Study on Preparation,Characterization and Comminution Mechanism of Nano-sized CL-20

2015-01-28GAOHanLIUJieHAOGaziXIAOLeiQIAOYuJIANGWeiLIFengsheng

GAO Han,LIU Jie,HAO Ga-zi,XIAO Lei,QIAO Yu,JIANG Wei,LI Feng-sheng

(National Special Superfine Powder Engineering Research Center of China,Nanjing University of Science and Technology,Nanjing 210094,China)

Introduction

2,4,6,8,10,12-Hexanitro-2,4,6,8,10,12-hexaazaisowurtzitane(CL-20),as a very excellent nitramine explosive with higher heat of detonation,detonation velocity and detonation pressure than hexahydro-1,3,5-trinitro-1,3,5-triazine(RDX)and 1,3,5,7-tetranitro-1,3,5,7-tetrazocine (HMX),can be used in composite modified double-base propellants (CMDB)[1-4],gun propellants[5]and plastic bonded explosives(PBX)[6-8].However,the micron-sized CL-20is very sensitive,and explosion would easily happen during production,processing,transportation,etc,which seriously restricts its actual applications.Researches have shown that the sensitivities of nitramine explosives are obviously affected by the particle sizes and their distributions[9-11].The sensitivities of nitramine explosives are cut down effectively by reducing the particle sizes,and if the nano-sized particles were obtained,the sensitivities would be greatly decreased[12-13].The nano-sized nitramine explosives can be generally prepared by solvent/nonsolvent method[14-15]and supercritical fluid method[16-17].However,it is scarcely possible to produce nano-sized CL-20in large-scale owing to the small capacity of material processing,the complicated technological parameters,and the bad reproducibility of experiments.

In this study,nano-sized CL-20is produced by 500gram per batch by controlling the material concentration,grinding time,rotation speed and grinding media filling volume of a welldesigned bi-directional rotation mill[18-19].At the same time,the comminution mechanism during the nanocrystallization process of CL-20is analyzed.It is very potentially expectable to promote the large-scale production and application of nano-sized CL-20.

1 Experiment

1.1 Materials and instruments

Micron-sized CL-20 with d50=40-60μm,produced by Qingyang Chemical Industry Corporation of China;polyoxyethylene sorbitan oleate dehydration (Tween-80), Sinopharm Chemical Reagent Limited Corporation.

The Malvern Master Sizer Micro and Zetasizer 3000 HS laser particle size analyzer;S-4800ⅡScanning Electron Microscope(SEM),Hitachi High-Technologies Corporation;Advance D8X-ray Diffractometer,Bruker.

1.2 Production of nano-sized CL-20

Micron-sized CL-20is suspended in water containing 1%(mass fraction)Tween-80 as the surfactant with the mass fraction of 15%.

The micron-sized CL-20is addressed 500g one time and its suspension is put into the bi-directional rotation mill for 4h,of which the axle and the barrel are rotating reversely and simultaneously.The rotation speeds of the axle and the barrel are controlled at 120r/min and 70r/min,respectively.The filling volume of grinding media is controlled at 70%.During comminution process,the machine is cooled down by the cycling water.The pulverized slurry is freezingly dried and the yield is 96%-98%.

1.3 Sensitivity tests

The friction sensitivities of micron-sized and nano-sized CL-20 are measured by sliding friction test at 2.45MPa.Fifty times of tests are carried out to obtain the mean explosion probability.

The impact sensitivities are measured by drop-hammer test and characterized by the characteristic heights50(50%probability of initiation),which are separately statistically calculated by 25effective test values obtained by using a 2.5kg drop-hammer.

The small scale gap test is selected to measure the shock sensitivities.In these tests,the donor charge is made from RDX refined by acetone,with a density of 1.48g/cm3,the gap material is polymethyl methacrylate polymer,and the acceptor charges have the densities of 1.80g/cm3.The inside diameter and the length of charges are 5.10mm and 5.45mm,respectively.The gap thicknesses(δ)are calculated by 25effective values.

2 Results and Discussions

2.1 SEM images and particle size distributions

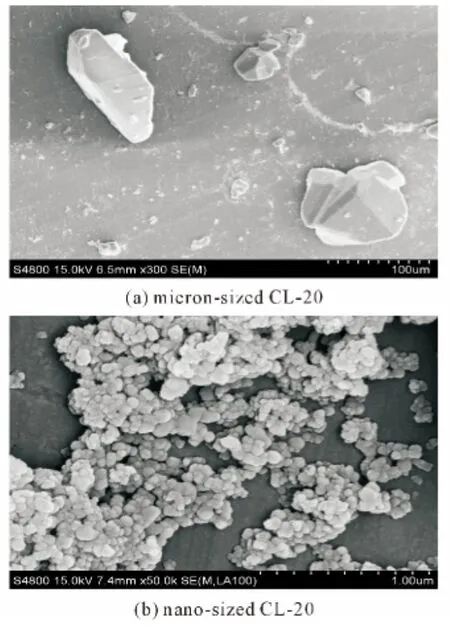

The SEM images and particle size distributions of CL-20 samples are shown in Figs.1and 2.

