatives to enhance the ability to resist market risks;provide professional and technical training to constantly improve the quality of rubber farmers;conduct unified purchase of production materials to reduce farmers' production costs and perform unified marketing of products to reduce transaction costs;change the small-scale production into large-scale production through the new rubber farmer cooperatives to improve the operation and management level of rubber industry.

[1]YE L,LIYP,LIUYQ,etal.Analysis on current development situation and countermeasure of natural rubber industry[J].Guangdong Agricultural Sciences,2014,41(4):68-73.(in Chinese).

[2]LIU JZ,CHEN JX.Suggestion on natural rubber industry in Yunnan[J].China Tropical Agriculture,2010,2(33):16-19.(in Chinese).

[3]ZHENG JP,LIR.China's private rubber industry:Current situation,problems and suggestions[J].Beijing Agriculture,2013(27):9.(in Chinese).

杂志排行

Asian Agricultural Research的其它文章

- Empirical Study on Formation Path of Fam ily Farms in Different Environments from the Perspective of ANT

- An Empirical Analysis of the Factors Influencing the Cooperative Relationship between Broiler Processing Enterprises and Broiler Raisers

- Prediction of Coal Consumption in China Based on the Partial Linear M odel

- Relation between Rural Financial Development and Rural Economic Grow th:A Case Study of Yunnan Province

- A Study of Regional Brand Positioning Strategy for Linhai Orange Based on Soft Laddering

- Evaluation of Arable Land Reserve Resources and Analysis of Restrictive Factors:A Case Study of Hangjin Banner in Inner Mongolia