Fig.1 SEM images of micron-sized and nano-sized CL-20

Fig.2 Particle size distributions of micron-sized and nano-sized CL-20

As shown in Figs.1and 2,the micron-sized CL-20is polyhedral,irregular and heterogeneous,with an average particle size of 49.29μm and a wide size distribution.The nano-sized CL-20 produced by comminution is semi-spherical and homogeneous,with an average particle size of 50-80nm and a narrow size distribution,which states that the crushing force field applied by the bi-directional rotation mill is sufficient.With good crushing effect and narrow particle size distribution,batch production of nano-sized CL-20can be achieved.

The XRD patterns of micron-sized and nano-sized CL-20are shown in Fig.3.

Fig.3 XRD patterns of micron-sized and nano-sized CL-20

As shown in Fig.3,the X-ray diffraction peak positions and shapes of nano-sized CL-20are the same with those of the micron-sized CL-20,and they are entirely corresponding with those of the standard spectrum PDF#00-050-2045.It means that the crystal form of CL-20is maintaining epsilon (ε)without any chemical changes happening after the micron-sized particles are comminuted to be nano-sized.

2.2 Sensitivities

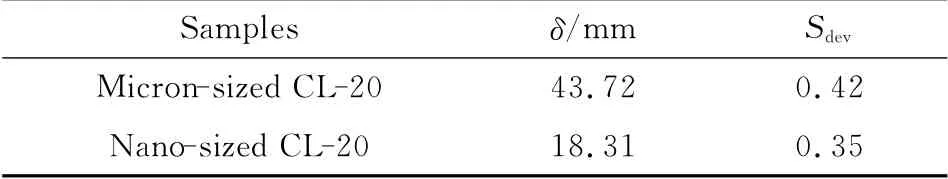

The friction,impact and shock sensitivities of CL-20are tested and presented in Tables 1and 2,respectively.

Table 1 Impact sensitivities of micron-sized and nano-sized CL-20

As for the friction sensitivity test,compared with the micron-sized CL-20,the average explosion percentage of the nanosized CL-20,which characterizes the fiction sensitivity,has changed from 88%to 66%,lower by 22% when the standard was taken at 80°and 2.45MPa.It means that the friction sensitivity has been reduced 25.0%after the micron-sized CL-20was comminuted to be nano-sized particles.

Table 2 Shock sensitivities of micron-sized and nano-sized CL-20 samples

As listed in Table 1,the characteristic drop height of nanosized CL-20is 15.8cm higher than that of micron-sized CL-20.Additionally,the standard deviation (Sdev)of the nano-sized sample is smaller than that of the micron-sized sample,which means better detonation stability under impact after the micronsized CL-20is pulverized to be nano-sized.

As listed in Table 2,compared with the micron-sized CL-20,the gap thickness(δ)of the nano-sized CL-20is 25.41 mm thinner,which means that the shock sensitivity of the nanosized sample is 58.1%lower than that of micron-sized CL-20.The Sdevvalue of the nano-sized sample is smaller than that of the micron-sized sample,which states that the detonation stability under shock is better if the micron-sized CL-20is smashed to be nano-sized.Nano-sized CL-20 has dense structure,smooth surface and regular shape.With high plastic yield strength,it′s not easy to produce adiabatic compression and viscoelastic deformation,and the mutual friction between the particles is small,the probability of hot-spot is greatly reduced.

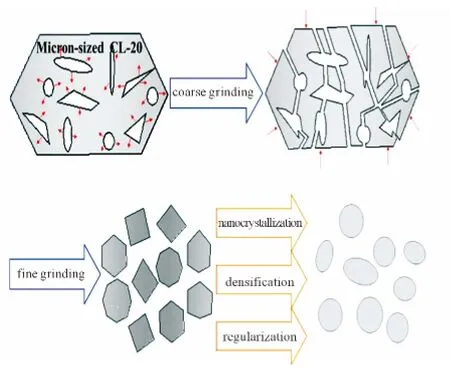

2.3 Comminution mechanism analysis

The comminution process of micron-sized CL-20is shown in Fig.4.

Fig.4 Schematic diagran of the mechanical comminution process of micron-sized CL-20

The micron-sized CL-20is polyhedral and irregular,what′s more,the crystal structure of the micron-sized particles may be imperfect with some pores,occlusions and dislocations.Firstly,the micron-sized particles are impacted,pressed and sheared when comminuted in the bi-directional mill.The stresses are preferentially concentrated on the defects,and then the micronsized particles are cracked,crushed and divided into some irregular small particles with lesser defects.Secondly,under the mechanical smashed force field,the small particles are further pressed,sheared and milled,their particle sizes are further decreased,their morphologies are gradually regular,and their defects are diminished little by little.Then they are repeatedly comminuted under the mechanical force field and finally to be regular nano-sized particles having hardly any defects.The comminution process of the micron-sized particles is not only to be nano-sized and homogeneous,but also to be regular.

3 Conclusions

(1)Nano-sized CL-20is successfully produced using a bidirectional rotation mill,and the prepared nanometer particles are semi-spherical,homogeneous,and regular with a narrow size distribution.

(2)Compared with the micron-sized CL-20,the crystal form of nano-sized CL-20is maintaining epsilon(ε).

(3)Compared with the micron-sized CL-20,the impact,friction and shock sensitivities of nano-sized CL-20are reduced by 25.0%,116.2%and 58.1%,respectively.

(4)The nanocrystallization and homogenization,regularization of micron-sized coarse particles are achieved.

Reference:

[1] An Chong-wei,Li Feng-sheng,Wang Jing-yu,et al.Surface coating of nitroamine explosives and its effects on the performance of composite modified double-base propellants[J].Journal of Propulsion and Power,2012,28(2):444-448.

[2] Xing Xiao-ling,Zhao Feng-qi,Ma Shun-mian,et al.Thermal decomposition behavior,kinetics,and thermal hazard evaluation of CMDB propellant containing CL-20by microcalorimetry[J].Journal of Thermal Analysis and Calorimetry,2011,110(3):1451-1455.

[3] Nair U R,Asthana S N,Rao A S,et al.Advances in high energy materials[J].Defence Science Journal,2010,60(2):137-151.

[4] Xu S Y,Zhao F Q,Yi J H,et al.Thermal behavior and nonisothermal decomposition reaction kinetics of composite modified double base propellant containing CL-20[J].Acta Physico-Chimica Sinica,2008,24(8):1371-1377.

[5] Divekar C N,Sanghavi R R,Nair U R,et al.Closed-vessel and thermal studies on triple-base gun propellants containing CL-20[J].Journal of Propulsion and Power,2010,26(1):120-124.

[6] Yu Lan,Jiang Xia-bing,Guo Xue-yong,et al.Effects of binders and graphite on the sensitivity ofε-HNIW [J].Journal of Thermal Analysis and Calorimetry,2012,112(3):1343-1349.

[7] Yan Qi-Long,Zeman S,Elbeih A.Recent advances in thermal analysis and stability evaluation of insensitive plastic bonded explosives(PBXs)[J].Thermochimica Acta,2012,537:1-12.

[8] Samudre S S,Nair U R,Gore G M,et al.Studies on an improved plastic bonded explosive(PBX)for shaped charges[J].Propellants,Explosives,Pyrotechnics,2009,34(2):145-150.

[9] Song Xiao-lan,Li Feng-sheng.Dependence of particle size and size distribution on mechanical sensitivity and thermal stability of hexahydro-1,3,5-trinitro-1,3,5-triazine[J].Defence Science Journal,2009,59(1):37-42.

[10]Song Xiao-lan,Wang Yi,An Chong-wei,et al.Dependence of particle morphology and size on the mechanical sensitivity and thermal stability of octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine[J].Journal of Hazardous Materials,2008,159(2-3):222-229.

[11]Siviour C R,Gifford M J,Walley S M,et al.Particle size effects on the mechanical properties of a polymer bonded explosive[J].Journal of Materials Science,2004,39(4):1255-1258.

[12]Liu Jie,Jiang Wei,Li Feng-sheng,et al.Preparation and study on nano-sized octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine[J].Acta Armamentarii,2013,34(2):174-180.

[13]Liu Jie,Wang Long-xiang,Li Qing,et al.Preparation and characterization of insensitive nano-sized RDX [J].Chinese Journal of Explosives and Propellants,2012,35(6):46-50.

[14]Bayat Y,Zeynali V.Preparation and characterization of nanosized-CL-20explosive [J].Journal of Energetic Materials,2011,29(4):281-291.

[15]Zhang Y X,Liu D B,Lv C X.Preparation and characterization of reticular nano-sized-HMX [J].Propellants,Explosives,Pyrotechnics,2005,30(6):438-441.

[16]Bayat Y,Pourmortazavi S M,Iravani H,et al.Statistical optimization of supercritical carbon dioxide antisolvent process for preparation of HMX nano-sizedparticles[J].Journal of Supercritical Fluids,2012,72:248-254.

[17]Stepanov V,Krasnoperov L N,Elkina I B,et al.Production of nano-sized crystalline RDX by rapid expansion of supercritical solutions [J].Propellants,Explosives,Pyrotechnics,2005,30(3):178-183.

[18]Li Feng-sheng,Liu Hong-ying,Jiang Wei,et al.Bi-directional rotation mill:CN,10096755.1[P].2006.

[19]Liu Hong-ying,Yang Yi,Deng Guo-song,et al.Study on the equipment and technique of bi-rolling superfine milling[J].New Technology and New Process,2005,12:58-60.